An Investigation of Processes for Glass Micromachining

Abstract

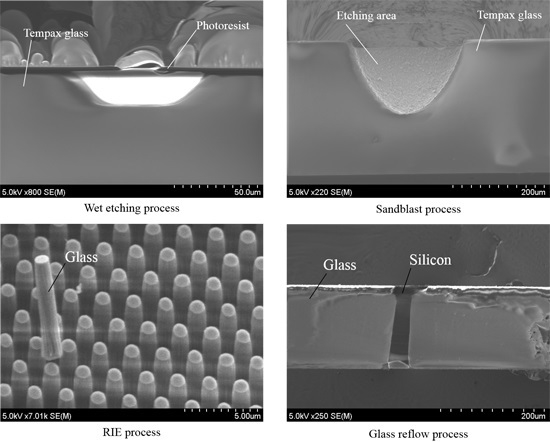

:1. Introduction

2. Experiments and Discussions

2.1. Sandblast

2.2. Wet Etching

2.3. Reactive Ion Etching

2.4. Glass Reflow Process

3. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yamaner, Y.F.; Zhang, X.; Oralkan, O. Fabrication of anodically bonded capacitive micromachined ultrasonic transducers with vacuum-sealed cavities. In Proceedings of the IEEE International Ultrasonics Symposium, Chicago, IL, USA, 3–9 September 2014; pp. 604–607.

- Toan, N.V.; Miyashita, H.; Toda, M.; Kawai, Y.; Ono, T. Fabrication of an hermetically packaged silicon resonator on LTCC substrate. Microsyst. Technol. 2013, 19, 1165–1175. [Google Scholar] [CrossRef]

- Kutchoukov, V.G.; Laugere, F.; Vlist, W.V.D.; Pakula, L.; Garni, Y.; Bossche, A. Fabrication of nanofluidic devices using glass-to-glass anodic bonding. Sens. Actuators A Phys. 2004, 114, 521–527. [Google Scholar] [CrossRef]

- Lee, K.I.; Lim, B.; Oh, S.W.; Kim, S.H.; Lee, C.S.; Cho, J.W.; Hong, Y. Fabrication of high aspect ratio insulating nozzle using glass reflow process and its electrohydrodynamic printing characterisitics. In Proceedings of 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS 2014), San Francisco, CA, USA, 26–30 January 2014; pp. 963–966.

- Merz, P.; Quenzer, H.J.; Bent, H.; Wanger, B.; Zoberbier, M. A novel micromaching technology for structuring borosilicate substrates. In Proceedings of the 12th International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers 2003), Boston, MA, USA, 8–12 June 2003; pp. 258–261.

- Lin, C.W.; Hsu, C.P.; Yang, H.A.; Wang, W.C.; Fang, W. Implementation of silicon-on-glass MEMS devices with embedded through-wafer silicon vias using the glass reflow process for wafer-level packaging and 3D chip integration. J. Micromech. Microeng. 2008, 18, 025018. [Google Scholar] [CrossRef]

- Toan, N.V.; Toda, M.; Kawai, Y.; Ono, T. A long bar type silicon resonator with a high quality factor. IEEJ Trans. Sens. Micromachines 2014, 134, 26–31. [Google Scholar] [CrossRef]

- Lee, T.M.H.; Lee, D.H.Y.; Liaw, C.Y.N.; Lao, A.I.K.; Hsing, I.M. Detailed characterization of anodic bonding process between glass and thin-film coated silicon substrates. Sens. Actuators A Phys. 2000, 86, 103–107. [Google Scholar] [CrossRef]

- Guo, M.; Chou, X.; Mu, J.; Liu, B.; Xiong, J. Fabrication of micro-trench structures with high aspect ratio based on DRIE process for MEMS device applications. Microsyst. Technol. 2013, 19, 1097–1103. [Google Scholar] [CrossRef]

- Ohtake, H.; Ishihara, H.; Fuse, T.; Koshiishi, A.; Samukawa, S. Highly selective and high rate SiO2 etching using argon-added C2F4/CF3I plasma. J. Vac. Sci. Technol. B 2003, 21, 2142–2146. [Google Scholar] [CrossRef]

- Toan, N.V.; Kubota, T.; Sekhar, H.; Samukaw, S.; Ono, T. Mechanical quality factor enhancement in a silicon micromechanical resonator by low-damage process using neutral beam etching technology. J. Micromech. Microeng. 2014, 24, 085005. [Google Scholar] [CrossRef]

- Chen, Q.; Fang, J.; Ji, H.F.; Varahramyan, K. Fabrication of SiO2 microcantilever using isotropic etching with ICP. IEEE Sens. J. 2007, 7, 1632–1638. [Google Scholar] [CrossRef]

- Wensink, H.; Berenschot, J.W.; Hanse, H.V.; Elwenspoel, M.C. High resolution powder blast micromachining. In Proceedings of the 13th Annual International Conference on Micro Electro Mechanical Systems (MEMS 2000), Miyazaki, Japan, 23–27 January 2000; pp. 769–774.

- Grosse, A.; Grewe, M.; Fouckhardt, H. Deep wet etching of fused silica glass for hollow capillary optical leaky waveguides in microfluidic devices. J. Micromech. Microeng. 2001, 11, 257–262. [Google Scholar] [CrossRef]

- Iliescu, C.; Chen, B.; Miao, J. On the wet etching of Pyrex glass. Sens. Actuators A Phys. 2008, 143, 154–161. [Google Scholar] [CrossRef]

- Li, X.; Abe, T.; Esashi, M. Deep reactive ion etching of Pyrex glass. In Proceedings of the 13th Annual International Conference on Micro Electro Mechanical Systems (MEMS 2000), Miyazaki, Japan, 23–27 January 2000; pp. 271–276.

- Ceyssens, F.; Puers, R. Deep etching of glass wafers using sputtered molybdenum masks. J. Micromech. Microeng. 2009, 19, 067001. [Google Scholar] [CrossRef]

- Iliescu, C.; Tan, K.L.; Tay, F.E.H.; Miao, J. Deep wet and dry etching of Pyrex glass: A review. In Proceedings of the International Conference on Materials for Advanced Technologies (ICMAT), Singapore, 3–7 July 2005; pp. 75–78.

- Eklund, E.J.; Shkel, A.M. Glass blowing on a wafer level. J. Microelectromech. Syst. 2007, 16, 232–239. [Google Scholar] [CrossRef]

- Senkal, D.; Ahamed, M.J.; Ardakani, M.H.A.; Askari, S.; Shkel, A.M. Demonstration of 1 million Q-factor on microglassblown wineglass resonators with out-of-plane electrostatic transduction. J. Microelectromech. Syst. 2015, 24, 29–37. [Google Scholar] [CrossRef]

- Huang, C.Y.; Hsiao, W.T.; Huang, K.C.; Chang, K.S.; Chou, H.Y.; Chou, C.P. Fabrication of a double-sided micro-lens array by a glass molding technique. J. Micromech. Microeng. 2011, 21, 085020. [Google Scholar] [CrossRef]

- Haque, R.M.; Wise, K.D. A glass-in-silicon reflow process for three-dimensional microsystems. J. Microelectromech. Syst. 2013, 22, 1470–1477. [Google Scholar] [CrossRef]

- Kong, S.; Minami, K.; Esashi, M. Fabrication of reactive ion etching systems for deep silicon machining. IEEJ Trans. Sens. Micromach. 1997, 117, 10–14. [Google Scholar] [CrossRef]

- Janse, H.; Wiegerink, R.; Tas, N.; Smulders, E.; Neagu, C.; Elwenspoek, M. RIE lag in high aspect ratio trench etching of silicon. Microelectron. Eng. 1997, 35, 45–50. [Google Scholar] [CrossRef]

- Toan, N.V.; Sangu, S.; Inomata, N.; Ono, T. Glass capillaries based on a glass reflow into nano-trench for controlling light transmission. Microsyst. Technol. 2015. [Google Scholar] [CrossRef]

| Etching Material | Mask Material | Nozzle Pressure | X Velocity | Y Velocity |

|---|---|---|---|---|

| Tempax Glass | Dry thin film resist (MS7050) | 0.1 Pa | 10 mm/s | 20 mm/s |

| Parameters | Sandblast | Wet Etching | RIE | Glass Reflow |

|---|---|---|---|---|

| Feature size | ||||

| Minimum size | 100 μm | 1 μm | <1 μm | <1 μm |

| Side etching | No | Yes | No | No |

| Etching profile | V shapes | U shapes | Vertical | Vertical |

| Aspect ratio | Low | Low | High | High |

| Surfaces | Rough | Smooth | Smooth | Smooth |

| Process time | Short | Short | Medium | Long |

| Mask materials | Dry film resist | Metal and photoresist | Metal mask for high selectivity | Silicon mold |

| Selectivity between Tempax glass and mask material | Low | High | High | Glass fills into cavity |

| Etching environment | Al2O3 particles | Liquid | Plasma | Atmospheric furnace with a high temperature |

| Post processes | Particles | Good | Good | Good |

| Etching Material | Mask Material | Etching Solution | Etching Rate | Side Etching |

|---|---|---|---|---|

| Tempax Glass | Photoresist on metal (Cr-Au) | HF:DI = 2:1 | 2 µm/min | 2 µm/min |

| Etching Material | Mask Material | Gas | RF Power | Gas Pressure | Etching Rate |

|---|---|---|---|---|---|

| Tempax Glass | Nickel | SF6 & O2 | 100 W | 0.25 Pa | 300 nm/min |

| Molds | Diameter | Pitch | Depth |

|---|---|---|---|

| Pillar mold | 1.2 μm | 2 μm | 8 μm |

| Capillary mold | 1 μm | 2 μm | 6.5 μm |

| Parameters | 1st Reflow Condition | 2nd Reflow Condition | 3rd Reflow Condition |

|---|---|---|---|

| Temperature | 1000 °C | 1050 °C | 1100 °C |

| Process time | 3 h | 16 h | 20 h |

| Mold surface | Silicon | Silicon | SiO2 |

| Penetration depth of pillar mold | 1.5 μm | 5 μm | 8 μm |

| Penetration depth of capillary mold | 0 μm | 1 μm | 2.5 μm |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Toan, N.; Toda, M.; Ono, T. An Investigation of Processes for Glass Micromachining. Micromachines 2016, 7, 51. https://doi.org/10.3390/mi7030051

Van Toan N, Toda M, Ono T. An Investigation of Processes for Glass Micromachining. Micromachines. 2016; 7(3):51. https://doi.org/10.3390/mi7030051

Chicago/Turabian StyleVan Toan, Nguyen, Masaya Toda, and Takahito Ono. 2016. "An Investigation of Processes for Glass Micromachining" Micromachines 7, no. 3: 51. https://doi.org/10.3390/mi7030051

APA StyleVan Toan, N., Toda, M., & Ono, T. (2016). An Investigation of Processes for Glass Micromachining. Micromachines, 7(3), 51. https://doi.org/10.3390/mi7030051