1. Introduction

A microprocessor is composed of various blocks producing different amounts of heat, and the logic-block being the highest contributor creates a localized high heat flux region known as “hotspot” [

1]. Design complexity and dynamic power dissipation in a single core processor caused the design architecture to shift towards multicore [

2]. In a multicore processor, most of the heat is concentrated at the cores creating multiple hotspots. High temperatures at the hotspots create large temperature gradients which induce thermal stresses creating circuit imbalances that could affect the efficiency and service life of a microprocessor [

3]. With the advancement in manufacturing techniques [

4], a microprocessor with 5.4 billion transistors was recently developed at IBM [

5]. The thermal design powers (TDPs) of central processing units (CPUs) and graphics processing units (GPUs) have reached 150 W and 250 W, respectively [

6]. Air-cooling techniques have reached their limits [

7], and thus there is an eminent need to explore more effective cooling solutions that can keep up with the heat dissipation requirement of the advanced microprocessors.

Tuckerman and Pease [

8] showed promising results by using a microchannel heat sink with water as a coolant. Following their work, numerous studies have been presented to explore and enhance the thermo-hydraulic performance of microchannel heat sinks. Liu and Garimella [

9] performed numerical and experimental study on fluid flow in microchannels with wide ranges of hydraulic diameters and Reynolds numbers. They concluded that the conventional Navier–Stokes theory can be employed using commercial software packages to understand the flow in microchannels. Several active [

10,

11] and passive [

11,

12,

13,

14] heat transfer augmentation techniques have been explored to enhance the heat transfer capacity. Passive techniques (as considered in the present work) are the preferred choice over active techniques as they have simple design and also do not require external power therefore eliminating additional complexity and costs [

11].

Double-layer microchannel heat sink gained attention for its higher heat transfer capability over single-layer microchannel heat sink [

15,

16]. A better temperature uniformity is offered by the double-layer counter-flow arrangement as compared to the double-layer parallel-flow arrangement [

17]. Performance enhancements of double-layer microchannel heat sinks were reported by using converging channels [

18,

19] and passive microstructures [

12,

13,

14,

20], and by optimizing channel shapes [

21,

22,

23]. Along with double-layer parallel-flow and counter-flow heat sinks, Ansari and Kim [

24] analyzed the performance of a double-layer transverse-flow heat sink design with various flow configurations. They reported that the transverse-flow heat sink showed better temperature uniformity and lower thermal resistance as compared to double-layer parallel-flow and counter-flow heat sinks. Use of temperature-dependent fluid properties for numerical analysis is recommended by many researchers unless the temperature difference is very small as the constant fluid property method is crude approximation of the real phenomenon [

25,

26].

In a single core processor, the maximum clock frequency has saturated around 4 GHz due to increased design complexity [

2]. Since 2004, the processor architecture has shifted towards multicore to keep up with the increasing requirement for computational capability [

2,

27]. The high heat flux concentrated at the cores as compared to the remaining chip area [

28,

29,

30,

31], creates large temperature gradient across the chip which leads to circuit imbalances and eventually degradation in the microchip performance [

32]. Using spatially-resolved imaging of microprocessor power (SIMP) technique, Hamann et al. [

33] analyzed the power distribution of a fully working dual core microprocessor. They presented that the flux intensity as well as the actual position of a hotspot in a dual core microprocessor changes quite drastically depending upon the level of utilization.

Hotspots in a microchip are currently being identified as a prevalent challenge in the design of an efficient heat sink. If heat sinks are designed considering the maximum heat flux at the hotspots, it would lead to over-cooling of the remaining background area of the microchip, while designing it considering average heat flux generated by microchip would lead to under-cooling of high heat flux regions. Abdoli et al. [

34] numerically investigated performance of a micro pin-fin array heat sink with a single hotspot at the center and presented the effects of the pin-fin shape and the height on the thermo-hydraulic performance using six different pin-fin shapes. Effect of manifold design on the performance of a microchannel heat sink with non-uniform heating was presented by Liu et al. [

35]. Various cooling techniques have been proposed for hotspot management using minichannel heat sink and thermoelectric cooler [

36], hierarchical manifold microchannel heat sink [

37], and micro heat sink with non-uniform pin-fin distribution [

38]. Feng et al. [

39] performed an analysis of a pin-fin heat sink under non-uniform impingement heating, and presented an analogy model for the fast calculation of thermal resistance with reasonable accuracy as compared to numerical calculation.

With maximum clock frequency of a single core processor at its limits [

2], almost all future CPUs and GPUs would have multiple cores, creating multiple high heat flux zones. In addition, the intensity and the location of high heat flux varies with the processors utilization [

33]. Thermal analysis of heat sinks considering random non-uniform heating schemes, would closely imitate the actual heating conditions of future multicore processors, and the results would be more reliable and practical. In the present study, performance of a previously proposed flow configuration of double-layer transverse-flow microchannel heat sink [

24], was evaluated under random non-uniform heating condition and compared with that of double-layer parallel-flow and counter-flow heat sinks. Three different heating schemes with eleven random hotspots in each scheme were selected as heating conditions. Heat flux, area, and location were selected as the hotspots parameters. Latin hypercube sampling (LHS) [

40,

41] method was used to generate the hotspots in each set. Full heat sink was selected as the computational domain and a three-dimensional (3-D) conjugate heat transfer analysis was performed using Navier–Stokes and energy equations with temperature-dependent fluid properties. The performances of the heat sinks were evaluated in terms of maximum temperature rise at the hotspots, temperature variation among the hotspots, pressure drop and the total thermal resistance.

2. Heat Sink Models and Heating Conditions

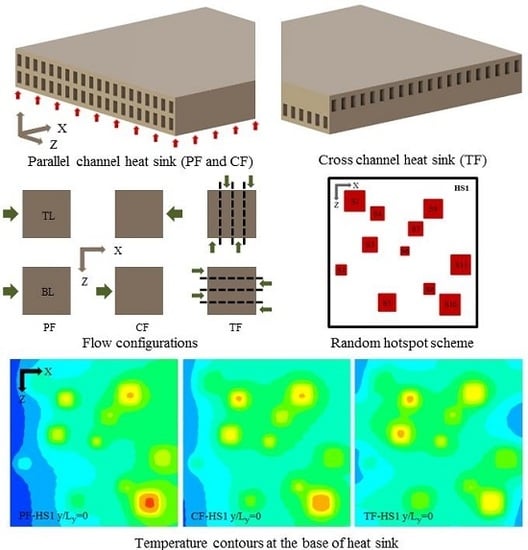

The schematic configurations of two double-layer microchannel heat sinks (parallel-channel and cross-channel) analyzed under random non-uniform heating conditions are shown in

Figure 1a,b. Each heat sink model was composed of total forty microchannels with twenty microchannels in each layer. In case of the parallel-channel design (

Figure 1a), the channels in both the top and the bottom layers are aligned parallel to each other, whereas, in case of the cross-channel design (

Figure 1b), the channels in the top layer are transversal (at right angles) to those in the bottom layer. To evaluate the performances of these two heat sink designs under non-uniform heating conditions, three flow configurations were selected. The two flow configurations from the parallel-channel design (PF and CF) and one flow configuration from the cross-channel design (TF) are shown in

Figure 1d. In the PF configuration, the flow directions in both the bottom and the top layers are same. In the CF configuration, the flow direction in the top layer is opposite to that in the bottom layer. In the TF configuration, these two flow directions are transversal (at right angles); moreover, each layer is subdivided into quarters with opposite flow directions in the adjacent quarters. The TF flow configuration considered here showed the best performance among all the analyzed flow configurations of the parallel-channel and cross-channel designs in the previous study presented by the authors [

24].

Both the heat sinks were designed with exactly same values of the geometric parameters as listed in

Table 1. The analyzed heat sink designs can be manufactured using the process presented by Wei et al. [

17]. Improper selection of inlet manifold could lead to non-uniformity in flow distribution resulting in high temperature rise [

35] and increased pressure drop at high flow rates [

35,

42]. To uniformly distribute the coolant in microchannels, a multi-layer manifold design can be employed as presented by Wei et al. [

17]. In this work, however, the inlet manifold design was not included in the computational domain due to the limitation of computational resources. Thus, to minimize the computational cost, the present research was concentrated to understand the effect of randomly distributed hotspots on the performance of the double-layer microchannel heat sinks.

Three hotspot schemes (HS1, HS2, and HS3) were considered with eleven hotspots in each scheme, where the hotspots were generated randomly by using a design-of-experiment technique, LHS [

41]. The heat flux (

qhs), area (

Ahs), and location (

x and

z) of the hotspots were selected as the hotspot parameters.

Table 2 shows the hotspot design parameters with their ranges. The hotspot design schemes, HS1, HS2, and HS3, are shown in

Figure 2, and their hotspots are listed in

Table 3,

Table 4 and

Table 5, respectively. In experimental case, the temperature measurements at the hotspots can be performed by utilizing infrared (IR) imaging technique using an IR-transparent heat sink as presented by Hamann et al. [

33].

3. Numerical Analysis

A general purpose commercial CFD code, ANSYS CFX 15.0 [

43] was used to perform three-dimensional conjugate heat transfer analyses in microchannel heat sinks. The code uses an implicitly coupled algebraic multigrid solver [

44], which solves the governing equations for mass, momentum, and energy conservation. In the multigrid technique, the solver performs initial iterations on a fine mesh, then, on a coarser mesh which is created virtually, and finally the results are transferred back to the finer mesh to obtain accurate results. The coupled solver reduces the convergence time by solving an entire set of the equations simultaneously. The calculation of each equation was considered to have converged when the root-mean-square residual was less than 10

−6.

Several assumptions were made to simplify the numerical calculation. Flow inside the microchannels was considered to be steady, incompressible, and laminar. The gravitational effect and radiation heat transfer were neglected. The steady-state governing equations for conjugate heat transfer in fluid and solid regions are describe as follows:

Energy equation (liquid domain):

Energy equation (solid domain):

To evaluate the performance of the heat sinks, total thermal resistance, maximum temperature rise at hotspots, temperature variation among hotspots, and total pressure drop, were calculated. The total thermal resistance of heat sinks under uniform as well as non-uniform heating conditions was defined as follows [

8,

39]:

where

Ts,max is the maximum temperature at the bottom surface (solid) of heat sink,

Tf,in is the inlet fluid temperature, and

Qtot is the total heat applied at the bottom surface (solid) of the heat sink.

The

Qtot for heat sink without hotspots was defined as:

where

qb and

Ab are the heat flux applied at the bottom surface and the total area of the bottom surface of the heat sink, respectively. For heat sink with hotspots, it was defined as:

where

qbg is the heat flux applied at the background area of the heat sink (area excluding the hotspots) and

Abg is the background area of the heat sink.

qhs and

Ahs are the heat flux applied at each hotspot and the area of each hotspot, respectively.

is the total heat applied at all (eleven) the hotspots.

The total pumping power required to pump the coolant through the channels was calculated as:

where

is the total number of channels in both layers,

is the average inlet velocity of fluid,

is the channels cross-sectional area, and

is the pressure drop within a single channel.

The Reynolds number was defined as:

where ρ

f is the fluid (water) density,

Dh is the channel hydraulic diameter, and μ

f is the dynamic viscosity of the fluid.

In the case of cross-channel design (TF configuration) (

Figure 1b), selection of a periodic or symmetric computational domain is not possible, while it is possible for the parallel-channel design (PF and CF configurations) (

Figure 1a). However, to maintain the consistency in result presentation, the complete heat sinks were selected as the computational domain for all the flow configurations (PF, CF, and TF). As boundary conditions, a uniform mass flow rate was assigned at all the channel inlets (thus, the flow rates in the bottom and top layers are same), and atmospheric pressure condition was assigned at the outlets. A uniform heat flux (100 W/cm

2) was applied at the bottom surface of heat sinks without hotspots (

qb) and the same was used as the background heat flux (area excluding hotspots) of heat sinks with hotspots (

qbg).

Water represents superior thermophysical properties [

16], and thus it was selected as the coolant. The inlet temperature of water

and the heat sink (silicon) was set at 300 K. Silicon being the most widely used semiconductor material was selected as the heat sink material. The thermophysical properties of silicon, i.e., the density (ρ

s), specific heat (

Cp,s), and the thermal conductivity (

ks), were assigned as 2330 kg/m

3, 712 J/kg·K, and 148 W/m·K, respectively [

45].

The thermophysical properties of water were allowed to vary with temperature. Polynomial correlations, between the thermophysical properties of water and temperature in the property table [

45], were developed and verified by using MATLAB [

40] in this work. The correlations for density (ρ

w), specific heat (

Cp,w), thermal conductivity(

kw), and dynamic viscosity (μ

w) are described as follows:

where

T is the temperature in degrees Celsius (°C).

The prediction accuracies of the above correlations were verified by comparing the predicted values obtained by the correlations with the values obtained from the property table [

45], as shown in

Figure 3. Excellent agreements between the predicted values from the correlations and the original data [

45] can be observed in

Figure 3. The maximum percentage residuals for the density, specific heat, thermal conductivity, and dynamic viscosity were 0.04%, 0.01%, 0.16%, and 0.71%, respectively. The goodness-of-fit parameters [

40] to assess the prediction quality of the correlations, such as

R-square (

), adjusted

R-square (

), sum of squares due to error (SSE), and the root mean squared error (RMSE), are listed in

Table 6. Values of

and

closer to unity indicate that the fit is accurate, whereas for SSE and RMSE, a value closer to zero implies a better fit.

4. Results and Discussion

To create finite volumes in the computational domains for numerical calculations, unstructured tetrahedral and hexahedral elements were generated in the solid and fluid computational domains, respectively (with fine meshes near the walls of the fluid domain to resolve the boundary layer flow). A comprehensive grid sensitivity analysis was performed for consistent grid-independent results. Double-layer PF configuration with a single hotspot was selected for grid analysis at total flow rate of 0.006 kg/s. A wide range of grid nodes were tested; the number of nodes was varied from 3.9 million to 19.2 million. A grid with about 11 million nodes was determined to be optimum grid as no noticeable change in the results was observed with further increase in the grid density as shown in

Figure 4 (13.1 million nodes showed 0.007% and 0.154% changes in the maximum temperature rise and the pressure drop, respectively, as compared to 11 million nodes and a grid with 8.7 million nodes showed 0.04% and 0.4% changes in the maximum temperature rise and the pressure drop, respectively, as compared to 11 million nodes).

The numerical results using temperature-dependent fluid properties were validated with the previous numerical and experimental results [

17,

46] for the temperature distribution and the pressure drop, as shown in

Figure 5. The present numerical results show good agreements with the numerical and experimental results presented by Wei et al. [

17] for the temperature variation at the base of a double-layer counter-flow heat sink with rectangular microchannels as shown in

Figure 5a. Qu and Mudawar [

46] presented experimental results for the pressure drop within a rectangular microchannel.

Figure 5b shows good agreements between the present numerical and previous experimental data for the pressure drop in a range of Reynolds number.

In the present study, PF, CF, and TF heat sink designs were selected for the performance analysis under three randomly generated non-uniform heating schemes. The cross-channel heat sink design with the TF configuration considered in the present work showed the lowest thermal resistance as compared to various other cross-channel and parallel-channel designs in the previous work [

24]. The maximum increase in temperature at the hotspots, the pressure drop variation, the thermal resistance and the temperature variation among all the hotspots were selected as the performance parameters to be evaluated. A total flow rate range of 0.006 to 0.014 kg/s (Re range from 400 to 933) was used to analyze the performance variation with flow rate. The minimum value of flow rate was selected so that the maximum temperature rise at the hotspots became below the recommended temperature range for reliable performance of a microprocessor [

7].

The local temperature contours at

y/

Ly = 0 (bottom) and

y/

Ly = 0.5 (middle) for the three heat sinks without hotspots (PF-WHS, CF-WHS, and TF-WHS) at total flow rate of 0.01 kg/s are shown in

Figure 6. In the case of PF heat sink, the hottest zone is observed near the outlet region for both the bottom (

y/

Ly = 0) and the top layers (

y/

Ly = 0.5) (

Figure 6a). Due to the opposite flow arrangement in the top layer of the CF heat sink, the hottest zone is almost at the center in the top layer, however, in the bottom layer, the hottest zone is still closer to the outlet with a slight shift towards the center (

Figure 6b). The hottest zone in the TF heat sink is concentrated around the central region for both the bottom and the top layer as shown in

Figure 6c. The TF heat sink showed lower thermal resistance and better temperature uniformity as compared to the PF and CF heat sinks in the previous work [

24]. The better performance of the TF heat sink was attributed to the ubiquitous heat transfer present all over the heat sink as a result of quarterly opposite flow in the same layer and the transversal flow arrangement between the bottom and the top layers. The detailed analysis was presented by Ansari and Kim [

24]. The wavy pattern observed in the temperature contours was due to the difference in conduction heat transfer in the heat sink walls and convection heat transfer in the channels. The total thermal resistance and maximum temperature increase at the bottom surface of the heat sinks without hotspots are listed in

Table 7. The TF heat sink showed a 7.5% and 0.1% lower thermal resistance (and also temperature increase at the bottom surface) as compared to the PF and CF heat sinks, respectively. A variation in total pressure drop was observed among the PF, CF, and TF heat sinks even though all the design parameters were exactly the same [

24]. This variation in the pressure drop was due to the consideration of variable fluid properties. The CF heat sink showed the lowest total pressure drop among the three heat sinks due to lowest average fluid temperature in both the layers [

24].

The local temperature contours for the three heat sink designs (PF, CF, and TF) of the HS1 scheme (PF-HS1, CF-HS1, and TF-HS1), at total flow rate of 0.01 kg/s, are shown in

Figure 7. The temperature contours are plotted at the bottom (

y/

Ly = 0) and middle height of the heat sink (

y/

Ly = 0.5). The comparison among the maximum temperatures at the hotspots of the PF, CF, and TF with the HS1 scheme is shown in

Figure 8. The PF heat sink has a large temperature gradient in the direction of flow (

Figure 6a), which causes overcooling of the hotspots (S

1, S

2, …) close to the inlet (

x = 0) and undercooling of the hotspots (S

11, S

10, …) near the outlet (

x =

Lx) creating large temperature difference between hotspots (

Figure 7a). Due to the opposite flow arrangement in the top layer, the CF heat sink shows lower temperatures at the hotspots, S

10 and S

11, as compared to the PF heat sink (

Figure 8). The TF heat sink shows relatively uniform temperature distribution all over the heat sink (

Figure 6c). Due to the uniform temperature distribution in the TF heat sink, the hotspots near

x = 0 are not overcooled (exhibits higher temperatures than the PF and CF heat sinks) and the hotspots near

x =

Lx are not undercooled (exhibits lower temperatures than the PF and CF heat sinks) (

Figure 8). The maximum temperatures in the PF and CF heat sinks are observed at the hotspot S10, whereas the maximum temperature in the TF heat sink is found at the hotspot S4, as shown in

Figure 7 and

Figure 8.

Table 8 shows the maximum temperature rise at the hotspots, temperature variation between the hotspots, and the total thermal resistance for the HS1 scheme. The PF heat sink exhibits the highest temperature variation of 21.959 K among the hotspots. The CF heat sink exhibits a temperature variation of 17.692 K, which is 24.1% lower than that of the PF heat sink. Due to ubiquitous temperature distribution, the TF heat sink shows the lowest temperature variation among the three heat sinks (14.980 K), which is 46.6% and 18.1% lower than those of the PF and CF heat sinks, respectively. Along with significantly lower temperature variation among hotspots, the TF heat sink exhibits 9.3% and 6.2% lower thermal resistance (or maximum temperature rise) as compared to those of the PF and CF heat sinks, respectively.

Figure 9 shows the local temperature contours for the three heat sink designs (PF, CF, and TF) of the HS2 scheme (PF-HS2, CF-HS2, and TF-HS2), at total flow rate of 0.01 kg/s. The temperature contours are plotted at the bottom (

y/

Ly = 0) and middle height of the heat sink (

y/

Ly = 0.5). The maximum temperature rise at the hotspots, the temperature variation between the hotspots, and the total thermal resistance for the HS2 scheme are shown in

Table 9. All the heat sinks with the HS2 scheme show the results similar to those for the HS1 scheme. The PF heat sink exhibits lower temperatures at the hotspots closer to the inlet due to overcooling, and due to undercooling the hotspots closer to outlet exhibits higher temperatures, producing 23.278 K temperature variation among the hotspots (

Table 9). The temperature variation among hotspots in the CF heat sink is 17.278 K, which is 34.7% lower than that of the PF heat sink (

Table 9). The TF heat sink exhibits the lowest temperature variation of 14.232 K, which is 63.6% and 21.4% lower than those of the PF and CF heat sinks, respectively (

Table 9). Thermal resistance (or maximum temperature rise) is also lower for the TF heat sink, which is 13.3% and 6.3% lower than those of the PF and CF heat sinks, respectively (

Table 9). The maximum temperatures in the PF and CF heat sinks occur at the hotspot S11 whereas the maximum temperature in the TF heat sink is found at the hotspot S8, as shown in

Figure 9 and

Figure 10.

The local temperature contours for all the heat sink designs (PF, CF, and TF) of the HS3 scheme (PF-HS3, CF-HS3, and TF-HS3), at total flow rate of 0.01 kg/s are shown in

Figure 11. The temperature contours are plotted at the bottom (

y/

Ly = 0) and middle height of the heat sink (

y/

Ly = 0.5). The results are consistent with those for the HS1 and HS2 schemes. The TF heat sink exhibits the lowest temperature variation of 17.106 K, which is 48.0% and 16.1% lower than those of the PF (25.316 K) and CF (19.854 K) heat sinks, respectively (

Table 10). The thermal resistance (or maximum temperature rise) of the TF heat sink is 11.7% and 6.4% lower than those of the PF and CF heat sinks, respectively (

Table 10). The maximum temperatures at the hotspots are shown in

Figure 12, which exhibits the highest temperatures at the hotspot S11 for the PF and CF heat sinks and at the hotspot S9 for the TF heat sink.

Figure 13 shows the temperature variations among the hotspots for different total flow rate (in a range from 0.006 to 0.014 kg/s) for all the heat sink designs with the HS1, HS2, and HS3 schemes. The TF heat sink exhibits the lowest temperature variations for all the three hotspot schemes (HS1, HS2, and HS3) throughout the flow rate range, while the PF heat sink exhibits the highest temperature variations (

Figure 13). The PF heat sink exhibits the highest decrease in the temperature variation with the increase in the total flow rate, whereas the CF and TF heat sinks show similar trends (

Figure 13).

Although all the heat sinks (PF, CF, and TF) were designed using exactly same microchannels, a slight variation in the pressure drop is observed in

Table 11. The variation in the pressure drop was caused by the temperature-dependent fluid properties. With the increase in fluid temperature, the pressure drop reduces [

47,

48].

Table 11 shows the pressure drop and average fluid temperature variation in each layer of heat sink at the total flow rate of 0.01 kg/s. The pressure drops in the bottom layer (Δ

pbl) are lower than that of the top layer (Δ

ptl) in all the cases, because the average fluid temperatures in the bottom layer are higher than those of the top layer (

Table 11). The total pressure drops in all the heat sinks (PF, CF, and TF)—with all the hotspot schemes (HS1, HS2, and HS3) at the total flow rate of 0.01 kg/s are shown in

Figure 14. The lowest total pressure drop is exhibited by the CF heat sink for all the hotspots schemes, because of the highest average fluid temperature in each layer as compared to those of the PF and TF heat sinks (

Figure 14 and

Table 11). On the other hand, the PF heat sink exhibits the lowest fluid temperature in each layer resulting in the highest total pressure drop. The relative pressure drop variation among the three heat sink designs is only about 1% for all the hotspot schemes at the total flow rate of 0.01 kg/s. The total pumping power is minimum for the CF-HS2, and maximum for the PF-HS1, but the total variation is less than 1 mW as shown in

Table 11.