A Study of the Application and the Limitations of GPR Investigation on Underground Survey of the Korean Expressways

Abstract

:1. Introduction

2. Background

2.1. Principle of GPR

2.2. Attenuation

2.3. Relative Permittivity (Dielectric Constant) and Depth Converting

3. Research Targets and Methods

3.1. Testbed

3.2. GPR Equipment

3.3. GPR Data Analysis

4. Test Results

4.1. Asphalt Pavement

4.2. Concrete Pavement

4.3. Signal Characteristics of GPR According by the Type of Abnormality

4.3.1. Investigation Performance According to the Type of Pavement

4.3.2. Cavity

4.3.3. PE Bottle

4.3.4. Steel Plate

5. Discussion

5.1. The Effective Depth of Investigation

5.2. The Detection Ability on Buried Objects

5.3. The Depth Analysis of Buried Objects

6. Conclusions

- (1)

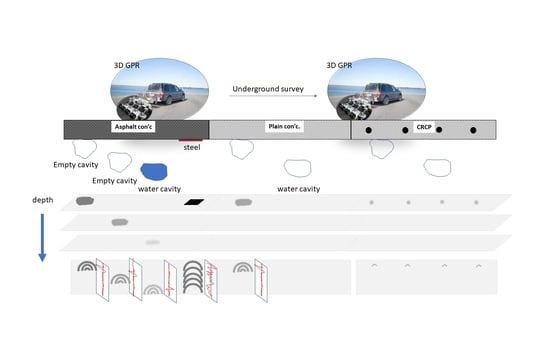

- The combination of the plan view by depth and cross- and longitudinal sections of the GPR data achieved from the 3D GPR such as the multichannel GPR, which makes analysis easier and more accurate.

- (2)

- The deeper the depth of survey, the greater the attenuation of the received GPR wave, resulting in lower sensitivity of the signal. Signal attenuation occurred more severe in concrete pavements than in the asphalt pavement. This seems to be the result of greater attenuation per unit depth in propagation through concrete, because it has a higher dielectric constant and conductivity of young concrete than asphalt [19,43,50].

- (3)

- The effective depth of cavity investigation under asphalt pavement was estimated to be about 1 to 1.5 m. Reflected GPR signals from subsurface anomalies at shallower depths appeared clearer within this range.

- (4)

- Under the concrete pavement, most of subsurface anomalies could not be detected by the GPR, except for a simulated ground cavity, which is an EPS hemisphere placed next to the pavement layer made of plain concrete. In addition, reflected waves (scattering) were found to be occurring from rebars embedded in the CRCP, which hindered the detection of objects beneath the rebar. Therefore, the GPR survey under the concrete pavement is not reasonable and practical because of high signal attenuation and scattering.

- (5)

- The estimated depth from TWTT converted by assuming one dielectric constant based on experience and engineering judgement could cause significant errors in the actual test in which as the depth increases the error also increases. This is believed to be due to the practice of assuming only one dielectric constant for a multilayered road. Therefore, it is required to use core data when depth information is required, such as for mapping of 3D underground utilities or underground objects.

- (6)

- The negative polarity reflection of the received GPR signal was found to be reflected from a simulated cavity, which is the EPS (cavity), and a PE bottle with air. On the other hand, the positive polarity reflection of the received GPR signal was found in GPR data reflected from a PE bottle filled with water and a steel plate. This is because the GPR signal changed in amplitude direction according to the EM characteristics of the reflector. In other words, the reflection polarity in GPR data can be associated with different relative permittivity objects, i.e., cavities or buried things. Therefore, it is believed that it is helpful to check the reflection polarity in GPR data when estimating the characteristics of the buried materials. Moreover, even individual reflection traces can be studied for polarity changes, which can help in identifying the types of buried mediums that are producing such reflections.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Serzu, M.H.; Kozak, E.T.; Lodha, G.S.; Everitt, R.A.; Woodcock, D.R. Use of borehole radar techniques to characterize fractured granitic bedrock at AECL’s Underground Research Laboratory. J. Appl. Geophys. 2004, 55, 137–150. [Google Scholar] [CrossRef]

- Dorn, C.; Linde, N.; Doetsch, J.; Le Borgne, T.; Bour, O. Borehole GPR fracture imaging of a crystalline rock aquifer, Stang-er-Brune, Brittany, France. In Proceedings of the Near Surface 2010—16th European Meeting of Environmental and Engineering Geophysics, Zurich, Switzerland, 6–8 September 2010. [Google Scholar]

- Schwartz, R.C.; Evett, S.R.; Pelletier, M.G.; Bell, J.M. Complex permittivity model for time domain reflectometry soil water content sensing: I. Theory. Soil Sci. Soc. Am. J. 2009, 73, 886–897. [Google Scholar] [CrossRef]

- Mahmoudzadeh Ardekani, M.R. Off- and on-ground GPR techniques for field-scale soil moisture mapping. Geoderma 2013, 200, 55–66. [Google Scholar] [CrossRef]

- Sevil, J.; Gutiérrez, F.; Zarroca, M.; Desir, G.; Carbonel, D.; Guerrero, J.; Linares, R.; Roqué, C.; Fabregat, I. Sinkhole investigation in an urban area by trenching in combination with GPR, ERT and high-precision leveling. Mantled evaporite karst of Zaragoza city, NE Spain. Eng. Geol. 2017, 231, 9–20. [Google Scholar] [CrossRef]

- Baek, J.; Yoon, J.S.; Lee, C.M.; Choi, Y. A case study on detection of subsurface cavities of urban roads using ground-coupled GPR. In Proceedings of the 2018 17th International Conference on Ground Penetrating Radar, GPR 2018, Rapperswil, Switzerland, 18–21 June 2018. [Google Scholar] [CrossRef]

- Porsani, J.L.; Ruy, Y.B.; Ramos, F.P.; Yamanouth, G.R.B. GPR applied to mapping utilities along the route of the Line 4 (yellow) subway tunnel construction in São Paulo City, Brazil. J. Appl. Geophys. 2012, 80, 25–31. [Google Scholar] [CrossRef]

- Wimsatt, A.; White, J.; Leung, C.; Scullion, T.; Hurlebaus, S.; Zollinger, D.; Grasley, Z.; Nazarian, S.; Azari, H.; Yuan, D.; et al. Mapping Voids, Debonding, Delaminations, Moisture, and other Defects Behind or within Tunnel Linings; SHRP 2 Report S2-R06G-RR-1; Transportation Research Board: Washington, DC, USA, 2014. [Google Scholar] [CrossRef]

- Balasubramaniam, V.R.; Jha, P.C. Imaging for foundation defects using GPR. In Proceedings of the 13th International Conference on Ground Penetrating Radar, GPR 2010, Lecce, Italy, 21–25 June 2010. [Google Scholar] [CrossRef]

- Pupatenko, V.V.; Sukhobok, Y.A.; Stoyanovich, G.M. Lithological profiling of rocky slopes using geo reader software based on the results of ground penetrating radar method. Procedia Eng. 2017, 189, 643–649. [Google Scholar] [CrossRef]

- Ni, S.H.; Huang, Y.H.; Lo, K.F.; Lin, D.C. Buried pipe detection by ground penetrating radar using the discrete wavelet transform. Comput. Geotech. 2010, 37, 440–448. [Google Scholar] [CrossRef]

- Jaw, S.W.; Hashim, M. Locational accuracy of underground utility mapping using ground penetrating radar. Tunn. Undergr. Space Technol. 2013, 35, 20–29. [Google Scholar] [CrossRef]

- Singh, K.K.K.; Kumar, I.; Singh, U.K. Interpretation of voids or buried pipes using ground penetrating radar modeling. J. Geol. Soc. India 2013, 81, 397–404. [Google Scholar] [CrossRef]

- Shangguan, P.; Al-Qadi, I.; Coenen, A.; Zhao, S. Algorithm development for the application of ground-penetrating radar on asphalt pavement compaction monitoring. Int. J. Pavement Eng. 2016, 17, 189–200. [Google Scholar] [CrossRef]

- Zhao, S.; Al-Qadi, I.L. Development of an analytic approach utilizing the extended common midpoint method to estimate asphalt pavement thickness with 3-D ground-penetrating radar. NDT E Int. 2016, 78, 29–36. [Google Scholar] [CrossRef]

- Hugenschmidt, J. Railway track inspection using GPR. Proc. J. Appl. Geophys. 2000, 43, 147–155. [Google Scholar] [CrossRef]

- Tosti, F.; Bianchini Ciampoli, L.; Calvi, A.; Alani, A.M.; Benedetto, A. An investigation into the railway ballast dielectric properties using different GPR antennas and frequency systems. NDT E Int. 2018, 93, 131–140. [Google Scholar] [CrossRef]

- Dinh, K.; Gucunski, N.; Kim, J.; Duong, T.H.; La, H.M. Attenuation-based methodology for condition assessment of concrete bridge decks using GPR. In Proceedings of the 32nd International Symposium on Automation and Robotics in Construction and Mining: Connected to the Future, Proceedings, Oulu, Finland, 15–18 June 2015. [Google Scholar]

- Rhee, J.Y.; Kee, S.H.; Kim, H.S.; Choi, J.J. Seasonal variation and age-related changes in the relative permittivity of concrete bridge decks on Korea expressways. Int. J. Concr. Struct. Mater. 2018, 12, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Rhee, J.Y.; Choi, J.J.; Kee, S.H. Evaluation of the depth of deteriorations in concrete bridge decks with asphalt overlays using air-coupled GPR: A case study from a pilot bridge on Korean expressway. Int. J. Concr. Struct. Mater. 2019, 13, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Hakim, Y. Sinkhole Opens Up Beneath South Korean Pedestrians. BBC News, British Broadcasting Corporation (BBC). Available online: https://www.bbc.com/news/av/world-asia-31602247 (accessed on 29 August 2020).

- Kim, Y.; Park, S.W. Dem simulation on the initiation and development of road subsidence. J. Korean Geotech. Soc. 2017, 7, 43–53. (In Korean) [Google Scholar] [CrossRef]

- ABC News, Sinkhole Swallows Two Pedestrians in SEOUL, Pair Survive Fall with Only Minor Injuries. Australian Broadcasting Corporation. Available online: http://www.abc.net.au/news/2015-02-25/two-pedestrians-rescued-after-falling-into-a-sinkhole/6260590 (accessed on 25 February 2015).

- Seoul Metropolitan Government. White Paper on Road Management: Road Management by Smart System; 51-6110000-001542-10; Seoul Metropolitan Government: Seoul, Korea, 2016. (In Korean)

- Yoon, J.S.; Baek, J.; Choi, Y.W.; Choi, H.; Lee, C.M. Signal pattern analysis of ground penetrating radar for detecting road Cavities. Int. J. Highw. Eng. 2016, 6, 61–67. [Google Scholar] [CrossRef]

- Kim, Y.T.; Kim, B.; Kim, J.W.; Park, H.M.; Yoon, J.S. Determining the optimal frequency of ground penetrating radar for detecting voids in pavements. Int. J. Highw. Eng. 2016, 18, 37–42. [Google Scholar] [CrossRef]

- Kim, Y.T.; Choi, J.Y.; Kim, K.D.; Park, H.M. A study on the selection of GPR type suitable for road cavity detection. Int. J. Highw. Eng. 2017, 19, 69–75. [Google Scholar] [CrossRef]

- Lee, H.H. Image processing of GPR detection data. J. Korea Inst. Struct. Maint. Insp. 2016, 20, 104110. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.H. Pattern template construction of buried pipes and cavities. J. Korea Inst. Struct. Maint. Insp. 2017, 21, 8086. [Google Scholar] [CrossRef]

- Kim, B.; Seol, S.J.; Byun, J. Application of image processing techniques to GPR data for the reliability improvement in subsurface void analysis. Geophys. Geophys. Explor. 2017, 20, 6171. [Google Scholar] [CrossRef]

- Lee, S.H.; Jang, I.H. A study on the underground condition of road using 3D-GPR exploration. J. Korean Geoenviron. Soc. 2019, 20, 49–58. [Google Scholar] [CrossRef]

- Korea Ministry of Government Legislation (KMGL). The Special Law on Underground Safety Act. Law No. 13749; KMGL: Seoul, Korea, 2016. (In Korean)

- Ministry of Land, Infrastructure and Transport (MLIT), Press Release: 192 Cases of Ground Settlement in 2019 Decrease Compared to the Previous Year. Available online: https://www.molit.go.kr/USR/NEWS/m_71/dtl.jsp?lcmspage=2&id=95083566 (accessed on 12 February 2021).

- Park, D.H.; Jang, Y.G.; Choi, H.S. A study on the construction plan of 3D geotechnical information for the support of underground space safety. J. Korean Assoc. Geogr. Inf. Stud. 2018, 21, 23–34. [Google Scholar] [CrossRef]

- Korea Expressway Corporation (KEC). Available online: http://www.ex.co.kr (accessed on 17 March 2021).

- Yoon, W.; Jeong, J.; Lee, J.; Shin, D.; Ko, M. A Study on NDT Techniques for Evaluating Subsurface Condition of Road Pavement; EXTRI-2018-40-534.9607; Expressway & Transportation Research Institute (ETRI): Hwaseong, Korea, 2018. (In Korean) [Google Scholar]

- Expressway & Transportation Research Institute (ETRI). 50 Years of Technology History on Expressways; 0021979; ETRI: Hwaseong, Korea, 2019. (In Korean) [Google Scholar]

- Mostapha, A.M.M.; Faize, A.; Alsharahi, G.; Louzazni, M.; Driouach, A. Effect of external noise on ground penetrating radar ability to detect objects. Int. J. Microw. Opt. Technol. 2019, 14, 124–131. [Google Scholar]

- Quinta-Ferreira, M. Ground penetration radar in geotechnics. advantages and limitations. IOP Conf. Ser. Earth Environ. Sci. 2019, 221, 012019. [Google Scholar] [CrossRef] [Green Version]

- Daniels, D.J. Ground Penetrating Radar: IET Radar, Sonar, Navigation and Avionics Series 15; The Institution of Engineering and Technology: London, UK, 2004. [Google Scholar]

- Rehman, F.; Abouelnaga, H.S.O.; Rehman, F. Estimation of dielectric permittivity, water content, and porosity for environmental engineering and hydrogeological studies using ground penetrating radar, a short review. Arab. J. Geosci. 2016, 9, 312. [Google Scholar] [CrossRef]

- Rhee, J.; Choi, J. Relative permittivity of damaged concrete bridge deck according to the weather condition: A case study. J. Korea Acad.-Ind. Coop. Soc. 2017, 18, 209–215. [Google Scholar] [CrossRef]

- Rhee, J.; Shim, J.; Lee, S.; Lee, K.H. A consideration on the electromagnetic properties of road pavement using ground penetrating radar (GPR). J. Korean Soc. Civ. Eng. 2020, 24, 2049–2062. [Google Scholar] [CrossRef]

- Rhee, J.Y.; Shim, J.; Kee, S.H.; Lee, S.Y. Different characteristics of radar signal attenuation depending on concrete condition of bare bridge deck. KSCE J. Civ. Eng. 2020, 24, 2049–2062. [Google Scholar] [CrossRef]

- Sumiyoshi, T.; Masahashi, H. Outdoor Model Experiment on Exploration Technology for Subsurface Cavity (Deep Part); Tokyo Metropolitan Civil Engineering Assistance and Human Resource Development Center Annual Report; Japan International Cooperation Agency: Tokyo, Japan, 2009; pp. 159–178. [Google Scholar]

- Sumiyoshi, T.; Hashihara, M.; Oishi, M. Outdoor Model Experiment on Subsurface Cavity (Deep) Exploration Technology (Part 2); Tokyo Metropolitan Civil Engineering Technical Support and Human Resource Development Center Annual Report; Japan International Cooperation Agency: Tokyo, Japan, 2011; pp. 101–114. [Google Scholar]

- Lai, W.W.L.; Chang, R.K.W.; Sham, J.F.C. A blind test of nondestructive underground void detection by ground penetrating radar (GPR). J. Appl. Geophys. 2018, 149, 10–17. [Google Scholar] [CrossRef]

- Seoul Metropolitan Government. Seoul Metropolitan Government Announces ‘Bidding for Cavity Exploration Service to Prevent Road Sink’. Press Release, Seoul, Korea. Available online: https://www.seoul.go.kr/news/news_report.do#list/1 (accessed on 25 July 2020).

- Morey, R.M. Ground Penetrating Radar for Evaluating Subsurface Conditions for Transportation Facilities; NCHRP Synthesis Report No. 255. Synth. Highw. Pract.; Transportation Research Board (TRB): Washington, DC, USA, 1998. [Google Scholar]

- ASTM D 6432. Standard Guide for Using the Surface Ground Penetrating Radar Method for Subsurface Investigation; American Society for Testing and Materials (ASTM), ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Al-Qadi, I.L.; Lahouar, S.; Loulizi, A. GPR: From the state-of-the-art to the state-of-the-Practice. In Proceedings of the International Symposium of Non-destructive Testing in Civil Engineering, Berlin, Germany, 16–19 September 2003. CD-ROM. [Google Scholar]

- Conyers, L.B. Analysis and interpretation of GPR datasets for integrated archaeological mapping. Near Surface Geophys. 2015, 13, 645–651. [Google Scholar] [CrossRef] [Green Version]

- Park, B.; Kim, J.; Lee, J.; Kang, M.S.; An, Y.K. Underground object classification for urban roads using instantaneous phase analysis of ground-penetrating radar (GPR) data. Remote. Sens. 2018, 10, 1417. [Google Scholar] [CrossRef] [Green Version]

- Duan, C.; Wu, R.; Liu, J. Estimation of airfield pavement void thickness using GPR. In Proceedings of the 2011 3rd International Asia-Pacific Conference, Seoul, Korea, 26–30 September 2011. [Google Scholar]

- Olhoeft, G.R. Applications and limitations of ground penetrating radar. In Proceedings of the 1984 SEG Annual Meeting, SEG Atlanta, Georgia, 26 December 1984. [Google Scholar] [CrossRef]

- Balanis, C.A. Advanced Engineering Electromagnetics; John Wiley & Sons: New York, NY, USA, 1989. [Google Scholar]

- Maser, K.R.; Scullion, T. Automated Detection of Pavement Layer Thicknesses and Subsurface Moisture Using Ground Penetrating Radar; TRB Paper: Washington, DC, USA, 1991. [Google Scholar]

- Saarenketo, T. Electrical Properties of Road Materials and Subgrade Soils and the Use of Ground Penetrating Radar in Traffic Infrastructure Surveys. Doctoral Dissertation, Department of Geosciences, University of Oulu, Oulu, Finland, 2006. [Google Scholar]

- Al-Qadi, I.L.; Leng, Z.; Lahouar, S.; Baek, J. In-place hot-mix asphalt density estimation using ground-penetrating radar. Transp. Res. Rec. 2010, 2152, 19–27. [Google Scholar] [CrossRef] [Green Version]

- Korea Expressway Corporation (KEC). Quality Standards for Highway Construction Materials, 16th ed.; KEC: Hwaseong, Korea, 2016. (In Korean) [Google Scholar]

- MALÅ, Guideline Geo. Available online: https://www.guidelinegeo.com (accessed on 17 March 2021).

- Isung Coporation. Available online: https://www.isung.com:6066 (accessed on 17 March 2021).

- Radar Portal Systems Pty. Ltd. Available online: http://www.radarportal.com/ (accessed on 17 March 2021).

- Baek, J.E.; Choe, J.S. Underground survey technique of the road using GPR. J. Korean Soc. Road Eng. Road. 2014, 16, 11–16. [Google Scholar]

- Reeves, B.A.; Müller, W.B. Traffic-speed 3-D noise modulated ground penetrating radar (NM-GPR). In Proceedings of the In 2012 14th International Conference on Ground Penetrating Radar (GPR), IEEE, Shanghai, China, 4–8 June 2012; pp. 165–171. [Google Scholar]

- Korea Meteorological Administration (KMA). Available online: https://www.weather.go.kr/weather/climate/past_cal.jsp (accessed on 20 August 2020).

- Bianchini Ciampoli, L.; Tosti, F.; Economou, N.; Benedetto, F. Signal processing of GPR data for road surveys. Geosciences 2019, 9, 96. [Google Scholar] [CrossRef] [Green Version]

- Rhee, J.Y.; Jung, J.D.; Kim, N.Y.; Shim, J. Recommendations for Guidelines for Underground Survey on Road Using Ground Penetrating Radar, ETRI-2018-17-534.2; Expressway & Transportation Research Institute (ETRI): Hwaseong, Korea, 2018. (In Korean) [Google Scholar]

EPS,

EPS,  empty PE bottle,

empty PE bottle,  water PE bottle,

water PE bottle,  empty earthenware,

empty earthenware,  water earthenware,

water earthenware,  ascon block,

ascon block,  concrete block,

concrete block,  steel plate,

steel plate,  sand + EPS particles,

sand + EPS particles,  rock and

rock and  drainage). CL centerline and A-A’ & B-B’ measuring lines.

drainage). CL centerline and A-A’ & B-B’ measuring lines.

EPS,

EPS,  empty PE bottle,

empty PE bottle,  water PE bottle,

water PE bottle,  empty earthenware,

empty earthenware,  water earthenware,

water earthenware,  ascon block,

ascon block,  concrete block,

concrete block,  steel plate,

steel plate,  sand + EPS particles,

sand + EPS particles,  rock and

rock and  drainage). CL centerline and A-A’ & B-B’ measuring lines.

drainage). CL centerline and A-A’ & B-B’ measuring lines.

| Division | Cavity | Relaxed Zones | ||

|---|---|---|---|---|

| EPS | Earthenware | PE Bottle | Sand + EPS Fragments | |

| Depth | 0.27–3 m | 2–2.5 m | 0.27–1 m | 0.27–2 m |

| Dimension | Φ 0.5 m, Φ 1 m | Φ 0.4 m | 4 L | 2–6 m |

| Appearance |  |  |  |  |

| Note | Filled with air/water | |||

| Division | Others | |||

| Ascon Block | Concrete Block | Rock | Drainage | |

| Depth | 0.27–2.5 m | 0.27–2.5 m | 2–2.5 m | 1.5 m |

| Dimension | 0.1–1 m | 0.1–0.5 m | Φ 0.6 m | Φ 0.9 m |

| Appearance |  |  |  |  |

| Division | System A | System B |

|---|---|---|

| Antenna frequency (MHz) | 400 | 100–4000 |

| Antenna type | Impulse | Coded signal |

| No. of channels | 25 | 30 |

| Survey width(m) | 2.4 | 2.4 |

| Sampling rate(m) | Length 0.08, width 0.1 | Length 0.045, width 0.08 |

| Range(ns) | 40 | 50 |

| Operating software | MIRA Soft ver. 3.82 | Radar Portal Control ver. 2 |

| Analysis software | rSlicer-090902 GPRIS System Vision 1.17.1.11 | Radar Portal Control ver. 2 |

| Survey Date | R.H. | Season | Average Temperature | Note |

|---|---|---|---|---|

| 4 December 2019 | About 45% | Winter | 0.8–5.7 °C (min. 3.9–max. 11.2 °C) | 3 raining days 2, 3 foggy days |

| Division | Asphalt Pavement | Plain Concrete Pavement | CRCP |

|---|---|---|---|

| A-A’ | EPS 4 ea. | EPS 1 ea. | - |

| B-B’ | Steel plate 1 ea., PE bottle 2 ea. | - | - |

| Depth | 0.27–1.0 m | 0.45 m | - |

| Division | Status | Test Result | |||||||

|---|---|---|---|---|---|---|---|---|---|

| System A | System B | ||||||||

| Size (m) | Location in Length (m) | Depth (m) | Depth (m) | Error (m) | Ratio (%) | Depth (m) | Error (m) | Ratio (%) | |

| AP-A01 | D0.5 | 2.00 | 0.27 | 0.30 | 0.03 | 11.11 | 0.30 | 0.03 | 11.11 |

| AP-A02 | D0.5 | 5.00 | 0.75 | 0.87 | 0.12 | 16.00 | 0.80 | 0.05 | 6.67 |

| AP-A03 | D0.5 | 8.00 | 1.00 | 1.27 | 0.27 | 27.00 | 1.20 | 0.20 | 20.00 |

| CP-A02 | D1.0 | 2.00 | 0.45 | 0.35 | 0.10 | 22.22 | 0.50 | 0.05 | 11.11 |

| Assumed dielectrics | 9.0 1 | 8.0 1 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rhee, J.-Y.; Park, K.-T.; Cho, J.-W.; Lee, S.-Y. A Study of the Application and the Limitations of GPR Investigation on Underground Survey of the Korean Expressways. Remote Sens. 2021, 13, 1805. https://doi.org/10.3390/rs13091805

Rhee J-Y, Park K-T, Cho J-W, Lee S-Y. A Study of the Application and the Limitations of GPR Investigation on Underground Survey of the Korean Expressways. Remote Sensing. 2021; 13(9):1805. https://doi.org/10.3390/rs13091805

Chicago/Turabian StyleRhee, Ji-Young, Keon-Tae Park, Jin-Woo Cho, and Sang-Yum Lee. 2021. "A Study of the Application and the Limitations of GPR Investigation on Underground Survey of the Korean Expressways" Remote Sensing 13, no. 9: 1805. https://doi.org/10.3390/rs13091805

APA StyleRhee, J. -Y., Park, K. -T., Cho, J. -W., & Lee, S. -Y. (2021). A Study of the Application and the Limitations of GPR Investigation on Underground Survey of the Korean Expressways. Remote Sensing, 13(9), 1805. https://doi.org/10.3390/rs13091805