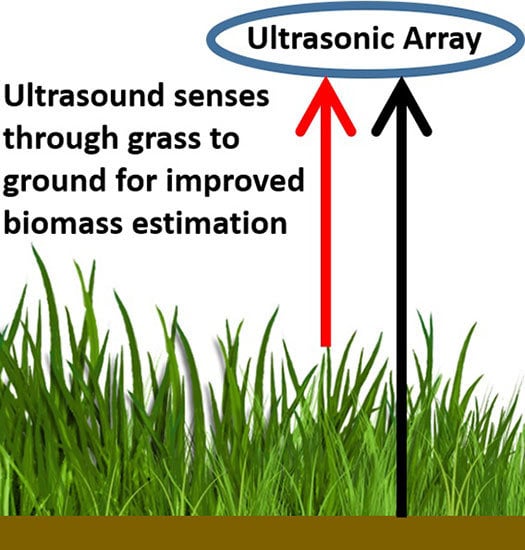

Ultrasonic Arrays for Remote Sensing of Pasture Biomass

Abstract

:1. Introduction

2. Simulation of Arrays

Beam Pattern Properties

3. Transducer Selection

3.1. Transducer Characteristics

3.2. Transducer Transient Response

4. Array Hardware Developed

4.1. Version 1 Array

4.2. Version 2 Hardware—High Resolution Array

4.3. Mounting of V1 and V2 Arrays

4.4. Experimental Measurement of Beam Patterns

5. Example Field Trial Results

5.1. Horizontal Position Measurement using IR Sensors

5.2. Improved Grass Height Measurements

5.2.1. New Height Measurement Technique

5.2.2. Evaluation of Height Measurement Techniques

6. Conclusions

7. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beukes, P.; McCarthy, S.; Wims, C.; Gregorini, P.; Romera, A. Regular estimates of herbage mass can improve profitability of pasture-based dairy systems. Anim. Prod. Sci. 2019, 59, 359–367. [Google Scholar] [CrossRef]

- Clarke, D.; Litherland, A.; Mata, G.; Burling-Claridge, R. Pasture monitoring from space. In Proceedings of the South Island Dairy Event (SIDE) Conference, Kent, UK, 26–28 June 2006; pp. 26–28. [Google Scholar]

- Ali, I.; Cawkwell, F.; Dwyer, E.; Barrett, B.; Green, S. Satellite remote sensing of grasslands: From observation to management. J. Plant Ecol. 2016, 9, 649–671. [Google Scholar] [CrossRef] [Green Version]

- Earle, D.; McGowan, A. Evaluation and calibration of an automated rising plate meter for estimating dry matter yield of pasture. Aust. J. Exp. Agric. 1979, 19, 337–343. [Google Scholar] [CrossRef]

- Angelone, A.; Toledo, J.M.; Burns, J.C. Herbage measurement in situ by electronics. 1. The multiple-probe-type capacitance meter: A brief review. Grass Forage Sci. 1980, 35, 25–33. [Google Scholar] [CrossRef]

- Murphy, W.; Silman, J.; Barreto, A.M. A comparison of quadrat, capacitance meter, HFRO sward stick, and rising plate for estimating herbage mass in a smooth-stalked, meadowgrass-dominant white clover sward. Grass Forage Sci. 1995, 50, 452–455. [Google Scholar] [CrossRef]

- López-Díaz, J.; Roca-Fernández, A.; González-Rodríguez, A. Measuring herbage mass by non-destructive methods: A review. J. Agric. Sci. Technol. 2011, 1, 303–314. [Google Scholar]

- Wachendorf, M.; Fricke, T.; Möckel, T. Remote sensing as a tool to assess botanical composition, structure, quantity and quality of temperate grasslands. Grass Forage Sci. 2018, 73, 1–14. [Google Scholar] [CrossRef]

- Chao, Z.; Liu, N.; Zhang, P.; Ying, T.; Song, K. Estimation methods developing with remote sensing information for energy crop biomass: A comparative review. Biomass Bioenergy 2019, 122, 414–425. [Google Scholar] [CrossRef]

- Sanderson, M.A.; Rotz, C.A.; Fultz, S.W.; Rayburn, E.B. Estimating forage mass with a commercial capacitance meter, rising plate meter, and pasture ruler. Agron. J. 2001, 93, 1281–1286. [Google Scholar] [CrossRef] [Green Version]

- Xue, J.; Su, B. Significant remote sensing vegetation indices: A review of developments and applications. J. Sens. 2017, 2017, 1353691. [Google Scholar] [CrossRef] [Green Version]

- Hanna, M.; Steyn-Ross, D.; Steyn-Ross, M. Estimating biomass for New Zealand pasture using optical remote sensing techniques. Geocarto Int. 1999, 14, 89–94. [Google Scholar] [CrossRef]

- Gu, Y.; Wylie, B.K.; Howard, D.M.; Phuyal, K.P.; Ji, L. NDVI saturation adjustment: A new approach for improving cropland performance estimates in the Greater Platte River Basin, USA. Ecol. Indic. 2013, 30, 1–6. [Google Scholar] [CrossRef]

- Andersson, K.; Trotter, M.; Robson, A.; Schneider, D.; Frizell, L.; Saint, A.; Lamb, D.; Blore, C. Estimating pasture biomass with active optical sensors. Adv. Anim. Biosci. 2017, 8, 754–757. [Google Scholar] [CrossRef]

- Fricke, T.; Wachendorf, M. Combining ultrasonic sward height and spectral signatures to assess the biomass of legume–grass swards. Comput. Electron. Agric. 2013, 99, 236–247. [Google Scholar] [CrossRef]

- Safari, H.; Fricke, T.; Wachendorf, M. Determination of fibre and protein content in heterogeneous pastures using field spectroscopy and ultrasonic sward height measurements. Comput. Electron. Agric. 2016, 123, 256–263. [Google Scholar] [CrossRef]

- Safari, H. Combined Use of Spectral Signatures and Ultrasonic Sward Height for the Assessment of Biomass and Quality Parameters in Heterogeneous Pastures. Ph.D. Thesis, Department of Grassland Science and Renewable Plant Resourses, University of Kassel, Witzenhausen, Germany, 2017. [Google Scholar]

- Moeckel, T.; Safari, H.; Reddersen, B.; Fricke, T.; Wachendorf, M. Fusion of ultrasonic and spectral sensor data for improving the estimation of biomass in grasslands with heterogeneous sward structure. Remote Sens. 2017, 9, 98. [Google Scholar] [CrossRef] [Green Version]

- Möckel, T.; Fricke, T.; Wachendorf, M. Multi-temporal estimation of forage biomass in heterogeneous pastures using static and mobile ultrasonic and hyperspectral measurements. In Sustainable Meat and Milk Production from Grasslands, Proceedings of the 27th General Meeting of the European Grassland Federation, Cork, Ireland, 17–21 June 2018; Teagasc, Animal & Grassland Research and Innovation Centre, Moorepark, Fermoy: Co. Cork, Ireland, 2018; pp. 813–815. [Google Scholar]

- Cao, Z.; Cheng, T.; Ma, X.; Tian, Y.; Zhu, Y.; Yao, X.; Chen, Q.; Liu, S.; Guo, Z.; Zhen, Q.; et al. A new three-band spectral index for mitigating the saturation in the estimation of leaf area index in wheat. Int. J. Remote Sens. 2017, 38, 3865–3885. [Google Scholar] [CrossRef]

- Barthram, G. Experimental Techniques: The HFRO Sward Stick; Technical Report; The Hill Farming Research Organization, Biennial Report; HFRO: Midlothian, UK, 1985. [Google Scholar]

- Cooper, S.D.; Roy, D.P.; Schaaf, C.B.; Paynter, I. Examination of the potential of terrestrial laser scanning and structure-from-motion photogrammetry for rapid nondestructive field measurement of grass biomass. Remote Sens. 2017, 9, 531. [Google Scholar] [CrossRef] [Green Version]

- Hutchings, N.; Phillips, A.; Dobson, R. An ultrasonic rangefinder for measuring the undisturbed surface height of continuously grazed grass swards. Grass Forage Sci. 1990, 45, 119–127. [Google Scholar] [CrossRef]

- Hutchings, N. Spatial heterogeneity and other sources of variance in sward height as measured by the sonic and HFRO sward sticks. Grass Forage Sci. 1991, 46, 277–282. [Google Scholar] [CrossRef]

- Hutchings, N. Factors affecting sonic sward stick measurements: The effect of different leaf characteristics and the area of sward sampled. Grass Forage Sci. 1992, 47, 153–160. [Google Scholar] [CrossRef]

- King, W.; Rennie, G.; Dalley, D.; Dynes, R.; Upsdell, M. Pasture mass estimation by the C-DAX pasture meter: Regional calibrations for New Zealand. In Proceedings of the 4th Australasian Dairy Science Symposium 2010: Meeting the Challenges for Pasture-Based Dairying, Christchurch, New Zealand, 31 August–2 September 2010; Volume 31, pp. 223–238. [Google Scholar]

- Schaefer, M.T.; Lamb, D.W. A combination of plant NDVI and LiDAR measurements improve the estimation of pasture biomass in tall fescue (Festuca arundinacea var. Fletcher). Remote Sens. 2016, 8, 109. [Google Scholar] [CrossRef] [Green Version]

- Naroaka Enterprises. Pasture Reader. Available online: http://pasturereader.com.au/ (accessed on 29 December 2019).

- Schaare, P. Improved Paster Meter. NZ Patent WO2006009472A2, 26 January 2006. [Google Scholar]

- Reusch, S. Use of ultrasonic transducers for on-line biomass estimation in winter wheat. In Precision Agriculture; Wageningen Academic Publishers: Wageningen, The Netherlands, 2009; pp. 69–175. [Google Scholar]

- Legg, M.; Bradley, S. Ultrasonic Proximal Sensing of Pasture Biomass. Remote Sens. 2019, 11, 2459. [Google Scholar] [CrossRef] [Green Version]

- Legg, M. Microphone Phased Array 3D Beamforming and Deconvolution. Ph.D. Thesis, University of Auckland, Auckland, New Zealand, 2012. [Google Scholar]

- Nakamura, K.; Gomez, R. Self-calibration of flexible microphone array for speaker localization in meeting conversations using emitters. In Proceedings of the 2018 16th International Workshop on Acoustic Signal Enhancement (IWAENC), Tokyo, Japan, 17–20 September 2018; pp. 311–315. [Google Scholar]

- Bradley, S.; Legg, M. Systems, Apparatus and Methods for Vegetation Measurement; Gallagher Group Limited: Hamilton, New Zealand, 2019; No.753949. [Google Scholar]

- Bradley, S.; Legg, M. Vegetation Measurement Apparatus, Systems, and Methods; Gallagher Group Limited: Melbourne, Australia, 2019; No.2019201425. [Google Scholar]

| V1 | V2 | |||

|---|---|---|---|---|

| PBC Diameter (mm) | 80 | 190 | ||

| Transmit/Receive Array | TX | RX | TX | RX |

| Array Diameter (mm) | 61 | 61 | 150 | 150 |

| Total No. of Elements | 29 | 28 | 160 | 204 |

| No. of Spiral Arms | 7 | 7 | 17 | 17 |

| No. of Rings (or No. Elements Per Arm) | 4 | 4 | 10 | 12 |

| Version | Transducer Rings | Receiver Rings | Beamwidth | MSL |

|---|---|---|---|---|

| V1 | – | – | 122 mm (8.7°) | 25 dB |

| V2 | 1 | 1 | 148 mm (10.5°) | 10 dB |

| V2 | All | 1 | 66 mm (4.7°) | 15 dB |

| V2 | 1 | All | 63 mm (4.5°) | 27 dB |

| V2 | All | All | 46 mm (3.3°) | 33 dB |

| Hardware Version | Traditional Method | New Method |

|---|---|---|

| V1 | ||

| RMSE = 342 kg/ha | RMSE = 272 kg/ha | |

| V2 | ||

| RMSE = 359 kg/ha | RMSE = 267 kg/ha |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Legg, M.; Bradley, S. Ultrasonic Arrays for Remote Sensing of Pasture Biomass. Remote Sens. 2020, 12, 111. https://doi.org/10.3390/rs12010111

Legg M, Bradley S. Ultrasonic Arrays for Remote Sensing of Pasture Biomass. Remote Sensing. 2020; 12(1):111. https://doi.org/10.3390/rs12010111

Chicago/Turabian StyleLegg, Mathew, and Stuart Bradley. 2020. "Ultrasonic Arrays for Remote Sensing of Pasture Biomass" Remote Sensing 12, no. 1: 111. https://doi.org/10.3390/rs12010111

APA StyleLegg, M., & Bradley, S. (2020). Ultrasonic Arrays for Remote Sensing of Pasture Biomass. Remote Sensing, 12(1), 111. https://doi.org/10.3390/rs12010111