Study on the Development Law of Mining-Induced Ground Cracks under Gully Terrain

Abstract

:1. Introduction

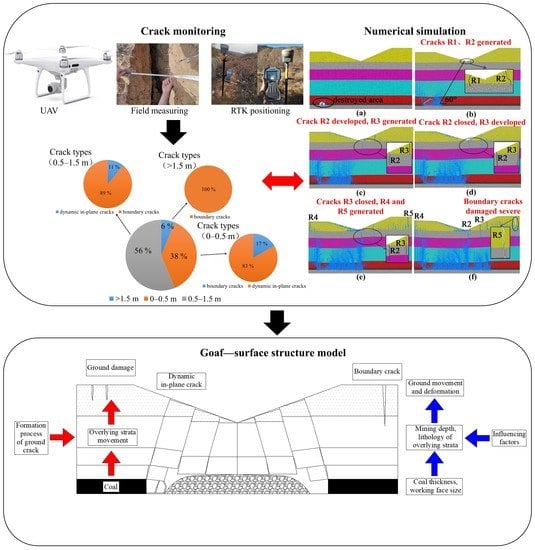

- The ground cracks formed by coal mining under gully terrain are divided into dynamic in-plane cracks and boundary cracks. The characteristics of reduced closure of the dynamic in-plane cracks are revealed.

- The development process of ground cracks is divided into three stages: the initial formation stage, the dynamic development stage, and the gradual stable stage. The “goaf–surface” structure model and force chain arch structure model are established to analyze the formation mechanism of ground cracks.

2. Materials and Methods

2.1. Overview of the Study Area

2.2. Monitoring Measures

2.3. PFC Numerical Simulation

2.3.1. Principles of Particle Flow Code

2.3.2. Model Establishment and Parameter Selection

- (1)

- Model establishment

- (2)

- Parameter selection

3. Results and Analysis

3.1. Static Distribution Characteristics of Ground Cracks

3.2. Dynamic Change Characteristics of Ground Cracks

3.3. Analysis of Numerical Simulation Results

3.3.1. Analysis of Overlying Strata Failure

3.3.2. Analysis of the Development Law of Ground Cracks

- (1)

- Initial formation period: In the early stage of mining, that is, the downhill stage of the working face, the direct top was not completely collapsed, and the damaged area was small. Although there were cracks around the goaf, they had not yet spread to the surface. The surface movement and deformation of the slope under mining were slight, and there were no cracks. When the working face advanced to 72 m, the slope was damaged. Due to its uneven settlement, tension cracks appeared near the bottom of the ditch. The first crack on the surface was recorded as R1, as shown in Figure 12a,b.

- (2)

- Dynamic development period: As the working face continued advancing, the slope was affected by mining and sliding, and the crack width (R2) increased. When the working face advanced to 144 m, there was crack R3 forming on the surface. Crack R2 gradually closed, and crack R3 continued to develop. When the working face advanced to 208 m, the surface movement and deformation extended upward along the slope, and there were cracks R4 and R5 forming at the boundary of the goaf (on both sides of the slope top position). Then, crack R3 gradually closed, as shown in Figure 12c–e. The stable crack width (R2 and R3) was greater than the initial crack width, which was consistent with the field observation results (Figure 13).

- (3)

- Gradually stable period: After mining the working face, the cracks under the slope closed, and the slopes on both sides tended toward stable. Finally, cracks R4 and R5 formed at the boundary. Due to the inconsistent slope gradients on both sides, the damage range of the overlying strata was not symmetrical about the gully center, as shown in Figure 12f. The crack R4 angle was 80° and the crack angle was 67.2°.

3.3.3. Analysis of Force Chain Evolution Law

3.3.4. Analysis of Abutment Pressure Variation in Stope

4. Discussion

4.1. Characteristics of Mining-Induced Ground Cracks under Gully Terrain

- (1)

- The location of crack development: The distribution of ground cracks in the working face is shown in Figure 7. The ground cracks mainly concentrated in the internal scope of the working face and the boundary of the goaf. The extension length ranged from a few meters to tens of meters, and the extension width range a few centimeters to several meters. The boundary cracks were mainly distributed on both sides of the gully slope top and the flat roadway boundary, which were mainly in an arc shape and generally parallel to the goaf boundary. The dynamic in-plane cracks were distributed near the bottom of the gully and both sides of the slope, mostly in a straight line, and the extension direction of the dynamic in-plane cracks was generally perpendicular to the mining direction of the working face.

- (2)

- The obvious step cracks: The ground cracks were mainly the step cracks and collapse cracks. The vertical opening scale or horizontal opening scale of step cracks was large, and the failure range of collapse cracks was large. The formation of ground cracks was closely related to the structure and lithology of overlying strata. Due to the overall collapse of overlying strata after the breaking of the basic roof, the cracks above the goaf spread to the surface, leading to the lateral cracking of the surface soil, the longitudinal subsidence, and the emergence of steps.

- (3)

- The dynamic closure: The size of ground cracks had dynamic changes with coal seam mining. When the working face advanced to a certain distance, the dynamic in-plane crack width gradually reduced and became stable, showing closure. Affected by the coal seam goaf on both sides of the slope and topography, the closure of the cracks was lower than that of the cracks generated under the plain terrain (see Figure 6a; although crack 1 was located above the slope, it was not completely closed after the mining of the working face). However, the cracking degree of the cracks on top of the slope increased (see Figure 6b; crack 2 was located above the slope top, and the damage was more serious), and the direction of cracking tended to the free face.

4.2. Formation Process of Ground Cracks

4.3. Comparison of Different Methods to Study Ground Cracks

5. Conclusions

- (1)

- The development degree of mining-induced ground cracks under gully terrain is strong. The number of cracks with a width of 0–0.5 m accounts for 38%, the number of cracks with a width of 0.5 m to 1.5 m accounts for 56%, and the number of cracks with a width greater than 1.5 m accounts for 6%. Combined with field investigation and numerical simulation results, the ground cracks can be divided into dynamic in-plane cracks (in the working face and parallel to the open-off cut) and boundary cracks (near the stop line, open-off cut, and roadway).

- (2)

- The dynamic in-plane cracks have the activity law of “mountain peak”, and the crack width shows the variation characteristics of “opening first and closing later”. The activity time is 12 days. The slopes on both sides are affected by mining and sliding, and the closure of the cracks will be reduced. The stable crack width is greater than the initial crack width. The width of the boundary crack shows the variation characteristics of “only opening and not closing”, and the activity time is 12 days.

- (3)

- The development process of the cracks experiences three stages: the initial formation stage, the dynamic development stage, and the gradual stable stage. Based on the chain structure between particles, this paper holds that in the process of coal seam mining, the force chain arch structure is formed inside the overlying strata, which is the primary bearing capacity system of the overlying strata, and its development state is closely related to the ground cracks.

- (4)

- The formation of ground cracks is a dynamic development process from bottom to top, namely “coal mining–overlying strata movement–surface deformation–ground cracks”. In this paper, a “goaf–surface” structure model is established to intuitively analyze the formation mechanism and influencing factors of ground cracks.

Author Contributions

Funding

Conflicts of Interest

References

- Brodny, J.; Tutak, M. Analysing the Utilisation Effectiveness of Mining Machines Using Independent Data Acquisition Systems: A Case Study. Energies 2019, 12, 2505. [Google Scholar] [CrossRef] [Green Version]

- Cicmanec, P.; Hrabovsky, J.; Durove, J.B. Mechanized Mining of Might Coal Seams into Complicated Geological and Underground Conditions. Gospod. Surowcami Miner. 2008, 24, 37–47. [Google Scholar]

- Kratzsch, H. Mining Subsidence Engineering; Springer: Berlin/Heidelberg, Germany, 1983. [Google Scholar]

- Zhang, Y.; Kong, J.; Long, S.; Zhu, Y.; Zhu, W.; Wu, T. Study on the Ground Fissure Development Law of Coal Mining Based on UAV Photogrammetry and the Particle Flow Theory. Front. Environ. Sci. 2022, 10, 915645. [Google Scholar] [CrossRef]

- Wang, R.; Wu, K.; He, Q.; He, Y.; Gu, Y.; Wu, S. A Novel Method of Monitoring Surface Subsidence Law Based on Probability Integral Model Combined with Active and Passive Remote Sensing Data. Remote Sens. 2022, 14, 299. [Google Scholar] [CrossRef]

- Li, G.; Wan, Y.; Guo, J.; Ma, F.; Zhao, H.; Li, Z. A Case Study on Ground Subsidence and Backfill Deformation Induced by Multi-Stage Filling Mining in a Steeply Inclined Ore Body. Remote Sens. 2022, 14, 4555. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, Y.; Zhu, Y.; Cai, J.; Wang, J. Quantitative Study on the Law of Surface Subsidence Zoning in Steeply Inclined Extra-Thick Coal Seam Mining. Sustainability 2022, 14, 6758. [Google Scholar] [CrossRef]

- Dulias, R. The Impact of Mining on the Landscape: A Study of the Upper Silesian Coal Basin in Poland; Environmental Science and Engineering; Springer International Publishing: Cham, Switzerland, 2016; p. 209. [Google Scholar]

- Marschalko, M.; Yilmaz, I.; Kfistkova, V.; Fuka, M.; Kubecka, K.; Bouchal, T. An indicative method for determination of the mosthazardous changes in slopes of the subsidence basins in underground coal mining area in Ostrava (Czech Republic). Environ. Monit. Assess. 2013, 185, 509–522. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, P.; Qin, Q.; Wang, H. The effects of land subsidence and rehabilitation on soil hydraulic properties in a mining area in the loess plateau of china. CATENA 2017, 159, 51–59. [Google Scholar] [CrossRef]

- Xu, Y.K.; Wu, K.; Li, L.; Zhou, D.W.; Hu, Z.Q. Ground cracks development and characteristics of strata movement under fast excavation: A case study at Bulianta coal mine, China. Bull. Eng. Geol. Environ. 2019, 78, 325–340. [Google Scholar] [CrossRef]

- Henselowsky, F.; Rlkens, J.; Kelterbaum, D.; Bubenzer, O. Anthropogenic relief changes in a long-lasting lignite mining area (“ville”, Germany) derived from historic maps and digital elevation models. Earth Surf. Process. Landf. 2021, 46, 1725–1738. [Google Scholar] [CrossRef]

- Harnischmacher, S.; Zepp, H. Mining and its impact on the earth surface in the Ruhr district (Germany). Z. Geomorphol. Suppl. Issues 2014, 58, 3–22. [Google Scholar] [CrossRef]

- Solarski, M. Anthropogenic transformations of the bytom area relief in the period of 1883–1994. Environ. Socio-Econ. Stud. 2013, 1, 1–8. [Google Scholar] [CrossRef]

- Nadudvari, A. Using radar interferometry and SBAS technique to detect surface subsidence relating to coal mining in Upper Silesia from 1993–2000 and 2003–2010. Environ. Socio-Econ. Stud. 2016, 4, 24–34. [Google Scholar] [CrossRef] [Green Version]

- Hejmanowski, R.; Malinowska, A.A. The Impact of Deep Underground Coal Mining on Earth Fissure Occurrence. Acta Geodyn. Geomater. 2016, 13, 321–330. [Google Scholar]

- Malinowska, A.A.; Misa, R.; Tajdus, K. Geomechanical modeling of subsidence related strains causing earth fissures. Acta Geodyn. Geomater. 2018, 15, 197–204. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.K.; Mojtabai, N.; Lee, H.B.; Song, W.K. Assessment of the influencing factors on subsidence at abandoned coal mines in south korea. Environ. Earth Sci. 2013, 68, 647–654. [Google Scholar] [CrossRef]

- Deb, D.; Choi, S.O. Analysis of sinkhole occurrences over abandoned mines using fuzzy reasoningm: A case study. Geotech. Geol. Eng. 2006, 24, 1243–1258. [Google Scholar] [CrossRef]

- Akcin, H.; Kutoglu, H.S.; Kemaldere, H.; Deguchi, T.; Koksal, E. Monitoring subsidence effects in the urban area of Zonguldak Hardcoal Basin of Turkey by InSAR-GIS integration. Nat. Hazards Earth Syst. Sci. 2010, 10, 1807–1814. [Google Scholar] [CrossRef]

- Genis, M.; Akn, H.; Aydan, M.; Bacak, G. Investigation of possible causes of sinkhole incident at the Zonguldak coal basin, turkey. Geomech. Eng. 2018, 16, 177–185. [Google Scholar]

- Ghosh, G.K.; Sivakumar, C. Application of underground microseismic monitoring for ground failure and secure longwall coal mining operation: A case study in an Indian mine. J. Appl. Geophys. 2018, 150, 21–39. [Google Scholar] [CrossRef]

- Tiwari, A.; Narayan, A.B.; Dwivedi, R.; Swadeshi, A.; Pasari, S.; Dikshit, O. Geodetic investigation of landslides and land subsidence: Case study of the Bhurkunda coal mines and the Sirobagarh landslide. Surv. Rev. 2018, 52, 134–149. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Zhao, Y.; Zhu, Y.; Yan, Y. Study on Stability Discrimination Technology of Stope Arch Structure. Sustainability 2022, 14, 11082. [Google Scholar] [CrossRef]

- Tudor, G.; Catalin, N.M.; Camelia, B.; Diana, M. Impacts of mining activities on surface deformation. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management—SGEM, Florence, Italy, 23–26 October 2018; Volume 18, pp. 489–495. [Google Scholar]

- Liu, H.; He, C.G.; Deng, K.Z.; Bian, Z.F.; Fan, H.D. Analysis of Forming Mechanism of Collapsing Ground Fissure Caused by Mining. J. Min. Saf. Eng. 2013, 30, 380–384. [Google Scholar]

- Che, X.Y.; Hou, E.K.; Sun, X.Y.; Jiang, Y.Q.; Xie, X.S. Research on Overburden Breaking Characteristics and Ground Crack Formation Mechanism of Shallow Coal Seam Under the Gully. J. Xi’an Univ. Sci. Technol. 2021, 41, 104–111. [Google Scholar]

- Liu, H.; Deng, K.Z.; Lei, S.G.; Bian, Z.F.; Chen, D.Y. Dynamic Developing Law and Governance Standard of Ground Fissures Caused by Underground Mining. J. Min. Saf. Eng. 2017, 34, 884–890. [Google Scholar]

- Pilecka, E.; Szwarkowski, D. An Application of the Ground Laser Scanning to Recognise Terrain Surface Deformation over a Shallowly Located Underground Excavation. E3S Web Conf. 2017, 24, 01006. [Google Scholar] [CrossRef]

- Kang, J.R. Analysis of Effect of Fissures Caused by Underground Mining on Ground Movement and Deformation. Chin. J. Rock Mech. Eng. 2008, 27, 59–64. [Google Scholar]

- He, W.L.; Kang, J.R. Laws of Ground Movement and Deformation in Mountainous Areas. J. China Coal Soc. 1992, 17, 1–15. [Google Scholar]

- Hu, Z.Q.; Wang, X.J.; He, A.M. Distribution characteristic and development rules of ground fissures due to coal mining in windy and sandy region. J. China Coal Soc. 2014, 39, 11–18. [Google Scholar]

- Xu, J.L.; Zhu, W.B.; Wang, X.Z.; Zhang, Z.Q. Influencing Mechanism of Gully Terrain on Ground Pressure Behaviors in Shallow Seam Longwall Mining. J. China Coal Soc. 2012, 37, 179–185. [Google Scholar]

- Zhang, Z.Q.; Xu, J.L.; Liu, H.L.; Li, H.W. Influencing Laws Study of Depth of Gully on Dynamic Strata Pressure of Working Face in Shallow Coal Seams. J. Min. Saf. Eng. 2013, 30, 501–505. [Google Scholar]

- Li, J.W.; Liu, C.A.; Zhao, J.; Wang, W.C.; Bu, Q.W. Study on Occurrence Mechanism and Control Technology of Mining-induced Strata Pressure in Shallow Depth Coal Seams of Valley Region. Coal Sci. Technol. 2018, 46, 104–110. [Google Scholar]

- Zhao, J.; Liu, C.A.; Li, J.W. Overburden Failure and Strata Pressure Behavior Characteristics Under Condition of Shallow Coal Seam in Gully Terrain. Coal Sci. Technol. 2017, 45, 34–40. [Google Scholar]

- Zhao, J.; Liu, C.A.; Li, J.W. Three-dimensional Geological Modeling and Surface Damage in Gully Area Due to Shallow Coal Seam Mining. J. Min. Saf. Eng. 2018, 35, 97–105. [Google Scholar]

- Liu, H.; Liu, X.Y.; Deng, K.Z.; Lei, S.G.; Bian, Z.F. Developing Law of Sliding Ground Fissures Based on Numerical Simulation Using UDEC. J. China Coal Soc. 2016, 41, 625–632. [Google Scholar]

- Salmi, E.F.; Nazem, M.; Karakus, M. Numerical Analysis of a Large Landslide Induced by Coal Mining Subsidence. Eng. Geol. 2017, 217, 141–152. [Google Scholar] [CrossRef]

- Trong, N.D.; Wu, J.H. Simulating a Mining-triggered Rock Avalanche Using DDA, a Case Study in Nattai North Australia. Eng. Geol. 2019, 264, 105386. [Google Scholar]

- Wang, C.L.; Zhang, C.S.; Zhao, X.D.; Liao, L.; Zhang, S.L. Dynamic Structural Evolution of Overlying Strata During Shallow Coal Seam Longwall Mining. Int. J. Rock Mech. Min. Sci. 2018, 103, 20–32. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, Y.; Dai, H.; Zhu, Y.; Wu, T. Stability and force chain characteristics of “inclined step cutting body” in stope. Appl. Sci. 2021, 11, 10276. [Google Scholar] [CrossRef]

- Zhou, J.; Chi, Y.; Chi, Y.W.; Xu, J.P. The Method of Particle Flow and PFC2D Code. Rock Soil Mech. 2000, 21, 271–274. [Google Scholar]

- Chen, P.Y. Research Progress on Pfc2d Simulation of Crack Propagation Characteristics of Cracked Rock. J. Eng. Geol. 2018, 124, 253–264. [Google Scholar]

- Lee, H.; Jeon, S. An Experimental and Numerical Study of Fracture Coalescence in Pre-cracked Specimens Under Uniaxial Compression International. J. Solids Struct. 2011, 48, 979–999. [Google Scholar] [CrossRef]

- Sun, Q.C.; Wang, G.Q. Review on Granular Flow Dynamics and Its Discrete Element Method. Adv. Mech. 2008, 38, 87–100. [Google Scholar]

- Dai, H.Y.; Zhai, J.C.; Hu, Y.J. Testing Study on Surface Displacement of Mountainous Region with Similar Material Chinese. J. Rock Mech. Eng. 2000, 19, 501–504. [Google Scholar]

- Hou, E.K.; Cong, T.; Xie, X.S.; Wei, J.B. Ground surface fracture development characteristics of shallow double coal seam staggered mining based on particle flow. J. Min. Strata Control Eng. 2020, 2, 013521. [Google Scholar]

- Cai, M.F. Key theories and technologies for surrounding rock stability and ground control in deep mining. J. Min. Strata Control Eng. 2020, 2, 033037. [Google Scholar]

- Hu, Q.F.; Cui, X.M.; Liu, W.K.; Ma, T.J.; Geng, H.R. Law of overburden and surface movement and deformation due to mining super thick coal seam. J. Min. Strata Control Eng. 2020, 2, 023021. [Google Scholar]

| Description | Loess Layer | Mudstone | Medium-Coarse Sandstone | Fine Sandstone | Siltstone | Coal | Mudstone |

|---|---|---|---|---|---|---|---|

| Volume-weight | 18 | 24 | 25 | 24 | 24 | 14 | 24 |

| Minimum radius of particles | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Particle Radius Ratio | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Effective modulus of flat joint | 0.4 | 13.2 | 18 | 16 | 26.4 | 4 | 13.2 |

| Rigidity ratio of flat joint | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Average tensile strength and standard deviation of flat joints | 0.1/0.025 | 0.8/0.2 | 1.1/0.275 | 1/0.25 | 1.2/0.3 | 0.25/0.0625 | 0.8/0.2 |

| Average cohesion and standard deviation of flat joints | 4/1 | 20/5 | 20/5 | 20/5 | 20/5 | 10/2.5 | 20/5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lian, X.; Yan, Y.; Zhu, Y.; Dai, H. Study on the Development Law of Mining-Induced Ground Cracks under Gully Terrain. Remote Sens. 2022, 14, 5985. https://doi.org/10.3390/rs14235985

Zhang Y, Lian X, Yan Y, Zhu Y, Dai H. Study on the Development Law of Mining-Induced Ground Cracks under Gully Terrain. Remote Sensing. 2022; 14(23):5985. https://doi.org/10.3390/rs14235985

Chicago/Turabian StyleZhang, Yanjun, Xugang Lian, Yueguan Yan, Yuanhao Zhu, and Huayang Dai. 2022. "Study on the Development Law of Mining-Induced Ground Cracks under Gully Terrain" Remote Sensing 14, no. 23: 5985. https://doi.org/10.3390/rs14235985

APA StyleZhang, Y., Lian, X., Yan, Y., Zhu, Y., & Dai, H. (2022). Study on the Development Law of Mining-Induced Ground Cracks under Gully Terrain. Remote Sensing, 14(23), 5985. https://doi.org/10.3390/rs14235985