Measurement of Heat Dissipation and Thermal-Stability of Power Modules on DBC Substrates with Various Ceramics by SiC Micro-Heater Chip System and Ag Sinter Joining

Abstract

:1. Introduction

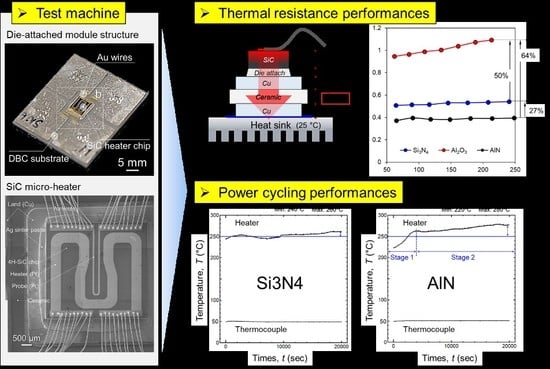

2. Materials and Methods

2.1. SiC Micro-Heater Chip and Direct Bonded Copper (DBC) Substrate

2.2. Die Attach Material

2.3. Test Machine and Method

3. Results and Discussion

3.1. Steady-State Thermal Resistance

3.2. Power Cycling Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gao, Y.; Zhang, H.; Li, W.; Jiu, J.; Nagao, S.; Sugahara, T.; Suganuma, K. Die bonding performance using bimodal Cu particle paste under different sintering atmospheres. J. Electron. Mater. 2017, 46, 4575–4581. [Google Scholar] [CrossRef]

- Wong, K.Y.; Chen, W.; Liu, X.; Zhou, C.; Chen, K.J. GaN smart power IC technology. Phys. Status Solidi Basic Res. 2010, 247, 1732–1734. [Google Scholar] [CrossRef]

- Roccaforte, F.; Giannazzo, F.; Iucolano, F.; Eriksson, J.; Weng, M.H.; Raineri, V. Surface and interface issues in wide band gap semiconductor electronics. Appl. Surf. Sci. 2010, 256, 5727–5735. [Google Scholar] [CrossRef]

- Kim, D.; Chen, C.; Pei, C.; Zhang, Z.; Nagao, S.; Suetake, A.; Sugahara, T.; Suganuma, K. Thermal shock reliability of a GaN die-attach module on DBA substrate with Ti/Ag metallization by using micron/submicron Ag sinter paste. Jpn. J. Appl. Phys. 2019, 58, SBBD15. [Google Scholar] [CrossRef] [Green Version]

- Noh, S.; Choe, C.; Chen, C.; Suganuma, K. Heat-resistant die-attach with cold-rolled Ag sheet. Appl. Phys. Express 2018, 11, 016501. [Google Scholar] [CrossRef]

- Kunimune, T.; Kuramoto, M.; Ogawa, S.; Sugahara, T.; Nagao, S.; Suganuma, K. Ultra thermal stability of LED die-attach achieved by pressureless Ag stress-migration bonding at low temperature. Acta Mater. 2015, 89, 133–140. [Google Scholar] [CrossRef]

- Millan, J.; Godignon, P.; Perpina, X.; Perez-Tomas, A.; Rebollo, J. A survey of wide bandgap power semiconductor devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Noh, S.; Choe, C.; Chen, C.; Zhang, H.; Suganuma, K. Printed wire interconnection using Ag sinter paste for wide band gap power semiconductors. J. Mater. Sci. Mater. Electron. 2018, 29, 15223–15232. [Google Scholar] [CrossRef]

- Pérez-Tomás, A.; Fontserè, A.; Placidi, M.; Jennings, M.R.; Gammon, P.M. Modelling the metal–semiconductor band structure in implanted ohmic contacts to GaN and SiC. Model. Simul. Mater. Sci. Eng. 2013, 21, 035004. [Google Scholar] [CrossRef]

- Hung, T.Y.; Chiang, S.Y.; Huang, C.J.; Lee, C.C.; Chiang, K.N. Thermal-mechanical behavior of the bonding wire for a power module subjected to the power cycling test. Microelectron. Reliab. 2011, 51, 1819–1823. [Google Scholar] [CrossRef]

- Chen, C.; Suganuma, K.; Iwashige, T.; Sugiura, K.; Tsuruta, K. High-temperature reliability of sintered microporous Ag on electroplated Ag, Au, and sputtered Ag metallization substrates. J. Mater. Sci. Mater. Electron. 2018, 29, 1785–1797. [Google Scholar] [CrossRef]

- Park, S.; Nagao, S.; Kato, Y.; Ishino, H.; Sugiura, K.; Tsuruta, K.; Suganuma, K. High-temperature die attachment using Sn-plated Zn solder for power electronics. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 902–909. [Google Scholar] [CrossRef]

- Yu, F.; Cui, J.; Zhou, Z.; Fang, K.; Johnson, R.W.; Hamilton, M.C. Reliability of Ag sintering for power semiconductor die attach in high-temperature applications. IEEE Trans. Power Electron. 2017, 32, 7083–7095. [Google Scholar] [CrossRef]

- Chen, C.; Suganuma, K. Microstructure and mechanical properties of sintered Ag particles with flake and spherical shape from nano to micro size. Mater. Des. 2019, 162, 311–321. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, C.; Yang, Y.; Zhang, H.; Kim, D.; Sugahara, T.; Nagao, S.; Suganuma, K. Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air. J. Alloys Compd. 2019, 780, 435–442. [Google Scholar] [CrossRef]

- Park, S.; Nagao, S.; Sugahara, T.; Suganuma, K. Mechanical stabilities of ultrasonic Al ribbon bonding on electroless nickel immersion gold finished Cu substrates. Jpn. J. Appl. Phys. 2014, 53, 2–9. [Google Scholar] [CrossRef]

- Park, S.; Nagao, S.; Sugahara, T.; Suganuma, K. Heel crack propagation mechanism of cold-rolled Cu/Al clad ribbon bonding in harsh environment. J. Mater. Sci. Mater. Electron. 2015, 26, 7277–7289. [Google Scholar] [CrossRef]

- Jiu, J.; Zhang, H.; Nagao, S.; Sugahara, T.; Kagami, N.; Suzuki, Y.; Akai, Y.; Suganuma, K. Die-attaching silver paste based on a novel solvent for high-power semiconductor devices. J. Mater. Sci. 2016, 51, 3422–3430. [Google Scholar] [CrossRef]

- Lindemann, A.; Strauch, G. Properties of direct aluminium bonded substrates for power semiconductor components. PESC Rec. IEEE Annu. Power Electron. Spec. Conf. 2004, 6, 4171–4177. [Google Scholar]

- Xu, L.; Wang, M.; Zhou, Y.; Qian, Z.; Liu, S. An optimal structural design to improve the reliability of Al2O3-DBC substrates under thermal cycling. Microelectron. Reliab. 2016, 56, 101–108. [Google Scholar] [CrossRef]

- Fei, M.; Fu, R.; Agathopoulos, S.; Fang, J.; Wang, C.; Zhu, H. A preparation method for Al/AlN ceramics substrates by using a CuO interlayer. Mater. Des. 2017, 130, 373–380. [Google Scholar] [CrossRef]

- Lin, C.Y.; Tuan, W.H. Direct bonding of aluminum to alumina for thermal dissipation purposes. Int. J. Appl. Ceram. Technol. 2016, 13, 170–176. [Google Scholar] [CrossRef]

- Choe, C.; Chen, C.; Noh, S. Thermal shock performance of DBA/AMB substrates plated by Ni and Ni—P layers for high-temperature applications of power device modules. Materials 2018, 11, 2394. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Nagao, S.; Suganuma, K.; Jiu, J.; Sugahara, T.; Zhang, H.; Iwashige, T.; Sugiura, K.; Tsurutab, K. Macroscale and microscale fracture toughness of microporous sintered Ag for applications in power electronic devices. Acta Mater. 2017, 129, 41–51. [Google Scholar] [CrossRef]

- Ning, X.S.; Lin, Y.; Xu, W.; Peng, R.; Zhou, H.; Chen, K. Development of a directly bonded aluminum/alumina power electronic substrate. Mater. Sci. Eng. B Solid State Mater. Adv. Technol. 2003, 99, 479–482. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Yamamoto, Y.; Nagao, S.; Wakasugi, N.; Chen, C.; Suganuma, K. Measurement of Heat Dissipation and Thermal-Stability of Power Modules on DBC Substrates with Various Ceramics by SiC Micro-Heater Chip System and Ag Sinter Joining. Micromachines 2019, 10, 745. https://doi.org/10.3390/mi10110745

Kim D, Yamamoto Y, Nagao S, Wakasugi N, Chen C, Suganuma K. Measurement of Heat Dissipation and Thermal-Stability of Power Modules on DBC Substrates with Various Ceramics by SiC Micro-Heater Chip System and Ag Sinter Joining. Micromachines. 2019; 10(11):745. https://doi.org/10.3390/mi10110745

Chicago/Turabian StyleKim, Dongjin, Yasuyuki Yamamoto, Shijo Nagao, Naoki Wakasugi, Chuantong Chen, and Katsuaki Suganuma. 2019. "Measurement of Heat Dissipation and Thermal-Stability of Power Modules on DBC Substrates with Various Ceramics by SiC Micro-Heater Chip System and Ag Sinter Joining" Micromachines 10, no. 11: 745. https://doi.org/10.3390/mi10110745

APA StyleKim, D., Yamamoto, Y., Nagao, S., Wakasugi, N., Chen, C., & Suganuma, K. (2019). Measurement of Heat Dissipation and Thermal-Stability of Power Modules on DBC Substrates with Various Ceramics by SiC Micro-Heater Chip System and Ag Sinter Joining. Micromachines, 10(11), 745. https://doi.org/10.3390/mi10110745