Composite Soil Made of Rubber Fibers from Waste Tires, Blended Sugar Cane Molasses, and Kaolin Clay

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Materials Characterization

3.2. Soil Mixtures

3.3. UCS Test

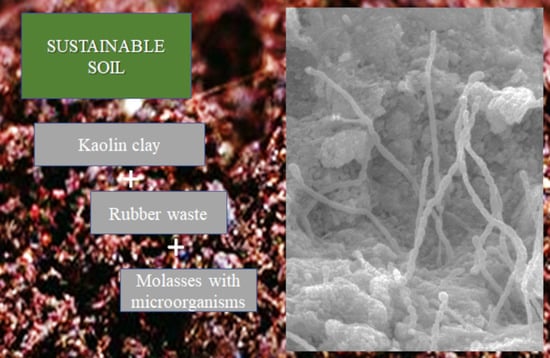

3.4. SEM Images Results

4. Discussions

Biological Activity

5. Conclusions

- The RTPF mixed with molasses represent a feasible, environmentally positive, economical, and technical alternative for ground improvement.

- Molasses are a byproduct of the repeated crystallization of sugar with no toxic elements and are environment-friendly. Due to its viscosity, molasses allows the separation of RTPF in soil, thereby producing a good composite solution.

- The improvement in the UCS achieved was of about 43%, this is, from 1.42 MPa for the reference sample, to 2.04 MPa for the mixture sample, which contains 2% of molasses and 0.1% of RTPF.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef] [PubMed]

- Rubber Manufactures Association. 2017 US Scrap tire Management Summary; Publisher Rubber Manufactures Association: Washington, DC, USA, 2019; pp. 1–20. [Google Scholar]

- Ministry of Environment, Housing and Territorial Development. Available online: https://www.minambiente.gov.co/images/AsuntosambientalesySectorialyUrbana/pdf/Programa_posconsumo_existente/RESOLUCION_1457_de_2010_llantas.pdf (accessed on 10 February 2019).

- District Secretary of the Environment. Available online: https://ambientebogota.gov.co/c/document_library/get_file?uuid=2b1cb194-bfd7-43d9-9350-11dd98b6f426groupId=10157 (accessed on 10 February 2019).

- Observatorio Ambiental de Bogotá. Available online: https://oab.ambientebogota.gov.co/es/indicadores?id=1057v=l# (accessed on 10 February 2019).

- Stevenson, K.; Stallwood, B.; Hart, A.G. Tire rubber recycling and bioremediation: A review. Bioremediat. J. 2008, 12, 1–11. [Google Scholar] [CrossRef]

- Lebreton, B.; Tuma, A. A quantitative approach to assessing the profitability of car and truck tire remanufacturing. Int. J. Prod. Econ. 2006, 104, 639–652. [Google Scholar] [CrossRef]

- Zebala, J.; Ciepka, P.; Reza, A.; Janczur, R. Influence of rubber compound and tread pattern of retreaded tyres on vehicle active safety. Forensic Sci. Int. 2007, 167, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Gieré, R.; Smith, K.; Blackford, M. Chemical composition of fuels and emissions from a coal+ tire combustion experiment in a power station. Fuel 2006, 85, 2278–2285. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Ma, L.; Chang, J. Vacuum pyrolysis of waste tires with basic additives. Waste Manag. 2008, 28, 2301–2310. [Google Scholar] [CrossRef]

- Agudelo, G.; Cifuentes, S.; Colorado, H.A. Ground tire rubber and bitumen with wax and its application in a real highway. J. Clean. Prod. 2019, 228, 1048–1061. [Google Scholar] [CrossRef]

- Shi, S.Q.; Wang, M.; Yin, P.; Luo, X. Experimental Study on a New Type of Waste Tires Combined Stone-blocking Structure. J. Disaster Prev. Mitig. Eng. 2011, 31, 501–505. [Google Scholar]

- Yoon, Y.W.; Heo, S.B.; Kim, K.S. Geotechnical performance of waste tires for soil reinforcement from chamber tests. Geotext. Geomembr. 2008, 26, 100–107. [Google Scholar] [CrossRef]

- Baricevic, A.; Pezer, M.; Rukavina, M.J.; Serdar, M.; Stirmer, N. Effect of polymer fibers recycled from waste tires on properties of wet-sprayed concrete. Constr. Build. Mater. 2018, 176, 135–144. [Google Scholar] [CrossRef]

- Huang, B.; Li, G.; Pang, S.S.; Eggers, J. Investigation into waste tire rubber-filled concrete. J. Mater. Civil. Eng. 2004, 16, 187–194. [Google Scholar] [CrossRef]

- Son, K.S.; Hajirasouliha, I.; Pilakoutas, K. Strength and deformability of waste tyre rubber-filled reinforced concrete columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar] [CrossRef]

- Papakonstantinou, C.G.; Tobolski, M.J. Use of waste tire steel beads in Portland cement concrete. Cem. Concr. Res. 2006, 36, 1686–1691. [Google Scholar] [CrossRef]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Proc. ICE-Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Hataf, N.; Rahimi, M.M. Experimental investigation of bearing capacity of sand reinforced with randomly distributed tire shreds. Constr. Build. Mater. 2006, 20, 910–916. [Google Scholar] [CrossRef]

- Revelo, F.C.; Colorado, H.A. A green composite material of calcium phosphate cement matrix with additions of car tire waste particles. Int. J. Appl. Ceram. Technol. 2021, 18, 182–191. [Google Scholar] [CrossRef]

- Srivastava, A.; Pandey, S.; Rana, J. Use of shredded tyre waste in improving the geotechnical properties of expansive black cotton soil. Geomech. Geoengin. 2014, 9, 303–311. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.M.; Chang, J.M.; Yao, Y.; Cui, Q. Sound insulation property of wood–waste tire rubber composite. Compos. Sci. Technol. 2010, 70, 2033–2038. [Google Scholar] [CrossRef]

- Rodriguez-Kabana, R.; King, P.S. Use of mixtures of urea and blackstrap molasses for control of root-knot nematodes in soil. Nematropica 1980, 10, 38–44. [Google Scholar]

- Yunus, M.; Ohba, N.; Shimojo, M.; Furuse, M.; Masuda, Y. Effects of adding urea and molasses on Napiergrass silage quality. Asian-Australas. J. Anim. Sci. 2000, 13, 1542–1547. [Google Scholar] [CrossRef]

- Tiwari, S.P.; Singh, U.B.; Mehra, U.R. Urea molasses mineral blocks as a feed supplement: Effect on growth and nutrient utilization in buffalo calves. Anim. Feed. Sci. Technol. 1990, 29, 333–341. [Google Scholar] [CrossRef]

- Aalm, A.; Singh, P. Experimental Study on Strength Characteristics of Cement Concrete by Adding Sugar Waste. Int. J. Enhanc. Res. Sci. Technol. Eng. 2016, 5, 33–34. [Google Scholar]

- Zhang, Y.; Fei, A.; Li, D. Utilization of waste glycerin, industry lignin and cane molasses as grinding aids in blended cement. Constr. Build. Mater. 2016, 123, 785–791. [Google Scholar] [CrossRef]

- M’Ndegwa, J.K. The effect of cane molasses on strength of expansive clay soil. J. Emerg. Trends Eng. Appl. Sci. 2011, 2, 1034–1041. [Google Scholar]

- Boopathy, R. Bioremediation of explosives contaminated soil. Int. Biodeterior. Biodegrad. 2000, 46, 29–36. [Google Scholar] [CrossRef]

- Prasada, M.S.; Reid, K.J.; Murray, H.H. Kaolin: Processing, properties and application. Appl. Clay Sci. 1991, 6, 87–119. [Google Scholar] [CrossRef]

- Ordoñez, E.; Gallego, J.M.; Colorado, H.A. 3D printing via the direct ink writing technique of ceramic pastes from typical formulations used in traditional ceramics industry. Appl. Clay Sci. 2019, 182, 105285. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. 3D printing of kaolinite clay ceramics using the Direct Ink Writing (DIW) technique. Ceram. Int. 2018, 44, 5673–5682. [Google Scholar] [CrossRef]

- Shafiq, N.; Nuruddin, M.F.; Khan, S.U.; Ayub, T. Calcined kaolin as cement replacing material and its use in high strength concrete. Constr. Build. Mater. 2015, 81, 313–323. [Google Scholar] [CrossRef]

- Heah, C.Y.; Kamarudin, H.; Al Bakri, A.M.; Bnhussain, M.; Luqman, M.; Nizar, I.K.; Liew, Y.M. Study on solids-to-liquid and alkaline activator ratios on kaolin-based geopolymers. Constr. Build. Mater. 2012, 35, 912–922. [Google Scholar] [CrossRef]

- Babu, G.S.; Chouksey, S.K. Stress–strain response of plastic waste mixed soil. Waste Manag. 2011, 31, 481–488. [Google Scholar] [CrossRef] [PubMed]

- Sivakumar Babu, G.L.; Chouksey, S.K. Analytical model for stress-strain response of plastic waste mixed soil. J. Hazard. Toxic Radioact. Waste 2011, 16, 219–228. [Google Scholar] [CrossRef]

- García, F.E.; Pérez, A.C.; Colorado, H.A. Kaolinite-based clay ceramics blended with residual fique fibers for potential plastic soil applications. Int. J. Appl. Ceram. Technol. 2021, 18, 1086–1096. [Google Scholar] [CrossRef]

- Sezer, A.; İnan, G.; Yılmaz, H.R.; Ramyar, K. Utilization of a very high lime fly ash for improvement of Izmir clay. Build. Environ. 2006, 41, 150–155. [Google Scholar] [CrossRef]

- ASTM International (n.d). ASTM D1557-12e1 Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3)). Available online: https://www.astm.org/d1557-12r21.html (accessed on 10 February 2019).

- Mišljenović, N.; Schüller, R.B.; Rukke, E.O.; Bringas, C.S. Rheological characterization of liquid raw materials for solid biofuel production. Annu. Trans. Nord. Rheol. Soc. 2013, 21, 61–68. [Google Scholar]

- Cities of the World Where You Don’t Need AC or Heat, Mapped. Available online: https://mnolangray.medium.com/cities-of-the-world-where-you-dont-need-ac-or-heat-mapped-2a3d6e018970 (accessed on 10 January 2022).

- ASTM International (n.d). ASTM D2487-17 Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). Available online: https://www.astm.org/d2487-17e01.html (accessed on 10 February 2019).

- ASTM International (n.d). D2166M-16 Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. Available online: https://www.astm.org/d2166_d2166m-16.html (accessed on 10 February 2019).

- Rahgozar, M.A.; Saberian, M.; Li, J. Soil stabilization with non-conventional eco-friendly agricultural waste materials: An experimental study. Transp. Geotech. 2018, 14, 52–60. [Google Scholar] [CrossRef]

- Abdulhussein Saeed, K.; Anuar Kassim, K.; Nur, H. Physicochemical characterization of cement treated kaolin clay. Građevinar 2014, 66, 513–521. [Google Scholar]

- Hareru, W.; Ghebrab, T. Rheological Properties and Application of Molasses Modified Bitumen in Hot Mix Asphalt (HMA). Appl. Sci. 2020, 10, 1931. [Google Scholar] [CrossRef] [Green Version]

- Alther, G.R. The qualifications of bentonite as a soil sealant. Eng. Geol. 1987, 23, 177–191. [Google Scholar] [CrossRef]

- Ministerio de Transporte. Manual de Diseño Geométricos de Carreteas; Instituto Nacional de Vías: Bogotá, Colombia, 2008. [Google Scholar]

- Departamento Nacional de Planeación. Available online: https://colaboracion.dnp.gov.co/CDT/Prensa/Presentaciones/RED%20TERCIARIA%20CCI%20-%20DNP.pdf (accessed on 27 May 2019).

- Kristensen, H.G. Particle agglomeration in high shear mixers. Powder Technol. 1996, 88, 197–202. [Google Scholar] [CrossRef]

- Lian, G.; Thornton, C.; Adams, M.J. Discrete particle simulation of agglomerate impact coalescence. Chem. Eng. Sci. 1998, 53, 3381–3391. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Umar, M.; Kassim, K.A.; Chiet, K.T.P. Biological process of soil improvement in civil engineering: A review. J. Rock Mech. Geotech. Eng. 2016, 8, 767–774. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, V.; Chu, J. Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev. Environ. Sci. Bio/Technol. 2008, 7, 139–153. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Santamarina, J.C. Biological considerations in geotechnical engineering. J. Geotech. Geoenviron. Eng. 2005, 131, 1222–1233. [Google Scholar] [CrossRef] [Green Version]

| Element | O | C | K | Cl | Ca | Mg | S | Total |

|---|---|---|---|---|---|---|---|---|

| Weight (%) | 41.23 | 46.67 | 6.86 | 2.08 | 2.1 | 0.64 | 0.41 | 99.99 |

| Atomic (%) | 51.42 | 43.7 | 2.63 | 0.88 | 0.78 | 0.39 | 0.19 | 99.99 |

| Parameters | Values |

|---|---|

| Soil classification | |

| USCS | CL |

| Atterberg limits | |

| Liquid limit (%) | 44 |

| Plastic limit (%) | 23 |

| Plasticity index (%) | 21 |

| Specific gravity | |

| Specific gravity (20 °C) | 2.75 |

| Particle-size distribution | |

| Gravel (%) | 0.1 |

| Sand (%) | 20.2 |

| Silt (%) | 40.5 |

| Clay (%) | 39.2 |

| Parameters of compaction | |

| Maximum dry density (kg/m3) | 1417 |

| Optimum moisture content (%) | 32 |

| Designation | Molasses(%) | Fibers (%) | Soil(%) | Total %(By Dry Soil) | % Water Content |

|---|---|---|---|---|---|

| M0 | 0 | 0 | 100 | 100 | 35 |

| M2 | 2 | 0.1 | 97.9 | 100 | 35 |

| M4 | 4 | 0.1 | 95.9 | 100 | 35 |

| M6 | 6 | 0.1 | 93.9 | 100 | 35 |

| M8 | 8 | 0.1 | 91.9 | 100 | 35 |

| M10 | 10 | 0.1 | 89.9 | 100 | 35 |

| M12 | 12 | 0.1 | 87.9 | 100 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiménez, J.E.; Fontes Vieira, C.M.; Colorado, H.A. Composite Soil Made of Rubber Fibers from Waste Tires, Blended Sugar Cane Molasses, and Kaolin Clay. Sustainability 2022, 14, 2239. https://doi.org/10.3390/su14042239

Jiménez JE, Fontes Vieira CM, Colorado HA. Composite Soil Made of Rubber Fibers from Waste Tires, Blended Sugar Cane Molasses, and Kaolin Clay. Sustainability. 2022; 14(4):2239. https://doi.org/10.3390/su14042239

Chicago/Turabian StyleJiménez, Juan E., Carlos Mauricio Fontes Vieira, and Henry A. Colorado. 2022. "Composite Soil Made of Rubber Fibers from Waste Tires, Blended Sugar Cane Molasses, and Kaolin Clay" Sustainability 14, no. 4: 2239. https://doi.org/10.3390/su14042239

APA StyleJiménez, J. E., Fontes Vieira, C. M., & Colorado, H. A. (2022). Composite Soil Made of Rubber Fibers from Waste Tires, Blended Sugar Cane Molasses, and Kaolin Clay. Sustainability, 14(4), 2239. https://doi.org/10.3390/su14042239