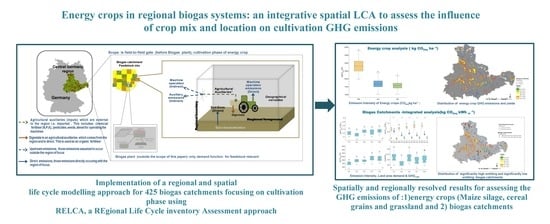

Energy Crops in Regional Biogas Systems: An Integrative Spatial LCA to Assess the Influence of Crop Mix and Location on Cultivation GHG Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Regional Description—Central Germany (CG)

2.2. Overview of Life Cycle Approach—RELCA

2.3. Functional Unit Combined with Spatial Indicators

2.4. RELCA Step 1: Crop Allocation Modelling (CRAM)

2.5. RELCA Step 2: Biogas Conversion Systems

2.6. RELCA Step 3: Biogas Catchment Modelling

2.7. RELCA Step 4: Life Cycle Inventory for Biomass Management

2.7.1. Nitrogen (N) Management and Spreading of Digestate

2.7.2. Other Farm Management—Auxiliary Inputs

2.7.3. Field Machinery Operations

2.8. Cultivation Emissions

2.8.1. Soil Emissions (Direct)—Soil N2O

2.8.2. MachineOpsEmis (Direct and Indirect)

2.8.3. Non-Regional—Indirect Cultivation Emissions (AuxillaryEmis)

2.9. Statistical and Spatial Analysis

3. Results

3.1. Energy Crops—CultiEmis

3.1.1. Crop GHG Emission Profiles

3.1.2. Contribution Analysis

3.1.3. Spatial Distribution of CultiEmis

3.1.4. Hypothesis for GHGculti (kgCO2eq/kWhel) Based on Crops’ CultiEmis (kgCO2eq/ha)

3.2. Effect of Crop Mixtures on Biogas Catchments GHGculti

3.2.1. SLdom Biogas Catchments

3.2.2. ECdom Biogas Catchments

3.2.3. The Effect of Crop Mixtures and the Role of MS on GHGculti Performance

3.3. Location Effects on Biogas Catchments

3.3.1. North, East, and Southern Border Locations (Poorest Performing Bcats)

3.3.2. Central and South-Central Locations (Best Performing Bcats)

4. Discussion

4.1. Location Types and Opportunities for Altering Feedstock Mix in CG

4.2. Application of an Integrated Regional Assessment

4.3. Influence of Energy Crops and Location on Overall GHG Balances

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Energy Resources, Bioenergy, World Energy Council. Available online: https://www.worldenergy.org/assets/images/imported/2016/10/World-Energy-Resources-Full-report-2016.10.03.pdf (accessed on 1 February 2017).

- Daniel-Gromke, J.; Rensberg, N.; Denysenko, V.; Stinner, W.; Schmalfuß, T.; Scheftelowitz, M.; Nelles, M.; Liebetrau, J. Current Developments in Production and Utilization of Biogas and Biomethane in Germany. Chem. Ing. Tech. 2018, 90, 17–35. [Google Scholar] [CrossRef]

- Appel, F.; Ostermeyer-Wiethaup, A.; Balmann, A. Effects of the German Renewable Energy Act on structural change in agriculture—The case of biogas. Util. Policy 2016, 41, 172–182. [Google Scholar] [CrossRef]

- Auburger, S.; Petig, E.; Bahrs, E. Assessment of grassland as biogas feedstock in terms of production costs and greenhouse gas emissions in exemplary federal states of Germany. Biomass Bioenergy 2017, 101, 44–52. [Google Scholar] [CrossRef]

- Meyer-Aurich, A.; Lochmann, Y.; Klauss, H.; Prochnow, A. Comparative Advantage of Maize- and Grass-Silage Based Feedstock for Biogas Production with Respect to Greenhouse Gas Mitigation. Sustainability 2016, 8, 617. [Google Scholar] [CrossRef] [Green Version]

- FNR, Fachagentur Nachwachsende Rohstoffe e.V. Biogas, an Introduction. Available online: https://mediathek.fnr.de/media/downloadable/files/samples/b/r/brosch.biogas-2013-en-web-pdf.pdf (accessed on 1 April 2015).

- Fachverband Biogas. What Is Needed for Successful Biogas Development from a German Point of View? Available online: http://european-biogas.eu/wp-content/uploads/2017/02/5-17-02-08_Biogas-in-Germany_FvB-1.pdf (accessed on 1 June 2017).

- Jacobs, A.; Auburger, S.; Bahrs, E.; Brauer-Siebrecht, W.; Christen, O.; Götze, P.; Koch, H.-J.; Rücknagel, J.; Märländer, B. Greenhouse gas emission of biogas production out of silage maize and sugar beet—An assessment along the entire production chain. Appl. Energy 2017, 190, 114–121. [Google Scholar] [CrossRef]

- Bachmaier, H.; Effenberger, M.; Gronauer, A.; Boxberger, J. Changes in greenhouse gas balance and resource demand of biogas plants in southern Germany after a period of three years. Waste Manag. Res. 2012, 31, 368–375. [Google Scholar] [CrossRef] [PubMed]

- O’Keeffe, S.; Franko, U.; Oehmichen, K.; Daniel-Gromke, J.; Thrän, D. Give them Credit the GHG performance of regional biogas systems. GCB Bioenergy 2019, 11, 791–808. [Google Scholar] [CrossRef] [Green Version]

- BMEL. Scientific Advisory Board on Agricultural Policy at the Federal Ministry of Food, Agriculture and Consumer Protection. Promotion of biogas production through the Renewable Energy Sources Act (EEG). Available online: http://www.bmel.de/SharedDocs/Downloads/EN/Ministry/Biogas-EEG.pdf?__blob=publicationFile (accessed on 1 June 2017).

- EU Commission. Commission Staff Working Document—State of Play on the Sustainability of Solid and Gaseous Biomass Used for Electricity, Heating and Cooling in the EU. 2014. Available online: https://ec.europa.eu/energy/sites/ener/files/2014_biomass_state_of_play_.pdf (accessed on 1 July 2015).

- Cherubini, F.; Strømman, A.H. Life cycle assessment of bioenergy systems: State of the art and future challenges. Bioresour. Technol. 2011, 102, 437–451. [Google Scholar] [CrossRef]

- Com. 670 Communication from the Commission of 21 December 2005, Thematic Strategy on the Sustainable Use of Natural Resources. 2005. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=LEGISSUM%3Al28167 (accessed on 1 April 2013).

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC. OJL 140/16. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32009L0028 (accessed on 1 April 2013).

- Meyer-Aurich, A.; Schattauer, A.; Hellebrand, H.J.; Klauss, H.; Plöchl, M.; Berg, W. Impact of uncertainties on greenhouse gas mitigation potential of biogas production from agricultural resources. Renew. Energy 2012, 37, 277–284. [Google Scholar] [CrossRef]

- Scholz, L.; Meyer-Aurich, A.; Kirschke, D. Greenhouse gas mitigation potential and mitigation costs of biogas production in Brandenburg, Germany. AgBioForum 2011, 14, 133–141. [Google Scholar]

- Bachmaier, J.; Effenberger, M.; Gronauer, A. Greenhouse gas balance and resource demand of biogas plants in agriculture. Eng. Life Sci. 2010, 10, 560–569. [Google Scholar] [CrossRef]

- Lansche, J.; Müller, J. Life cycle assessment of energy generation of biogas fed combined heat and power plants: Environmental impact of different agricultural substrates. Eng. Life Sci. 2012, 12, 313–320. [Google Scholar] [CrossRef]

- Styles, D.; Gibbons, J.; Williams, A.P.; Stichnothe, H.; Chadwick, D.R.; Healey, J.R. Cattle feed or bioenergy? Consequential life cycle assessment of biogas feedstock options on dairy farms. GCB Bioenergy 2014, 7, 1034–1049. [Google Scholar] [CrossRef] [Green Version]

- Lijó, L.; Lorenzo-Toja, Y.; González-García, S.; Bacenetti, J.; Negri, M.; Moreira, M.T. Eco-efficiency assessment of farm-scaled biogas plants. Bioresour. Technol. 2017, 237, 146–155. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Marvuglia, A.; Rege, S.; Benetto, E. Applying consequential LCA to support energy policy: Land use change effects of bioenergy production. Sci. Total Environ. 2014, 472, 78–89. [Google Scholar] [CrossRef]

- Dressler, D.; Loewen, A.; Nelles, M. Life cycle assessment of the supply and use of bioenergy: Impact of regional factors on biogas production. Int. J. Life Cycle Assess. 2012, 17, 1104–1115. [Google Scholar] [CrossRef]

- O’Keeffe, S.; Majer, S.; Bezama, A.; Thrän, D. When considering no man is an island—Assessing bioenergy systems in a regional and LCA context: A review. Int. J. Life Cycle Assess. 2016, 21, 885–902. [Google Scholar] [CrossRef]

- O’Keeffe, S.; Wochele-Marx, S.; Thrän, D. RELCA: A REgional Life Cycle inventory for Assessing bioenergy systems within a region. Energy Sustain. Soc. 2016, 6, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Weather Report for Central German Region; DWD, German Weather Service: Offenbach, Germany, 2010.

- LfULG, Landesamt Für Umwelt Landwirtschaft UND Geologie. Daten UND Fackten, Energiepflanzenanbau in Sachsen. Available online: http://www.lfulg.sachsen.de/download/lfulg/DuF_Energiepflanzenanbau_Endfassung_070815.pdf (accessed on 1 August 2016).

- TLL, Thüringer Landesanstalt Für Landwirtschaft. Standpunkt, Maisanbau Für Die Biogaserzeugung in THüringen. Available online: http://www.tll.de/www/daten/publikationen/standpunkte/st_biom.pdf (accessed on 1 August 2016).

- FNR, Fachagentur Nachwachsende Rohstoffe e.V. Energiepflanzen für Biogasanlagen, Sachsen-Anhalt. Available online: https://mediathek.fnr.de/media/downloadable/files/samples/f/n/fnr_brosch_energiepflanzen_s-a_web.pdf (accessed on 1 August 2016).

- Monitoring zur Wirkung des Erneuerbare Energien-Gesetz (EEG) auf die Entwicklung der Stromerzeugung aus Biomasse; Report Nr. 12; DBFZ, Deutsches Biomasseforschungszentrum: Leipzig, Germany; Available online: http://www.qucosa.de/fileadmin/data/qucosa/documents/13769/DBFZ_Report_12.pdf (accessed on 1 May 2012).

- Wochele, S.; Priess, J.; Thrän, D.; O’Keeffe, S. Crop allocation model “CRAM”—An approach for dealing with biomass supply from arable land as part of a life cycle inventory. In EU BC & E Proceedings 2014; Hoffmann, C., Baxter, D., Maniatis, K., Grassi, A., Helm, P., Eds.; ETA-Florence Renewable Energies: Florence, Italy, 2014; pp. 36–40. [Google Scholar]

- Tobler, W.R. A Computer Movie Simulating Urban Growth in the Detroit Region. Econ. Geogr. 1970, 46, 234–240. [Google Scholar] [CrossRef]

- KTBL. Kuratorium Für Technik UND Bauwesen in Der Landwirtschaft. Leistungs-Kostenrechnung Pflanzenbau. Available online: http://daten.ktbl.de/dslkrpflanze/postHv.html#Auswahl (accessed on 1 May 2016).

- Thünen-Institue. Calculations of Emission from German Agriculture-National Emission Inventory Report (Nir) 2011 for 2009—Methods and Data; Special Issue (Sonderheft) 342; Thünen-Institue: Braunschweig, Germany, 2011. [Google Scholar]

- Brocks, S.; Jungkunst, H.F.; Bareth, G. A regionally disaggregated inventory of nitrous oxide emissions from agricultural soils in Germany-A GIS based empirical approach. ERDKUNDE 2014, 1, 125–144. [Google Scholar] [CrossRef]

- RStudio Team (Ed.) RStudio: Integrated Development for R; RStudio, Inc.: Boston, MA, USA, 2017; Available online: http://www.rstudio.com/ (accessed on 1 January 2017).

- ArcGIS® and ArcMap™. Version 10.7.0, Software for Technical Computation; ESRI: Redlands, CA, USA, 2019. [Google Scholar]

- MATLAB. MATLAB and Statistics Toolbox Release 2017b; The MathWorks, Inc.: Natick, MA, USA, 2017. [Google Scholar]

- Senbayram, M.; Chen, R.; Wienforth, B.; Herrmann, A.; Kage, H.; Mühling, K.H.; Dittert, K. Emission of N2O from Biogas Crop Production Systems in Northern Germany. Bioenergy Res. 2014, 7, 1223–1236. [Google Scholar] [CrossRef]

- Bessou, C.; Lehuger, S.; Gabrielle, B.; Mary, B. Using a crop model to account for the effects of local factors on the LCA of sugar beet ethanol in Picardy region, France. Int. J. Life Cycle Assess. 2013, 18, 24–36. [Google Scholar] [CrossRef]

- FNR, Fachagentur Nachwachsende Rohstoffe e.V. Energiepflanzen Für Biogasanlagen. Sachsen. Available online: https://mediathek.fnr.de/media/downloadable/files/samples/f/n/fnr_brosch.energiepflanzen-sachsen.pdf (accessed on 1 August 2016).

- FNR, Fachagentur Nachwachsende Rohstoffe e.V. Energiepflanzen für Biogasanlagen. Thüringen. Available online: https://mediathek.fnr.de/media/downloadable/files/samples/b/r/brosch.energiepflanzen-thueringen-web_1.pdf (accessed on 1 August 2016).

- Klenk, I.; Landquist, B.; Ruiz de Imana, O. The product carbon footprint of EU beet sugar. Sugar Ind. 2012, 137, 169–177. [Google Scholar] [CrossRef]

- Chaplin-Kramer, R.; Sim, S.; Hamel, P.; Bryant, B.; Noe, R.; Mueller, C.; Rigarlsford, G.; Kulak, M.; Kowal, V.; Sharp, R.; et al. Life cycle assessment needs predictive spatial modelling for biodiversity and ecosystem services. Nat. Commun. 2017, 8, 15065. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hiloidhari, M.; Baruah, D.C.; Singh, A.; Kataki, S.; Medhi, K.; Kumari, S.; Ramachandra, T.V.; Jenkins, B.M.; Thakur, I.S. Emerging role of Geographical Information System (GIS), Life Cycle Assessment (LCA) and spatial LCA (GIS-LCA) in sustainable bioenergy planning. Bioresour. Technol. 2017, 242, 218–226. [Google Scholar] [CrossRef]

- Com. 767/f2 European Commission. Proposal for a Directive of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources. 2016. Available online: https://ec.europa.eu/transparency/regdoc/rep/1/2016/EN/COM-2016-767-F2-EN-MAIN-PART-1.PDF (accessed on 1 August 2017).

| Cluster 2 | AM | AS | MS | Cer | GS | |

|---|---|---|---|---|---|---|

| SLdom | 1 | 3 (5) | 87 (47) | 7 (24) | 2 (20) | 1 (4) |

| 2 | 3 (6) | 83 (42) | 9 (31) | 1 (13) | 3 (8) | |

| 4 | 3 (4) | 80 (34) | 12 (34) | 2 (19) | 3 (9) | |

| 7 | 3 (6) | 81 (39) | 11 (35) | 1 (13) | 3 (8) | |

| 8 | 4 (6) | 77 (32) | 14 (37) | 2 (16) | 3 (8) | |

| ECdom | 3 | 6 (4) | 29 (6) | 62 (82) | 1 (5) | 3 (3) |

| 5 | 12 (8) | 17 (3) | 65 (77) | 2 (9) | 3 (3) | |

| 6 3 | 0 (0) | 22 (4) | 74 (84) | 3 (11) | 1 (1) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

O’Keeffe, S.; Thrän, D. Energy Crops in Regional Biogas Systems: An Integrative Spatial LCA to Assess the Influence of Crop Mix and Location on Cultivation GHG Emissions. Sustainability 2020, 12, 237. https://doi.org/10.3390/su12010237

O’Keeffe S, Thrän D. Energy Crops in Regional Biogas Systems: An Integrative Spatial LCA to Assess the Influence of Crop Mix and Location on Cultivation GHG Emissions. Sustainability. 2020; 12(1):237. https://doi.org/10.3390/su12010237

Chicago/Turabian StyleO’Keeffe, Sinéad, and Daniela Thrän. 2020. "Energy Crops in Regional Biogas Systems: An Integrative Spatial LCA to Assess the Influence of Crop Mix and Location on Cultivation GHG Emissions" Sustainability 12, no. 1: 237. https://doi.org/10.3390/su12010237

APA StyleO’Keeffe, S., & Thrän, D. (2020). Energy Crops in Regional Biogas Systems: An Integrative Spatial LCA to Assess the Influence of Crop Mix and Location on Cultivation GHG Emissions. Sustainability, 12(1), 237. https://doi.org/10.3390/su12010237