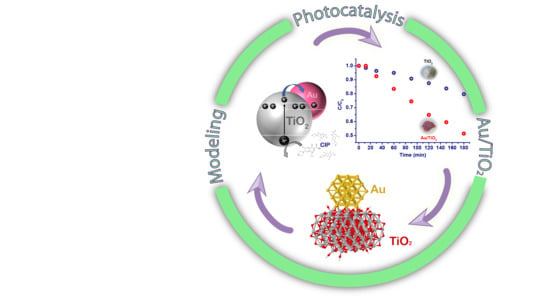

Enhanced Photocatalytic Activity of Au/TiO2 Nanoparticles against Ciprofloxacin

Abstract

:1. Introduction

2. Results and Discussion

2.1. Nanocomposite Characterization

2.2. Nanocomposites’ Optimization and Photocatalytic Experiments

Nanocomposite Optimization

2.3. Photocatalytic Degradation

3. Computational Modeling: Gold on Titanium Dioxide and Charge Transfer

Adsorption of Ciprofloxacin on Au55(TiO2)97H8+58

4. Materials and Methods

4.1. Materials

4.2. Nanocomposite Synthesis

4.3. Characterization

4.4. Photocatalytic Degradation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- An, T.; Yang, H.; Song, W.; Li, G.; Luo, H.; Cooper, W.J. Mechanistic considerations for the advanced oxidation treatment of fluoroquinolone pharmaceutical compounds using TiO2 heterogeneous catalysis. J. Phys. Chem. A 2010, 114, 2569–2575. [Google Scholar] [CrossRef]

- Li, W.C. Occurrence, sources, and fate of pharmaceuticals in aquatic environment and soil. Environ. Pollut. 2014, 187, 193–201. [Google Scholar] [CrossRef]

- Ayati, A.; Ahmadpour, A.; Bamoharram, F.F.; Tanhaei, B.; Mänttäri, M.; Sillanpää, M. A review on catalytic applications of Au/TiO2 nanoparticles in the removal of water pollutant. Chemosphere 2014, 107, 163–174. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.-Q.; Ashekuzzaman, S.M. Development of novel inorganic adsorbent for water treatment. Curr. Opin. Chem. Eng. 2012, 1, 191–199. [Google Scholar] [CrossRef]

- Kumar, S.; Ahlawat, W.; Bhanjana, G.; Heydarifard, S.; Nazhad, M.M.; Dilbaghi, N. Nanotechnology-based water treatment strategies. J. Nanosci. Nanotechnol. 2014, 14, 1838–1858. [Google Scholar] [CrossRef] [PubMed]

- Pawar, R.C.; Lee, C.S. Heterogeneous Nanocomposite-Photocatalysis for Water Purification; William Andrew: London, UK, 2015. [Google Scholar]

- Lu, S.-Y.; Wu, D.; Wang, Q.-L.; Yan, J.; Buekens, A.G.; Cen, K.-F. Photocatalytic decomposition on nano-TiO2: Destruction of chloroaromatic compounds. Chemosphere 2011, 82, 1215–1224. [Google Scholar] [CrossRef]

- Khaki, M.R.D.; Shafeeyan, M.S.; Raman, A.A.A.; Daud, W.M.A.W. Application of doped photocatalysts for organic pollutant degradation—A review. J. Environ. Manag. 2017, 198, 78–94. [Google Scholar] [CrossRef]

- Fabregat-Santiago, F.; Barea, E.M.; Bisquert, J.; Mor, G.K.; Shankar, K.; Grimes, C.A. High carrier density and capacitance in TiO2 nanotube arrays induced by electrochemical doping. J. Am. Chem. Soc. 2008, 130, 11312–11316. [Google Scholar] [CrossRef]

- Hoffmann, M.R.; Martin, S.T.; Choi, W.; Bahnemann, D.W. Environmental applications of semiconductor photocatalysis. Chem. Rev. 1995, 95, 69–96. [Google Scholar] [CrossRef]

- Vargas Hernández, J.; Coste, S.; García Murillo, A.; Carrillo Romo, F.; Kassiba, A. Effects of metal doping (Cu, Ag, Eu) on the electronic and optical behavior of nanostructured TiO2. J. Alloy. Compd. 2017, 710, 355–363. [Google Scholar] [CrossRef]

- Shen, L.; Liang, R.; Wu, L. Strategies for engineering metal-organic frameworks as efficient photocatalysts. Chin. J. Catal. 2015, 36, 2071–2088. [Google Scholar] [CrossRef]

- Ahmad, R.; Ahmad, Z.; Khan, A.U.; Mastoi, N.R.; Aslam, M.; Kim, J. Photocatalytic systems as an advanced environmental remediation: Recent developments, limitations and new avenues for applications. J. Environ. Chem. Eng. 2016, 4, 4143–4164. [Google Scholar] [CrossRef]

- Carneiro, J.T.; Yang, C.-C.; Moma, J.A.; Moulijn, J.A.; Mul, G. How gold deposition affects anatase performance in the photo-catalytic oxidation of cyclohexane. Catal. Lett. 2009, 129, 12–19. [Google Scholar] [CrossRef] [Green Version]

- Martins, P.M.; Gomez, V.; Lopes, A.C.; Tavares, C.J.; Botelho, G.; Irusta, S.; Lanceros-Mendez, S. Improving photocatalytic performance and recyclability by development of Er-doped and Er/Pr-codoped TiO2/Poly(vinylidene difluoride)–trifluoroethylene composite membranes. J. Phys. Chem. C 2014, 118, 27944–27953. [Google Scholar] [CrossRef]

- Barakat, M.A.; Kumar, R. Photocatalytic activity enhancement of titanium dioxide nanoparticles. In Photocatalytic Activity Enhancement of Titanium Dioxide Nanoparticles; Springer: Berlin, Germany, 2016; pp. 1–29. [Google Scholar]

- Almeida, N.A.; Martins, P.M.; Teixeira, S.; Lopes da Silva, J.A.; Sencadas, V.; Kühn, K.; Cuniberti, G.; Lanceros-Mendez, S.; Marques, P.A.A.P. TiO2/graphene oxide immobilized in P(VDF-TrFE) electrospun membranes with enhanced visible-light-induced photocatalytic performance. J. Mater. Sci. 2016, 51, 6974–6986. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Xia, N.; Jiang, M.; Liu, R.; Huang, J.; Li, Q.; Luo, Z.; Liu, L.; Xu, W.; et al. Novel ZnO-TiO2 nanocomposite arrays on Ti fabric for enhanced photocatalytic application. J. Mol. Struct. 2017, 1148, 347–355. [Google Scholar] [CrossRef]

- Momeni, M.M.; Ghayeb, Y. Fabrication, characterization and photocatalytic properties of Au/TiO2-WO3 nanotubular composite synthesized by photo-assisted deposition and electrochemical anodizing methods. J. Mol. Catal. A Chem. 2016, 417, 107–115. [Google Scholar] [CrossRef]

- Momeni, M.M. Fabrication of copper decorated tungsten oxide-titanium oxide nanotubes by photochemical deposition technique and their photocatalytic application under visible light. Appl. Surf. Sci. 2015, 357, 160–166. [Google Scholar] [CrossRef]

- Momeni, M.M.; Ghayeb, Y. Cobalt modified tungsten–titania nanotube composite photoanodes for photoelectrochemical solar water splitting. J. Mater. Sci. Mater. Electron. 2016, 27, 3318–3327. [Google Scholar] [CrossRef]

- Angkaew, S.; Limsuwan, P. Preparation of silver-titanium dioxide core-shell (Ag@TiO2) nanoparticles: Effect of Ti-Ag mole ratio. Procedia Eng. 2012, 32, 649–655. [Google Scholar] [CrossRef] [Green Version]

- Daskalaki, V.M.; Antoniadou, M.; Li Puma, G.; Kondarides, D.I.; Lianos, P. Solar light-responsive Pt/CdS/TiO2 photocatalysts for hydrogen production and simultaneous degradation of inorganic or organic sacrificial agents in wastewater. Environ. Sci. Technol. 2010, 44, 7200–7205. [Google Scholar] [CrossRef]

- Bian, Z.; Tachikawa, T.; Kim, W.; Choi, W.; Majima, T. Superior electron transport and photocatalytic abilities of metal-nanoparticle-loaded TiO2 superstructures. J. Phys. Chem. C 2012, 116, 25444–25453. [Google Scholar] [CrossRef]

- Tian, Y.; Tatsuma, T. Mechanisms and applications of plasmon-induced charge separation at TiO2 films loaded with gold nanoparticles. J. Am. Chem. Soc. 2005, 127, 7632–7637. [Google Scholar] [CrossRef] [PubMed]

- Seh, Z.W.; Liu, S.; Low, M.; Zhang, S.-Y.; Liu, Z.; Mlayah, A.; Han, M.-Y. Janus Au-TiO2 photocatalysts with strong localization of plasmonic near-fields for efficient visible-light hydrogen generation. Adv. Mater. 2012, 24, 2310–2314. [Google Scholar] [CrossRef] [PubMed]

- Al-Akraa, I.M.; Mohammad, A.M.; El-Deab, M.S.; El-Anadouli, B.E. Flower-shaped gold nanoparticles: Preparation, characterization, and electrocatalytic application. Arab. J. Chem. 2017, 10, 877–884. [Google Scholar] [CrossRef]

- Santhoshkumar, J.; Rajeshkumar, S.; Venkat Kumar, S. Phyto-assisted synthesis, characterization and applications of gold nanoparticles—A review. Biochem. Biophys. Rep. 2017, 11, 46–57. [Google Scholar] [CrossRef] [PubMed]

- Haruta, M. Catalysis of gold nanoparticles deposited on metal oxides. Cattech 2002, 6, 102–115. [Google Scholar] [CrossRef]

- Thompson, D.T. Using gold nanoparticles for catalysis. Nano Today 2007, 2, 40–43. [Google Scholar] [CrossRef]

- Barakat, T.; Rooke, J.C.; Genty, E.; Cousin, R.; Siffert, S.; Su, B.-L. Gold catalysts in environmental remediation and water-gas shift technologies. Energy Environ. Sci. 2013, 6, 371–391. [Google Scholar] [CrossRef]

- Okumura, M.; Tanaka, K.; Ueda, A.; Haruta, M. The reactivities of dimethylgold(III)β-diketone on the surface of TiO2: A novel preparation method for Au catalysts. Solid State Ion. 1997, 95, 143–149. [Google Scholar] [CrossRef]

- Su, R.; Tiruvalam, R.; He, Q.; Dimitratos, N.; Kesavan, L.; Hammond, C.; Lopez-Sanchez, J.A.; Bechstein, R.; Kiely, C.J.; Hutchings, G.J.; et al. Promotion of phenol photodecomposition over TiO2 using Au, Pd, and Au–Pd nanoparticles. ACS Nano 2012, 6, 6284–6292. [Google Scholar] [CrossRef] [PubMed]

- Haugen, A.B.; Kumakiri, I.; Simon, C.; Einarsrud, M.-A. TiO2, TiO2/Ag and TiO2/Au photocatalysts prepared by spray pyrolysis. J. Eur. Ceram. Soc. 2011, 31, 291–298. [Google Scholar] [CrossRef]

- Chandrasekharan, N.; Kamat, P.V. Assembling gold nanoparticles as nanostructured films using an electrophoretic approach. Nano Lett. 2001, 1, 67–70. [Google Scholar] [CrossRef]

- Fackler, J.P. Catalysis by Gold By Geoffrey C. Bond (Brunel University, U.K.), Catherine Louis (Université Pierre et Marie Curie, France), and David, T. Thompson (Consultant, World Gold Council, UK). From the Series: Catalytic Science Series, Volume 6. Series Edited by Graham J. Hutchings. Imperial College Press: London. 2006. xvi + 366 pp. ISBN 1-86094-658-5. J. Am. Chem. Soc. 2007, 129, 4107. [Google Scholar] [CrossRef]

- Luna, M.; Gatica, J.M.; Vidal, H.; Mosquera, M.J. One-pot synthesis of Au/N-TiO2 photocatalysts for environmental applications: Enhancement of dyes and NOx photodegradation. Powder Technol. 2019, 355, 793–807. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, X.; Zheng, Z.; Ke, X.; Jaatinen, E.; Zhao, J.; Guo, C.; Xie, T.; Wang, D. Mechanism of supported gold nanoparticles as photocatalysts under ultraviolet and visible light irradiation. Chem. Commun. 2009, 7524–7526. [Google Scholar] [CrossRef]

- Kamely, N.; Ujihara, M. Confeito-like Au/TiO2 nanocomposite: Synthesis and plasmon-induced photocatalysis. J. Nanoparticle Res. 2018, 20, 172. [Google Scholar] [CrossRef]

- Li, J.; Zeng, H.C. Preparation of monodisperse Au/TiO2 nanocatalysts via self-assembly. Chem. Mater. 2006, 18, 4270–4277. [Google Scholar] [CrossRef]

- D’Amato, C.A.; Giovannetti, R.; Zannotti, M.; Rommozzi, E.; Ferraro, S.; Seghetti, C.; Minicucci, M.; Gunnella, R.; Di Cicco, A. Enhancement of visible-light photoactivity by polypropylene coated plasmonic Au/TiO2 for dye degradation in water solution. Appl. Surf. Sci. 2018, 441, 575–587. [Google Scholar] [CrossRef]

- Singh, J.; Manna, A.K.; Soni, R.K. Bifunctional Au–TiO2 thin films with enhanced photocatalytic activity and SERS based multiplexed detection of organic pollutant. J. Mater. Sci. Mater. Electron. 2019, 30, 16478–16493. [Google Scholar] [CrossRef]

- Mompelat, S.; Le Bot, B.; Thomas, O. Occurrence and fate of pharmaceutical products and by-products, from resource to drinking water. Environ. Int. 2009, 35, 803–814. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.M.P.T.; Silva, L.J.G.; Meisel, L.M.; Lino, C.M.; Pena, A. Environmental impact of pharmaceuticals from Portuguese wastewaters: Geographical and seasonal occurrence, removal and risk assessment. Environ. Res. 2015, 136, 108–119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, M.; Bian, L.; Zhou, T.; Zhao, X. Surface ζ potential and photocatalytic activity of rare earths doped TiO2. J. Rare Earths 2008, 26, 693–699. [Google Scholar] [CrossRef]

- Sentein, C.; Guizard, B.; Giraud, S.; Yé, C.; Ténégal, F. Dispersion and stability of TiO2nanoparticles synthesized by laser pyrolysis in aqueous suspensions. J. Phys. Conf. Ser. 2009, 170, 012013. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Zhang, J.; Cai, W. Sonochemical preparation of Au, Ag, Pd/SiO2 mesoporous nanocomposites. Scr. Mater. 2003, 48, 1061–1066. [Google Scholar] [CrossRef]

- Kuge, K.i.; Calzaferri, G. Gold-loaded zeolite A. Microporous Mesoporous Mater. 2003, 66, 15–20. [Google Scholar] [CrossRef]

- Mihai, S.; Cursaru, D.; Ghita, D.; Dinescu, A. Morpho ierarhic TiO2 with plasmonic gold decoration for highly active photocatalysis properties. Mater. Lett. 2016, 162, 222–225. [Google Scholar] [CrossRef]

- Cojocaru, B.; Andrei, V.; Tudorache, M.; Lin, F.; Cadigan, C.; Richards, R.; Parvulescu, V.I. Enhanced photo-degradation of bisphenol pollutants onto gold-modified photocatalysts. Catal. Today 2017, 284, 153–159. [Google Scholar] [CrossRef]

- Kumar, S.G.; Devi, L.G. Review on modified TiO2 photocatalysis under UV/visible light: Selected results and related mechanisms on interfacial charge carrier transfer dynamics. J. Phys. Chem. A 2011, 115, 13211–13241. [Google Scholar] [CrossRef]

- Lu, M. Photocatalysis and Water Purification: From Fundamentals to Recent Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Wang, H.; Faria, J.L.; Dong, S.; Chang, Y. Mesoporous Au/TiO2 composites preparation, characterization, and photocatalytic properties. Mater. Sci. Eng. B 2012, 177, 913–919. [Google Scholar] [CrossRef]

- Wang, X.; Caruso, R.A. Enhancing photocatalytic activity of titania materials by using porous structures and the addition of gold nanoparticles. J. Mater. Chem. 2011, 21, 20–28. [Google Scholar] [CrossRef]

- Wongwisate, P.; Chavadej, S.; Gulari, E.; Sreethawong, T.; Rangsunvigit, P. Effects of monometallic and bimetallic Au–Ag supported on sol–gel TiO2 on photocatalytic degradation of 4-chlorophenol and its intermediates. Desalination 2011, 272, 154–163. [Google Scholar] [CrossRef]

- Scarabelli, L.; Sánchez-Iglesias, A.; Pérez-Juste, J.; Liz-Marzán, L.M. A “tips and tricks” practical guide to the synthesis of gold nanorods. J. Phys. Chem. Lett. 2015, 6, 4270–4279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Emeline, A.V.; Ryabchuk, V.; Serpone, N. Factors affecting the efficiency of a photocatalyzed process in aqueous metal-oxide dispersions: Prospect of distinguishing between two kinetic models. J. Photochem. Photobiol. A Chem. 2000, 133, 89–97. [Google Scholar] [CrossRef]

- Evgenidou, E.; Fytianos, K.; Poulios, I. Semiconductor-sensitized photodegradation of dichlorvos in water using TiO2 and ZnO as catalysts. Appl. Catal. B Environ. 2005, 59, 81–89. [Google Scholar] [CrossRef]

- Le, H.N.; Babick, F.; Kühn, K.; Nguyen, M.T.; Stintz, M.; Cuniberti, G. Impact of ultrasonic dispersion on the photocatalytic activity of titania aggregates. Beilstein J. Nanotechnol. 2015, 6, 2423–2430. [Google Scholar] [CrossRef] [Green Version]

- Behnajady, M.A.; Modirshahla, N.; Hamzavi, R. Kinetic study on photocatalytic degradation of C.I. Acid Yellow 23 by ZnO photocatalyst. J. Hazard. Mater. 2006, 133, 226–232. [Google Scholar] [CrossRef]

- Grimme, S.; Bannwarth, C.; Shushkov, P. A robust and accurate tight-binding quantum chemical method for structures, vibrational frequencies, and noncovalent interactions of large molecular systems parametrized for all spd-block elements (Z = 1–86). J. Chem. Theory Comput. 2017, 13, 1989–2009. [Google Scholar] [CrossRef]

- Lamiel-Garcia, O.; Ko, K.C.; Lee, J.Y.; Bromley, S.T.; Illas, F. When anatase nanoparticles become bulklike: Properties of realistic TiO2 nanoparticles in the 1–6 nm size range from all electron relativistic density functional theory based calculations. J. Chem. Theory Comput. 2017, 13, 1785–1793. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Sun, C.Q.; Hirao, H. Guanine binding to gold nanoparticles through nonbonding interactions. Phys. Chem. Chem. Phys. 2013, 15, 19284–19292. [Google Scholar] [CrossRef] [Green Version]

- Marenich, A.V.; Jerome, S.V.; Cramer, C.J.; Truhlar, D.G. Charge model 5: An extension of hirshfeld population analysis for the accurate description of molecular interactions in gaseous and condensed phases. J. Chem. Theory Comput. 2012, 8, 527–541. [Google Scholar] [CrossRef] [PubMed]

- Green, I.X.; Tang, W.; Neurock, M.; Yates, J.T. Insights into catalytic oxidation at the Au/TiO2 dual perimeter sites. Acc. Chem. Res. 2014, 47, 805–815. [Google Scholar] [CrossRef] [PubMed]

- Sakthivel, S.; Hidalgo, M.C.; Bahnemann, D.W.; Geissen, S.U.; Murugesan, V.; Vogelpohl, A. A fine route to tune the photocatalytic activity of TiO2. Appl. Catal. B Environ. 2006, 63, 31–40. [Google Scholar] [CrossRef]

| Au loading (wt. %) | UV | Simulated Visible |

|---|---|---|

| k (min−1) | k (h−1) | |

| 0 | 0.047 | 0.073 |

| 0.025 | 0.078 | 0.211 |

| 0.05 | 0.099 | 0.242 |

| 0.1 | 0.131 | 0.211 |

| 0.25 | 0.089 | 0.195 |

| 0.5 | 0.076 | 0.202 |

| Temperature (°C) | UV | Simulated Visible | ||

|---|---|---|---|---|

| k (min−1) | Degradation (%) | k (h−1) | Degradation (%) | |

| TiO2 | 0.66 | 80 | 0.073 | 20 |

| 25 | 0.131 | 88 | 0.221 | 48 |

| 60 | 0.117 | 91 | 0.226 | 49 |

| 80 | 0.047 | 80 | 0.176 | 41 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, P.; Kappert, S.; Nga Le, H.; Sebastian, V.; Kühn, K.; Alves, M.; Pereira, L.; Cuniberti, G.; Melle-Franco, M.; Lanceros-Méndez, S. Enhanced Photocatalytic Activity of Au/TiO2 Nanoparticles against Ciprofloxacin. Catalysts 2020, 10, 234. https://doi.org/10.3390/catal10020234

Martins P, Kappert S, Nga Le H, Sebastian V, Kühn K, Alves M, Pereira L, Cuniberti G, Melle-Franco M, Lanceros-Méndez S. Enhanced Photocatalytic Activity of Au/TiO2 Nanoparticles against Ciprofloxacin. Catalysts. 2020; 10(2):234. https://doi.org/10.3390/catal10020234

Chicago/Turabian StyleMartins, Pedro, Sandro Kappert, Hoai Nga Le, Victor Sebastian, Klaus Kühn, Madalena Alves, Luciana Pereira, Gianaurelio Cuniberti, Manuel Melle-Franco, and Senentxu Lanceros-Méndez. 2020. "Enhanced Photocatalytic Activity of Au/TiO2 Nanoparticles against Ciprofloxacin" Catalysts 10, no. 2: 234. https://doi.org/10.3390/catal10020234

APA StyleMartins, P., Kappert, S., Nga Le, H., Sebastian, V., Kühn, K., Alves, M., Pereira, L., Cuniberti, G., Melle-Franco, M., & Lanceros-Méndez, S. (2020). Enhanced Photocatalytic Activity of Au/TiO2 Nanoparticles against Ciprofloxacin. Catalysts, 10(2), 234. https://doi.org/10.3390/catal10020234