Antireflective SiC Surface Fabricated by Scalable Self-Assembled Nanopatterning

Abstract

:1. Introduction

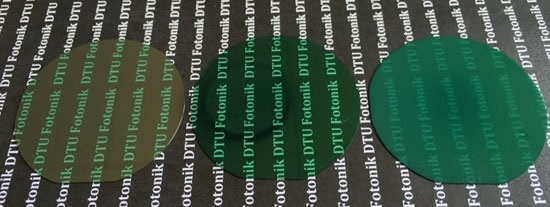

2. Fabrication Process Flow

3. Nanopatterning

4. Dry Etching and Characterization

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wan, D.; Chen, H.-L.; Tseng, T.-C.; Fang, C.-Y.; Lai, Y.-S.; Yeh, F.-Y. Antireflective nanoparticle arrays enhance the efficiency of silicon solar cells. Adv. Funct. Mater. 2010, 20, 3064–3075. [Google Scholar] [CrossRef]

- Sheng, X.; Broderick, L.Z.; Hu, J.; Yang, L.; Eshed, A.; Fitzgerald, E.A.; Michel, J.; Kimerling, L.C. Design and fabrication of high-index-contrast self-assembled texture for light extraction enhancement in LEDs. Opt. Express 2011, 19, A701–A709. [Google Scholar] [CrossRef] [PubMed]

- Sainiemi, L.; Jokinen, V.; Shah, A.; Shpak, M.; Aura, S.; Suvanto, P.; Franssila, S. Non-reflecting silicon and polymer surfaces by plasma etching and replication. Adv. Mater. 2011, 23, 122–126. [Google Scholar] [CrossRef] [PubMed]

- Noda, S.; Fujita, M. Light-emitting diodes: Photonic crystal efficiency boost. Nat. Photonics 2009, 3, 129–130. [Google Scholar] [CrossRef]

- Li, X.; Gao, J.; Xue, L.; Han, Y. Porous Polymer Films with Gradient-refractive-index structure for broadband and omnidirectional antireflection coatings. Adv. Funct. Mater. 2010, 20, 259–265. [Google Scholar] [CrossRef]

- Boden, S.A.; Bagnall, D.M. Tunable reflection minima of nanostructured antireflective surfaces. Appl. Phys. Lett. 2008, 93, 133108. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, S.H.; Xu, J.; Zhao, L.; Sun, H.C.; Li, J.; Mu, W.W.; Xu, L.; Chen, K.J. Broadband antireflection and absorption enhancement by forming nano-patterned Si structures for solar cells. Opt. Express 2011, 19, A1051–A1056. [Google Scholar] [CrossRef] [PubMed]

- Matioli, E.; Brinkley, S.; Kelchner, K.M.; Nakamura, S.; DenBaars, S.; Speck, J.; Weisbuch, C. Polarized light extraction in m-plane GaN light-emitting diodes by embedded photonic-crystals. Appl. Phys. Lett. 2011, 98, 251112. [Google Scholar] [CrossRef]

- Seko, T.; Mabuchi, S.; Teramae, F.; Suzuki, A.; Kaneko, Y.; Kawai, R.; Kamiyama, S.; Iwaya, M.; Amano, H.; Akasaki, I. Fabrication technique for moth-eye structure using low-energy electron-beam projection lithography for high-performance blue-light-emitting diode on SiC substrate. In Proceedings of the Gallium Nitride Materials and Devices IV, San Jose, CA, USA, 24 January 2009; p. 721628.

- Kawai, R.; Kondo, T.; Suzuki, A.; Teramae, F.; Kitano, T.; Tamura, K.; Sakurai, H.; Iwaya, M.; Amano, H.; Kamiyama, S.; et al. Realization of extreme light extraction efficiency for moth-eye LEDs on SiC substrate using high-reflection electrode. Phys. Status Solidi C 2010, 7, 2180–2182. [Google Scholar] [CrossRef]

- Chen, Q.; Hubbard, G.; Shields, P.A.; Liu, C.; Allsopp, D.W.; Wang, W.N.; Abbott, S. Broadband moth-eye antireflection coatings fabricated by low-cost nanoimprinting. Appl. Phys. Lett. 2009, 94, 263118. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, X.; Jokubavicius, V.; Yakimova, R.; Mortensen, N.A.; Syväjärvi, M.; Xiao, S.; Ou, H. Broadband antireflection and light extraction enhancement in fluorescent SiC with nanodome structures. Sci. Rep. 2014, 4, 4662. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Shin, D.; Kang, G.; Baek, S.; Kim, K.; Padilla, W.J. Broadband optical antireflection enhancement by integrating antireflective nanoislands with silicon nanoconical-frustum arrays. Adv. Mater. 2011, 23, 5796–5800. [Google Scholar] [CrossRef] [PubMed]

- Chiu, C.H.; Lu, T.C.; Huang, H.W.; Lai, C.F.; Kao, C.C.; Chu, J.T.; Yu, C.C.; Kuo, H.C.; Wang, S.C.; Lin, C.F.; et al. Fabrication of InGaN/GaN nanorod light-emitting diodes with self-assembled Ni metal islands. Nanotechnology 2007, 18, 445201. [Google Scholar] [CrossRef]

- Wang, S.; Yu, X.Z.; Fan, H.T. Simple lithographic approach for subwavelength structure antireflection. Appl. Phys. Lett. 2007, 91, 061105. [Google Scholar] [CrossRef]

- Leem, J.W.; Yu, J.S. Wafer-scale highly-transparent and superhydrophilic sapphires for high-performance optics. Opt. Express 2012, 20, 26160–26166. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Choi, E.S.; Yu, J.S.; Lee, Y.T. Light-extraction enhancement of red AlGaInP light-emitting diodes with antireflective subwavelength structures. Opt. Express 2009, 17, 20991–20997. [Google Scholar] [CrossRef] [PubMed]

- Kojima, Y.; Kato, T. Nanoparticle formation in Au thin film by electron-beam induced dewetting. Nanotechnology 2008, 19, 255605. [Google Scholar] [CrossRef] [PubMed]

- Ou, H.; Ou, Y.; Argyraki, A.; Schimmel, S.; Kaiser, M.; Wellmann, P.; Linnarsson, M.K.; Jokubavicius, V.; Sun, J.; Liljedahl, R.; et al. Advances in wide bandgap SiC for optoelectronics. Eur. Phys. J. B 2014, 87, 1–16. [Google Scholar] [CrossRef]

- Syväjärvi, M.; Ma, Q.; Jokubavicius, V.; Galeckas, A.; Sun, J.; Liu, X.; Jansson, M.; Wellmann, P.; Linnarsson, M.; Runde, P.; et al. Cubic silicon carbide as a potential photovoltaic material. Sol. Energy Mater. Sol. Cells 2016, 145, 104–108. [Google Scholar] [CrossRef]

| Au Film Thickness (nm) | Nanoparticle Density (/µm2) | Nanoparticle Coverage (%) | Nanoparticle Height (nm) | Nanoparticle Aspect Ratio |

|---|---|---|---|---|

| 3 | 1910 | 39.2 | 7.7 | 0.50 |

| 5 | 200 | 32.3 | 15.5 | 0.37 |

| 7 | 88.9 | 32.8 | 21.3 | 0.33 |

| 9 | 19 | 26.4 | 34.1 | 0.27 |

| 11 | 4.3 | 19.4 | 56.7 | 0.25 |

| 13 | 1.7 | 16.3 | 79.8 | 0,25 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, Y.; Fadil, A.; Ou, H. Antireflective SiC Surface Fabricated by Scalable Self-Assembled Nanopatterning. Micromachines 2016, 7, 152. https://doi.org/10.3390/mi7090152

Ou Y, Fadil A, Ou H. Antireflective SiC Surface Fabricated by Scalable Self-Assembled Nanopatterning. Micromachines. 2016; 7(9):152. https://doi.org/10.3390/mi7090152

Chicago/Turabian StyleOu, Yiyu, Ahmed Fadil, and Haiyan Ou. 2016. "Antireflective SiC Surface Fabricated by Scalable Self-Assembled Nanopatterning" Micromachines 7, no. 9: 152. https://doi.org/10.3390/mi7090152

APA StyleOu, Y., Fadil, A., & Ou, H. (2016). Antireflective SiC Surface Fabricated by Scalable Self-Assembled Nanopatterning. Micromachines, 7(9), 152. https://doi.org/10.3390/mi7090152