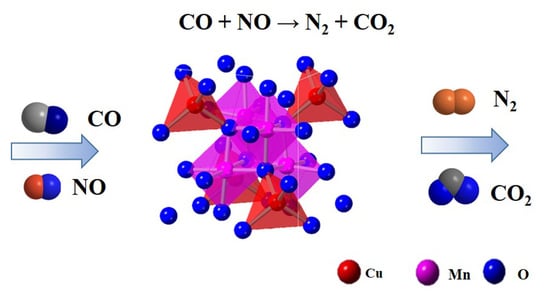

Low-Temperature Selective NO Reduction by CO over Copper-Manganese Oxide Spinels

Abstract

:1. Introduction

2. Results and Discussion

2.1. XRD Analysis of Catalysts

2.2. N2 Sorption Analysis of Catalysts

2.3. SEM and TEM Observation

2.4. H2-TPR Analysis

2.5. XPS Analysis

3. Catalytic Performances of the Catalysts

3.1. Catalytic Reduction of NO with CO

3.2. Structure Activity Relationship and Catalystic Reaction Mechanism

4. Experimental

4.1. Material Synthesis

4.2. Characterization

4.3. Measurement

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, K.; Yu, Q.; Liu, J.; Wang, K.; Han, Z.; Xuan, Y.; Qin, Q. Selection of catalytically active elements for removing NO and CO from flue gas at low temperatures. New J. Chem. 2017, 41, 13993–13999. [Google Scholar] [CrossRef]

- Qin, Y.; Fan, S.; Li, X.; Gan, G.; Wang, L.; Yin, Z.; Guo, X.; Tadé, M.O.; Liu, S. Peanut-shaped Cu–Mn nano-hollow spinel with oxygen vacancies as catalysts for low-temperature NO reduction by CO. ACS App. Nano Mater. 2021, 4, 11969–11979. [Google Scholar] [CrossRef]

- Li, S.; Chen, X.; Wang, F.; Xie, Z.; Hao, Z.; Liu, L.; Shen, B. Promotion effect of Ni doping on the oxygen resistance property of Fe/CeO2 catalyst for CO-SCR reaction: Activity test and mechanism investigation. J. Hazard. Mater. 2022, 431, 128622. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Hegde, M.; Madras, G. Catalysis for NOx abatement. Appl. Energy 2009, 86, 2283–2297. [Google Scholar] [CrossRef]

- Fernandez, E.; Liu, L.; Boronat, M.; Arenal, R.; Concepcion, P.; Corma, A. Low-temperature catalytic NO reduction with CO by subnanometric Pt clusters. ACS Catal. 2019, 9, 11530–11541. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Dong, L.; Shen, M.; Liu, D.; Wang, J.; Ding, W.; Chen, Y. Influence of supports on the activities of copper oxide species in the low-temperature NO+CO reaction. Appl. Catal. B 2001, 31, 61–69. [Google Scholar] [CrossRef]

- Ilieva, L.; Pantaleo, G.; Velinov, N.; Tabakova, T.; Petrova, P.; Ivanov, I.; Avdeev, G.; Paneva, D.; Venezia, A. NO reduction by CO over gold catalysts supported on Fe-loaded ceria. Appl. Catal. B 2015, 174, 176–184. [Google Scholar] [CrossRef]

- Zhang, S.; Shan, J.; Zhu, Y.; Nguyen, L.; Huang, W.; Yoshida, H.; Takeda, S.; Tao, F. Restructuring transition metal oxide nanorods for 100% selectivity in reduction of nitric oxide with carbon monoxide. Nano Lett. 2013, 13, 3310–3314. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Mu, J.; Fan, S.; Chen, X.; Wang, L.; Yin, Z.; Tade, M.; Liu, S. Oxygen vacancy-rich porous Co3O4 nanosheets toward boosted NO reduction by CO and CO oxidation: Insights into the structure-activity relationship and performance enhancement mechanism. ACS Appl. Mater. Interfaces 2019, 11, 41988–41999. [Google Scholar] [CrossRef]

- Lima, T.; Pereira, C.; Castelblanco, W.; Santos, B.; Silva, S.; Santana, R.; González, U.; Sartoratto, C. Zirconia-supported cobalt catalysts: Activity and selectivity in NO reduction by CO. Chem. Select 2017, 2, 11565–11573. [Google Scholar]

- Salker, A.; Desai, M. Catalytic activity and mechanistic approach of NO reduction by CO over M0.05Co2.95O4 (M = Rh, Pd & Ru) spinel system. Appl. Surf. Sci. 2016, 389, 344–353. [Google Scholar]

- Liu, L.; Yao, Z.; Deng, Y.; Gao, F.; Liu, B.; Dong, L. Morphology and crystal-plane effects of nanoscale ceria on the activity of CuO/CeO2 for NO reduction by CO. ChemCatChem 2011, 3, 978–989. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Li, R.; He, H.; Huang, L. MOFs-based coating derived Me-ZIF-67@CuOx materials as low-temperature NO-CO catalysts. Chem. Eng. J. 2019, 381, 122757. [Google Scholar] [CrossRef]

- Xiaoyuan, J.; Guanghui, D.; Liping, L.; Yingxu, C.; Xiaoming, Z. Catalytic activities of CuO/TiO2 and CuO-ZrO2/TiO2 in NO+CO reaction. J. Mol. Catal. A Chem. 2004, 218, 187–195. [Google Scholar] [CrossRef]

- Boningari, T.; Pavani, S.; Ettireddy, P.; Chuang, S.; Smirniotis, P. Mechanistic investigations on NO reduction with CO over Mn/TiO2 catalyst at low temperatures. Mol. Catal. 2017, 451, 33–42. [Google Scholar] [CrossRef]

- Shan, J.; Zhu, Y.; Zhang, S.; Zhu, T.; Rouvimov, S.; Tao, F. Catalytic Performance and in Situ Surface Chemistry of Pure α-MnO2 Nanorods in Selective Reduction of NO and N2O with CO. J. Phys. Chem. C 2013, 117, 8329–8335. [Google Scholar] [CrossRef]

- Deng, C.; Li, B.; Dong, L.; Zhang, F.; Fan, M.; Jin, G.; Gao, J.; Gao, L.; Zhang, F. NO reduction by CO over CuO supported on CeO2-doped TiO2: The effect of the amount of a few CeO2. Phys. Chem. 2015, 17, 16092–16109. [Google Scholar] [CrossRef]

- Li, Y.; Wan, Y.; Li, Y.; Zhan, S.; Guan, Q.; Tian, Y. Low-temperature selective catalytic reduction of NO with NH(3) over Mn(2)O(3)-Doped Fe(2)O(3) hexagonal microsheets. ACS Appl. Mater. Interfaces 2016, 8, 5224–5233. [Google Scholar] [CrossRef]

- Liu, J.; Wei, Y.; Li, P.; Zhang, P.; Su, W.; Sun, Y.; Zou, R.; Zhao, Y. Experimental and theoretical investigation of mesoporous MnO2 nanosheets with oxygen vacancies for high-efficiency catalytic deNOx. ACS Catal. 2018, 8, 3865–3874. [Google Scholar] [CrossRef]

- Pan, K.; Young, C.; Pan, G.; Chang, M. Catalytic reduction of NO by CO with Cu-based and Mn-based catalysts. Catal. Today 2020, 348, 15–25. [Google Scholar] [CrossRef]

- Yao, X.; Xiong, Y.; Sun, J.; Gao, F.; Deng, Y.; Tang, C.; Dong, L. Influence of MnO2 modification methods on the catalytic performance of CuO/CeO2 for NO reduction by CO. J. Rare Earths 2014, 32, 131–138. [Google Scholar] [CrossRef]

- Li, D.; Yu, Q.; Li, S.; Wan, H.; Liu, L.; Qi, J.; Liu, L.; Gao, F.; Dong, L.; Chen, Y. The remarkable enhancement of CO-pretreated CuO-Mn2O3/gamma-Al2O3 supported catalyst for the reduction of NO with CO: The formation of surface synergetic oxygen vacancy. Chem. A Eur. J. 2011, 17, 5668–5679. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Lu, Y.; Tan, W.; Liu, A.; Ji, J.; Wan, H.; Sun, C.; Tang, C.; Dong, L. Insights into the precursor effect on the surface structure of gamma-Al2O3 and NO+CO catalytic performance of CO-pretreated CuO/MnOx/gamma-Al2O3 catalysts. J. Colloid Interface Sci. 2019, 554, 611–618. [Google Scholar] [CrossRef] [PubMed]

- Spassova, I.; Khristova, M.; Panayotov, D.; Mehandjiev, D. Coprecipitated CuO–MnOx vatalysts for low-temperature CO–NO and CO–NO–O2 reactions. J. Catal. 1999, 185, 43–57. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Zhang, L.; Yu, Y.; He, H. Low-temperature selective catalytic reduction of NOx on MnO2 octahedral molecular sieves (OMS-2) doped with Co. Catalysts 2020, 10, 396. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Chu, Q.; Xiong, W.; Gao, J.; Ding, Y. A new type bimetallic NiMn-MOF-74 as an efficient low-temperatures catalyst for selective catalytic reduction of NO by CO. Chem. Eng. Process. 2020, 159, 108232. [Google Scholar] [CrossRef]

- Yi, Y.; Liu, H.; Chu, B.; Qin, Z.; Dong, L.; He, H.; Tang, C.; Fan, M.; Bin, L. Catalytic removal NO by CO over LaNi0.5M0.5O3 (M = Co, Mn, Cu) perovskite oxide catalysts: Tune surface chemical composition to improve N2 selectivity. Chem. Eng. J. 2019, 369, 511–521. [Google Scholar] [CrossRef]

- Shi, X.; Chu, B.; Wang, F.; Wei, X.; Teng, L.; Fan, M.; Li, B.; Dong, L. Mn-Modified CuO, CuFe2O4, and γ-Fe2O3 Three-phase strong synergistic coexistence catalyst system for NO reduction by CO with a wider active window. ACS Appl. Mater. Interfaces 2018, 10, 40509–40522. [Google Scholar] [CrossRef]

- Wan, H.; Li, D.; Dai, Y.; Hu, Y.; Liu, B.; Dong, L. Catalytic behaviors of CuO supported on Mn2O3 modified γ-Al2O3 for NO reduction by CO. J. Mol. Catal. A Chem. 2010, 332, 32–44. [Google Scholar] [CrossRef]

- Liu, T.; Yao, Y.; Wei, L.; Shi, Z.; Han, L.; Yuan, H.; Li, B.; Dong, L.; Wang, F.; Sun, C. Preparation and evaluation of copper–manganese oxide as a high-efficiency catalyst for CO oxidation and NO reduction by CO. J. Phys. Chem. C. 2017, 121, 12757–12770. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, C.; He, C. Efficient catalytic degradation of toluene at a readily prepared Mn-Cu catalyst: Catalytic performance and reaction pathway. J. Colloid Interface Sci. 2021, 591, 396–408. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Shi, L.; Huang, L.; Zhang, J.; Gao, R.; Zhang, D. Rational design of high-performance seNOx catalysts based on MnxCo3−xO4 nanocages derived from metal–organic frameworks. ACS Catal. 2014, 4, 1753–1763. [Google Scholar] [CrossRef]

- Salker, A.V.; Desai, M. CO-NO/O2 redox reactions over Cu substituted cobalt oxide spinels. Catal. Commun. 2016, 87, 116–119. [Google Scholar] [CrossRef]

- Salker, A.; Desai, M. Low-temperature nitric oxide reduction over silver-substituted cobalt oxide spinels. Catal. Sci. Technol. 2016, 6, 430–433. [Google Scholar] [CrossRef]

- Liu, S.; Ji, Y.; Xu, W.; Zhang, J.; Jiang, R.; Li, L.; Jia, L.; Zhong, Z.; Xu, G.; Zhu, T.; et al. Hierarchically interconnected porous MnxCo3−xO4 spinels for low-temperature catalytic reduction of NO by CO. J. Catal. 2022, 406, 72–86. [Google Scholar] [CrossRef]

| Sample | Crystal Size nm | Lattice Parameter a nm | Actual Molar Ratios of Cu:Mn b | BET Surface Area m2 g−1 c |

|---|---|---|---|---|

| Mn2O3 | 63.07 | a = b = c = 0.9423 | - | 18.2 |

| Cu1Mn2O4 | 42.69 | a = b = c = 0.8290 | 0.93:2.05 | 18.9 |

| Cu1.5Mn1.5O4 | 31.79 | a = b = c = 0.8284 | 1.46:1.54 | 19.7 |

| Cu2Mn1O4 | 31.76 | a = b = c = 0.8282 | 1.97:1.02 | 18.7 |

| CuO | 42.43 | a = 0.4687, b = 0.3427, c = 0.5135 | - | 28.9 |

| Sample | Mn4+/Mn | Mn3+/Mn | Mn2+/Mn | Cu2+/Cu | Oα/O | Oβ/O |

|---|---|---|---|---|---|---|

| Mn2O3 | 2.7 | 50.7 | 46.6 | - | 55.4 | 44.6 |

| Cu1Mn2O4 | 31.6 | 50.8 | 17.6 | 70.1 | 53.1 | 46.9 |

| Cu1.5Mn1.5O4 | 54.4 | 36.0 | 9.6 | 66.2 | 32.3 | 67.7 |

| Cu2Mn1.5O4 | 33.4 | 54.4 | 12.2 | 86.7 | 37.5 | 62.5 |

| CuO | - | - | - | 100 | 51.1 | 48.9 |

| Sample | Cu(NO3)2·3H2O (g) | 50% Mn(NO3)2 Solution (g) | Citric Acid Monohydrate (g) |

|---|---|---|---|

| Mn2O3 | - | 23.4 | 11.7 |

| Cu1Mn2O4 | 5.1 | 15.0 | 11.7 |

| Cu1.5Mn1.5O4 | 7.5 | 11.1 | 11.7 |

| Cu2Mn1.5O4 | 9.8 | 7.3 | 11.7 |

| CuO | 15.1 | - | 11.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, F.; Wang, L.; Wang, L.; Liu, J.; Wang, M. Low-Temperature Selective NO Reduction by CO over Copper-Manganese Oxide Spinels. Catalysts 2022, 12, 591. https://doi.org/10.3390/catal12060591

Fan F, Wang L, Wang L, Liu J, Wang M. Low-Temperature Selective NO Reduction by CO over Copper-Manganese Oxide Spinels. Catalysts. 2022; 12(6):591. https://doi.org/10.3390/catal12060591

Chicago/Turabian StyleFan, Fenglan, Lingjuan Wang, Lei Wang, Jinyu Liu, and Minghui Wang. 2022. "Low-Temperature Selective NO Reduction by CO over Copper-Manganese Oxide Spinels" Catalysts 12, no. 6: 591. https://doi.org/10.3390/catal12060591

APA StyleFan, F., Wang, L., Wang, L., Liu, J., & Wang, M. (2022). Low-Temperature Selective NO Reduction by CO over Copper-Manganese Oxide Spinels. Catalysts, 12(6), 591. https://doi.org/10.3390/catal12060591