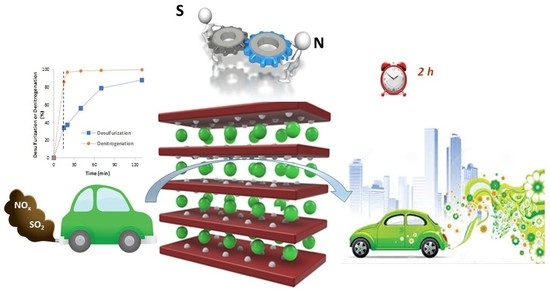

High Catalytic Efficiency of a Layered Coordination Polymer to Remove Simultaneous Sulfur and Nitrogen Compounds from Fuels

Abstract

:1. Introduction

2. Results and Discussion

2.1. Preparation of the Catalyst

2.2. Optimization of Desulfurization Process

2.3. Reusability Versus Recyclability

2.4. Denitrogenation Process

2.5. Simultaneous Desulfurization and Denitrogenation Processes

2.6. Reusability Studies

2.7. Structural Stability of [Gd(H4nmp)(H2O)2]Cl·2H2O

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Chossière, G.P.; Malina, R.; Allroggen, F.; Eastham, S.D.; Speth, R.L.; Barrett, S.R.H. Country- and manufacturer-level attribution of air quality impacts due to excess NOx emissions from diesel passenger vehicles in Europe. Atmos. Environ. 2018, 189, 89–97. [Google Scholar] [CrossRef]

- Frey, H.C. Trends in onroad transportation energy and emissions. J. Air Waste Manag. Assoc. 2018, 68, 514–563. [Google Scholar] [CrossRef] [PubMed]

- Koolen, C.D.; Rothenberg, G. Air Pollution in Europe. ChemSusChem 2019, 12, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Stanislaus, A.; Marafi, A.; Rana, M.S. Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production. Catal. Today 2010, 153, 1–68. [Google Scholar] [CrossRef]

- Chandra Srivastava, V. An evaluation of desulfurization technologies for sulfur removal from liquid fuels. RSC Adv. 2012, 2, 759–783. [Google Scholar] [CrossRef]

- Houda, S.; Lancelot, C.; Blanchard, P.; Poinel, L.; Lamonier, C. Oxidative Desulfurization of Heavy Oils with High Sulfur Content: A Review. Catalysts 2018, 8, 344. [Google Scholar] [CrossRef] [Green Version]

- Reşitoğlu, İ.A.; Altinişik, K.; Keskin, A. The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean Technol. Environ. Policy Vol. 2015, 17, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Roy, S.; Baiker, A. NOx Storage−Reduction Catalysis: From Mechanism and Materials Properties to Storage−Reduction Performance. Chem. Rev. 2009, 109, 4054–4091. [Google Scholar] [CrossRef]

- Yang, L.; Franco, V.; Mock, P.; Kolke, R.; Zhang, S.; Wu, Y.; German, J. Experimental Assessment of NOx Emissions from 73 Euro 6 Diesel Passenger Cars. Environ. Sci. Technol. 2015, 49, 14409–14415. [Google Scholar] [CrossRef]

- Prado, G.H.C.; Rao, Y.; de Klerk, A. Nitrogen Removal from Oil: A Review. Energy Fuels 2017, 31, 14–36. [Google Scholar] [CrossRef]

- Laredo, G.C.; Vega-Merino, P.M.; Trejo-Zarraga, F.; Castillo, J. Denitrogenation of middle distillates using adsorbent materials towards ULSD production. Fuel Process. Echnol. 2013, 106, 21–32. [Google Scholar] [CrossRef]

- García-Gutiérrez, J.L.; Laredo, G.C.; García-Gutiérrez, P.; Jiménez-Cruz, F. Oxidative desulfurization of diesel using promising heterogeneous tungsten catalysts and hydrogen peroxide. Fuel 2014, 138, 118–125. [Google Scholar] [CrossRef]

- Rana, M.S.; Al-Barood, A.; Brouresli, R.; Al-Hendi, A.W.; Mustafa, N. Effect of organic nitrogen compounds on deep hydrodesulfurization of middle distillate. Fuel Process. Technol. 2018, 177, 170–178. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, S.; Liu, S.; Liang, D.; Li, S.; Tang, Q.; Wang, X.; Miao, J.; Shi, Z.; Zheng, Z. Facile Synthesis of a Nanocrystalline Metal–Organic Framework Impregnated with a Phosphovanadomolybdate and Its Remarkable Catalytic Performance in Ultradeep Oxidative Desulfurization. ChemCatChem 2013, 5, 3086–3091. [Google Scholar] [CrossRef]

- Julião, D.; Gomes, A.C.; Pillinger, M.; Cunha-Silva, L.; de Castro, B.; Gonçalves, I.S.; Balula, S.S. Desulfurization of model diesel by extraction/oxidation using a zinc-substituted polyoxometalate as catalyst under homogeneous and heterogeneous (MIL-101(Cr) encapsulated) conditions. Fuel Process. Technol. 2015, 131, 78–86. [Google Scholar] [CrossRef]

- Julião, D.; Gomes, A.C.; Pillinger, M.; Valença, R.; Ribeiro, J.C.; de Castro, B.; Gonçalves, I.S.; Cunha Silva, L.; Balula, S.S. Zinc-Substituted Polyoxotungstate@amino-MIL-101(Al)—An Efficient Catalyst for the Sustainable Desulfurization of Model and Real Diesels. Eur. J. Inorg. Chem. 2016, 2016, 5114–5122. [Google Scholar] [CrossRef]

- Granadeiro, C.M.; Nogueira, L.S.; Julião, D.; Mirante, F.; Ananias, D.; Balula, S.S.; Cunha-Silva, L. Influence of a porous MOF support on the catalytic performance of Eu-polyoxometalate based materials: Desulfurization of a model diesel. Catal. Sci. Technol. 2016, 6, 1515–1522. [Google Scholar] [CrossRef]

- Xu, C.; Fang, R.; Luque, R.; Chen, L.; Li, Y. Functional metal–organic frameworks for catalytic applications. Coord. Chem. Rev. 2019, 388, 268–292. [Google Scholar] [CrossRef]

- Shimizu, G.K.H.; Vaidhyanathan, R.; Taylor, J.M. Phosphonate and sulfonate metal organic frameworks. Chem. Soc. Rev. 2009, 38, 1430–1449. [Google Scholar] [CrossRef]

- Firmino, A.D.G.; Figueira, F.; Tome, J.P.C.; Almeida Paz, F.A.; Rocha, J. Robust Metal-Organic Frameworks assembled from tetraphosphonic ligands and lanthanides. Coord. Chem. Rev. 2018, 355, 133–149. [Google Scholar] [CrossRef]

- Pereira, C.F.; Figueira, F.; Mendes, R.F.; Rocha, J.; Hupp, J.T.; Farha, O.K.; Simoes, M.M.Q.; Tome, J.P.C.; Paz, F.A.A. Bifunctional Porphyrin-Based Nano-Metal-Organic Frameworks: Catalytic and Chemosensing Studies. Inorg. Chem. 2018, 57, 3855–3864. [Google Scholar] [CrossRef] [PubMed]

- Mendes, R.F.; Silva, P.; Antunes, M.M.; Valente, A.A.; Paz, F.A.A. Sustainable synthesis of a catalytic active one-dimensional lanthanide-organic coordination polymer. Chem. Commun. 2015, 51, 10807–10810. [Google Scholar] [CrossRef] [PubMed]

- Firmino, A.D.G.; Mendes, R.F.; Antunes, M.M.; Barbosa, P.C.; Vilela, S.M.F.; Valente, A.A.; Figueiredo, F.M.L.; Tome, J.P.C.; Paz, F.A.A. Robust Multifunctional Yttrium-Based Metal Organic Frameworks with Breathing Effect. Inorg. Chem. 2017, 56, 1193–1208. [Google Scholar] [CrossRef] [PubMed]

- Mendes, R.F.; Antunes, M.M.; Silva, P.; Barbosa, P.; Figueiredo, F.; Linden, A.; Rocha, J.; Valente, A.A.; Almeida Paz, F.A. A Lamellar Coordination Polymer with Remarkable Catalytic Activity. Chem. A Eur. J. 2016, 22, 13136–13146. [Google Scholar] [CrossRef]

- Otsuki, S.; Nonaka, T.; Takashima, N.; Qian, W.; Ishihara, A.; Imai, T.; Kabe, T. Oxidative Desulfurization of Light Gas Oil and Vacuum Gas Oil by Oxidation and Solvent Extraction. Energy Fuels 2000, 14, 1232–1239. [Google Scholar] [CrossRef]

- Ribeiro, S.; Barbosa, A.D.S.; Gomes, A.C.; Pillinger, M.; Gonçalves, I.S.; Cunha-Silva, L.; Balula, S.S. Catalytic oxidative desulfurization systems based on Keggin phosphotungstate and metal-organic framework MIL-101. Fuel Process. Technol. 2013, 116, 350–357. [Google Scholar] [CrossRef]

- Xu, J.; Zhao, S.; Chen, W.; Wang, M.; Song, Y.-F. Highly Efficient Extraction and Oxidative Desulfurization System Using Na7H2LaW10O36⋅32 H2O in [bmim]BF4 at Room Temperature. Chem. A Eur. J. 2012, 18, 4775–4781. [Google Scholar] [CrossRef]

- Zhu, W.; Huang, W.; Li, H.; Zhang, M.; Jiang, W.; Chen, G.; Han, C. Polyoxometalate-based ionic liquids as catalysts for deep desulfurization of fuels. Fuel Process. Technol. 2011, 92, 1842–1848. [Google Scholar] [CrossRef]

- Ribeiro, S.O.; Nogueira, L.S.; Gago, S.; Almeida, P.L.; Corvo, M.C.; Castro, B.D.; Granadeiro, C.M.; Balula, S.S. Desulfurization process conciliating heterogeneous oxidation and liquid extraction: Organic solvent or centrifugation/water? Appl. Catal. A Gen. 2017, 542, 359–367. [Google Scholar] [CrossRef]

- Julião, D.; Gomes, A.C.; Pillinger, M.; Valença, R.; Ribeiro, J.C.; Gonçalves, I.S.; Balula, S.S. Desulfurization of liquid fuels by extraction and sulfoxidation using H2O2 and [CpMo(CO)3R] as catalysts. Appl. Catal. B Environ. 2018, 230, 177–183. [Google Scholar] [CrossRef]

- Jiao, T.; Zhuang, X.; He, H.; Zhao, L.; Li, C.; Chen, H.; Zhang, S. An ionic liquid extraction process for the separation of indole from wash oil. Green Chem. 2015, 17, 3783–3790. [Google Scholar] [CrossRef]

- Liu, D.; Gui, J.; Sun, Z. Adsorption structures of heterocyclic nitrogen compounds over Cu(I)Y zeolite: A first principle study on mechanism of the denitrogenation and the effect of nitrogen compounds on adsorptive desulfurization. J. Mol. Catal. A Chem. 2008, 291, 17–21. [Google Scholar] [CrossRef]

- Zhou, Z.Q.; Li, W.S.; Liu, J. Removal of nitrogen compounds from fuel oils using imidazolium-based ionic liquids. Pet. Sci. Technol. 2017, 35, 45–50. [Google Scholar] [CrossRef]

- Xie, L.-L.; Favre-Reguillon, A.; Wang, X.-X.; Fu, X.; Pellet-Rostaing, S.; Toussaint, G.; Geantet, C.; Vrinat, M.; Lemaire, M. Selective extraction of neutral nitrogen compounds found in diesel feed by 1-butyl-3-methyl-imidazolium chloride. Green Chem. 2008, 10, 524–531. [Google Scholar] [CrossRef]

- Hansmeier, A.R.; Meindersma, G.W.; de Haan, A.B. Desulfurization and denitrogenation of gasoline and diesel fuels by means of ionic liquids. Green Chem. 2011, 13, 1907–1913. [Google Scholar] [CrossRef]

- Mendes, R.F.; Barbosa, P.; Domingues, E.M.; Silva, P.; Figueiredo, F.; Paz, F.A.A. Enhanced proton conductivity in a layered coordination polymer. Chem. Sci. 2020. In Press. [Google Scholar] [CrossRef]

- Silva, P.; Mendes, R.F.; Fernandes, C.; Gomes, A.C.; Ananias, D.; Remião, F.; Borges, F.; Valente, A.A.; Paz, F.A.A. Multifunctionality and cytotoxicity of a layered coordination polymer. Dalton Trans. 2020, 49, 3989–3998. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirante, F.; Mendes, R.F.; Paz, F.A.A.; Balula, S.S. High Catalytic Efficiency of a Layered Coordination Polymer to Remove Simultaneous Sulfur and Nitrogen Compounds from Fuels. Catalysts 2020, 10, 731. https://doi.org/10.3390/catal10070731

Mirante F, Mendes RF, Paz FAA, Balula SS. High Catalytic Efficiency of a Layered Coordination Polymer to Remove Simultaneous Sulfur and Nitrogen Compounds from Fuels. Catalysts. 2020; 10(7):731. https://doi.org/10.3390/catal10070731

Chicago/Turabian StyleMirante, Fátima, Ricardo F. Mendes, Filipe A. Almeida Paz, and Salete S. Balula. 2020. "High Catalytic Efficiency of a Layered Coordination Polymer to Remove Simultaneous Sulfur and Nitrogen Compounds from Fuels" Catalysts 10, no. 7: 731. https://doi.org/10.3390/catal10070731

APA StyleMirante, F., Mendes, R. F., Paz, F. A. A., & Balula, S. S. (2020). High Catalytic Efficiency of a Layered Coordination Polymer to Remove Simultaneous Sulfur and Nitrogen Compounds from Fuels. Catalysts, 10(7), 731. https://doi.org/10.3390/catal10070731