Direct Metal Forming of a Microdome Structure with a Glassy Carbon Mold for Enhanced Boiling Heat Transfer

Abstract

:1. Introduction

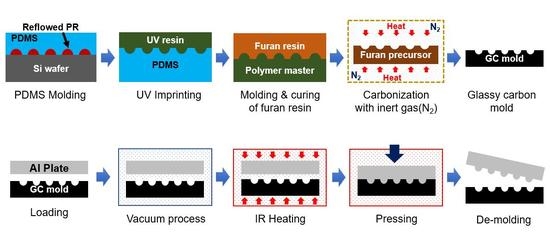

2. Fabrication the GC Mold with Macrodome Cavity

3. Fabrication of a Microdome Patterned Al Substrate by DMF

4. Application of the DMF Microdome Al Substrate to Enhanced Boiling Heat Transfer

4.1. Experimental Setup and Measuring Method for Boiling Heat Transfer

4.2. Uncertainty Analysis

4.3. Experimental Result and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Wei, J.J.; Honda, H. Effects of fin geometry on boiling heat transfer from silicon chips with micro-pin-fins immersed in FC-72. Int. J. Heat Mass Transfer 2003, 46, 4059–4070. [Google Scholar] [CrossRef]

- Chu, K.H.; Enright, R.; Wang, E.N. Structured surfaces for enhanced pool boiling heat transfer. Appl. Phys. Lett. 2012, 100. [Google Scholar] [CrossRef]

- Dong, L.; Quan, X.; Cheng, P. An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano-structures. Int. J. Heat Mass Transfer 2014, 71, 189–196. [Google Scholar] [CrossRef]

- Lu, M.C.; Huang, C.H.; Huang, C.T.; Chen, Y.C. A modified hydrodynamic model for pool boiling CHF considering the effects of heater size and nucleation site density. Int. J. Therm. Sci. 2015, 91, 133–141. [Google Scholar] [CrossRef]

- Javidmand, P.; Hoffmann, K.A. Une modélisation complète d’écoulement diphasique réduit dans des orifices de courts tubes appliquée aux frigorigènes alternatifs HFO-1234yf et HFO-1234ze. Int. J. Refrig. 2016, 69, 114–135. [Google Scholar] [CrossRef]

- Santini, L.; Cioncolini, A.; Butel, M.T.; Ricotti, M.E. Flow boiling heat transfer in a helically coiled steam generator for nuclear power applications. Int. J. Heat Mass Transfer 2016, 92, 91–99. [Google Scholar] [CrossRef]

- Van Gils, R.W.; Danilov, D.; Notten, P.H.L.; Speetjens, M.F.M.; Nijmeijer, H. Battery thermal management by boiling heat-transfer. Energy Convers. Manag. 2014, 79, 9–17. [Google Scholar] [CrossRef]

- Shin, H.S.; Park, M.S.; Chu, C.N. Electrochemical etching using laser masking for multilayered structures on stainless steel. CIRP Ann. Manuf. Technol. 2010, 59, 585–588. [Google Scholar] [CrossRef]

- Zhu, D.; Qu, N.S.; Li, H.S.; Zeng, Y.B.; Li, D.L.; Qian, S.Q. Electrochemical micromachining of microstructures of micro hole and dimple array. CIRP Ann. Manuf. Technol. 2009, 58, 177–180. [Google Scholar] [CrossRef]

- Datta, M.; Landolt, D. Fundamental aspects and applications of electrochemical microfabrication. Electrochim. Acta 2000, 45, 2535–2558. [Google Scholar] [CrossRef]

- Xiao, Y.; Wehrs, J.; Ma, H.; Al-Samman, T.; Korte-Kerzel, S.; Göken, M.; Michler, J.; Spolenak, R.; Wheeler, J.M. Investigation of the deformation behavior of aluminum micropillars produced by focused ion beam machining using Ga and Xe ions. Scr. Mater. 2017, 127, 191–194. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kumar, A.; Nagpure, D.C.; Rai, S.K.; Singh, M.K.; Khooha, A.; Singh, A.K.; Singh, A.; Tiwari, M.K.; Ganesh, P.; et al. Comparison of Stress Corrosion Cracking Susceptibility of Laser Machined and Milled 304 L Stainless Steel. Lasers Manuf. Mater. Process. 2016, 3, 191–203. [Google Scholar] [CrossRef]

- Ramulu, M.; Paul, G.; Patel, J. EDM surface effects on the fatigue strength of a 15 vol% SiCp/Al metal matrix composite material. Compos. Struct. 2001, 54, 79–86. [Google Scholar] [CrossRef]

- Tran, N.K.; Lam, Y.C.; Yue, C.Y.; Tan, M.J. Manufacturing of an aluminum alloy mold for micro-hot embossing of polymeric micro-devices. J. Micromech. Microeng. 2010, 20, 055020. [Google Scholar] [CrossRef]

- Tran, N.; Lam, Y.; Yue, C.; Tan, M. Fabricating protruded micro-features on AA 6061 substrates by hot embossing method. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2012, 6, 983–986. [Google Scholar]

- Buzzi, S.; Robin, F.; Callegari, V.; Löffler, J.F. Metal direct nanoimprinting for photonics. Microelectron. Eng. 2008, 85, 419–424. [Google Scholar] [CrossRef]

- Hirai, Y.; Ushiro, T.; Kanakugi, T.; Matsuura, T.; Industries, S.E. Fine gold grating fabrication on glass plate by imprint lithography. Proc. SPIE 2003, 5220, 74–81. [Google Scholar]

- Nagato, K.; Miyazaki, S.; Yamada, S.; Nakao, M. Nano/microcomposite surface fabricated by chemical treatment/microembossing for control of bubbles in boiling heat transfer. CIRP Ann. Manuf. Technol. 2016, 65, 511–514. [Google Scholar] [CrossRef]

- Franklin, R.E. Crystallite Growth in Graphitizing and Non-Graphitizing Carbons. Proc. R. Soc. A Math. Phys. Eng. Sci. 1951, 209, 196–218. [Google Scholar] [CrossRef]

- Pierson, H.O. Handbook of Carbon, Graphite, Diamond and Fullerenes; Elsevier: New York, NY, USA, 1993; pp. 122–140. ISBN 0-8155-1339-1. [Google Scholar]

- Jang, H.; Haq, M.R.; Ju, J.; Kim, Y.; Kim, S.; Lim, J. Fabrication of all glass bifurcation microfluidic chip for blood plasma separation. Micromachines 2017, 8, 67. [Google Scholar] [CrossRef]

- Jang, H.; Haq, M.R.; Kim, Y.; Kim, J.; Oh, P.; Ju, J.; Kim, S.; Lim, J. Fabrication of glass microchannel via glass imprinting using a vitreous carbon stamp for flow focusing droplet generator. Sensors 2018, 18, 83. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.K.; Ju, J.H.; Kim, S. Replication of a glass microlens array using a vitreous carbon mold. Opt. Express 2018, 26, 14936–14944. [Google Scholar] [CrossRef]

- Ju, J.; Lim, S.; Seok, J.; Kim, S. A method to fabricate Low-Cost and large area vitreous carbon mold for glass molded microstructures. Int. J. Precis. Eng. Manuf. 2015, 16, 287–291. [Google Scholar] [CrossRef]

- Badshah, M.A.; Kim, J.; Jang, H.; Kim, S. Fabrication of Highly Packed Plasmonic Nanolens Array Using Polymer Nanoimprinted Nanodots for an Enhanced Fluorescence Substrate. Polymers 2018, 10, 649. [Google Scholar] [CrossRef]

- Cooke, D.; Kandlikar, S.G. Pool Boiling Heat Transfer and Bubble Dynamics Over Plain and Enhanced Microchannels. J. Heat Transfer 2011, 133, 052902. [Google Scholar] [CrossRef]

- Kline, S.J.; McClintock, F.A. Describing Uncertainties in Single-Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

| Uncertainty Source | Error |

|---|---|

| Machining error for measuring position | ±0.01 mm |

| J-type thermocouple reading | ±0.15 K |

| Thermal conductivity of Cu | ±2% |

| Thermal conductivity of Al | ±2.1% |

| Thermal contact resistance | ±2.37% |

| Surface temperature reading | ±0.62% |

| Heat flux | ±8.72% |

| Heat transfer coefficient | ±8.74% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Hong, D.; Badshah, M.A.; Lu, X.; Kim, Y.K.; Kim, S.-m. Direct Metal Forming of a Microdome Structure with a Glassy Carbon Mold for Enhanced Boiling Heat Transfer. Micromachines 2018, 9, 376. https://doi.org/10.3390/mi9080376

Kim J, Hong D, Badshah MA, Lu X, Kim YK, Kim S-m. Direct Metal Forming of a Microdome Structure with a Glassy Carbon Mold for Enhanced Boiling Heat Transfer. Micromachines. 2018; 9(8):376. https://doi.org/10.3390/mi9080376

Chicago/Turabian StyleKim, Jun, Dongin Hong, Mohsin Ali Badshah, Xun Lu, Young Kyu Kim, and Seok-min Kim. 2018. "Direct Metal Forming of a Microdome Structure with a Glassy Carbon Mold for Enhanced Boiling Heat Transfer" Micromachines 9, no. 8: 376. https://doi.org/10.3390/mi9080376

APA StyleKim, J., Hong, D., Badshah, M. A., Lu, X., Kim, Y. K., & Kim, S. -m. (2018). Direct Metal Forming of a Microdome Structure with a Glassy Carbon Mold for Enhanced Boiling Heat Transfer. Micromachines, 9(8), 376. https://doi.org/10.3390/mi9080376