Distinct Roles of Tensile and Compressive Stresses in Graphitizing and Properties of Carbon Nanofibers

Abstract

:1. Introduction

2. Materials and Methods

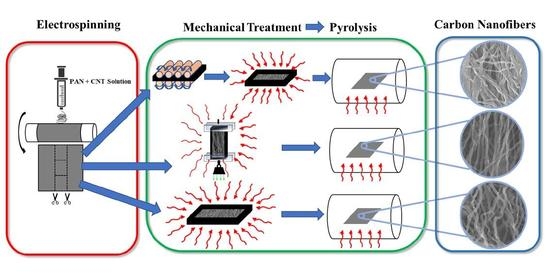

2.1. Electrospinning

2.2. Mechanical Treatment and Stabilization

2.3. Carbonization

2.4. Characterization

3. Results and Discussion

3.1. Morphology Analysis of Stress-Induced Carbon Nanofibers

3.2. Structural Analysis of CIPC and TIPC by Raman Spectroscopy

3.3. Chemical Composition Analysis of CIPC and TIPC

3.4. Transmission Electron Microscopy and Microstructure

3.5. Mechanical Characterization of CIPC and TIPC

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chawla, S.; Cai, J.; Naraghi, M. Mechanical tests on individual carbon nanofibers reveals the strong effect of graphitic alignment achieved via precursor hot-drawing. Carbon N. Y. 2017, 117, 208–219. [Google Scholar] [CrossRef]

- Cai, J.; Naraghi, M. The formation of highly ordered graphitic interphase around embedded CNTs controls the mechanics of ultra-strong carbonized nanofibers. Acta Mater. 2019, 162, 46–54. [Google Scholar] [CrossRef]

- Maitra, T.; Sharma, S.; Srivastava, A.; Cho, Y.K.; Madou, M.; Sharma, A. Improved graphitization and electrical conductivity of suspended carbon nanofibers derived from carbon nanotube/polyacrylonitrile composites by directed electrospinning. Carbon N. Y. 2012, 50, 1753–1761. [Google Scholar] [CrossRef]

- Ghazinejad, M.; Holmberg, S.; Pilloni, O.; Oropeza-Ramos, L.; Madou, M. Graphitizing Non-graphitizable Carbons by Stress-induced Routes. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Kipling, J.J.; Sherwood, J.N.; Shooter, P.V.; Thompson, N.R. Factors influencing the graphitization of polymer carbons. Carbon N. Y. 1964, 1, 315–320. [Google Scholar] [CrossRef]

- Mohan, S.D.; Mitchell, G.R.; Davis, F.J. Chain extension in electrospun polystyrene fibres: A SANS study. Soft Matter 2011, 7, 4397–4404. [Google Scholar] [CrossRef]

- Arinstein, A. Confinement mechanism of electrospun polymer nanofiber reinforcement. J. Polym. Sci. Part B Polym. Phys. 2013, 51, 756–763. [Google Scholar] [CrossRef]

- Okuda, H.; Young, R.J.; Wolverson, D.; Tanaka, F.; Yamamoto, G.; Okabe, T. Investigating nanostructures in carbon fibres using Raman spectroscopy. Carbon N. Y. 2018, 130, 178–184. [Google Scholar] [CrossRef]

- Cai, J.; Chawla, S.; Naraghi, M. Microstructural evolution and mechanics of hot-drawn CNT-reinforced polymeric nanofibers. Carbon N. Y. 2016, 109, 813–822. [Google Scholar] [CrossRef]

- Cho, E.; Perebikovsky, A.; Benice, O.; Holmberg, S.; Madou, M.; Ghazinejad, M. Rapid iodine sensing on mechanically treated carbon nanofibers. Sensors 2018, 18, 1486. [Google Scholar] [CrossRef] [Green Version]

- Pollack, B.; Holmberg, S.; George, D.; Tran, I.; Madou, M.; Ghazinejad, M. Nitrogen-rich polyacrylonitrile-based graphitic carbons for hydrogen peroxide sensing. Sensors 2017, 17, 2407. [Google Scholar] [CrossRef] [Green Version]

- Holmberg, S.; Ghazinejad, M.; Cho, E.B.; George, D.; Pollack, B.; Perebikovsky, A.; Ragan, R.; Madou, M. Stress-activated pyrolytic carbon nanofibers for electrochemical platforms. Electrochim. Acta 2018, 290, 639–648. [Google Scholar] [CrossRef] [Green Version]

- Ceretti, E.; Ginestra, P.S.; Ghazinejad, M.; Fiorentino, A.; Madou, M. Electrospinning and characterization of polymer–graphene powder scaffolds. CIRP Ann.-Manuf. Technol. 2017, 66, 233–236. [Google Scholar] [CrossRef] [Green Version]

- Ji, Y.; Li, C.; Wang, G.; Koo, J.; Ge, S.; Li, B.; Jiang, J.; Herzberg, B.; Klein, T.; Chen, S.; et al. Confinement-induced super strong PS/MWNT composite nanofibers. EPL Europhys. Lett. 2008, 84, 56002. [Google Scholar] [CrossRef]

- Wang, Y.; Alsmeyer, D.C.; McCreery, R.L. Raman Spectroscopy of Carbon Materials: Structural Basis of Observed Spectra. Chem. Mater. 1990, 2, 557–563. [Google Scholar] [CrossRef]

- Ali, A.B.; Slawig, D.; Schlosser, A.; Koch, J.; Bigall, N.C.; Renz, F.; Tegenkamp, C.; Sindelar, R. Polyacrylonitrile (PAN) based electrospun carbon nanofibers (ECNFs): Probing the synergistic effects of creep assisted stabilization and CNTs addition on graphitization and low dimensional electrical transport. Carbon N. Y. 2021, 172, 283–295. [Google Scholar] [CrossRef]

- Brownson, D.A.C.; Kampouris, D.K.; Banks, C.E. Graphene electrochemistry: Fundamental concepts through to prominent applications. Chem. Soc. Rev. 2012, 41, 6944–6976. [Google Scholar] [CrossRef] [PubMed]

- McCreery, R.L. Advanced carbon electrode materials for molecular electrochemistry. Chem. Rev. 2008, 108, 2646–2687. [Google Scholar] [CrossRef] [PubMed]

- Gooding, J.J. Nanostructuring electrodes with carbon nanotubes: A review on electrochemistry and applications for sensing. Proc. Electrochim. Acta 2005, 50, 3049–3060. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, Y.; Matson, D.W.; Li, J.; Lin, Y. Nitrogen-doped graphene and its application in electrochemical biosensing. ACS Nano 2010, 4, 1790–1798. [Google Scholar] [CrossRef]

- Wang, H.; Maiyalagan, T.; Wang, X. Review on recent progress in nitrogen-doped graphene: Synthesis, characterization, and its potential applications. ACS Catal. 2012, 2, 781–794. [Google Scholar] [CrossRef]

- Harris, P.J.F. Structure of non-graphitising carbons. Int. Mater. Rev. 1997, 42, 206–218. [Google Scholar] [CrossRef]

- Vander Wal, R.L.; Tomasek, A.J.; Pamphlet, M.I.; Taylor, C.D.; Thompson, W.K. Analysis of HRTEM images for carbon nanostructure quantification. J. Nanopart. Res. 2004, 6, 555–568. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Y.; Wang, X.; Lu, H.; Liu, G.; Wei, J.; Shan, Z.; Liu, P.; Jiang, K.; Fan, S. Carbon-nanotube-templated carbon nanofibers with improved mechanical performance. J. Appl. Phys. 2021, 129, 044303. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Zhao, Y.; Lou, J.; Zhao, X.; Wang, R.; Liang, Q.; Huang, Z. Electrospinning fabrication and in situ mechanical investigation of individual graphene nanoribbon reinforced carbon nanofiber. Carbon N. Y. 2017, 114, 717–723. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Mottaleb, M.M.; Mohamed, A.; Karim, S.A.; Osman, T.A.; Khattab, A. Preparation, characterization, and mechanical properties of polyacrylonitrile (PAN)/graphene oxide (GO) nanofibers. Mech. Adv. Mater. Struct. 2020, 27, 346–351. [Google Scholar] [CrossRef]

- Yue, L.; Yue, L.; Zhao, H.; Wu, Z.; Liang, J.; Lu, S.; Chen, G.; Gao, S.; Zhong, B.; Guo, X.; et al. Recent advances in electrospun one-dimensional carbon nanofiber structures/heterostructures as anode materials for sodium ion batteries. J. Mater. Chem. A 2020, 8, 11493–11510. [Google Scholar] [CrossRef]

- Zhu, B.; Kou, H.; Liu, Z.; Wang, Z.; MacHaria, D.K.; Zhu, M.; Wu, B.; Liu, X.; Chen, Z. Flexible and Washable CNT-Embedded PAN Nonwoven Fabrics for Solar-Enabled Evaporation and Desalination of Seawater. ACS Appl. Mater. Interfaces 2019, 11, 35005–35014. [Google Scholar] [CrossRef]

- Perebikovsky, A.; Hwu, A.T.; Yale, A.R.; Ghazinejad, M.; Madou, M. Nanofibrous Carbon Multifunctional Smart Scaffolds for Simultaneous Cell Differentiation and Dopamine Detection. ACS Biomater. Sci. Eng. 2020, 6, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Kurek, M.; Larsen, F.K.; Larsen, P.E.; Schmid, S.; Boisen, A.; Keller, S.S. Nanomechanical pyrolytic carbon resonators: Novel fabrication method and characterization of mechanical properties. Sensors 2016, 16, 1097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, Z.; Wang, X.; Faraji, S.; Bradford, P.D.; Li, Q.; Zhu, Y. Mechanical and electrical properties of aligned carbon nanotube/carbon matrix composites. Carbon N. Y. 2014, 75, 307–313. [Google Scholar] [CrossRef]

- Liu, F.; Wang, H.; Xue, L.; Fan, L.; Zhu, Z. Effect of microstructure on the mechanical properties of PAN-based carbon fibers during high-temperature graphitization. J. Mater. Sci. 2008, 43, 4316–4322. [Google Scholar] [CrossRef]

- Wang, M.L.; Bian, W.F. The relationship between the mechanical properties and microstructures of carbon fibers. New Carbon Mater. 2020, 35, 42–49. [Google Scholar] [CrossRef]

- Stein, I.Y.; Constable, A.J.; Morales-Medina, N.; Sackier, C.V.; Devoe, M.E.; Vincent, H.M.; Wardle, B.L. Structure-mechanical property relations of non-graphitizing pyrolytic carbon synthesized at low temperatures. Carbon N. Y. 2017, 117, 411–420. [Google Scholar] [CrossRef] [Green Version]

- Deng, H.; Li, K.; Zheng, J.; Cui, H.; Li, H.; He, Y.; Song, G. Floating catalyst chemical vapor infiltration of nanofilamentous carbon reinforced carbon/carbon composites—Integrative improvement on the mechanical and thermal properties. J. Eur. Ceram. Soc. 2018, 38, 3793–3803. [Google Scholar] [CrossRef]

- Ye, C.; Wu, H.; Huang, D.; Li, B.; Shen, K.; Yang, J.; Liu, J.; Li, X. The microstructures and mechanical properties of ultra-high-strength PAN-based carbon fibers during graphitization under a constant stretching. Carbon Lett. 2019, 29, 497–504. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Lau, E.; Mager, D.; Madou, M.J.; Ghazinejad, M. Distinct Roles of Tensile and Compressive Stresses in Graphitizing and Properties of Carbon Nanofibers. Micromachines 2021, 12, 1096. https://doi.org/10.3390/mi12091096

Liu Y, Lau E, Mager D, Madou MJ, Ghazinejad M. Distinct Roles of Tensile and Compressive Stresses in Graphitizing and Properties of Carbon Nanofibers. Micromachines. 2021; 12(9):1096. https://doi.org/10.3390/mi12091096

Chicago/Turabian StyleLiu, Yujia, Edmund Lau, Dario Mager, Marc J. Madou, and Maziar Ghazinejad. 2021. "Distinct Roles of Tensile and Compressive Stresses in Graphitizing and Properties of Carbon Nanofibers" Micromachines 12, no. 9: 1096. https://doi.org/10.3390/mi12091096

APA StyleLiu, Y., Lau, E., Mager, D., Madou, M. J., & Ghazinejad, M. (2021). Distinct Roles of Tensile and Compressive Stresses in Graphitizing and Properties of Carbon Nanofibers. Micromachines, 12(9), 1096. https://doi.org/10.3390/mi12091096