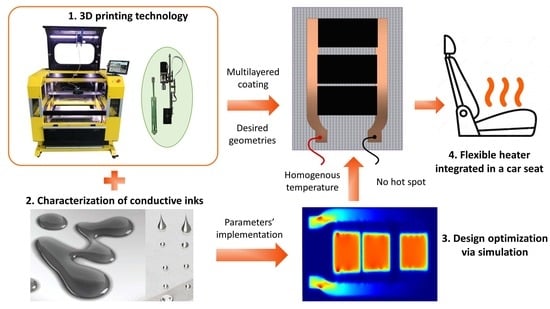

Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications

Abstract

:1. Introduction

2. Material Process and Design Architecture

2.1. Materials Selection

2.2. Printing Process of the Conductive Coating

3. Optimization of Design Architecture

3.1. Specifications and Design Rule

- Generated temperatures between 40 °C and 43.5 °C on the back side of the heating surface;

- Good homogeneity between different heating areas, with a maximum discrepancy of 0.5 °C;

- The response time in a transient regime (i.e., time needed to reach the target temperature) must not exceed 2 min;

- The occurrence of hot spots must be avoided at all costs

3.2. Design Optimization Based on FEM

3.2.1. Simulation Model Built in COMSOL

3.2.2. Optimization of the Heating Behavior in a Steady Regime

- Area 3 has the highest average temperature and dispersion of data, regardless of which design is selected.

- increases from area 1 to area 3, explaining why DT3 of area 1 is at a maximum with respect to the other areas.

- A smaller value of RV compared to that of D0 leads to an improvement in the heat regularity of each area of D1, explaining the reduction in the hot spots. However, no change in DT3 indicates that, similar to D0, the heat transfer in D1 is not homogenous for all three areas.

- For all areas, D2 results in the smallest DT3 and RV compared to the other designs. This demonstrates that only D2 reaches expectations, as it is capable of dissipating heat evenly over all areas (maximum 0.6 °C discrepancy) and has small dispersion of data collected on each surface (~2%).

- The center profile seems to be more stable and homogenous than the lateral profile, in which hot spots appear caused by the connection of the subdivided copper electrodes.

- D1 and D0 have significant hot spots in area 3 in excess of 45 °C (i.e., beyond the allowed limit).

- In area 3, D1 and D0 have higher lateral and center temperatures than D2. This behavior is contrary to the other areas.

- Both the lateral and center profiles of D1 and D0 exhibit an obvious decrease along the length of the tablecloth, while those of D2 are almost constant.

- Only D2 succeeds in homogenizing the temperature of the three heating surfaces, as well as in preventing the presence of significant hot spots.

3.3. A First-Order Response in Transient Regime

4. Characterization Methods

| Materials | λ | Cp | σ | ρ |

|---|---|---|---|---|

| Polymer matrix | [77,78] | [79,80] | [76] | - |

| Polyurethane (PU) | 0.23 | 1500 | ~10–10 | 1.13 |

| Butyl Glycol Acetate (BGA) | 0.19 | 2000 | ~10–10 | 0.94 |

| Conductive particles | [81,82] | [83,84] | [85,86,87] | - |

| Copper particles (C) | 138 | 720 | ~1.0 × 105 | 2.26 |

| Carbon particles (Cu) | 380 | 380 | 5.98 × 107 | 8.96 |

| Silver particles (Ag) | 420 | 240 | 6.30 × 107 | 10.4 |

4.1. Morphological Characterization

4.2. Thermal Characterization

4.3. Electrical Characterization

4.4. Heatmap Characterization

5. Results and Discussions

5.1. Morphological Analysis

5.2. Thermal Analysis

5.3. Electrical Analysis

- Regarding the mean and median values of the electrical conductivity, it is clear that the copper composite has a higher electrical performance than the carbon composite.

- In all cases, the data distributions are asymmetrical, as the median (horizonal lines inside the whisker box) was revealed to be higher than the mean (the cross). As a result, the distributions obtained from both copper and carbon samples were skewed to the left (or negative skew), appearing as right-leaning curves.

- No measurements exhibited any outliers or extremes values (i.e., falling below or above Q3 + 1.5 IQR), meaning that the highest and lowest occurring value were within this interval.

- A finer analysis regarding the data dispersion via two relative coefficients, and :

- The and coefficients were computed in different manners but had similar values, regardless of which composite was studied. Both coefficients are considered as relevant indicators that allow for an efficient analysis of the data variability.

- The electrical measurements of the copper coating exhibit significantly higher dispersion than those of the carbon coating, which is ultimately related to the measure precision.

- In the carbon coating, both and values are relatively low, confirming a good repeatability of the data (<7%). This is contrary to the case of the copper coating, where these coefficients were found to be higher than 20%. This is as a result of the small resistance values of the copper, which in turn drastically increase the measurement uncertainties.

5.4. Heatmap Analysis

5.5. Preliminary Results of Aging Performances

- Increased from 20 °C to 80 °C for 1 h at a rate of 1 °C/min;

- Kept stable at 80 °C for 4 h;

- Lowered to −40 °C at a rate of 1 °C/min for 2 h;

- Maintained constant at −40 °C for 4 h;

- Increased up to 20 °C at a rate of 1 °C/min for 1 h.

- Increased from 30% to 80% at a rate of 0.83%/min for 1 h;

- Maintained at 80% for 4 h;

- Decreased to 30% at a rate of 0.83%/min for 1 h;

- Maintained at 30% for 6 h.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rogier, H. Textile Antenna Systems: Design, Fabrication, and Characterization. In Handbook of Smart Textiles; Tao, X., Ed.; Springer: Singapore, 2015; pp. 433–458. ISBN 978-981-4451-45-1. [Google Scholar]

- Capsal, J.-F.; Galineau, J.; Le, M.-Q.; Domingues Dos Santos, F.; Cottinet, P.-J. Enhanced Electrostriction Based on Plasticized Relaxor Ferroelectric P (VDF-TrFE-CFE/CTFE) Blends. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1368–1379. [Google Scholar] [CrossRef]

- Liu, Q.; Le, M.Q.; Richard, C.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Enhanced Pseudo-Piezoelectric Dynamic Force Sensors Based on Inkjet-Printed Electrostrictive Terpolymer. Org. Electron. 2019, 67, 259–271. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Bordet, M.; Le, M.Q.; Della Schiava, N.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Structuring BaTiO3/PDMS Nanocomposite via Dielectrophoresis for Fractional Flow Reserve Measurement. Adv. Eng. Mater. 2021, 23, 2100341. [Google Scholar] [CrossRef]

- Zhang, X.; Le, M.-Q.; Nguyen, V.-C.; Mogniotte, J.-F.; Capsal, J.-F.; Grinberg, D.; Cottinet, P.-J.; Petit, L. Characterization of Micro-ZnO/PDMS Composite Structured via Dielectrophoresis—Toward Medical Application. Mater. Des. 2021, 208, 109912. [Google Scholar] [CrossRef]

- Kumari, S.; Dinbandhu Abhishek, K. Study of Machinability Aspects of Shape Memory Alloys: A Critical Review. Mater. Today Proc. 2021, 44, 1336–1343. [Google Scholar] [CrossRef]

- Subash, A.; Kandasubramanian, B. 4D Printing of Shape Memory Polymers. Eur. Polym. J. 2020, 134, 109771. [Google Scholar] [CrossRef]

- Hong, H.; Jung, Y.H.; Lee, J.S.; Jeong, C.; Kim, J.U.; Lee, S.; Ryu, H.; Kim, H.; Ma, Z.; Kim, T. Anisotropic Thermal Conductive Composite by the Guided Assembly of Boron Nitride Nanosheets for Flexible and Stretchable Electronics. Adv. Funct. Mater. 2019, 29, 1902575. [Google Scholar] [CrossRef]

- Ruan, K.; Shi, X.; Guo, Y.; Gu, J. Interfacial Thermal Resistance in Thermally Conductive Polymer Composites: A Review. Compos. Commun. 2020, 22, 100518. [Google Scholar] [CrossRef]

- Sato, J.; Sekine, T.; Yi-Fei, W.; Takeda, Y.; Matsui, H.; Kumaki, D.; Santos, F.D.D.; Miyabo, A.; Tokito, S. Ferroelectric Polymer-Based Fully Printed Flexible Strain Rate Sensors and Their Application for Human Motion Capture. Sens. Actuators A Phys. 2019, 295, 93–98. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, M.; Qi, X.; Li, H.; Zhang, Y.-F.; Li, Z.; Peng, Z.; Yang, J.; Qian, L.; Xu, Q.; et al. Templateless, Plating-Free Fabrication of Flexible Transparent Electrodes with Embedded Silver Mesh by Electric-Field-Driven Microscale 3D Printing and Hybrid Hot Embossing. Adv. Mater. 2021, 33, 2007772. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Zhu, X.; Peng, Z.; Zhang, G.; Yang, J.; Wang, F.; Zhang, Y.-F.; Sun, L.; Wang, R.; et al. Directly Printed Embedded Metal Mesh for Flexible Transparent Electrode via Liquid Substrate Electric-Field-Driven Jet. Adv. Sci. 2022, 9, 2105331. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Xu, Q.; Li, H.; Liu, M.; Li, Z.; Yang, K.; Zhao, J.; Qian, L.; Peng, Z.; Zhang, G.; et al. Fabrication of High-Performance Silver Mesh for Transparent Glass Heaters via Electric-Field-Driven Microscale 3D Printing and UV-Assisted Microtransfer. Adv. Mater. 2019, 31, 1902479. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Li, Z.; Li, N.; Zhu, X.; Zhang, Y.-F.; Sun, L.; Wang, R.; Zhang, J.; Yang, Z.; Yi, H.; et al. 3D Printed High Performance Silver Mesh for Transparent Glass Heaters through Liquid Sacrificial Substrate Electric-Field-Driven Jet. Small 2022, 18, 2107811. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, Q.; Wang, Z.; Nie, W.; Wang, P.; Li, C. Roll-to-Roll Layer-by-Layer Assembly Bark-Shaped Carbon Nanotube/Ti3C2Tx MXene Textiles for Wearable Electronics. J. Colloid Interface Sci. 2021, 602, 680–688. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, P.; Zhang, X.; Hu, Q.; Wang, Z.; Nie, W.; Zou, L.; Li, C.; Han, X. Breathable, Durable and Bark-Shaped MXene/Textiles for High-Performance Wearable Pressure Sensors, EMI Shielding and Heat Physiotherapy. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106700. [Google Scholar] [CrossRef]

- Cottinet, P.-J.; Le, M.-Q.; Degraff, J.; Souders, C.; Liang, Z.; Wang, B.; Zhang, C. Strain Phenomenon in Carbon Nanotube Buckpaper Actuator: Experiments and Modeling. Sens. Actuators A Phys. 2013, 194, 252–258. [Google Scholar] [CrossRef]

- Pedroli, F.; Marrani, A.; Le, M.-Q.; Froidefond, C.; Cottinet, P.-J.; Capsal, J.-F. Processing Optimization: A Way to Improve the Ionic Conductivity and Dielectric Loss of Electroactive Polymers. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1164–1173. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Hebrard, Y.; Le, M.Q.; Cottinet, P.-J.; Capsal, J.-F. Micro-Structuration of Piezoelectric Composites Using Dielectrophoresis: Toward Application in Condition Monitoring of Bearings. Adv. Eng. Mater. 2021, 23, 2000773. [Google Scholar] [CrossRef]

- Zhang, X.; Le, M.-Q.; Zahhaf, O.; Capsal, J.-F.; Cottinet, P.-J.; Petit, L. Enhancing Dielectric and Piezoelectric Properties of Micro-ZnO/PDMS Composite-Based Dielectrophoresis. Mater. Des. 2020, 192, 108783. [Google Scholar] [CrossRef]

- Della Schiava, N.; Thetpraphi, K.; Le, M.-Q.; Lermusiaux, P.; Millon, A.; Capsal, J.-F.; Cottinet, P.-J. Enhanced Figures of Merit for a High-Performing Actuator in Electrostrictive Materials. Polymers 2018, 10, 263. [Google Scholar] [CrossRef] [Green Version]

- Xiang, Z.; Jakkpat, K.-I.; Ducharne, B.; Capsal, J.-F.; Mogniotte, J.-F.; Lermusiaux, P.; Cottinet, P.-J.; Schiava, N.D.; Le, M.Q. Enhancing the Low-Frequency Induction Heating Effect of Magnetic Composites for Medical Applications. Polymers 2020, 12, 386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grinberg, D.; Siddique, S.; Le, M.-Q.; Liang, R.; Capsal, J.-F.; Cottinet, P.-J. 4D Printing Based Piezoelectric Composite for Medical Applications. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 109–115. [Google Scholar] [CrossRef]

- Guo, R.; Wang, H.; Sun, X.; Yao, S.; Chang, H.; Wang, H.; Liu, J.; Zhang, Y. Semiliquid Metal Enabled Highly Conductive Wearable Electronics for Smart Fabrics. ACS Appl. Mater. Interfaces 2019, 11, 30019–30027. [Google Scholar] [CrossRef]

- Singh, A.V.; Rahman, A.; Sudhir Kumar, N.V.G.; Aditi, A.S.; Galluzzi, M.; Bovio, S.; Barozzi, S.; Montani, E.; Parazzoli, D. Bio-Inspired Approaches to Design Smart Fabrics. Mater. Des. 2012, 36, 829–839. [Google Scholar] [CrossRef]

- Hu, Y.; Zheng, Z. Progress in Textile-Based Triboelectric Nanogenerators for Smart Fabrics. Nano Energy 2019, 56, 16–24. [Google Scholar] [CrossRef]

- Nguyen, V.-C.; Le, M.-Q.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Design Rules of Bidirectional Smart Sensor Coating for Condition Monitoring of Bearings. Polymers 2023, 15, 826. [Google Scholar] [CrossRef]

- D’Ambrogio, G.; Zahhaf, O.; Le, M.-Q.; Bordet, M.; Lermusiaux, P.; Della Schiava, N.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Piezoelectric Biosensor for Smart Cardiovascular Grafts Based on NaNbO3 Fibers/PDMS Structured Composite. Mater. Des. 2022, 223, 111195. [Google Scholar] [CrossRef]

- Zahhaf, O.; D’Ambrogio, G.; Giunta, A.; Le, M.-Q.; Rival, G.; Cottinet, P.-J.; Capsal, J.-F. Molten-State Dielectrophoretic Alignment of EVA/BaTiO3 Thermoplastic Composites: Enhancement of Piezo-Smart Sensor for Medical Application. Int. J. Mol. Sci. 2022, 23, 15745. [Google Scholar] [CrossRef] [PubMed]

- Alam, F.E.; Dai, W.; Yang, M.; Du, S.; Li, X.; Yu, J.; Jiang, N.; Lin, C.-T. In Situ Formation of a Cellular Graphene Framework in Thermoplastic Composites Leading to Superior Thermal Conductivity. J. Mater. Chem. A 2017, 5, 6164–6169. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.; Zhou, J.; Li, B. Thermal Conductivity of Polymers and Their Nanocomposites. Adv. Mater. 2018, 30, 1705544. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Huang, X.; Zhu, Y.; Jiang, P. Cellulose Nanofiber Supported 3D Interconnected BN Nanosheets for Epoxy Nanocomposites with Ultrahigh Thermal Management Capability. Adv. Funct. Mater. 2017, 27, 1604754. [Google Scholar] [CrossRef]

- Wang, X.; Wu, P. Preparation of Highly Thermally Conductive Polymer Composite at Low Filler Content via a Self-Assembly Process between Polystyrene Microspheres and Boron Nitride Nanosheets. ACS Appl. Mater. Interfaces 2017, 9, 19934–19944. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Yao, Y.; Zeng, X.; Pan, G.; Hu, J.; Huang, Y.; Sun, R.; Xu, J.-B.; Wong, C.-P. Preparation of Boron Nitride Nanosheet/Nanofibrillated Cellulose Nanocomposites with Ultrahigh Thermal Conductivity via Engineering Interfacial Thermal Resistance. Adv. Mater. Interfaces 2017, 4, 1700563. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, C.; Songfeng, E.; Xie, L.; Geng, R.; Lin, C.-T.; Li, L.; Yao, Y. Enhanced Thermal Conductivity of Polyurethane Composites via Engineering Small/Large Sizes Interconnected Boron Nitride Nanosheets. Compos. Sci. Technol. 2019, 170, 93–100. [Google Scholar] [CrossRef]

- Morishita, T.; Matsushita, M.; Katagiri, Y.; Fukumori, K. A Novel Morphological Model for Carbon Nanotube/Polymer Composites Having High Thermal Conductivity and Electrical Insulation. J. Mater. Chem. 2011, 21, 5610–5614. [Google Scholar] [CrossRef]

- Zhang, L.; Hou, G.; Zhai, W.; Ai, Q.; Feng, J.; Zhang, L.; Si, P.; Ci, L. Aluminum/Graphene Composites with Enhanced Heat-Dissipation Properties by in-Situ Reduction of Graphene Oxide on Aluminum Particles. J. Alloys Compd. 2018, 748, 854–860. [Google Scholar] [CrossRef]

- Zahhaf, O.; D’Ambrogio, G.; Le, M.-Q.; Coativy, G.; Grasland, F.; Cottinet, P.-J.; Capsal, J.-F. Dielectrophoretic Alignment of Al2O3/PDMS Composites: Enhancement of Thermal and Dielectric Properties through Structural Sedimentation Analysis. Mater. Des. 2021, 211, 110134. [Google Scholar] [CrossRef]

- An, F.; Li, X.; Min, P.; Liu, P.; Jiang, Z.-G.; Yu, Z.-Z. Vertically Aligned High-Quality Graphene Foams for Anisotropically Conductive Polymer Composites with Ultrahigh Through-Plane Thermal Conductivities. ACS Appl. Mater. Interfaces 2018, 10, 17383–17392. [Google Scholar] [CrossRef]

- Yao, Y.; Zeng, X.; Wang, F.; Sun, R.; Xu, J.; Wong, C.-P. Significant Enhancement of Thermal Conductivity in Bioinspired Freestanding Boron Nitride Papers Filled with Graphene Oxide. Chem. Mater. 2016, 28, 1049–1057. [Google Scholar] [CrossRef]

- Xiang, Z.; Nguyen, V.-C.; Ducharne, B.; Schiava, N.D.; Capsal, J.-F.; Cottinet, P.-J.; Le, M.-Q. 3D Printing of Flexible Composites via Magnetophoresis: Toward Medical Application Based on Low-Frequency Induction Heating Effect. Macromol. Mater. Eng. 2021, 306, 2100211. [Google Scholar] [CrossRef]

- Dou, J.; Tang, L.; Mou, L.; Zhang, R.; Jiang, X. Stretchable Conductive Adhesives for Connection of Electronics in Wearable Devices Based on Metal-Polymer Conductors and Carbon Nanotubes. Compos. Sci. Technol. 2020, 197, 108237. [Google Scholar] [CrossRef]

- Pan, Y.; Xiao, S.; Lu, X.; Zhou, C.; Li, Y.; Liu, Z.; Liu, B.; Xu, W.; Jia, C.; Qu, X. Fabrication, Mechanical Properties and Electrical Conductivity of Al2O3 Reinforced Cu/CNTs Composites. J. Alloys Compd. 2019, 782, 1015–1023. [Google Scholar] [CrossRef]

- Ke, K.; Yue, L.; Shao, H.; Yang, M.-B.; Yang, W.; Manas-Zloczower, I. Boosting Electrical and Piezoresistive Properties of Polymer Nanocomposites via Hybrid Carbon Fillers: A Review. Carbon 2021, 173, 1020–1040. [Google Scholar] [CrossRef]

- Caradonna, A.; Badini, C.; Padovano, E.; Pietroluongo, M. Electrical and Thermal Conductivity of Epoxy-Carbon Filler Composites Processed by Calendaring. Materials 2019, 12, 1522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ohm, Y.; Pan, C.; Ford, M.J.; Huang, X.; Liao, J.; Majidi, C. An Electrically Conductive Silver–Polyacrylamide–Alginate Hydrogel Composite for Soft Electronics. Nat. Electron. 2021, 4, 185–192. [Google Scholar] [CrossRef]

- Li, R.; Yang, X.; Li, J.; Shen, Y.; Zhang, L.; Lu, R.; Wang, C.; Zheng, X.; Chen, H.; Zhang, T. Review on Polymer Composites with High Thermal Conductivity and Low Dielectric Properties for Electronic Packaging. Mater. Today Phys. 2022, 22, 100594. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT Composites with Improved Electrical and Thermal Properties Suitable for FDM 3D Printing Applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef] [Green Version]

- Repon, M.R.; Mikučionienė, D. Progress in Flexible Electronic Textile for Heating Application: A Critical Review. Materials 2021, 14, 6540. [Google Scholar] [CrossRef] [PubMed]

- Thetpraphi, K.; Kanlayakan, W.; Chaipo, S.; Moretto, G.; Kuhn, J.; Audigier, D.; Le, M.Q.; Cottinet, P.-J.; Petit, L.; Capsal, J.-F. 3D-Printed Electroactive Polymer Force-Actuator for Large and High Precise Optical Mirror Applications. Addit. Manuf. 2021, 47, 102199. [Google Scholar] [CrossRef]

- Le, M.Q.; Ganet, F.; Audigier, D.; Capsal, J.-F.; Cottinet, P.-J. Printing of Microstructure Strain Sensor for Structural Health Monitoring. Appl. Phys. A 2017, 123, 354. [Google Scholar] [CrossRef]

- Nakashima, H.; Higgins, M.J.; O’Connell, C.; Torimitsu, K.; Wallace, G.G. Liquid Deposition Patterning of Conducting Polymer Ink onto Hard and Soft Flexible Substrates via Dip-Pen Nanolithography. Langmuir 2012, 28, 804–811. [Google Scholar] [CrossRef]

- Small, W.R.; in het Panhuis, M. Inkjet Printing of Transparent, Electrically Conducting Single-Walled Carbon-Nanotube Composites. Small 2007, 3, 1500–1503. [Google Scholar] [CrossRef] [PubMed]

- Glatzel, S.; Schnepp, Z.; Giordano, C. From Paper to Structured Carbon Electrodes by Inkjet Printing. Angew. Chem. Int. Ed. 2013, 52, 2355–2358. [Google Scholar] [CrossRef] [PubMed]

- Walker, S.B.; Lewis, J.A. Reactive Silver Inks for Patterning High-Conductivity Features at Mild Temperatures. J. Am. Chem. Soc. 2012, 134, 1419–1421. [Google Scholar] [CrossRef]

- Zenou, M.; Grainger, L. 3—Additive Manufacturing of Metallic Materials. In Additive Manufacturing; Zhang, J., Jung, Y.-G., Eds.; Butterworth-Heinemann: Oxford, UK, 2018; pp. 53–103. ISBN 978-0-12-812155-9. [Google Scholar]

- Kazani, I.; Hertleer, C.; Mey, G.; Schwarz-Pfeiffer, A.; Guxho, G.; Van Langenhove, L. Electrical Conductive Textiles Obtained by Screen Printing. Fibres Text. East. Eur. 2012, 20, 57–63. [Google Scholar]

- Mbise, E.; Dias, T.; Hurley, W. Design and Manufacture of Heated Textiles. In Electronic Textiles; Elsevier: Amsterdam, The Netherlands, 2015; pp. 117–213. ISBN 978-0-08-100201-8. [Google Scholar]

- Nguyen, V.-C.; Le, M.-Q.; Fimbel, A.; Bernadet, S.; Hebrard, Y.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Printing Smart Coating of Piezoelectric Composite for Application in Condition Monitoring of Bearings. Mater. Des. 2022, 215, 110529. [Google Scholar] [CrossRef]

- Carbone, C.; Benwadih, M.; D’Ambrogio, G.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Influence of Matrix and Surfactant on Piezoelectric and Dielectric Properties of Screen-Printed BaTiO3/PVDF Composites. Polymers 2021, 13, 2166. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.-C.; Le, M.-Q.; Mogniotte, J.-F.; Capsal, J.-F.; Cottinet, P.-J. Extrusion-Based 3D Printing of Stretchable Electronic Coating for Condition Monitoring of Suction Cups. Micromachines 2022, 13, 1606. [Google Scholar] [CrossRef] [PubMed]

- Upholstery Applications, Automotive Fabrics, Seat Covering Materials. Available online: http://technicaltextile.net/articles/upholstery-in-automobiles-3100 (accessed on 21 June 2022).

- Cortés, A.; Jiménez-Suárez, A.; Campo, M.; Ureña, A.; Prolongo, S.G. 3D Printed Epoxy-CNTs/GNPs Conductive Inks with Application in Anti-Icing and de-Icing Systems. Eur. Polym. J. 2020, 141, 110090. [Google Scholar] [CrossRef]

- Kamyshny, A.; Magdassi, S. Conductive Nanomaterials for 2D and 3D Printed Flexible Electronics. Chem. Soc. Rev. 2019, 48, 1712–1740. [Google Scholar] [CrossRef]

- Tommasi, A.; Cocuzza, M.; Perrone, D.; Pirri, C.; Mosca, R.; Villani, M.; Delmonte, N.; Zappettini, A.; Calestani, D.; Marasso, S. Modeling, Fabrication and Testing of a Customizable Micromachined Hotplate for Sensor Applications. Sensors 2016, 17, 62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Y.; He, J.; Li, Q.; Gao, L.; Hu, J.; Zeng, R.; Qin, J.; Wang, S.X.; Wang, Q. Self-Healing of Electrical Damage in Polymers Using Superparamagnetic Nanoparticles. Nat. Nanotechnol. 2019, 14, 151. [Google Scholar] [CrossRef] [PubMed]

- Kosky, P.; Balmer, R.; Keat, W.; Wise, G. Chapter 12—Mechanical Engineering. In Exploring Engineering, 3rd ed.; Kosky, P., Balmer, R., Keat, W., Wise, G., Eds.; Academic Press: Boston, MA, USA, 2013; pp. 259–281. ISBN 978-0-12-415891-7. [Google Scholar]

- Ida, N. Engineering Electromagnetics; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-07805-2. [Google Scholar]

- Gadeikytė, A.; Barauskas, R. Investigation of Influence of Forced Ventilation through 3D Textile on Heat Exchange Properties of the Textile Layer. J. Meas. Eng. 2020, 8, 72–78. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Bergman, Adrienne Lavine Fundamentals of Heat and Mass Transfer, 6th ed.; Eyrolles: Paris, France, 2006; p. 5e. ISBN 978-0-471-45728-2. [Google Scholar]

- Ganie, A.H.; Memon, A.A.; Memon, M.A.; Al-Bugami, A.M.; Bhatti, K.; Khan, I. Numerical Analysis of Laminar Flow and Heat Transfer through a Rectangular Channel Containing Perforated Plate at Different Angles. Energy Rep. 2022, 8, 539–550. [Google Scholar] [CrossRef]

- Zandi, S.; Saxena, P.; Razaghi, M.; Gorji, N.E. Simulation of CZTSSe Thin-Film Solar Cells in COMSOL: Three-Dimensional Optical, Electrical, and Thermal Models. IEEE J. Photovolt. 2020, 10, 1503–1507. [Google Scholar] [CrossRef]

- Métais, A. Numerical Simulation of Thermal-Hydraulic Phenomena and Diffusion of Chemical Elements during the Laser Welding of Steels of Different Nature. Ph.D. Thesis, University of Bourgogne, Dijon, France, 2017. [Google Scholar]

- Pitchai, K.; Chen, J.; Birla, S.; Gonzalez, R.; Jones, D.; Subbiah, J. A Microwave Heat Transfer Model for a Rotating Multi-Component Meal in a Domestic Oven: Development and Validation. J. Food Eng. 2014, 128, 60–71. [Google Scholar] [CrossRef]

- Xiang, Z.; Le, M.Q.; Cottinet, P.-J.; Griffiths, P.; Baeza, G.P.; Capsal, J.-F.; Lermusiaux, P.; Della Schiava, N.; Ducharne, B. Development of Anisotropic Ferromagnetic Composites for Low-Frequency Induction Heating Technology in Medical Applications. Mater. Today Chem. 2021, 19, 100395. [Google Scholar] [CrossRef]

- Athanasopoulos, N.; Baltopoulos, A.; Matzakou, M.; Vavouliotis, A.; Kostopoulos, V. Electrical Conductivity of Polyurethane/MWCNT Nanocomposite Foams. Polym. Compos. 2012, 33, 1302–1312. [Google Scholar] [CrossRef]

- Tsai, P.-Y.; Chen, T.-E.; Lee, Y.-L. Development and Characterization of Anticorrosion and Antifriction Properties for High Performance Polyurethane/Graphene Composite Coatings. Coatings 2018, 8, 250. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y. Thermal Conductivity. In Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007; pp. 155–163. [Google Scholar]

- Overview of Materials for Thermoset Polyurethane Foam, Unreinforced. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=91d44cae736e4b36bcba94720654eeae&ckck=1BASF_E-CPI_1015e_Butylglycol_Acetate-3.Pdf (accessed on 14 June 2022).

- Carbon—Thermal Properties—Melting Point—Thermal Conductivity—Expansion. Available online: https://material-properties.org/carbon-thermal-properties-melting-point-thermal-conductivity-expansion/ (accessed on 28 April 2022).

- Carvill, J. 3—Thermodynamics and Heat Transfer. In Mechanical Engineer’s Data Handbook; Butterworth-Heinemann: Oxford, UK, 1993; pp. 102–145. ISBN 978-0-08-051135-1. [Google Scholar]

- Heat Capacity. Available online: https://www2.chem.wisc.edu/deptfiles/genchem/netorial/modules/thermodynamics/enthalpy/enthalpy3.htm (accessed on 3 May 2022).

- Specific Heat Capacity of Metals Table Chart. Available online: https://www.engineersedge.com/materials/specific_heat_capacity_of_metals_13259.htm (accessed on 3 May 2022).

- What Makes Metals Conductive? Available online: https://www.thoughtco.com/electrical-conductivity-in-metals-2340117 (accessed on 2 May 2022).

- Bardeen, J. Electrical Conductivity of Metals. J. Appl. Phys. 1940, 11, 88–111. [Google Scholar] [CrossRef]

- Pantea, D.; Darmstadt, H.; Kaliaguine, S.; Sümmchen, L.; Roy, C. Electrical Conductivity of Thermal Carbon Blacks: Influence of Surface Chemistry. Carbon 2001, 39, 1147–1158. [Google Scholar] [CrossRef]

- Wang, J.; Carson, J.K.; North, M.F.; Cleland, D.J. A New Structural Model of Effective Thermal Conductivity for Heterogeneous Materials with Co-Continuous Phases. Int. J. Heat Mass Transf. 2008, 51, 2389–2397. [Google Scholar] [CrossRef]

- Xiang, Z.; Ducharne, B.; Della Schiava, N.; Capsal, J.-F.; Cottinet, P.-J.; Coativy, G.; Lermusiaux, P.; Le, M.Q. Induction Heating-Based Low-Frequency Alternating Magnetic Field: High Potential of Ferromagnetic Composites for Medical Applications. Mater. Des. 2019, 174, 107804. [Google Scholar] [CrossRef]

- Riviere, L.; Causse, N.; Lonjon, A.; Dantras, E.; Lacabanne, C. Specific Heat Capacity and Thermal Conductivity of PEEK/Ag Nanoparticles Composites Determined by Modulated-Temperature Differential Scanning Calorimetry. Polym. Degrad. Stab. 2016, 127, 98–104. [Google Scholar] [CrossRef] [Green Version]

- Budiansky, B. Thermal and Thermoelastic Properties of Isotropic Composites. J. Compos. Mater. 1970, 4, 286–295. [Google Scholar] [CrossRef]

- Birks, J.B. Progress in Dielectrics; Heywood: London, UK, 1967; Volume 7. [Google Scholar]

- Uvarov, N.F. Estimation of Composites Conductivity Using a General Mixing Rule. Solid State Ion. 2000, 136–137, 1267–1272. [Google Scholar] [CrossRef]

- Sazhin, B.I.; Lobanov, A.M.; Romanovskaia, O.S.; Eidel’nant, M.P.; Koikov, S.N. Electrical Properties of Polymers, 3rd ed.; number EDB-87-178954; USSR-Russia, 1986; 224p. [Google Scholar]

- Shahariar, H.; Kim, I.; Soewardiman, H.; Jur, J.S. Inkjet Printing of Reactive Silver Ink on Textiles. ACS Appl. Mater. Interfaces 2019, 11, 6208–6216. [Google Scholar] [CrossRef] [PubMed]

- Xie, L.; Mäntysalo, M.; Cabezas, A.L.; Feng, Y.; Jonsson, F.; Zheng, L.-R. Electrical Performance and Reliability Evaluation of Inkjet-Printed Ag Interconnections on Paper Substrates. Mater. Lett. 2012, 88, 68–72. [Google Scholar] [CrossRef]

- Li, Z.; Le, T.; Wu, Z.; Yao, Y.; Li, L.; Tentzeris, M.; Moon, K.-S.; Wong, C.P. Rational Design of a Printable, Highly Conductive Silicone-Based Electrically Conductive Adhesive for Stretchable Radio-Frequency Antennas. Adv. Funct. Mater. 2015, 25, 464–470. [Google Scholar] [CrossRef]

- Faddoul, R.; Reverdy-Bruas, N.; Blayo, A. Formulation and Screen Printing of Water Based Conductive Flake Silver Pastes onto Green Ceramic Tapes for Electronic Applications. Mater. Sci. Eng. B 2012, 177, 1053–1066. [Google Scholar] [CrossRef]

- Hong, H.; Hu, J.; Yan, X. Effect of the Basic Surface Properties of Woven Lining Fabric on Printing Precision and Electrical Performance of Screen-Printed Conductive Lines. Text. Res. J. 2020, 90, 1212–1223. [Google Scholar] [CrossRef]

- Hrehorova, E.; Pekarovicova, A.; Fleming, P.D. Gravure Printability of Conducting Polymer Inks. NIP Digit. Fabr. Conf. 2006, 2006, 107–110. [Google Scholar]

- La, T.-G.; Qiu, S.; Scott, D.K.; Bakhtiari, R.; Kuziek, J.W.P.; Mathewson, K.E.; Rieger, J.; Chung, H.-J. Two-Layered and Stretchable e-Textile Patches for Wearable Healthcare Electronics. Adv. Healthc. Mater. 2018, 7, 1801033. [Google Scholar] [CrossRef] [PubMed]

- Looyenga, H. Dielectric Constants of Heterogeneous Mixtures. Physica 1965, 31, 401–406. [Google Scholar] [CrossRef]

- Landau, L.D.; Bell, J.S.; Kearsley, M.J.; Pitaevskii, L.P.; Lifshitz, E.M.; Sykes, J.B. Electrodynamics of Continuous Media, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 1984; Volume 8, ISBN 978-1-4832-9375-2. [Google Scholar]

- ETD—Technical Trading—SAE J826 H-POINT-MANIKIN—ATD Crash-Test-Dummies. Available online: http://h-point-manikin.com/uk/uk_k02_hp_manikin.html (accessed on 8 March 2023).

| Properties | C/PU Ink | Cu/PU Ink | Ag/BGA Ink |

|---|---|---|---|

| Polymer matrix | Polyurethane (PU) | Polyurethane (PU) | Butyl Glycol Acetate (BGA) |

| Particles | Carbon (C) | Copper (Cu) | Silver (Ag) |

| Particle size | ≤2.5 µm | 30–40 µm | ≤10 µm |

| 2 | 3 | 15 | |

| 30 | 40 | 62 | |

| 1.33 | 1.74 | 2.16 | |

| 17.6 | 7.8 | 12.9 |

| Parameter | Value |

|---|---|

| Layer Height (mm) | 0.2 |

| Number of Skirt Loops | 0 |

| Printing Speed (mm/s) | 15 |

| Travel Speed (mm/s) | 100 |

| Extrusion Multiplier | 1 |

| Nozzle Diameter (mm) | 0.4 |

| Retraction (mm) | 2 |

| Advanced | 1.5 |

| Materials | Dimension (mm3) | Thermal Conductivity | Heat Capacity | Electrical Conductivity | Density | Surface Emissivity ε |

|---|---|---|---|---|---|---|

| Fabric | 370 × 500 × 2 | 0.062 | 1200 | 1.0 × 10−9 | 0.8 | 0.9 |

| Copper | 40 × 440 × 0.6 | 0.367 | 1052 | 1.43 × 104 | 1.74 | 0.5 |

| Carbon | 100 × 170 × 0.4 | 0.296 | 1266 | 4.23 × 102 | 1.33 | 0.9 |

| Area | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| D0 | D1 | D2 | D0 | D1 | D2 | D0 | D1 | D2 | |

| 1 | 38.8 | 38.6 | 42.5 | 11.2 | 12.2 | 1.2 | 6.5 | 3.4 | 1.9 |

| 2 | 40.8 | 41.4 | 42.8 | 6.5 | 5.9 | 0.7 | 6.3 | 5.1 | 1.8 |

| 3 | 43.6 | 43.0 | 43.1 | 0 | 0 | 0 | 9.0 | 2.9 | 2.2 |

| Ink Composites | λ | Cp |

|---|---|---|

| C/PU composite | 0.377 | 1266 |

| Cu/PU composite | 0.289 | 1052 |

| Ag/BGA composite | 0.274 | 908 |

| Rth | λ | |

|---|---|---|

| Fabric sample without conductive coating | 20.16 | 0.062 |

| Fabric samples with conductive coating of: | ||

| 3-layer C/PU | 21.18 | 0.065 |

| 4-layer C/PU | 21.55 | 0.064 |

| 2-layer Cu/PU | 21.02 | 0.066 |

| 3-layer Cu/PU | 21.45 | 0.064 |

| 3-layer Ag/BGA | 21.52 | 0.064 |

| Conductive inks (1 layer) | ||

| C/PU | 0.34 | 0.367 |

| Cu/PU | 0.42 | 0.296 |

| Ag/BGA | 0.45 | 0.280 |

| Ink Composites | σ | α (Fitting Factor) |

|---|---|---|

| C/PU composite (17.6 vol%) | 4.23 × 102 | 0.317 |

| Cu/PU composite (7.8 vol%) | 1.43 × 104 | 0.307 |

| Ag/BGA composite (12.8 vol%) | 1.88 × 105 | 0.323 |

| Mean | VC | Min | Max | Q1 | Q2 | Q3 | |||

|---|---|---|---|---|---|---|---|---|---|

| C/PU composite | 4.3 × 102 | 28.7% | 3.3 × 102 | 4.6 × 102 | 4.0 × 102 | 4.4 × 102 | 4.5 × 102 | 5 | 23.7% |

| Cu/PU composite | 1.4 × 104 | 6.9% | 5 × 102 | 2.0 × 104 | 1.1 × 104 | 1.6 × 104 | 1.8 × 104 | 7 × 102 | 5.9% |

| Area | |||||

|---|---|---|---|---|---|

| Experiment | Simulation | Experiment | Simulation | ||

| 1 | 43.6 | 42.5 | 0.5 | 1.2 | 2.5 |

| 2 | 43.7 | 42.8 | 0.2 | 0.7 | 2.1 |

| 3 | 43.8 | 43.1 | 0 | 0 | 1.6 |

| Voltage (V) | Current (A) | Power (W) | Temperature (°C) | Response Time 95% (s) |

|---|---|---|---|---|

| 3 | 0.7 | 1.7 | 18 | 65 |

| 6 | 1.1 | 6.6 | 24 | 70 |

| 9 | 1.62 | 14.5 | 35 | 100 |

| 12 | 2.13 | 25.5 | 43 | 112 |

| 15 | 2.56 | 38.5 | 62 | 115 |

| 18 | 2.95 | 53.1 | 75 | 115 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diatezo, L.; Le, M.-Q.; Tonellato, C.; Puig, L.; Capsal, J.-F.; Cottinet, P.-J. Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications. Micromachines 2023, 14, 762. https://doi.org/10.3390/mi14040762

Diatezo L, Le M-Q, Tonellato C, Puig L, Capsal J-F, Cottinet P-J. Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications. Micromachines. 2023; 14(4):762. https://doi.org/10.3390/mi14040762

Chicago/Turabian StyleDiatezo, Léopold, Minh-Quyen Le, Christine Tonellato, Lluis Puig, Jean-Fabien Capsal, and Pierre-Jean Cottinet. 2023. "Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications" Micromachines 14, no. 4: 762. https://doi.org/10.3390/mi14040762

APA StyleDiatezo, L., Le, M. -Q., Tonellato, C., Puig, L., Capsal, J. -F., & Cottinet, P. -J. (2023). Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications. Micromachines, 14(4), 762. https://doi.org/10.3390/mi14040762