The SU-8 based “Lube-tape” films formed under the conditions provided in the experimental section have shown a total thickness of ~180 µm.

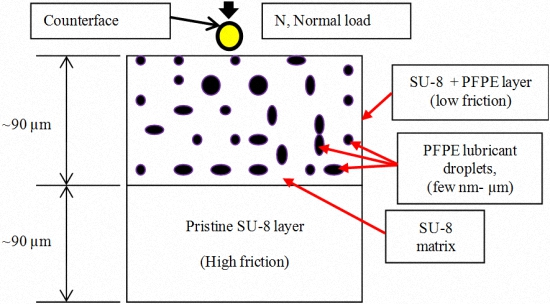

Figure 2 shows the low and high friction features of “Lube-tape” and descriptions about them.

Figure 2.

Free standing SU-8 composite based “Lube-tape” (left image) showing the top view. A graphical illustration of the cross-section of the Lube-tape (right image) showing different friction behavior of top surface and bottom surface, respectively. The lubricant droplets range from few nm to 5 µm (SEM images shown in subsequent figures can be referred for the morphology lubricant droplets inside SU-8 matrix).

Figure 2.

Free standing SU-8 composite based “Lube-tape” (left image) showing the top view. A graphical illustration of the cross-section of the Lube-tape (right image) showing different friction behavior of top surface and bottom surface, respectively. The lubricant droplets range from few nm to 5 µm (SEM images shown in subsequent figures can be referred for the morphology lubricant droplets inside SU-8 matrix).

The top surface of Lube-tape is shown in left image of

Figure 2, which is the low friction SU-8 + PFPE composite surface. The bottom layer is pristine SU-8 layer, which is the high friction layer and also can be easily stuck onto any surface.

3.1. Surface Free Energy Calculations on Fresh Surface

Surface free energy values of freshly spin-coated surfaces of pristine SU-8 and SU-8 + PFPE composite sides are shown in

Table 1a.

Figure 3 shows the distinction between the fresh surface and worn surface. Pristine SU-8 shows the highest surface free energy of 32.64 mN/m, hence it offers greater adhesion and friction, whereas SU-8 + PFPE shows the surface free energy of 24.14 mN/m. However, the pristine SU-8 shows the polar surface energy of 12 mN/m, which is four times higher than that of SU-8 + PFPE. This high polar nature of pristine SU-8 makes the surface much more hydrophilic. Hence high polar component of the surface free energy may lead to high adhesion and friction [

10].

Table 1.

Polar, dispersive and total Surface energies of pristine SU-8 side and SU-8 + PFPE side of Lube-tape, respectively. (a) At fresh surfaces; (b) At worn surfaces (wear track).

Table 1.

Polar, dispersive and total Surface energies of pristine SU-8 side and SU-8 + PFPE side of Lube-tape, respectively. (a) At fresh surfaces; (b) At worn surfaces (wear track).

| Composite Description | Polar Surface Energy (mN/m) | Dispersive Surface Energy (mN/m) | Total Surface Energy (mN/m) |

|---|

| (a) Condition: On Fresh Surface |

| SU-8 | 11.44 | 21.2 | 32.64 |

| SU-8 + PFPE | 3.36 | 20.78 | 24.14 |

| (b) Condition: On Worn Surface(Wear Track) |

| SU-8 | 26.1 | 23.38 | 49.48 |

| SU-8 + PFPE | 3.54 | 19.44 | 22.98 |

Figure 3.

Digital image shows the fresh surface and worn surface where the surface energy characterization was performed.

Figure 3.

Digital image shows the fresh surface and worn surface where the surface energy characterization was performed.

3.2. Tribological Characterization

Table 2 shows the initial coefficient of friction (µ

i), the steady-state coefficient of friction (µ

s) and the wear life data for Lube-tape films (conducted at both sides

i.e., high friction and low friction sides, respectively) with different PFPE concentrations and at different loads and rotational speeds, respectively. The tribological data summarized in

Table 2 were obtained from typical coefficient of friction (µ)

versus number of cycles (N) plots as shown in

Figure 4.

The tribological properties of 5 wt% Lube-tape, obtained at a normal load of 300 g and a rotational speed of 1000 rpm will be discussed in this section as also shown in

Table 2 (bottom) and

Figure 4b. The pristine SU-8 side has shown high friction properties (µ

i: ~0.56) and low wear life (

n ~ 10) when tested at a normal load of 300 g and at rotational speeds of 1000 rpm, respectively. Under the same loading conditions, SU-8 + PFPE side has shown very low coefficients of friction (µ

i: 0.05 and µ

s: 0.12) and high wear life (

n > 500,000). Therefore, the composite of SU-8 + PFPE side of the tape shows significant improvement in tribological properties (the µ

i has been reduced by ~8 times and the wear life has been improved by >250 times) when compared with the properties of high friction side (pristine SU-8). The friction behavior of the pristine SU-8 side, tested at 300 g and 1000 rpm is shown in

Figure 4b. The observed trend is quite unusual as the COF drops from higher value of 0.6 to 0.4 and from 0.4 to 0.2 in two steps. The high friction SU-8 side started wearing-off right at the beginning and partially exposing the SU-8 + PFPE layer underneath. As the wear process progresses further, the pristine SU-8 is worn-off completely and the counterface ball touches the SU-8 + PFPE layer. At this stage the coefficient of friction drops to a value matching the values equivalent to SU-8 + PFPE side. Small difference is because of the presence of large amount of debris material when sliding is started from pure SU-8 side.

Table 2.

Tribological test results of SU-8 Lube-tape (initial coefficient of friction (µi), steady-state coefficient of friction (µs) and wear life (number of sliding cycles)) of 10 and 5 wt % SU-8 + PFPE Lube-tapes, tested against 4 mm diameter Si3N4 ball at different loads and sliding speeds. (Both sides of the Lube-tape were tested, as indicated).

Table 2.

Tribological test results of SU-8 Lube-tape (initial coefficient of friction (µi), steady-state coefficient of friction (µs) and wear life (number of sliding cycles)) of 10 and 5 wt % SU-8 + PFPE Lube-tapes, tested against 4 mm diameter Si3N4 ball at different loads and sliding speeds. (Both sides of the Lube-tape were tested, as indicated).

| Composite Description | Initial coefficient of friction, COF (µi) | Steady-state coefficient of friction, COF (µs) | Wear Life (Number of Cycles, N) |

|---|

| 10 wt % SU-8 + PFPE Free-standing Lube-tape Film/Test Parameter: 300 g, 2000 rpm (0.4 m/s) |

| High Friction Side (SU-8 alone) | 0.62 | - | ~10 |

| Low friction Side | 0.08 | 0.19 | Failed at 700,000 ± 5000 cycles |

| 5 wt % SU-8 + PFPE Free Standing Lube-tape Film/Test Parameter: 300 g, 1000 rpm (0.2 m/s) |

| High Friction Side (SU-8 alone) | 0.56 | - | ~10 |

| Low friction Side | 0.05 | 0.12 | >500,000 ± 5000 cycles |

Figure 4.

Typical coefficient of friction versus number of cycles plot for different wt % SU-8 + PFPE composite based Lube-tape film obtained from the ball-on-disk sliding tests against 4 mm diameter Si3N4 ball at a normal load of 300 g and a sliding speed of 2000 rpm. (a) 10 wt %; (b) 5 wt %.

Figure 4.

Typical coefficient of friction versus number of cycles plot for different wt % SU-8 + PFPE composite based Lube-tape film obtained from the ball-on-disk sliding tests against 4 mm diameter Si3N4 ball at a normal load of 300 g and a sliding speed of 2000 rpm. (a) 10 wt %; (b) 5 wt %.

The high friction side (pristine SU-8 side) of the tape can be used to adhere to the surface of interest whereas the SU8 + PFPE layer will be exposed against the moving counterface material and can reduce the friction and increase the wear life. The PFPE concentration in the composites was increased from 5 wt% to 10 wt% and then the tribological behavior was evaluated at a normal load of 300 g and sliding speed of 2000 rpm. An increase of PFPE concentration from 5 wt% to 10 wt% has shown an improvement in the wear lives by 30%–40% at the identical speed and load configuration. Therefore, the concentration of the PFPE has to be optimized depending on the application requirements and the operating conditions of the Lube-tape once it is placed in the application.

3.3. Surface Free Energy Calculations on Worn Surface

Surface free energy measurements were performed on wear tracks of pristine SU-8 (10,000 cycles) and SU-8 + PFPE composite (after enduring 700,000 sliding cycles) sides of Lube-tape tested at a normal load of 300 g and sliding speed of 2000 rpm, as shown in

Table 1b. Pristine SU-8 shows the highest surface energy of 49.48 mN/m. It also shows the highest polar contribution of 26.1 mN/m, which is 15 mN/m more than that of the fresh surface, indicating that unsatisfied broken bonds make it highly hydrophilic [

10].

However, SU-8 + PFPE wear track shows very low surface free energy of 22.98 mN/m, which is ~2 mN/m less than that of the fresh surface, suggesting proper surface coverage by PFPE lubricant. It also indicates that the entire wear track is very well protected by thin film PFPE lubricant even after sliding for ~700,000 cycles. The polar surface energy of SU-8 and SU-8 + PFPE is ~27 and ~4 mN/m, respectively, at wear track conditions and it shows that SU-8 is more hydrophilic, offers high friction.

3.4. Boundary Layer Lubrication

Figure 5 shows SEM cross-sectional images of pristine SU-8 and SU-8 composite films. It is necessary to find the source of lubrication for the prolonged wear life of SU-8 + PFPE composites over pristine SU-8. Physical boundary layer lubrication was also found responsible along with chemical bonding between SU-8 and PFPE molecules. Before curing and UV exposure, the composite resin is in the gluey state, where the SU-8 matrix has lubricant (PFPE) droplets of sizes ranging from few nm to 5 µm dispersed throughout its matrix. After UV exposure and curing, the SU-8 undergoes cross-linking and becomes solid. As the lubricant remains unaffected by the UV radiation, the droplets remain trapped in liquid form inside the solid SU-8 bulk. This trapped lubricant in tiny cavities gives an advantage of storing lubricants for self-regeneration and lubrication. The sectioned images are the measure of the lubricant dispersion and agglomeration within the composites. However, pristine SU-8 (

Figure 5a) shows plain surface without any surface feature except some rough surface ridges, which is due to brittle nature of SU-8. SU-8 + PFPE (

Figure 5b) shows uniformly dispersed round shaped droplets in greater number all across the film. Once the lubricant layer over the surface is worn away with counterface sliding, the lubricant droplets beneath the worn surface is released which forms the boundary layer to reduce the friction and wear and the same cycle repeats till the complete wear of the composite. This model also emphasizes that the tribological performance of composites depends on the uniform dispersion of lubricants and bonding of the lubricants with the surface. Hence, the effect of dispersion and bonding of the lubricant is vital in the wear durability of the SU-8 + PFPE composites.

Figure 5.

SEM cross-sectional images of ~90 µm thick Lube-tape layers; (a) Pristine SU-8 layer; (b) 5 wt % SU-8 + PFPE composite layer.

Figure 5.

SEM cross-sectional images of ~90 µm thick Lube-tape layers; (a) Pristine SU-8 layer; (b) 5 wt % SU-8 + PFPE composite layer.

The significant improvement in tribological properties of SU-8 by the addition of PFPE can be attributed to the possible ether bond formation between the SU-8 and PFPE molecules [

11,

12]. The possible etherification reaction is depicted in Equation (2). It is postulated that the –OH terminal groups in the PFPE polymer and the carbocations (C

+) in the SU-8 polymer (epoxide ring) undergo the reaction, which breaks the existing bond and forms new linkage through ether bonds.

Few others have demonstrated the UV initiated graft polymerization of various polymers on SU-8 surface. Water-soluble monomers and other polymers like poly(acrylic acid) have been covalently grafted to SU-8 using UV-mediated grafting and also, chemically micro-patterned [

13]. Under controlled conditions, the remainder photo acid generator triarylsulfonium hexafluoroantimonate works as a photo initiator and generates free radicals such as C–OO, C–O, –COOH [

13]. These evidences can be found in the literature [

14,

15,

16]. The surface free energy calculation, tribological characterization and SEM images indicate the possibility of chemical reaction. It was thoroughly investigated and confirmed in our prior works [

7,

9].

3.5. Optical Micrographs of Worn Surfaces

Table 3 shows the optical micrographs of 10 wt % SU-8 + PFPE free standing Lube-tape film, tested on pristine SU-8 and SU-8 + PFPE sides at a normal load of 300 g and a sliding speed of 2000 rpm. Row 1 in

Table 3 shows the counterface ball immediately after the sliding test, counterface ball after cleaning with a solvent and the optical micrographs of the wear track (worn surface) of SU-8 side, respectively. Physical observation of the counterface ball before and after cleaning will reveal information about the amount of material transfer onto the counterface ball, mode of wear and damages caused to the counterface ball. The pristine SU-8 surface side shows severe wear with wide and deep wear track and loss of material too. The counterface ball also shows thick layer of material with some damages to the counterface ball. The counterface ball also shows distinct wear after cleaning with acetone. These images qualitatively support the tribological behavior mentioned in preceding sections. Row 2 in

Table 3 shows the counterface ball, counterface ball after cleaning with the solvent and the micrographs of wear track of SU-8 + PFPE side, respectively. SU-8 + PFPE shows very mild wear track with less material removal and the presence of lubricant droplets on the counterface can also be witnessed. There is very less material transfer onto the counterface ball, which confirms less chance of adhesive wear and no wear debris are accumulated in and around the wear track. It is necessary to analyze the contents of the transferred material, whether it is SU-8 or PFPE film, therefore, the counterface ball was washed with PFPE solvent H-Gladen which washed away ~80% (in terms of surface area) of the transfer materialand left only ~20% which may be SU-8, which could be cleaned with acetone. These optical micrographs indeed confirm that SU-8 + PFPE side is highly resistant against friction and wear. They also supported the mechanisms explained in earlier sections.

Table 3.

Optical micrographs of counterface balls surface after sliding tests, tested counterface balls after cleaning with solvents and worn surfaces, for both SU-8 side (at 10,000 cycles) and SU-8 + PFPE side of Lube-tape (at 700,000 cycles), respectively. The length of the scale bar is 100 µm in all images.