1. Introduction

In metallurgy, the blast furnace (BF) is a crucial component of the iron-making process. It serves as the main reactor in which raw materials, such as iron ore, coke, and limestone, are transformed into molten iron [

1]. The efficiency and effectiveness of a BF heavily rely on various factors, one of which is the shape of the burden surface profile. This factor refers to the distribution of materials and plays a significant role in maintaining optimal conditions for efficient operation. A well-maintained burden surface profile ensures that there is an even flow of gases and liquids throughout the furnace, allowing for better heat transfer and chemical reactions, enhancing energy utilization, and decreasing emissions [

2].

However, the modern BF is a large-scale “black box” piece of equipment, and conventional optical gauging methods are unable to observe the true status of the enclosed environment. High temperatures, high pressure, high dust levels, and limited space inside the BF are the major obstacles. The synthetic aperture radar (SAR) imaging algorithm is a well-developed technique for high-resolution image reconstruction, which can be applied for burden surface profile imaging. In [

3], the TerraSAR-X add-on for digital elevation measurements (TanDEM-X) and Tandem-L were designed as the ideal databases for interferometric SAR techniques and applications. In [

4], a new polarimetric interferometry inverse synthetic aperture radar (Pol-InISAR) 3D imaging method was proposed. In [

5], an extended Omega-K (EOK) algorithm was proposed for high-speed–high-squint SAR with a curved trajectory.

In this case, the frequency-modulated continuous wave (FMCW) radar-based measurement system using a rotating SAR imaging mechanism was applied in this study for acquiring an accurate burden surface profile shape. The FMCW radar system is more suitable for the near range and limitation space, achieving higher imaging precision than pulse radar but being more costly. Compared with the array radars [

6] and MIMO antenna radar [

7] used for burden surface imaging before, the rotating SAR imaging mechanism is currently the best choice under the BF condition, which obtains the apertures in time series to form a virtual synthetic aperture; therefore, imaging resolution is higher than real aperture scanning radar [

8,

9], and then, the image-processing-based detection algorithm is employed to describe the true burden surface profile shape [

10,

11].

The material surfaces of the burden surface profile are atypically and randomly rough and in multiple states. Processing the scattering and diffusion of FMCW signals from these material surfaces poses a significant challenge. In [

12], the Hilbert–Huang transform was proposed for analyzing echo components aimed at decomposing background noise. On the basis of prior information, in [

13], a hybrid signal processing method, consisting of preprocessing, denoising, spectrum refinement, and frequency band interception, was proposed. In [

14], the theory of particle matter accumulation in soil slope mechanics was utilized to simulate the burden surface profile shape, with the purpose of calibrating the results calculated by the signal. In these methods, only individual signals are used to analyze the material surface characteristics, which neglected the burden surface profile’s spatial continuity. In the mechanical swing radar system, the sampled signal from one round of radar scanning can be expressed as a spectral matrix, which contains the frequency information of all the sample points on the radius of the burden surface profile. Variance extraction [

15] was proposed for estimating the correlation of each sample point, and the K-means [

16] method was proposed for separating false points polluted by random noise. The constant false alarm rate (CFAR) method has robust FMCW radar performance potential, and in [

17], a dual-focus SAR imaging (DfSAR) and fusion algorithm combined with CFAR was proposed.

All of the above methods use denoising to reconstruct high-resolution images under low signal-to-noise (SNR) conditions. However, they cannot consider the under-sampled FMCW signals caused by the harsh environment inside the BF, which critically reduces the precision of burden surface profile imaging. The sparsity of FMCW signals makes the compressive sensing (CS)-based SAR imaging technique an alternative solution that has been extensively applied in various domains, such as in urban areas, forests, and oceans [

18]. For inverse SAR (ISAR), a high-resolution gapped stepped-frequency waveform (GSFW) ISAR imaging framework was proposed in [

19]. CS theory was applied in conjunction with the newly devised cost function and particle swarm optimization in order to accurately estimate the translational motion parameter. For bistatic SAR, a CS-based method was proposed in [

20], which exploits the natural sparsity in depicting the illuminated scene to enhance the imaging quality under multi-aperture acquisition. For the ground moving-target imaging algorithm, a novel framework was proposed in [

21], whereby CS theory was utilized to decompose the sampled polynomial basis function signal series so that the various phase errors caused by higher-order movements can be removed. For the linear FMCW radar system [

22], a CS image reconstruction was implemented via the sub-gradient descent algorithm with an optimal step size.

However, in burden surface profile imaging inside a BF, high noise is always unavoidable. The traditional CS method, which only contains sparse priors, cannot evade high noise interference in the imaging process [

23]. Inspired by the fact that the low-rank signal matrix obtained from the mechanical swing radar measurement system has strong intra-correlations between its columns and rows, both the low-rank and sparsity priors must be considered in SAR image reconstruction [

24]. For example, in [

25], a combination of low-rank and CS with ISAR sparse imaging was proposed. In [

26], referencing prior knowledge, a nonlocal low-rank-based CS method was proposed for remote sense imaging. The over-smoothness of low-rank regularization was compensated for, and better groups were gained in a brief period. In [

27], a fast algorithm set was proposed for accelerated dynamic magnetic resonance imaging (MRI) based on traditional CS reconstruction, where the low-rank matrix model was assumed to have a three-level hierarchy. This study uses both the low-rank and sparsity priors to reconstruct appropriate burden surface profile images for accurate shape detection. The main contributions of this study are as follows:

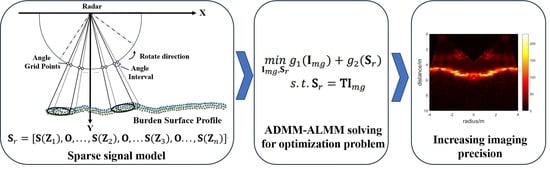

- (i)

The sparse FMCW signal is modeled based on the mechanical swing radar system and the rotating SAR imaging mechanism in the BF. The position transform matrix is embedded into the dictionary matrix for position calibration, whereby the position transform matrix is composed of the angle and distance transform matrixes calculated according to the BF dimensions.

- (ii)

The alternating direction method of multipliers (ADMM) is an efficient framework that has successfully converged in other sparse SAR imaging problems [

28,

29,

30]. The low-rank and sparsity priors can be reformulated as split variables, and the Hessian information of the objective function is exploited to establish the convex optimization problem. With the help of an augmented Lagrange multiplier (ALM), the ADMM can address the double priors’ constrained optimization problem.

- (iii)

Through iterative computations, the convergence output is the final imaging result. Based on these imaging results, subsequent shape detection is performed. The imaging precision is evaluated via the shape precision of the detected burden surface profile, and the robustness of the proposed algorithm is compared against others. The measurement data were collected from the Wuhan Iron & Steel Company in Wuhan China No. 7 BF and the Nanjing Iron & Steel Company in Nanjing China No. 4 BF.

The remainder of this article is organized as follows. In

Section 2, the constructed mechanical swing radar system is proposed, and the SAR imaging algorithm in a BF is described. Based on these, the reason for the under-sampled FMCW signals is explained. In

Section 3, a novel burden surface profile imaging algorithm jointly using low-rank and sparsity priors is proposed in detail. In

Section 4, the experimental results represent the evaluation of the proposed algorithm compared to other imaging algorithms.

Section 5 contains the discussion, and in

Section 6, the conclusions are presented.

2. SAR Imaging for Burden Surface Profile

2.1. Mechanical Swing Radar Measurement System

The mechanical swing radar system is stably applied to the BFs of the Wuhan Iron & Steel Company and Nanjing Iron & Steel Company, and the experimental data are provided in this work.

A schematic diagram of the mechanical swing radar system is shown in

Figure 1. On the top of the furnace, a secure position is selected, and the radar rotation instruments driven by the programmable logic controller (PLC) motor are installed symmetrically. The whole instrument is soldered on the install position, making translational motion impossible.

The plug-in-type structure has a baffle that protects the core circuit elements from the hostile internal environment. When the charging signal from the object linking and embedding (OLE) process control server is submitted, the horn-shaped antenna begins self-rotating with a fixed hub to gauge the entire radius of the burden surface profile. The temperature inside the BF is about 300–800 °C, and the rotation time is about 25 s. In the other time, the horn-shaped antenna is protected inside the instrument by the steel sleeve, cooling water flows through the water inlet pipe, and the flushing nitrogen is blown through the air tube.

The gas and water pipelines demand firm welding, and the whole protector occupies a large amount of space in the BF. Therefore, an adequate swing angle is required so that the mechanical swing radar does not collide with other instruments inside the BF, such as the distributing chute.

2.2. Imaging Model

For SAR imaging in a BF, the main measurement target is the burden surface profile, which is essentially an atypically, randomly rough, and multi-state material surface [

31]. The propagation and scattering of signals are chaotic and superimposed on each other, which easily causes artifacts.

To address the above problem, the burden surface profile is modeled as the distribution function

of the two-dimensional rough surface contour and texture (as shown in

Figure 2), which can be expressed as follows:

where

denotes the number of sample points in the

dimension and

denotes the number of sample points in the

dimension. Defining

and

as the intervals between adjacent sample points in the

and

dimensions, the Fourier function

is expressed as follows:

where

and

denote the discrete wavenumbers such that

.

denotes the imaginary component, and

denotes the normal distribution function. The burden surface profile is assumed to be a random material surface obeying Gaussian distribution, and the function

of the rough surface density can be expressed as follows:

where

and

are the root mean square and distance in the

dimension, respectively, while

and

are the root mean square and distance in the

dimension, respectively.

As confirmed by the experimental results of the rough surface on the cold-state burden surface profile, the average root mean square or and the average distance or conform to the preconditions of the Kirchhoff approximation, which can be employed to approximate the scattered field on the burden surface profile as many tangent planes. Then, the principle of the stationary phase (POSP) is implemented to simplify the calculation.

Through Kirchhoff approximation, for the sample point

with incident angle

, the distance

is calculated by

and

, and the root mean square

is calculated by

and

. Then, the scattering coefficient

can be expressed as follows:

where

and

is the wavelength of FMCW.

The SAR imaging model is shown in

Figure 3. The scattering point set

is arranged along the

Z-axis, and the signal response time series represents the propagation distance.

The scattering FMCW signal

is expressed as follows:

The scattering coefficient

is obtained from Equation (4). In the antenna design of the mechanical swing radar, the radiation intensity is assumed to be concentrated between two half-power points and uniformly distributed. Therefore, for the sample point

, the spectral power of signal

is written as follows:

where

is the transmitting power,

is the antenna gain, and

is the surface area of the sample point. The calculation results,

constitute the spectral matrix for imaging in the next subsection.

2.3. Image Reconstruction

Several sample point sets are acquired after a single scan of the radar instrument. These point sets consist of the signals received in the time series, which can be formulated into a spectral matrix,

, for calculation as follows:

where

is the spectral vector calculated in Equation (6) at time

. The intensity distribution of the spectral vector series can depict the radial shape of the burden surface profile, as shown in

Figure 4.

However, this direct imaging method cannot correctly depict the real radial distribution. An interpolation algorithm considering the position transform matrix

calculated by the dimensions of the BF is implemented to calibrate the burden surface profile shape [

32]. The interpolation model is shown in

Figure 5.

The white point set is the calibrated imaging result

, and the black point set is the postprocessed matrix

considering the position expressed as follows:

where

is the angle transform matrix and

is the distance transform matrix. In the given interpolation region

with

elements, the entropy weight

is obtained by the characteristics of matrix

, as shown in Equation (9). This is the critical index for completing the interpolation process.

Finally, the burden surface profile imaging matrix

is calculated as follows:

This entropy weight interpolation algorithm has been employed for a while in BFs, but it ignores the sparsity of signal.

2.4. Under-Sampled Signal

When measuring, the antenna can be directly damaged by the hostile internal environment. To prolong the system’s lifespan, the imaging geometry of the mechanical swing radar is shown in

Figure 6. The radar scanning area is a sector that can be adjusted by the rotation angle. During one round of scanning, electromagnetic waves are transmitted at equal time intervals to form a moving beam that irradiates the target area. The aperture is increased by synthetizing the overlap of multiple illumination areas, thereby improving imaging resolution through extended equivalent apertures.

However, it is necessary to set a long interval for antenna protection, which results in high angle intervals and sparse angle grid points on the edge of the sector. The imaging precision will be decreased by the insufficient accumulation of scattered energy and low imaging resolution resulting from the long intervals, and in reality, the spectral matrix is sparse. A new imaging algorithm is proposed in the next section.

4. Experiment

In this section, simulation and contrast experiments were conducted to validate the effectiveness of the proposed algorithm. The experimental data were collected from the Wuhan Iron & Steel Company No. 7 BF and Nanjing Iron & Steel Company No. 4 BF. The experimental platform was MATLAB R2016b running Windows 10. The parameter settings were and , the maximum number of iterations of was 150, and .

4.1. Comparative Simulation Results

In this subsection, a simulation test was conducted to compare the performances of the proposed algorithm (denoted as JLRS-BSP in the following) against others such as the traditional CS method (denoted as CS in the following) and the ISAR imaging algorithm jointly using low-rank and sparsity priors (denoted as JLRS in the following). A sample point target scattering simulation was conducted. The root mean square error (RMSE) was employed as the primary performance indicator, defined as follows:

where

is the iterative calculated result from Algorithm 3. A smaller RMSE value indicates a better performance. As shown in Algorithm 3, the final output

can be evaluated by another indicator, and the image correlation criterion (Corr) is defined as follows:

where

is obtained by entropy weight interpolation (denoted as EWI in the following), as shown in Equation (10), serving as the reference image, and

is the vector function. This index depicts the similarity between the imaging result and the reference image, indicating a better performance when the algorithm correlation is higher.

Furthermore, Gaussian white noise was added to the raw data to simulate high BF noise. Comparative simulations were conducted under both low-SNR and high-SNR conditions, and the SNR is expressed as follows:

where

is the starting frequency of the effective band in the FMCW, and

is the termination frequency. The effective band was estimated in order to determine the scattering intensity of the target.

Table 1 details the comparative results of the above methods under different SNR conditions. The values of RMSE and Corr were both average in 75 Monte Carlo simulations.

Table 1 shows that the RMSE of the proposed JLRS-BSP was the lowest, and the Corr was the highest. The traditional CS method was unable to overcome the noise interference caused by high temperatures, high dust levels, and high pressure in the BF, resulting in performance degradation as the SNR decreased. The JLRS was not suitable for the FMCW sample conditions originally designed for ISAR imaging.

The EWI algorithm has been used for a long time for calculating the Corr in BF production, but this ignores the sparsity and low-rank property of the spectral matrix. Using the EWI algorithm results as reference images may not be entirely reliable. The Corr discrepancy between the EWI and JLRS-BSP is small. Therefore, in the following subsection, the precision of and will be analyzed based on real data.

4.2. Real Data Comparison

In this subsection, the experimental data are collected by the mechanical swing radar measurement system installed on the BFs of the Iron & Steel Company, which measured the burden surface profile data during various stages of the iron-making process. The key parameters of the radar are shown in

Table 2.

Figure 7a shows the installation procedure of the mechanical swing radar measurement system, and

Figure 7b shows its working process.

Contrast experiments were conducted on the currently used EWI algorithm, the traditional CS method, and the JLRS-BSP. The precision and reliability during actual industrial production in the BF were evaluated. Before this, the validation of mechanical swing radar measurement results had to be confirmed, as the BF is a “black box”, and the real shape of the burden surface profile cannot be directly observed using an optical method. At the experimental base of the Nanjing Iron & Steel Company (as shown in

Figure 8), a cold-state burden surface profile was created, and a mechanical swing radar was deployed for testing.

For experimental purposes, a cold-state burden surface profile was constructed using coke and ore according to planned dimensions. The mechanical swing radar was installed approximately 3 m above the constructed burden surface profile.

Figure 9 shows the dimension diagrams of the constructed burden surface profile and the imaging results. In

Figure 9a, from right to left, the furnace wall to the furnace core (as shown in

Figure 1) is simulated; there is a higher platform that is 1.4 m wide, followed by a slope that is 0.4 m wide and 0.25 m high. Finally, the lower platform is 1.9 m wide. The whole width is approximately 3.7 m, and the whole height is approximately 2.4 m to 2.6 m.

Figure 9b is the imaging result of

Figure 9a; the color scale bar shows the spectral power value

calculated in Equation (6). The radar is located on the origin of the coordinates; the

-axis represents the relative radius position, and the

-axis represents the vertical distance from the radar.

It can be seen that the constructed dimension is completely consistent with the imaging results. Moreover, the dimensions of the platform and slope are changed, and the diagram and imaging results are shown in

Figure 9c and

Figure 9d, respectively.

The performances of different algorithms, including EWI, the traditional CS method, and the proposed JLRS-BSP, are compared. The imaging results are shown in

Figure 10; the color scale bar shows the spectral power value

. The

-axis represents the relative radius position of the furnace core, and the

-axis represents the vertical distance from the radars; dual radars are located on around (−3,0) and (3,0).

From left to right:

(1) EWI: cannot completely construct the radial shape of the burden surface profile target. The distribution of the scattering intensity is sparse, and there are many large pixel blocks contained in the images. (2) CS: when the noise is not high, the imaging results are clear; when the noise is high, it fails to achieve satisfactory imaging. The ability to constrain high noise levels is thus limited. (3) JLRS-BSP: the proposed algorithm can obtain clear imaging results and accurately construct the radial shape of the burden surface profile target, even under low-SNR conditions.

Three metrics for image resolution are calculated, and

Table 3 shows that the imaging resolution of the JLRS-BSP is the most superior and satisfactory for subsequent processing. The imaging resolution of CS is better in some cases, but when the noise is high, the imaging resolution is the worst, and the average metrics are thus pulled down.

Based on the above imaging results, the imaging precision of different algorithms are evaluated by reconstructed shape precision, and a shape detection method using deep learning-based key point estimation [

40] is employed. The exact shape of the burden surface profile is extracted by converting its band region into a geometric curve (burden line). Under the supervision of the BF experts and in conjunction with the mechanical probe data, a comparison of the average RMSE between the real and extracted burden lines using the above three algorithms was established. This is presented in

Table 4.

As can be seen in this table, comparing EWI with the proposed JLRS-BSP, the average RMSE decreases from 0.0156 to 0.0132 by 15.38%. For the traditional CS method and JLRS-BSP, the difference in average RMSE may not be obvious when the quantity of high-noise images in the experimental dataset is small; however, the average RMSE still decreases from 0.0148 to 0.0132 by 10.81%.

The testing dataset consisting of 850 images is divided into four classes based on SNRs of 5-dB, 5~10 dB, 10~30 dB, and 30+ dB, as shown in

Table 5.

From

Table 5, it can be seen that the RMSE of the traditional CS method increases rapidly when the SNR is lower. When the SNR is under 5 dB, comparing EWI with JLRS-BSP, the average RMSE decreases from 0.0275 to 0.0232 by 15.63%. The JLRS-BSP is more robust than the others, especially under low-SNR conditions.

6. Conclusions

For SAR imaging in both enclosed and harsh environments, imaging precision is limited by signal sparsity and high noise interference. In this case, the low-rank property of the signal matrix and the sparsity of imaging matrix must be considered. Based on the FMCW mechanical swing radar, this study proposed a valid algorithm jointly using low-rank and sparsity priors to increase the burden surface profile imaging precision. In the sparse signal model, the position transform matrix embedded in the dictionary matrix was used for position calibration according to the BF’s dimensions. Furthermore, the low-rank property of the signal matrix was analyzed, and a convex optimization problem was established in which low-rank and sparsity priors were reformulated as split variables with a regularized Hessian of the data-fidelity term. The ALM was then employed to address the two constraints, and the imaging result was finally obtained via ADMM. Finally, the imaging precision was evaluated according to the reconstructed shape precision. As confirmed through experiments using both simulated and real data, the proposed algorithm is not only superior in terms of imaging precision, achieving the lowest RMSE of 0.0132, but also more robust in high-noise environments, where RMSE is maintained at 0.0232 when the SNR is under 5 dB. The higher burden surface profile imaging precision can provide better assistance for BF operators in the iron-making process.

In future research, the algorithm proposed in this study will be further optimized to improve running speed. The pattern of hyperparameter selection will also be found and combined with the corresponding physical model inside a BF. Moreover, a system for 3D measurement will be explored and established, probably combined with the ISAR concept.