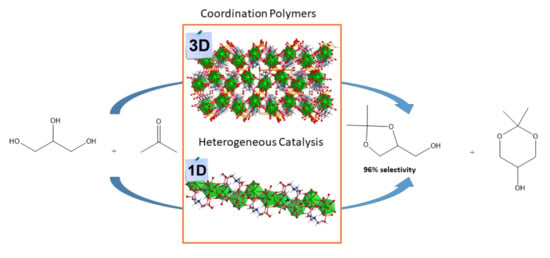

Solketal Production via Solvent-Free Acetalization of Glycerol over Triphosphonic-Lanthanide Coordination Polymers

Abstract

:1. Introduction

2. Results and Discussion

2.1. Catalysts Synthesis and Characterization

2.2. Reaction of Glycerol with Acetone

2.3. Catalyst Stability

3. Materials and Methods

3.1. Reagents

3.2. General Instrumentation

3.3. Catalyst Synthesis

3.4. Catalytic Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zahid, I.; Ayoub, M.; Abdullah, B.B.; Nazir, M.H.; Ameen, M.; Zulqarnain; Mohd Yusoff, M.H.; Inayat, A.; Danish, M. Production of Fuel Additive Solketal via Catalytic Conversion of Biodiesel-Derived Glycerol. Ind. Eng. Chem. Res. 2020, 59, 20961–20978. [Google Scholar] [CrossRef]

- Fatimah, I.; Sahroni, I.; Fadillah, G.; Musawwa, M.M.; Mahlia, T.M.I.; Muraza, O. Glycerol to Solketal for Fuel Additive: Recent Progress in Heterogeneous Catalysts. Energies 2019, 12, 2872. [Google Scholar] [CrossRef] [Green Version]

- Nda-Umar, U.I.; Ramli, I.; Taufiq-Yap, Y.H.; Muhamad, E.N. An overview of recent research in the conversion of glycerol into biofuels, fuel additives and other bio-based chemicals. Catalysts 2019, 9, 15. [Google Scholar] [CrossRef] [Green Version]

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Najaafi, N.; Tarighi, S. A review on the catalytic acetalization of bio-renewable glycerol to fuel additives. Front. Chem. 2018, 6, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, A.; Bordado, J.C.; Dos Santos, R.G. Upgrading the glycerol from biodiesel production as a source of energy carriers and chemicals—A technological review for three chemical pathways. Energies 2017, 10, 1817. [Google Scholar] [CrossRef] [Green Version]

- Szori, M.; Giri, B.R.; Wang, Z.; Dawood, A.E.; Viskolcz, B.; Farooq, A. Glycerol carbonate as a fuel additive for a sustainable future. Sustain. Energy Fuels 2018, 2, 2171–2178. [Google Scholar] [CrossRef] [Green Version]

- Rahaman, M.S.; Phung, T.K.; Hossain, M.A.; Chowdhury, E.; Tulaphol, S.; Lalvani, S.B.; O’Toole, M.; Willing, G.A.; Jasinski, J.B.; Crocker, M.; et al. Hydrophobic functionalization of HY zeolites for efficient conversion of glycerol to solketal. Appl. Catal. A Gen. 2020, 592. [Google Scholar] [CrossRef]

- Mota, C.J.A.; Da Silva, C.X.A.; Rosenbach, N.; Costa, J.; Da Silva, F. Glycerin derivatives as fuel additives: The addition of glycerol/acetone ketal (solketal) in gasolines. Energy Fuels 2010, 24, 2733–2736. [Google Scholar] [CrossRef]

- Oliveira, P.A.; Souza, R.O.M.A.; Mota, C.J.A. Atmospheric pressure continuous production of solketal from the acid-catalyzed reaction of glycerol with acetone. J. Braz. Chem. Soc. 2016, 27, 1832–1837. [Google Scholar] [CrossRef]

- Catuzo, G.L.; Santilli, C.V.; Martins, L. Hydrophobic-hydrophilic balance of ZSM-5 zeolites on the two-phase ketalization of glycerol with acetone. Catal. Today 2020. [Google Scholar] [CrossRef]

- Antunes, M.M.; Mendes, R.F.; Almeida Paz, F.A.; Valente, A.A. Versatile coordination polymer catalyst for acid reactions involving biobased heterocyclic chemicals. Catalysts 2021, 11, 190. [Google Scholar] [CrossRef]

- Ferreira, P.; Fonseca, I.M.; Ramos, A.M.; Vital, J.; Castanheiro, J.E. Valorisation of glycerol by condensation with acetone over silica-included heteropolyacids. Appl. Catal. B Environ. 2010, 98. [Google Scholar] [CrossRef]

- Vicente, G.; Melero, J.A.; Morales, G.; Paniagua, M.; Martín, E. Acetalisation of bio-glycerol with acetone to produce solketal over sulfonic mesostructured silicas. Green Chem. 2010, 12. [Google Scholar] [CrossRef]

- Kowalska-Kus, J.; Held, A.; Frankowski, M.; Nowinska, K. Solketal formation from glycerol and acetone over hierarchical zeolites of different structure as catalysts. J. Mol. Catal. A Chem. 2017, 426, 205–212. [Google Scholar] [CrossRef]

- Lee, J.; Farha, O.K.; Roberts, J.; Scheidt, K.A.; Nguyen, S.T.; Hupp, J.T. Metal-organic framework materials as catalysts. Chem. Soc. Rev. 2009, 38, 1450–1459. [Google Scholar] [CrossRef]

- Liu, J.; Chen, L.; Cui, H.; Zhang, J.; Zhang, L.; Su, C.Y. Applications of metal-organic frameworks in heterogeneous supramolecular catalysis. Chem. Soc. Rev. 2014, 43, 6011–6061. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mendes, R.F.; Silva, P.; Antunes, M.M.; Valente, A.A.; Almeida Paz, F.A. Sustainable synthesis of a catalytic active one-dimensional lanthanide-organic coordination polymer. Chem. Commun. 2015, 51, 10807–10810. [Google Scholar] [CrossRef]

- Mendes, R.F.; Antunes, M.M.; Silva, P.; Barbosa, P.; Figueiredo, F.; Linden, A.; Rocha, J.; Valente, A.A.; Almeida Paz, F.A. A Lamellar Coordination Polymer with Remarkable Catalytic Activity. Chem. A Eur. J. 2016, 22, 13136–13146. [Google Scholar] [CrossRef] [PubMed]

- Mirante, F.; Mendes, R.F.; Almeida Paz, F.A.; Balula, S.S. High catalytic efficiency of a layered coordination polymer to remove simultaneous sulfur and nitrogen compounds from fuels. Catalysts 2020, 10, 731. [Google Scholar] [CrossRef]

- Gascon, J.; Corma, A.; Kapteijn, F.; Llabrés I Xamena, F.X. Metal organic framework catalysis: Quo vadis? ACS Catal. 2014, 4, 361–378. [Google Scholar] [CrossRef]

- Bakuru, V.R.; Churipard, S.R.; Maradur, S.P.; Kalidindi, S.B. Exploring the Brønsted acidity of UiO-66 (Zr, Ce, Hf) metal-organic frameworks for efficient solketal synthesis from glycerol acetalization. Dalt. Trans. 2019, 48, 843–847. [Google Scholar] [CrossRef] [PubMed]

- Timofeeva, M.N.; Panchenko, V.N.; Khan, N.A.; Hasan, Z.; Prosvirin, I.P.; Tsybulya, S.V.; Jhung, S.H. Isostructural metal-carboxylates MIL-100(M) and MIL-53(M) (M: V, Al, Fe and Cr) as catalysts for condensation of glycerol with acetone. Appl. Catal. A Gen. 2017, 529, 167–174. [Google Scholar] [CrossRef]

- Mendes, R.F.; Almeida Paz, F.A. Dynamic breathing effect in metal-organic frameworks: Reversible 2D-3D-2D-3D single-crystal to single-crystal transformation. Inorganica Chim. Acta 2017, 460, 99–107. [Google Scholar] [CrossRef]

| Entry | Catalyst | Gly/Acet | Temp. (°C) | Conv. (%) | Selectivity (%) | |

|---|---|---|---|---|---|---|

1,3-Dioxolane  | 1,3-Dioxane  | |||||

| 1 | UAV-63 | 1/10 | 40 | 22 | 70 | 30 |

| 2 | UAV-63 | 1/10 | 55 | 84 | 96 | 4 |

| 3 | UAV-63 | 1/4 | 55 | 64 | 96 | 4 |

| 4 | UAV-20 | 1/10 | 40 | 8 | 72 | 28 |

| 5 | UAV-20 | 1/10 | 55 | 56 | 90 | 10 |

| 6 | UAV-20 | 1/4 | 55 | 44 | 93 | 7 |

| Entry | Catalyst | T | Gly/Ace | Cat/Gly | t | Conv. | Selectivity (%) | Ref. | |

|---|---|---|---|---|---|---|---|---|---|

| (Solvent) | (°C) | (%, w/w) | (h) | (%) |  |  | |||

| 1 | UAV-63 | 55 | 1:10 | 5 | 6 | 84 | 96 | 4 | This work |

| 2 | UAV-20 | 55 | 1:10 | 5 | 6 | 56 | 82 | 18 | This work |

| 3 | UiO-66(Zr) MOF | RT | 1:4 | 10 | 1 | 2 | 73 | 27 | [21] |

| 4 | UiO-66(Ce) MOF | RT | 1:4 | 10 | 1 | 70 | 90 | 10 | [21] |

| 5 | UiO-66(Hf) MOF | RT | 1:4 | 10 | 1 | 95 | 97 | 3 | [21] |

| 6 | MIL-100(V) (CH3CN) | 70 | 1:4.7 | 20 | 1.25 | 85.4 | 97.7 | 2.3 | [22] |

| 7 | MIL-100(V) (CH3CN) | 25 | 1:4.1 | 2.5 | 1.5 | 83 | 98 | n.m. | [22] |

| 9 | MIL-47(V) (CH3CN) | 70 | 1:4.7 | 20 | 1.25 | 75.9 | 97.5 | 2.5 | [22] |

| 10 | MIL-47(V) (CH3CN) | 25 | 1:4.1 | 2.5 | 1.5 | 73 | 87 | n.m. | [22] |

| 11 | MIL-53(Al:V) (25:75) (CH3CN) | 70 | 1:4.7 | 20 | 1.25 | 57.7 | 95.1 | 4.9 | [22] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos-Vieira, I.C.M.S.; Mendes, R.F.; Almeida Paz, F.A.; Rocha, J.; Simões, M.M.Q. Solketal Production via Solvent-Free Acetalization of Glycerol over Triphosphonic-Lanthanide Coordination Polymers. Catalysts 2021, 11, 598. https://doi.org/10.3390/catal11050598

Santos-Vieira ICMS, Mendes RF, Almeida Paz FA, Rocha J, Simões MMQ. Solketal Production via Solvent-Free Acetalization of Glycerol over Triphosphonic-Lanthanide Coordination Polymers. Catalysts. 2021; 11(5):598. https://doi.org/10.3390/catal11050598

Chicago/Turabian StyleSantos-Vieira, Isabel C.M.S., Ricardo F. Mendes, Filipe A. Almeida Paz, João Rocha, and Mário M. Q. Simões. 2021. "Solketal Production via Solvent-Free Acetalization of Glycerol over Triphosphonic-Lanthanide Coordination Polymers" Catalysts 11, no. 5: 598. https://doi.org/10.3390/catal11050598

APA StyleSantos-Vieira, I. C. M. S., Mendes, R. F., Almeida Paz, F. A., Rocha, J., & Simões, M. M. Q. (2021). Solketal Production via Solvent-Free Acetalization of Glycerol over Triphosphonic-Lanthanide Coordination Polymers. Catalysts, 11(5), 598. https://doi.org/10.3390/catal11050598