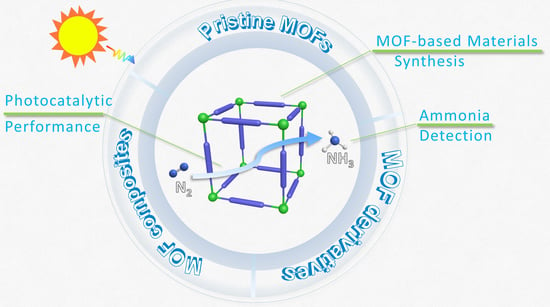

Achievements and Perspectives in Metal–Organic Framework-Based Materials for Photocatalytic Nitrogen Reduction

Abstract

:1. Introduction

2. Ammonia Determination Methods

3. Synthesis of MOF-Based Materials

4. MOF-Based Materials for Photocatalytic Nitrogen Fixation

4.1. Pristine MOFs

4.1.1. Transition Metal-Based MOFs

Cerium-Based MOFs

Titanium Metal-Based MOFs

Zirconium-Based MOFs

Iron-Based MOFs

Transitional Bimetallic MOFs

4.1.2. Post-Transition Metal-Based MOFs

Gadolinium-Based MOFs

Aluminium-Based MOFs

4.2. MOF Composites

4.3. MOF Derivatives

5. Summary and Future Perspective

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hoffman, B.M.; Lukoyanov, D.; Yang, Z.Y.; Dean, D.R.; Seefeldt, L.C. Mechanism of nitrogen fixation by nitrogenase: The next stage. Chem. Rev 2014, 114, 4041–4062. [Google Scholar] [PubMed]

- Canfield, D.E.; Glazer, A.N.; Falkowski, P.G. The evolution and future of Earth’s nitrogen cycle. Science 2010, 330, 192–196. [Google Scholar] [PubMed]

- Xiong, Q.; Chen, Y.; Xu, T.; Zhu, Z.; Chen, W.; Lu, W. Highly efficient purification of emerging pollutants and bacteria in natural water by g-C3N4-sheltered fibers containing TiO2. Appl. Surf. Sci. 2021, 559, 149839. [Google Scholar]

- Wang, T.; Dai, Z.; Kang, J.; Fu, F.; Zhang, T.; Wang, S. A TiO2 nanocomposite hydrogel for Hydroponic plants in efficient water improvement. Mater. Chem. Phys. 2018, 215, 242–250. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, Y.; Zhu, Y.; Fu, Y. Improved visible-light photocatalytic activity of sodium tantalum oxide via biomass-derived silk fibroin doping. Text. Res. J. 2018, 89, 1332–1339. [Google Scholar]

- Jiang, T.; Jiang, G.; Li, L.; Chen, H.; Zhou, H.; Yao, J.; Kong, X.; Chen, W. N-Doped carbon hybrid conjugates as vectors for photocatalytic CS2 production. Mater. Res. Express 2015, 2, 045603. [Google Scholar]

- Liu, B.; Xu, Y.; Cui, J.; Wang, S.; Wang, T. Carbon nanotubes-dispersed TiO2 nanoparticles with their enhanced photocatalytic activity. Mater. Res. Bull. 2014, 59, 278–282. [Google Scholar]

- Wang, S.; Wang, T.; Ding, Y.; Su, Q.; Xu, Y.; Xu, Z.; Jiang, G.; Chen, W. Air-Water Interface Photocatalysis: A Realizable Approach for Decomposition of Aqueous Organic Pollutants. Sci. Adv. Mater. 2013, 5, 1006–1012. [Google Scholar]

- Jiang, G.; Wang, R.; Wang, X.; Xi, X.; Hu, R.; Zhou, Y.; Wang, S.; Wang, T.; Chen, W. Novel highly active visible-light-induced photocatalysts based on BiOBr with Ti doping and Ag decorating. ACS Appl. Mater. Inter. 2012, 4, 4440–4444. [Google Scholar]

- Fang, Y.; Wang, R.; Jiang, G.; Jin, H.E.; Wang, Y.I.N.; Sun, X.; Wang, S.; Wang, T.A.O. CuO/TiO2 nanocrystals grown on graphene as visible-light responsive photocatalytic hybrid materials. Bull. Mater. Sci. 2012, 35, 495–499. [Google Scholar]

- Novas, N.; Garcia, R.M.; Camacho, J.M.; Alcayde, A. Advances in Solar Energy towards Efficient and Sustainable Energy. Sustainability 2021, 13, 6295. [Google Scholar]

- Yandulov, D.V.; Schrock, R.R. Catalytic reduction of dinitrogen to ammonia at a single molybdenum center. Science 2003, 301, 76–78. [Google Scholar] [CrossRef]

- Arashiba, K.; Miyake, Y.; Nishibayashi, Y. A molybdenum complex bearing PNP-type pincer ligands leads to the catalytic reduction of dinitrogen into ammonia. Nat. Chem. 2011, 3, 120–125. [Google Scholar] [PubMed]

- Rodriguez, M.M.; Bill, E.; Brennessel, W.W.; Holland, P.L. N(2)reduction and hydrogenation to ammonia by a molecular iron-potassium complex. Science 2011, 334, 780–783. [Google Scholar]

- Zhang, G.; Yang, X.; He, C.; Zhang, P.; Mi, H. Constructing a tunable defect structure in TiO2 for photocatalytic nitrogen fixation. J. Mater. Chem. A 2020, 8, 334–341. [Google Scholar] [CrossRef]

- Yang, J.; Guo, Y.; Jiang, R.; Qin, F.; Zhang, H.; Lu, W.; Wang, J.; Yu, J.C. High-Efficiency "Working-in-Tandem" Nitrogen Photofixation Achieved by Assembling Plasmonic Gold Nanocrystals on Ultrathin Titania Nanosheets. J. Am. Chem. Soc. 2018, 140, 8497–8508. [Google Scholar] [PubMed]

- Li, C.; Wang, T.; Zhao, Z.-J.; Yang, W.; Li, J.-F.; Li, A.; Yang, Z.; Ozin, G.A.; Gong, J. Promoted Fixation of Molecular Nitrogen with Surface Oxygen Vacancies on Plasmon-Enhanced TiO2 Photoelectrodes. Angew. Chem. Int. Ed. 2018, 130, 5376–5380. [Google Scholar] [CrossRef]

- Comer, B.M.; Liu, Y.H.; Dixit, M.B.; Hatzell, K.B.; Ye, Y.; Crumlin, E.J.; Hatzell, M.C.; Medford, A.J. The Role of Adventitious Carbon in Photo-catalytic Nitrogen Fixation by Titania. J. Am. Chem. Soc. 2018, 140, 15157–15160. [Google Scholar] [PubMed]

- Hirakawa, H.; Hashimoto, M.; Shiraishi, Y.; Hirai, T. Photocatalytic Conversion of Nitrogen to Ammonia with Water on Surface Oxygen Vacancies of Titanium Dioxide. J. Am. Chem. Soc. 2017, 139, 10929–10936. [Google Scholar] [CrossRef]

- Janet, C.M.; Navaladian, S.; Viswanathan, B.; Varadarajan, T.K.; Viswanath, R.P. Heterogeneous Wet Chemical Synthesis of Superlattice-Type Hierarchical ZnO Architectures for Concurrent H2 Production and N2 Reduction. J. Phys. Chem. C 2010, 114, 2622–2632. [Google Scholar]

- Song, M.; Wang, L.; Li, J.; Sun, D.; Guan, R.; Zhai, H.; Gao, X.; Li, X.; Zhao, Z.; Sun, Z. Defect density modulation of La2TiO5: An effective method to suppress electron-hole recombination and improve photocatalytic nitrogen fixation. J. Colloid Interface Sci. 2021, 602, 748–755. [Google Scholar] [PubMed]

- Zhang, W.; Xing, P.; Zhang, J.; Chen, L.; Yang, J.; Hu, X.; Zhao, L.; Wu, Y.; He, Y. Facile preparation of novel nickel sulfide modified KNbO3 heterojunction composite and its enhanced performance in photocatalytic nitrogen fixation. J. Colloid Interface Sci. 2021, 590, 548–560. [Google Scholar] [PubMed]

- Khan, F.; Yue, P.; Rizzuti, L.; Augugliaro, V.; Brucato, A. Photoassisted water cleavage and nitrogen fixation over titanium-exchanged zeolites. Ind. Eng. Chem. Prod. Res. Dev. 1983, 22, 238–241. [Google Scholar]

- Wang, S.; Hai, X.; Ding, X.; Chang, K.; Xiang, Y.; Meng, X.; Yang, Z.; Chen, H.; Ye, J. Light-Switchable Oxygen Vacancies in Ultrafine Bi5O7Br Nanotubes for Boosting Solar-Driven Nitrogen Fixation in Pure Water. Adv. Mater. 2017, 29, 1701774. [Google Scholar]

- Li, H.; Shang, J.; Ai, Z.; Zhang, L. Efficient Visible Light Nitrogen Fixation with BiOBr Nanosheets of Oxygen Vacancies on the Exposed {001} Facets. J. Am. Chem. Soc. 2015, 137, 6393–6399. [Google Scholar]

- Khader, M.M.; Lichtin, N.N.; Vurens, G.H.; Salmeron, M.; Somorjai, G.A. Photoassisted catalytic dissociation of water and reduction of nitrogen to ammonia on partially reduced ferric oxide. Langmuir 1987, 3, 303–304. [Google Scholar]

- Dong, G.; Ho, W.; Wang, C. Selective photocatalytic N2 fixation dependent on g-C3N4 induced by nitrogen vacancies. J. Mater. Chem. A 2015, 3, 23435–23441. [Google Scholar]

- Huang, Y.B.; Liang, J.; Wang, X.S.; Cao, R. Multifunctional metal-organic framework catalysts: Synergistic catalysis and tandem reactions. Chem. Soc. Rev. 2017, 46, 126–157. [Google Scholar]

- Li, H.; Eddaoudi, M.; O’Keeffe, M.; Yaghi, O.M. Design and synthesis of an exceptionally stable and highly porous metal-organic framework. Nature 1999, 402, 276–279. [Google Scholar]

- Shen, K.; Zhang, L.; Chen, X.; Liu, L.; Zhang, D.; Han, Y.; Chen, J.; Long, J.; Luque, R.; Li, Y.; et al. Ordered macro-microporous metal-organic framework single crystals. Science 2018, 359, 206–210. [Google Scholar]

- Jagadeesh, R.V.; Murugesan, K.; Alshammari, A.S.; Neumann, H.; Pohl, M.M.; Radnik, J.; Beller, M. MOF-derived cobalt nanoparticles catalyze a general synthesis of amines. Science 2017, 358, 326–332. [Google Scholar] [PubMed]

- Talin, A.A.; Centrone, A.; Ford, A.C.; Foster, M.E.; Stavila, V.; Haney, P.; Kinney, R.A.; Szalai, V.; El Gabaly, F.; Yoon, H.P.; et al. Tunable electrical conductivity in metal-organic framework thin-film devices. Science 2014, 343, 66–69. [Google Scholar] [PubMed]

- Ferey, G.; Mellot-Draznieks, C.; Serre, C.; Millange, F.; Dutour, J.; Surble, S.; Margiolaki, I. A chromium terephthalate-based solid with unusually large pore volumes and surface area. Science 2005, 309, 2040. [Google Scholar] [PubMed]

- Zhang, J.; Huang, J.; Wang, L.; Sun, P.; Wang, P.; Yao, Z.; Yang, Y. Coupling Bimetallic NiMn-MOF Nanosheets on NiCo2O4 Nanowire Arrays with Boosted Electrochemical Performance for Hybrid Supercapacitor. Mater. Res. Bull. 2022, 149, 111707. [Google Scholar]

- Yu, Z.; Kang, S.; Wang, J.; Tai, M.; Wang, X.; Ding, Y.; Jin, D.; Wang, L. Highly improved photoluminescence properties of novel ternary Eu(cpioa)phen metal–organic frameworks. Funct. Mater. Lett. 2022, 15, 2251026. [Google Scholar]

- Sun, P.; Zhang, J.; Huang, J.; Wang, L.; Wang, P.; Cai, C.; Lu, M.; Yao, Z.; Yang, Y. Bimetallic MOF-derived (CuCo)Se nanoparticles embedded in nitrogen-doped carbon framework with boosted electrochemical performance for hybrid supercapacitor. Mater. Res. Bull. 2021, 137, 111196. [Google Scholar]

- Chen, W.; Wei, W.; Wang, K.; Zhang, N.; Chen, G.; Hu, Y.; Ostrikov, K.K. Plasma-engineered bifunctional cobalt-metal organic framework derivatives for high-performance complete water electrolysis. Nanoscale 2021, 13, 6201–6211. [Google Scholar]

- Lei, Z.; Tang, Q.; Ju, Y.; Lin, Y.; Bai, X.; Luo, H.; Tong, Z. Block copolymer@ZIF-8 nanocomposites as a pH-responsive multi-steps release system for controlled drug delivery. J. Biomater. Sci. Polym. Ed. 2020, 31, 695–711. [Google Scholar]

- Li, G.; Cai, H.; Li, X.; Zhang, J.; Zhang, D.; Yang, Y.; Xiong, J. Construction of Hierarchical NiCo2O4@Ni-MOF Hybrid Arrays on Carbon Cloth as Superior Battery-Type Electrodes for Flexible Solid-State Hybrid Supercapacitors. ACS Appl. Mater. Inter. 2019, 11, 37675–37684. [Google Scholar]

- Phan, A.; Doonan, C.J.; Uribe-Romo, F.J.; Knobler, C.B.; O’Keeffe, M.; Yaghi, O.M. Synthesis, structure, and carbon dioxide capture properties of zeolitic imidazolate frameworks. Acc. Chem. Res. 2010, 43, 58–67. [Google Scholar]

- Wang, X.-S.; Chen, C.-H.; Ichihara, F.; Oshikiri, M.; Liang, J.; Li, L.; Li, Y.; Song, H.; Wang, S.; Zhang, T.; et al. Integration of adsorption and photosensitivity capabilities into a cationic multivariate metal-organic framework for enhanced visible-light photoreduction reaction. Appl. Catal. B Environ. 2019, 253, 323–330. [Google Scholar] [CrossRef]

- Cavka, J.H.; Jakobsen, S.; Olsbye, U.; Guillou, N.; Lamberti, C.; Bordiga, S.; Lillerud, K.P. A new zirconium inorganic building brick forming metal organic frameworks with exceptional stability. J. Am. Chem. Soc. 2008, 130, 13850–13851. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Xu, H.; Gao, J.; Du, W.; Shangguan, L.; Zhang, X.; Lin, R.-B.; Wu, H.; Zhou, W.; Liu, X.; et al. Tunable titanium metal–organic frameworks with infinite 1D Ti–O rods for efficient visible-light-driven photocatalytic H2 evolution. J. Mater. Chem. A 2019, 7, 11928–11933. [Google Scholar]

- Chen, C.-H.; Wang, X.-S.; Li, L.; Huang, Y.-B.; Cao, R. Highly selective sensing of Fe(3+) by an anionic metal-organic framework containing uncoordinated nitrogen and carboxylate oxygen sites. Dalton Trans. 2018, 47, 3452–3458. [Google Scholar] [PubMed]

- Wang, X.-S.; Li, L.; Yuan, D.-Q.; Huang, Y.-B.; Cao, R. Fast, highly selective and sensitive anionic metal-organic framework with nitrogen-rich sites fluorescent chemosensor for nitro explosives detection. J. Hazard. Mater. 2017, 344, 283–290. [Google Scholar]

- Wang, X.-S.; Liang, J.; Li, L.; Lin, Z.-J.; Bag, P.P.; Gao, S.-Y.; Huang, Y.-B.; Cao, R. An Anion Metal-Organic Framework with Lewis Basic Sites-Rich toward Charge-Exclusive Cationic Dyes Separation and Size-Selective Catalytic Reaction. Inorg. Chem. 2016, 55, 2641–2649. [Google Scholar]

- Gao, J.; Cai, Y.; Qian, X.; Liu, P.; Wu, H.; Zhou, W.; Liu, D.X.; Li, L.; Lin, R.B.; Chen, B. A Microporous Hydrogen-Bonded Organic Framework for the Efficient Capture and Purification of Propylene. Angew. Chem. Int. Ed. 2021, 60, 20400–20406. [Google Scholar] [CrossRef]

- Gao, J.; Qian, X.; Lin, R.B.; Krishna, R.; Wu, H.; Zhou, W.; Chen, B. Mixed Metal-Organic Framework with Multiple Binding Sites for Efficient C2H2/CO2 Separation. Angew. Chem. Int. Ed. 2020, 59, 4396–4400. [Google Scholar]

- Mohanty, A.; Singh, U.P.; Butcher, R.J.; Das, N.; Roy, P. Synthesis of fluorescent MOFs: Live-Cell imaging and sensing of a herbicide. CrystEngComm 2020, 22, 4468–4477. [Google Scholar]

- Xu, K.; Zhan, C.; Zhao, W.; Yu, X.; Zhu, Q.; Yang, L. Tunable resistance of MOFs films via an anion exchange strategy for advanced gas sensing. J. Hazard. Mater. 2021, 416, 125906. [Google Scholar]

- Xu, H.; Gao, J.; Qian, X.; Wang, J.; He, H.; Cui, Y.; Yang, Y.; Wang, Z.; Qian, G. Metal–organic framework nanosheets for fast-response and highly sensitive luminescent sensing of Fe3+. J. Mater. Chem. A 2016, 4, 10900–10905. [Google Scholar] [CrossRef]

- Deng, Z.; Zhang, H.; Yuan, P.; Su, Z.; Bai, Y.; Yin, Z.; He, J. Cobalt-Based Metal-Organic Framework Nanoparticles with Peroxidase-like Catalytic Activity for Sensitive Colorimetric Detection of Phosphate. Catalysts 2022, 12, 679. [Google Scholar] [CrossRef]

- Montoro, C.; Ocon, P.; Zamora, F.; Navarro, J.A. Metal-Organic Frameworks Containing Missing-Linker Defects Leading to High Hydroxide-Ion Conductivity. Chem. Eur. J. 2016, 22, 1646–1651. [Google Scholar] [CrossRef]

- Ren, X.; Liao, G.; Li, Z.; Qiao, H.; Zhang, Y.; Yu, X.; Wang, B.; Tan, H.; Shi, L.; Qi, X.; et al. Two-dimensional MOF and COF nanosheets for next-generation optoelectronic applications. Coord. Chem. Rev. 2021, 435, 213781. [Google Scholar] [CrossRef]

- Jiang, X.L.; Jiao, Y.E.; Hou, S.L.; Geng, L.C.; Wang, H.Z.; Zhao, B. Green Conversion of CO2 and Propargylamines Triggered by Triply Synergistic Catalytic Effects in Metal-Organic Frameworks. Angew. Chem. Int. Ed. 2021, 60, 20417–20423. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-S.; Li, L.; Liang, J.; Huang, Y.-B.; Cao, R. Boosting Oxidative Desulfurization of Model and Real Gasoline over Phosphotungstic Acid Encapsulated in Metal-Organic Frameworks: The Window Size Matters. ChemCatChem 2017, 9, 971–979. [Google Scholar] [CrossRef]

- Wang, X.-S.; Huang, Y.-B.; Lin, Z.-J.; Cao, R. Phosphotungstic acid encapsulated in the mesocages of amine-functionalized metal-organic frameworks for catalytic oxidative desulfurization. Dalton Trans. 2014, 43, 11950–11958. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Chen, G.; Chen, J.; Niu, H. Excellent Catalytic Performance of Ce–MOF with Abundant Oxygen Vacancies Supported Noble Metal Pt in the Oxidation of Toluene. Catalysts 2022, 12, 775. [Google Scholar] [CrossRef]

- Panda, J.; Biswal, S.P.; Jena, H.S.; Mitra, A.; Samantray, R.; Sahu, R. Role of Lewis Acid Metal Centers in Metal–Organic Frameworks for Ultrafast Reduction of 4-Nitrophenol. Catalysts 2022, 12, 494. [Google Scholar] [CrossRef]

- Wang, B.; Wang, X.; Yong, J.Y.; Song, Z.R.; Chen, J.Z.; Wang, X.S.; Gao, J.K. Hofmann-type Metal-Organic Framework Based Bimetal/Carbon Nanosheets for Efficient Electrocatalytic Oxygen Evolution. Z. Anorg. Allg. Chem. 2022, 648, 12–17. [Google Scholar] [CrossRef]

- Khan, U.; Nairan, A.; Gao, J.; Zhang, Q. Current Progress in Two-Dimensional Metal-Organic Frameworks for Electrocatalysis. Small Struct. 2022. [Google Scholar] [CrossRef]

- Bag, P.P.; Wang, X.-S.; Sahoo, P.; Xiong, J.; Cao, R. Efficient photocatalytic hydrogen evolution under visible light by ternary composite CdS@NU-1000/RGO. Catal. Sci. Technol. 2017, 7, 5113–5119. [Google Scholar] [CrossRef]

- Wang, X.; Yang, X.; Chen, C.; Li, H.; Huang, Y.; Cao, R. Graphene Quantum Dots Supported on Fe-based Metal-Organic Frameworks for Efficient Photocatalytic CO2 Reduction. Acta Chim. Sinica 2022, 80, 22–28. [Google Scholar] [CrossRef]

- Hu, N.; Cai, Y.; Li, L.; Wang, X.; Gao, J. Amino-Functionalized Titanium Based Metal-Organic Framework for Photocatalytic Hydrogen Production. Molecules 2022, 27, 4241. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Huang, Q.; Wu, Y.; Lan, Y.-Q.; Chen, B. Metal–Organic Frameworks for Photo/Electrocatalysis. Adv. Energy Sustain. Res. 2021, 2, 2100033. [Google Scholar] [CrossRef]

- Yan, Y.; Abazari, R.; Yao, J.; Gao, J. Recent strategies to improve the photoactivity of metal-organic frameworks. Dalton Trans. 2021, 50, 2342–2349. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.S.; Liu, T.F.; Ye, J. Titanium-Based MOF Materials: From Crystal Engineering to Photocatalysis. Small Methods 2020, 4, 2000486. [Google Scholar] [CrossRef]

- Wang, X.S.; Li, L.; Li, D.; Ye, J. Recent Progress on Exploring Stable Metal–Organic Frameworks for Photocatalytic Solar Fuel Production. Sol. RRL 2020, 4, 1900547. [Google Scholar] [CrossRef]

- Zhao, Y.; Shi, R.; Bian, X.; Zhou, C.; Zhao, Y.; Zhang, S.; Wu, F.; Waterhouse, G.I.N.; Wu, L.Z.; Tung, C.H.; et al. Ammonia Detection Methods in Photocatalytic and Electrocatalytic Experiments: How to Improve the Reliability of NH3 Production Rates? Adv. Sci. 2019, 6, 1802109. [Google Scholar] [CrossRef]

- Ivancic, I. An optimal manual procedure for ammonia analysis in natural waters by the indophenol blue method. Water Res. 1984, 18, 1143–1147. [Google Scholar] [CrossRef]

- Verdouw, H.; Van Echteld, C.J.A.; Dekkers, E.M.J. Ammonia determination based on indophenol formation with sodium salicylate. Water Res. 1978, 12, 399–402. [Google Scholar] [CrossRef]

- Fritz, J.S. Ion chromatography. Anal. Chem. 1987, 59, 335A–344A. [Google Scholar] [CrossRef]

- Zhang, H.; Nai, J.; Yu, L.; Lou, X.W. Metal-Organic-Framework-Based Materials as Platforms for Renewable Energy and Environmental Applications. Joule 2017, 1, 77–107. [Google Scholar] [CrossRef]

- Ni, Z.; Masel, R.I. Rapid production of metal-organic frameworks via microwave-assisted solvothermal synthesis. J. Am. Chem. Soc. 2006, 128, 12394–12395. [Google Scholar] [CrossRef]

- Lin, J.B.; Lin, R.B.; Cheng, X.N.; Zhang, J.P.; Chen, X.M. Solvent/additive-free synthesis of porous/zeolitic metal azolate frameworks from metal oxide/hydroxide. Chem. Commun. 2011, 47, 9185–9187. [Google Scholar] [CrossRef]

- Stassen, I.; Styles, M.; Grenci, G.; Gorp, H.V.; Vanderlinden, W.; Feyter, S.D.; Falcaro, P.; Vos, D.D.; Vereecken, P.; Ameloot, R. Chemical vapour deposition of zeolitic imidazolate framework thin films. Nat. Mater. 2016, 15, 304–310. [Google Scholar] [CrossRef]

- Bermudez-Garcia, J.M.; Vicent-Luna, J.M.; Yanez-Vilar, S.; Hamad, S.; Sanchez-Andujar, M.; Castro-Garcia, S.; Calero, S.; Senaris-Rodriguez, M.A. Liquid self-diffusion of H2O and DMF molecules in Co-MOF-74: Molecular dynamics simulations and dielectric spectroscopy studies. Phys. Chem. Chem. Phys. 2016, 18, 19605–19612. [Google Scholar] [CrossRef]

- Xiao, J.-D.; Qiu, L.-G.; Ke, F.; Yuan, Y.-P.; Xu, G.-S.; Wang, Y.-M.; Jiang, X. Rapid synthesis of nanoscale terbium-based metal–organic frameworks by a combined ultrasound-vapour phase diffusion method for highly selective sensing of picric acid. J. Mater. Chem. A 2013, 1, 8745. [Google Scholar] [CrossRef]

- Ameloot, R.; Stappers, L.; Fransaer, J.; Alaerts, L.; Sels, B.F.; De Vos, D.E. Patterned Growth of Metal-Organic Framework Coatings by Electrochemical Synthesis. Chem. Mater. 2009, 21, 2580–2582. [Google Scholar] [CrossRef]

- Friscic, T.; Reid, D.G.; Halasz, I.; Stein, R.S.; Dinnebier, R.E.; Duer, M.J. Ion- and liquid-assisted grinding: Improved mechanochemical synthesis of metal-organic frameworks reveals salt inclusion and anion templating. Angew. Chem. Int. Ed. 2010, 49, 712–715. [Google Scholar] [CrossRef]

- Samal, M.; Panda, J.; Biswal, B.P.; Sahu, R. Kitchen grinder: A tool for the synthesis of metal–organic frameworks towards size selective dye adsorption. CrystEngComm 2018, 20, 2486–2490. [Google Scholar] [CrossRef]

- Huang, H.; Wang, X.-S.; Philo, D.; Ichihara, F.; Song, H.; Li, Y.; Li, D.; Qiu, T.; Wang, S.; Ye, J. Toward visible-light-assisted photocatalytic nitrogen fixation: A titanium metal organic framework with functionalized ligands. Appl. Catal. B Environ. 2020, 267, 118686. [Google Scholar] [CrossRef]

- Gao, W.; Li, X.; Zhang, X.; Su, S.; Luo, S.; Huang, R.; Jing, Y.; Luo, M. Photocatalytic nitrogen fixation of metal-organic frameworks (MOFs) excited by ultraviolet light: Insights into the nitrogen fixation mechanism of missing metal cluster or linker defects. Nanoscale 2021, 13, 7801–7809. [Google Scholar] [CrossRef] [PubMed]

- Guo, B.; Cheng, X.; Tang, Y.; Guo, W.; Deng, S.; Wu, L.; Fu, X. Dehydrated UiO-66(SH)2: The Zr-O Cluster and Its Photocatalytic Role Mimicking the Biological Nitrogen Fixation. Angew. Chem. Int. Ed. 2022, 61, e202117244. [Google Scholar]

- Li, G.; Li, F.; Liu, J.; Fan, C. Fe-based MOFs for photocatalytic N2 reduction: Key role of transition metal iron in nitrogen activation. J. Solid State Chem. 2020, 285, 121245. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, D.; Ren, H.; An, K.; Chen, Y.; Zhou, Z.; Wang, W.; Jiang, Z. Nitrogenase-inspired mixed-valence MIL-53(FeII/FeIII) for photocatalytic nitrogen fixation. Chem. Eng. J. 2020, 400, 125929. [Google Scholar] [CrossRef]

- Shang, S.; Xiong, W.; Yang, C.; Johannessen, B.; Liu, R.; Hsu, H.Y.; Gu, Q.; Leung, M.K.H.; Shang, J. Atomically Dispersed Iron Metal Site in a Porphyrin-Based Metal-Organic Framework for Photocatalytic Nitrogen Fixation. ACS nano 2021, 15, 9670–9678. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, Y.; Lv, C.; Zhou, X.; Wang, Y.; Xing, W.; Meng, Q.; Kong, Y.; Chen, G. Mimicking pi Backdonation in Ce-MOFs for Solar-Driven Ammonia Synthesis. ACS Appl. Mater. Inter. 2019, 11, 29917–29923. [Google Scholar] [CrossRef]

- Hu, K.Q.; Qiu, P.X.; Zeng, L.W.; Hu, S.X.; Mei, L.; An, S.W.; Huang, Z.W.; Kong, X.H.; Lan, J.H.; Yu, J.P.; et al. Solar-Driven Nitrogen Fixation Catalyzed by Stable Radical-Containing MOFs: Improved Efficiency Induced by a Structural Transformation. Angew. Chem. Int. Ed. 2020, 59, 20666–20671. [Google Scholar] [CrossRef]

- An, K.; Ren, H.; Yang, D.; Zhao, Z.; Gao, Y.; Chen, Y.; Tan, J.; Wang, W.; Jiang, Z. Nitrogenase-inspired bimetallic metal organic frameworks for visible-light-driven nitrogen fixation. Appl. Catal. B: Environ. 2021, 292, 120167. [Google Scholar] [CrossRef]

- An, K.; Tan, J.; Yang, D.; Ren, H.; Zhao, Z.; Chen, Y.; Wang, W.; Xin, X.; Shi, Y.; Jiang, Z. Modular assembly of electron transfer pathways in bimetallic MOFs for photocatalytic ammonia synthesis. Catal. Sci. Technol. 2022, 12, 2015–2022. [Google Scholar] [CrossRef]

- Li, X.H.; He, P.; Wang, T.; Zhang, X.W.; Chen, W.L.; Li, Y.G. Keggin-Type Polyoxometalate-Based ZIF-67 for Enhanced Photocatalytic Nitrogen Fixation. ChemSusChem 2020, 13, 2769–2778. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.W.; Hao, Y.C.; Guo, Y.; Zhang, Q.; Li, J.; Gao, W.Y.; Ren, L.; Su, X.; Hu, L.; Zhang, N.; et al. Metal-Organic Framework Membranes Encapsulating Gold Nanoparticles for Direct Plasmonic Photocatalytic Nitrogen Fixation. J. Am. Chem. Soc. 2021, 143, 5727–5736. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Wang, S.; Chang, X.; Wang, D.H.; Zhang, T. Nano-MOF@defected film C3N4 Z-scheme composite for visible-light photocatalytic nitrogen fixation. RSC Adv. 2020, 10, 26246–26255. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Li, M.; Yang, X.; Li, F.; Xu, L.; Zou, Y. Constructing oxygen vacancies and linker defects in MIL-125@TiO2 for efficient photocatalytic nitrogen fixation. J. Alloys Compd. 2022, 909, 164751. [Google Scholar] [CrossRef]

- Liu, S.; Teng, Z.; Liu, H.; Wang, T.; Wang, G.; Xu, Q.; Zhang, X.; Jiang, M.; Wang, C.; Huang, W.; et al. A Ce-UiO-66 Metal-Organic Framework-Based Graphene-Embedded Photocatalyst with Controllable Activation for Solar Ammonia Fertilizer Production. Angew. Chem. Int. Ed. 2022, 134, e202207026. [Google Scholar] [CrossRef]

- Qin, J.; Liu, B.; Lam, K.-H.; Song, S.; Li, X.; Hu, X. 0D/2D MXene Quantum Dot/Ni-MOF Ultrathin Nanosheets for Enhanced N2 Photoreduction. ACS Sustain. Chem. Eng. 2020, 8, 17791–17799. [Google Scholar] [CrossRef]

- Vu, M.-H.; Quach, T.-A.; Do, T.-O. The construction of Ru-doped In2O3 hollow peanut-like structure for an enhanced photocatalytic nitrogen reduction under solar light irradiation. Sustain. Energ. Fuels 2021, 5, 2528–2536. [Google Scholar] [CrossRef]

- Legare, M.A.; Belanger-Chabot, G.; Dewhurst, R.D.; Welz, E.; Krummenacher, I.; Engels, B.; Braunschweig, H. Nitrogen fixation and reduction at boron. Science 2018, 359, 896–900. [Google Scholar] [CrossRef]

- Wang, S.; Ichihara, F.; Pang, H.; Chen, H.; Ye, J. Nitrogen Fixation Reaction Derived from Nanostructured Catalytic Materials. Adv. Funct. Mater. 2018, 28, 1803309. [Google Scholar] [CrossRef]

- Horiuchi, Y.; Toyao, T.; Saito, M.; Mochizuki, K.; Iwata, M.; Higashimura, H.; Anpo, M.; Matsuoka, M. Visible-Light-Promoted Photocatalytic Hydrogen Production by Using an Amino-Functionalized Ti(IV) Metal–Organic Framework. J. Phys. Chem. C 2012, 116, 20848–20853. [Google Scholar] [CrossRef]

- Nasalevich, M.A.; Becker, R.; Ramos-Fernandez, E.V.; Castellanos, S.; Veber, S.L.; Fedin, M.V.; Kapteijn, F.; Reek, J.N.H.; van der Vlugt, J.I.; Gascon, J. Co@NH2-MIL-125(Ti): Cobaloxime-Derived metal–organic framework-based composite for light-driven H2 production. Energy Environ. Sci. 2015, 8, 364–375. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.D.; Han, L.; Luo, J.; Yu, S.H.; Jiang, H.L. Integration of Plasmonic Effects and Schottky Junctions into Metal-Organic Framework Composites: Steering Charge Flow for Enhanced Visible-Light Photocatalysis. Angew. Chem. Int. Ed. 2018, 57, 1103–1107. [Google Scholar] [CrossRef]

- Fu, Y.; Sun, D.; Chen, Y.; Huang, R.; Ding, Z.; Fu, X.; Li, Z. An amine-functionalized titanium metal-organic framework photocatalyst with visible-light-induced activity for CO2 reduction. Angew. Chem. Int. Ed. 2012, 51, 3364–3367. [Google Scholar] [CrossRef]

- Logan, M.W.; Ayad, S.; Adamson, J.D.; Dilbeck, T.; Hanson, K.; Uribe-Romo, F.J. Systematic variation of the optical bandgap in titanium based isoreticular metal–organic frameworks for photocatalytic reduction of CO2 under blue light. J. Mater. Chem. A 2017, 5, 11854–11863. [Google Scholar] [CrossRef]

- Abou-Elyazed, A.S.; Ye, G.; Sun, Y.; El-Nahas, A.M. A Series of UiO-66(Zr)-Structured Materials with Defects as Heterogeneous Catalysts for Biodiesel Production. Ind. Eng. Chem. Res. 2019, 58, 21961–21971. [Google Scholar] [CrossRef]

- Cho, K.Y.; Seo, J.Y.; Kim, H.-J.; Pai, S.J.; Do, X.H.; Yoon, H.G.; Hwang, S.S.; Han, S.S.; Baek, K.-Y. Facile control of defect site density and particle size of UiO-66 for enhanced hydrolysis rates: Insights into feasibility of Zr(IV)-based metal-organic framework (MOF) catalysts. Appl. Catal. B: Environ. 2019, 245, 635–647. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, Q.; Jiang, M.; Yao, J. Tailoring the Properties of UiO-66 through Defect Engineering: A Review. Ind. Eng. Chem. Res. 2019, 58, 17646–17659. [Google Scholar] [CrossRef]

- Burgess, B.K.; Lowe, D.J. Mechanism of Molybdenum Nitrogenase. Chem Rev 1996, 96, 2983–3012. [Google Scholar] [CrossRef]

- Smith, J.M.; Lachicotte, R.J.; Pittard, K.A.; Cundari, T.R.; Lukat-Rodgers, G.; Rodgers, K.R.; Holland, P.L. Stepwise reduction of dinitrogen bond order by a low-coordinate iron complex. J. Am. Chem. Soc. 2001, 123, 9222–9223. [Google Scholar] [CrossRef]

- Smith, J.M.; Sadique, A.R.; Cundari, T.R.; Rodgers, K.R.; Lukat-Rodgers, G.; Lachicotte, R.J.; Flaschenriem, C.J.; Vela, J.; Holland, P.L. Studies of low-coordinate iron dinitrogen complexes. J. Am. Chem. Soc. 2006, 128, 756–769. [Google Scholar] [CrossRef] [PubMed]

- Stoian, S.A.; Vela, J.; Smith, J.M.; Sadique, A.R.; Holland, P.L.; Munck, E.; Bominaar, E.L. Mossbauer and computational study of an N2-bridged diiron diketiminate complex: Parallel alignment of the iron spins by direct antiferromagnetic exchange with activated dinitrogen. J. Am. Chem. Soc. 2006, 128, 10181–10192. [Google Scholar] [CrossRef] [PubMed]

- Anderson, J.S.; Cutsail, G.E., 3rd; Rittle, J.; Connor, B.A.; Gunderson, W.A.; Zhang, L.; Hoffman, B.M.; Peters, J.C. Characterization of an Fe identical withN-NH2 Intermediate Relevant to Catalytic N2 Reduction to NH3. J. Am. Chem. Soc. 2015, 137, 7803–7809. [Google Scholar] [CrossRef]

- Ma, X.; Chen, F.; Zhang, X.; Wang, T.; Yuan, S.; Wang, X.; Li, T.; Gao, J. Hierarchical Co@C-N synthesized by the confined pyrolysis of ionic liquid@metal–organic frameworks for the aerobic oxidation of alcohols. New J. Chem. 2022, 46, 7528–7536. [Google Scholar] [CrossRef]

- Cheng, N.; Wang, N.; Ren, L.; Casillas-Garcia, G.; Liu, N.; Liu, Y.; Xu, X.; Hao, W.; Dou, S.X.; Du, Y. In-situ grafting of N-doped carbon nanotubes with Ni encapsulation onto MOF-derived hierarchical hybrids for efficient electrocatalytic hydrogen evolution. Carbon 2020, 163, 178–185. [Google Scholar] [CrossRef]

- Xu, K.; Zhao, W.; Yu, X.; Duan, S.; Zeng, W. MOF-derived Co3O4/Fe2O3 p-n hollow cubes for improved acetone sensing characteristics. Phys. E: Low-Dimens. Syst. Nanostructures 2020, 118, 113869. [Google Scholar] [CrossRef]

- Zhai, C.; Zhang, H.; Du, L.; Wang, D.; Xing, D.; Zhang, M. Nickel/iron-based bimetallic MOF-derived nickel ferrite materials for triethylamine sensing. CrystEngComm 2020, 22, 1286–1293. [Google Scholar] [CrossRef]

- Wang, C.; Mutahir, S.; Wang, L.; Lei, W.; Xia, X.; Jiao, X.; Hao, Q. Hierarchical MOF-derived layered Fe3O4 QDs@C imbedded on graphene sheets as a high-performance anode for Lithium-ion storage. Appl. Surf. Sci. 2020, 509, 144882. [Google Scholar] [CrossRef]

- Ren, X.; Wei, S.; Wang, Q.; Shi, L.; Wang, X.-S.; Wei, Y.; Yang, G.; Philo, D.; Ichihara, F.; Ye, J. Rational construction of dual cobalt active species encapsulated by ultrathin carbon matrix from MOF for boosting photocatalytic H2 generation. Appl. Catal. B: Environ. 2021, 286, 119924. [Google Scholar] [CrossRef]

- Melchionna, M.; Fornasiero, P. Updates on the Roadmap for Photocatalysis. ACS Catal. 2020, 10, 5493–5501. [Google Scholar] [CrossRef] [Green Version]

| Photocatalyst | Light Source | Sacrificial Agents | NH3 Yield | AQY/% | Ref. |

|---|---|---|---|---|---|

| Pure MOFs | |||||

| NH2-MIL-125 (Ti) | Xe Lamp (300 W, L40) | None | 12.25 μmolg−1 h−1 | 0.26 (400 nm) | [82] |

| OH-MIL-125 (Ti) | Xe Lamp (300 W, L40) | None | 5.04 μmolg−1 h−1 | / | [82] |

| CH3-MIL-125 (Ti) | Xe Lamp (300 W, L40) | None | 1.39 μmolg−1 h−1 | / | [82] |

| UiO-66-UV-Vis | Xe Lamp (300 W, UV-vis) | None | 256.60 μmolg−1 h−1 | / | [83] |

| UiO-66(SH)2-200 | Xe Lamp (300 W, L40) | None | 32.40 μmolg−1 h−1 | 0.45 (420 nm) | [84] |

| MIL-101(Fe) | Xe Lamp (300 W, full-spectrum) | None | 50.36 μmolg−1 h−1 | / | [85] |

| MIL-100(Fe) | Xe Lamp (300 W, full-spectrum) | None | 46.53 μmolg−1 h−1 | / | [85] |

| MIL-88(Fe) | Xe Lamp (300 W, full-spectrum) | None | 40.04 μmolg−1 h−1 | / | [85] |

| MIL-53(FeII/FeIII)-0.1 | Xe Lamp (300 W, L42) | K2SO3 | 306.00 μmolg−1 h−1 | 0.12 (420 nm) | [86] |

| Al–PMOF(Fe) | Xe Lamp (100 mWcm−2, L42) | CH3OH | 7.06 μmolg−1 h−1 | / | [87] |

| MOF-76(Ce) | Xe Lamp (300 W, full-spectrum) | None | 34.20 μmolg−1 h−1 | / | [88] |

| Gd-IHEP-8 | Xe Lamp (300 W, AM 1.5 G filter) | None | 220.00 μmolg−1 h−1 | 2.25 (365 nm) | [89] |

| Gd-IHEP-7 | Xe Lamp (300 W, AM 1.5 G filter) | None | 128.00 μmolg−1 h−1 | 1.72 (365 nm) | [89] |

| U(0.5Hf) | Xe Lamp (300 W, full-spectrum) | K2SO3 | 351.80 μmolg−1 h−1 | 0.1 (420 nm) | [90] |

| U(0.5Hf)-2SH | Xe Lamp (300 W, L42) | K2SO3 | 116.10 μmolg−1 h−1 | 0.55 (420 nm) | [90] |

| NU6(Ce–Hf) | Xe Lamp (300 W, full-spectrum) | K2SO3 | 158.4 μmolg−1 h−1 | 0.65 (380 nm) | [91] |

| MOF composites | |||||

| ZIF-67@PMO12 | Xe Lamp (300 W, full-spectrum) | C2H5OH | 39.40 μmolg−1 h−1 | / | [92] |

| ZIF-67@PMO11V | Xe Lamp (300 W, full-spectrum) | C2H5OH | 70.00 μmolg−1 h−1 | / | [92] |

| ZIF-67@PMO10V2 | Xe Lamp (300 W, full-spectrum) | C2H5OH | 74.80 μmolg−1 h−1 | / | [92] |

| ZIF-67@PMO9V3 | Xe Lamp (300 W, full-spectrum) | C2H5OH | 134.60 μmolg−1 h−1 | / | [92] |

| ZIF-67@PMO4V8 | Xe Lamp (300 W, full-spectrum) | C2H5OH | 149.00 μmolg−1 h−1 | / | [92] |

| Au@UiO-66 | Xe Lamp (300 W, L42) | None | 18.90 μmolg−1 h−1 | 1.54 (520 nm) | [93] |

| MOF-74@C3N4 | Xe Lamp (300 W, L40) | CH3OH | 330.00 μmolg−1 h−1 | / | [94] |

| MIL-125@TiO2 | Xe Lamp (300 W, 200 mWcm−2) | None | 102.70 μmolg−1 h−1 | / | [95] |

| GSCe (Graphene@Ce-UiO-66) | LED (6 W, 365 nm) | None | 110.24 μmolg−1 h−1 | 9.25 (365 nm) | [96] |

| 9MX-MOF | Xe Lamp (300 W, full-spectrum) | Na2SO3 | 88.79 μmolg−1 h−1 | / | [97] |

| MOF derivatives | |||||

| Ru–In2O3 HPNs | Xe Lamp (300 W, AM 1.5 G filter) | CH3OH | 44.50 μmolg−1 h−1 | / | [98] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, L.; Yu, Q.; Chen, J.; Khan, U.; Wang, X.; Gao, J. Achievements and Perspectives in Metal–Organic Framework-Based Materials for Photocatalytic Nitrogen Reduction. Catalysts 2022, 12, 1005. https://doi.org/10.3390/catal12091005

Fan L, Yu Q, Chen J, Khan U, Wang X, Gao J. Achievements and Perspectives in Metal–Organic Framework-Based Materials for Photocatalytic Nitrogen Reduction. Catalysts. 2022; 12(9):1005. https://doi.org/10.3390/catal12091005

Chicago/Turabian StyleFan, Linkun, Qin Yu, Jiazhen Chen, Usman Khan, Xusheng Wang, and Junkuo Gao. 2022. "Achievements and Perspectives in Metal–Organic Framework-Based Materials for Photocatalytic Nitrogen Reduction" Catalysts 12, no. 9: 1005. https://doi.org/10.3390/catal12091005

APA StyleFan, L., Yu, Q., Chen, J., Khan, U., Wang, X., & Gao, J. (2022). Achievements and Perspectives in Metal–Organic Framework-Based Materials for Photocatalytic Nitrogen Reduction. Catalysts, 12(9), 1005. https://doi.org/10.3390/catal12091005