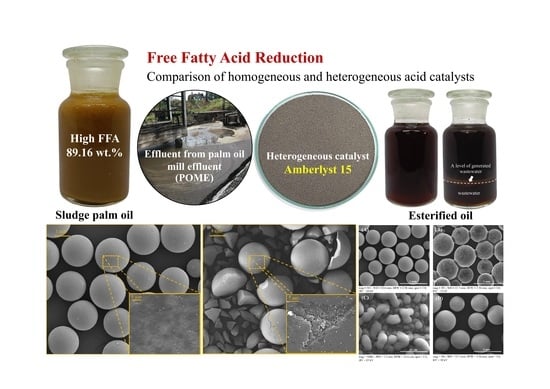

Reduction in Free Fatty Acid Concentration in Sludge Palm Oil Using Heterogeneous and Homogeneous Catalysis: Process Optimization, and Reusable Heterogeneous Catalysts

Abstract

:1. Introduction

2. Results and Discussion

2.1. Response Surface Methodology and Statistical Analyses

2.2. Response Surface Plots

2.3. Optimal Conditions for Reducing FFA Content in SPO

2.4. Reusability of Solid Acid Catalyst

3. Material and Methods

3.1. Materials

3.2. Procedure

3.2.1. Experimental Setup for Esterification

3.2.2. Recovery Method for Heterogeneous Catalysts

3.2.3. Surface Analysis of Amberlyst 15

3.3. Experimental Design

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karacan, R.; Mukhtarov, S.; Barış, İ.; İşleyen, A.; Yardımcı, M.E. The impact of oil price on transition toward renewable energy consumption? Evidence from Russia. Energies 2021, 14, 2947. [Google Scholar] [CrossRef]

- Sgouridis, S.; Csala, D.; Bardi, U. The sower’s way: Quantifying the narrowing net-energy pathways to a global energy transition. Environ. Res. Lett. 2016, 11, 094009. [Google Scholar] [CrossRef]

- Rivera-González, L.; Bolonio, D.; Mazadiego, L.F.; Naranjo-Silva, S.; Escobar-Segovia, K. Long-term forecast of energy and fuels demand towards a sustainable road transport sector in Ecuador (2016–2035): A leap model application. Sustainability 2020, 12, 472. [Google Scholar] [CrossRef]

- Noor, C.W.M.; Noor, M.M.; Mamat, R. Biodiesel as alternative fuel for marine diesel engine applications: A review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Shaah, M.A.H.; Hossain, M.S.; Allafi, F.A.S.; Alsaedi, A.; Ismail, N.; Ab Kadir, M.O.; Ahmad, M.I. A review on non-edible oil as a potential feedstock for biodiesel: Physicochemical properties and production technologies. RSC Adv. 2021, 11, 25018–25037. [Google Scholar] [CrossRef] [PubMed]

- Thailand Industry Outlook 2021–2023: Biodiesel. Available online: https://www.krungsri.com/getmedia/61faa668-cd22-4f7c-a923-11f60562864f/IO_Biodiesel_210520_EN_EX.pdf.aspx (accessed on 21 May 2022).

- Global Price of Palm Oil. 2022. Available online: https://fred.stlouisfed.org/series/PPOILUSDM/ (accessed on 17 May 2022).

- Muanruksa, P.; Kaewkannetra, P. Combination of fatty acids extraction and enzymatic esterification for biodiesel production using sludge palm oil as a low-cost substrate. Renew. Energy 2020, 146, 901–906. [Google Scholar] [CrossRef]

- Rachmadona, N.; Amoah, J.; Quayson, E.; Hama, S.; Yoshida, A.; Kondo, A.; Ogino, C. Lipase-catalyzed ethanolysis for biodiesel production of untreated palm oil mill effluent. Sustain. Energy Fuels 2020, 4, 1105–1111. [Google Scholar] [CrossRef]

- Poh, P.E.; Yong, W.J.; Chong, M.F. Palm oil mill effluent (POME) characteristic in high crop season and the applicability of high-rate anaerobic bioreactors for the treatment of POME. Ind. Eng. Chem. Res. 2010, 49, 11732–11740. [Google Scholar] [CrossRef]

- Igwe, J.C.; Onyegbado, C.C. A review of palm oil mill effluent (POME) water treatment. Glob. J. Environ. Res. 2007, 1, 54–62. [Google Scholar]

- Laohaprapanon, T.; Prasertsan, P. Screening of thermotolerant microorganisms and application for oil separation from palm oil mill wastewater. Songklanakarin J. Sci. Technol. 2007, 29, 801–808. [Google Scholar]

- Liew, W.L.; Kassim, M.A.; Muda, K.; Loh, S.K.; Affam, A.C. Conventional methods and emerging wastewater polishing technologies for palm oil mill effluent treatment: A review. J. Environ. Manag. 2015, 149, 222–235. [Google Scholar] [CrossRef] [PubMed]

- Esa, N.; Ibrahim, M.H.; Rupani, P.F.; Singh, R.P. Review of current palm oil mill effluent (POME) treatment methods: Vermicomposting as a sustainable practice. World Appl. Sci. J. 2010, 10, 1190–1201. [Google Scholar]

- Choi, W.H.; Shin, C.H.; Son, S.M.; Ghorpade, P.A.; Kim, J.J.; Park, J.Y. Anaerobic treatment of palm oil mill effluent using combined high-rate anaerobic reactors. Bioresour. Technol. 2013, 141, 138–144. [Google Scholar] [CrossRef] [PubMed]

- Low, S.S.; Bong, K.X.; Mubashir, M.; Cheng, C.K.; Lam, M.K.; Lim, J.W.; Ho, Y.C.; Lee, K.T.; Munawaroh, H.S.H.; Show, P.L. Microalgae cultivation in palm oil mill effluent (POME) treatment and biofuel production. Sustainability 2021, 13, 3247. [Google Scholar] [CrossRef]

- Igwe, J.C.; Onyegbado, C.O.; Abia, A.A. Adsorption isotherm studies of BOD, TSS and colour reduction from palm oil mill effluent (POME) using boiler fly ash. Eclet. Quím. 2010, 35, 195–208. [Google Scholar] [CrossRef]

- Poh, P.E.; Chong, M.F. Development of anaerobic digestion methods for palm oil mill effluent (POME) treatment. Bioresour. Technol. 2009, 100, 1–9. [Google Scholar] [CrossRef]

- Tabassum, S.; Zhang, Y.; Zhang, Z. An integrated method for palm oil mill effluent (POME) treatment for achieving zero liquid discharge—a pilot study. J. Clean. Prod. 2015, 95, 148–155. [Google Scholar] [CrossRef]

- Ohimain, E.I.; Izah, S.C. A review of biogas production from palm oil mill effluents using different configurations of bioreactors. Renew. Sustain. Energy Rev. 2017, 70, 242–253. [Google Scholar] [CrossRef]

- Kamarudin, K.F.; Yaakob, Z.; Sobri Takriff, M. A review on wastewater treatment and microalgal by-product production with a prospect of palm oil mill effluent (POME) utilization for algae. Pharma Chem. 2015, 7, 73–89. [Google Scholar]

- Demirbas, A.; Coban, V.; Taylan, O.; Kabli, M. Aerobic digestion of sewage sludge for waste treatment. Energy Sources A Recovery Util. Environ. Eff. 2017, 39, 1056–1062. [Google Scholar] [CrossRef]

- Adane, T.; Adugna, A.T.; Alemayehu, E. Textile industry effluent treatment techniques. J. Chem. 2021, 2021, 1–14. [Google Scholar] [CrossRef]

- Shete, B.S.; Shinkar, N.P. Anaerobic digestion of dairy industry waste water-biogas evolution-a review. Int. J. Appl. Environ. Sci. 2017, 12, 1117–1130. [Google Scholar]

- Al-Amshawee, S.K.; Yunus, M.Y.; Azoddein, A.A. A review on aerobic biological processes for palm oil mill effluent: Possible approaches. Mater. Sci. Eng. 2020, 736, 022035. [Google Scholar] [CrossRef]

- Okereke, J.N.; Ginikanwa, R.C. Environmental impact of palm oil mill effluent and its management through biotechnological approaches. Int. J. Adv. Res. Biol. Sci. 2020, 7, 117–127. [Google Scholar]

- Anwar, Z.; Irshad, M.; Fareed, I.; Saleem, A. Characterization and recycling of organic waste after co-composting—A review. J. Agric. Sci. 2015, 7, 68–79. [Google Scholar] [CrossRef]

- Kuchler, M. Sweet dreams (are made of cellulose): Sociotechnical imaginaries of second-generation bioenergy in the global debate. Ecol. Econ. 2014, 107, 431–437. [Google Scholar] [CrossRef] [Green Version]

- Nasaruddin, R.R.; Alam, M.Z.; Jami, M.S. Evaluation of solvent system for the enzymatic synthesis of ethanol-based biodiesel from sludge palm oil (SPO). Bioresour. Technol. 2014, 154, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Ricca, R.N.; Md, Z.A.; Mohammed, S.J. Enzymatic biodiesel production from sludge palm oil (SPO) using locally produced Candida cylindracea lipase. Afr. J. Biotechnol. 2013, 12, 4966–4974. [Google Scholar] [CrossRef]

- Hayyan, A.; Alam, M.Z.; Mirghani, M.E.S.; Kabbashi, N.A.; Hakimi, N.I.N.M.; Siran, Y.M.; Tahiruddin, S. Reduction of high content of free fatty acid in sludge palm oil via acid catalyst for biodiesel production. Fuel Process. Technol. 2011, 92, 920–924. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef]

- Kusdiana, D.; Saka, S. Effects of water on biodiesel fuel production by supercritical methanol treatment. Bioresour. Technol. 2004, 91, 289–295. [Google Scholar] [CrossRef]

- Su, C.-H. Recoverable and reusable hydrochloric acid used as a homogeneous catalyst for biodiesel production. Appl. Energy 2013, 104, 503–509. [Google Scholar] [CrossRef]

- Helwani, Z.; Othman, M.R.; Aziz, N.; Kim, J.; Fernando, W.J.N. Solid heterogeneous catalysts for transesterification of triglycerides with methanol: A review. Appl. Catal. A Gen. 2009, 363, 1–10. [Google Scholar] [CrossRef]

- Helwani, Z.; Othman, M.R.; Aziz, N.; Fernando, W.J.N.; Kim, J. Technologies for production of biodiesel focusing on green catalytic techniques: A review. Fuel Process. Technol. 2009, 90, 1502–1514. [Google Scholar] [CrossRef]

- Talha, N.S.; Sulaiman, S. Overview of catalysts in biodiesel production. ARPN J. Eng. Appl. Sci. 2016, 11, 439–448. [Google Scholar]

- Boz, N.; Degirmenbasi, N.; Kalyon, D.M. Esterification and transesterification of waste cooking oil over Amberlyst 15 and modified Amberlyst 15 catalysts. Appl. Catal. B Environ. 2015, 165, 723–730. [Google Scholar] [CrossRef]

- Park, J.-Y.; Kim, D.-K.; Lee, J.-S. Esterification of free fatty acids using water-tolerable Amberlyst as a heterogeneous catalyst. Bioresour. Technol. 2010, 101, 62–65. [Google Scholar] [CrossRef]

- Shu, Q.; Gao, J.; Nawaz, Z.; Liao, Y.; Wang, D.; Wang, J. Synthesis of biodiesel from waste vegetable oil with large amounts of free fatty acids using a carbon-based solid acid catalyst. Appl. Energy 2010, 87, 2589–2596. [Google Scholar] [CrossRef]

- Calgaroto, C.; Calgaroto, S.; Mazutti, M.A.; de Oliveira, D.; Pergher, S.; De Oliveira, J.V. Production of biodiesel from soybean and Jatropha Curcas oils with KSF and amberlyst 15 catalysts in the presence of co-solvents. Sustain. Chem. Process. 2013, 1, 1–6. [Google Scholar] [CrossRef]

- Lawer-Yolar, G.; Dawson-Andoh, B.; Atta-Obeng, E. Synthesis of biodiesel from tall oil fatty acids by homogeneous and heterogeneous catalysis. Sustain. Chem. 2021, 2, 12. [Google Scholar] [CrossRef]

- Zhang, H.; Tian, F.; Xu, L.; Peng, R.; Li, Y.; Deng, J. Batch and continuous esterification for the direct synthesis of high qualified biodiesel from waste cooking oils (WCO) with Amberlyst-15/Poly (vinyl alcohol) membrane as a bifunctional catalyst. Chem. Eng. J. 2020, 388, 124214. [Google Scholar] [CrossRef]

- Somnuk, K.; Smithmaitrie, P.; Prateepchaikul, G. Optimization of continuous acid-catalyzed esterification for free fatty acids reduction in mixed crude palm oil using static mixer coupled with high-intensity ultrasonic irradiation. Energy Conv. Manag. 2013, 68, 193–199. [Google Scholar] [CrossRef]

- Oo, Y.M.; Prateepchaikul, G.; Somnuk, K. Continuous acid-catalyzed esterification using a 3D printed rotor-stator hydrodynamic cavitation reactor reduces free fatty acid content in mixed crude palm oil. Ultrason. Sonochem. 2021, 72, 105419. [Google Scholar]

- Chandane, V.S.; Rathod, A.P.; Wasewar, K.L.; Sonawane, S.S. Esterification of propionic acid with isopropyl alcohol over ion exchange resins: Optimization and kinetics. Korean J. Chem. Eng. 2017, 34, 249–258. [Google Scholar] [CrossRef]

- Pantoja, S.S.; Mescouto, V.A.D.; Costa, C.E.F.D.; Zamian, J.R.; Rocha Filho, G.N.D.; Nascimento, L.A.S.D. High-quality biodiesel production from buriti (Mauritia flexuosa) oil soapstock. Molecules 2019, 24, 94. [Google Scholar] [CrossRef]

- Zare, M.; Golmakani, M.T.; Sardarian, A. Green synthesis of banana flavor using different catalysts: A comparative study of different methods. Green Chem. Lett. Rev. 2020, 13, 82–91. [Google Scholar] [CrossRef]

- Abdullah, R.F.; Rashid, U.; Taufiq-Yap, Y.H.; Ibrahim, M.L.; Ngamcharussrivichai, C.; Azam, M. Synthesis of bifunctional nanocatalyst from waste palm kernel shell and its application for biodiesel production. RSC Adv. 2020, 10, 27183–27193. [Google Scholar] [CrossRef]

- Fan, G.; Liao, C.; Fang, T.; Luo, S.; Song, G. Amberlyst 15 as a new and reusable catalyst for the conversion of cellulose into cellulose acetate. Carbohydr. Polym. 2014, 112, 203–209. [Google Scholar] [CrossRef]

- Amberlyst 15 Hydrogen Form. Available online: https://www.sigmaaldrich.com/TH/en/product/sial/216380 (accessed on 3 January 2011).

- Siril, P.F.; Cross, H.E.; Brown, D.R. New polystyrene sulfonic acid resin catalysts with enhanced acidic and catalytic properties. J. Mol. Catal. A Chem. 2008, 279, 63–68. [Google Scholar] [CrossRef]

| Author | Process | Reaction | Type of Reactor | Raw Material | Type of Catalyst | Molar Ratio of MeOH to Oil | Temperature (°C) | Time (min) | FFA (wt.%) | Yield (%) | Ester (wt.%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Boz et al. [38] | Batch | Esterification and transesterification | Three-necked batch reactor (600 rpm) | Waste cooking oil | Amberlyst 15 = 3 wt.% | 12:1 | 65 | 540 | - | 78 ± 3.39 | - |

| Park et al. [39] | Batch | Esterification | Pressurized stainless-steel reactor (4 kgf/cm2) | Soybean oil | Amberlyst 15 = 20 wt.%, Amberlyst BD20 = 20 wt.% | 6:1 | 80 | 120 | 0.3 0.1 | - | - |

| Gao et al. [40] | Batch | Esterification and transesterification | Mechanical stirrer (240 rpm) | Waste vegetable oil | Carbon-based solid acid catalyst = 0.2 wt.% | 16.8:1 | 220 | 270 | 2.6 | - | - |

| Calgaroto et al. [41] | Batch | Transesterification | Jacketed reactor (300 rpm) | Soybean oil Jatropha curcas | Amberlyst 15 = 4.8 wt.% | 9:1 | 160 | 360 | - | - | 70 |

| Lawer-Yolar et al. [42] | Batch | Esterification | Bath reactor (800 rpm) | Tall oil fatty acid | Amberlyst BD20 = 23.4 wt.% H2SO4 = 0.5 wt.% | 20.8:1 15:1 | 80 55 | 282 60 | - | 90.24 96.76 | - |

| Zhang et al. [43] | Batch | Esterification | Three-necked batch reactor (360 rpm) | Waste cooking oil | Amberlyst 15/Poly = 25 g | 29:1 | 65 | 480 | - | - | 98 |

| In this study | Batch | Esterification | Five-necked batch reactor (300 rpm) | SPO | Amberlyst 15 = 41.2 wt.% H2SO4 = 20.4 wt.% | 5.3:1 7.3:1 | 60 60 | 527 121 | 0.59 0.31 | 92.5 92.5 | 88.9 87.5 |

| Heterogeneous Catalytic Reaction | Homogeneous Catalytic Reaction | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Run | M1 (wt.%) | T1 (min) | C1 (wt.%) | FFA1 (wt.%) | Error | M2 (wt.%) | T2 (min) | C2 (wt.%) | FFA2 (wt.%) | Error | ||

| Actual | Predicted | Actual | Predicted | |||||||||

| 1 | 26.5 | 360.0 | 40.0 | 1.61 | 1.62 | −0.01 | 9.5 | 80.0 | 18.0 | 8.09 | 7.95 | 0.14 |

| 2 | 34.0 | 253.0 | 37.0 | 1.99 | 2.12 | −0.13 | 30.0 | 40.0 | 9.0 | 5.68 | 5.73 | −0.05 |

| 3 | 34.0 | 253.0 | 43.0 | 1.51 | 1.45 | 0.06 | 30.0 | 40.0 | 27.0 | 4.67 | 4.73 | −0.06 |

| 4 | 34.0 | 467.0 | 37.0 | 1.39 | 1.35 | 0.04 | 30.0 | 120.0 | 9.0 | 4.25 | 4.38 | −0.13 |

| 5 | 34.0 | 467.0 | 43.0 | 1.04 | 0.98 | 0.06 | 30.0 | 120.0 | 27.0 | 3.76 | 3.84 | −0.08 |

| 6 | 45.0 | 180.0 | 40.0 | 1.59 | 1.60 | −0.01 | 60.0 | 12.0 | 18.0 | 1.73 | 1.72 | 0.01 |

| 7 | 45.0 | 360.0 | 35.0 | 1.78 | 1.76 | 0.02 | 60.0 | 80.0 | 3.0 | 3.06 | 2.88 | 0.18 |

| 8 | 45.0 | 360.0 | 40.0 | 0.81 | 0.83 | −0.02 | 60.0 | 80.0 | 18.0 | 0.79 | 0.84 | −0.05 |

| 9 | 45.0 | 360.0 | 40.0 | 0.81 | 0.83 | −0.02 | 60.0 | 80.0 | 18.0 | 0.84 | 0.84 | 0.00 |

| 10 | 45.0 | 360.0 | 40.0 | 0.84 | 0.83 | 0.01 | 60.0 | 80.0 | 18.0 | 0.72 | 0.84 | −0.12 |

| 11 | 45.0 | 360.0 | 40.0 | 0.86 | 0.83 | 0.03 | 60.0 | 80.0 | 18.0 | 0.97 | 0.84 | 0.13 |

| 12 | 45.0 | 360.0 | 45.0 | 0.83 | 0.89 | −0.06 | 60.0 | 80.0 | 33.0 | 1.55 | 1.60 | −0.05 |

| 13 | 45.0 | 540.0 | 40.0 | 0.53 | 0.56 | −0.03 | 60.0 | 147.0 | 18.0 | 0.66 | 0.53 | 0.13 |

| 14 | 56.0 | 253.0 | 37.0 | 1.74 | 1.62 | 0.12 | 90.0 | 40.0 | 9.0 | 1.67 | 1.77 | −0.10 |

| 15 | 56.0 | 253.0 | 43.0 | 0.95 | 0.95 | 0.00 | 90.0 | 40.0 | 27.0 | 0.89 | 0.77 | 0.12 |

| 16 | 56.0 | 467.0 | 37.0 | 0.81 | 0.85 | −0.04 | 90.0 | 120.0 | 9.0 | 1.15 | 1.26 | −0.11 |

| 17 | 56.0 | 467.0 | 43.0 | 0.49 | 0.48 | 0.01 | 90.0 | 120.0 | 27.0 | 0.76 | 0.72 | 0.04 |

| 18 | 63.5 | 360.0 | 40.0 | 0.74 | 0.78 | −0.04 | 110.5 | 80.0 | 18.0 | 1.98 | 1.99 | −0.01 |

| Coefficient | Heterogeneous Catalytic Reaction | Homogeneous Catalytic Reaction | ||

|---|---|---|---|---|

| Value | p-Value | Value | p-Value | |

| β0 | 44.25 | 0.000000416494 | 15.394 | 0.000000000028 |

| β1 | −0.120 | 0.000011340215 | −0.267 | 0.000000000010 |

| β2 | −0.01789 | 0.000336667489 | −0.035 | 0.000091321525 |

| β3 | −1.738 | 0.000002087457 | −0.292 | 0.000000221153 |

| β4 | 0.00108 | 0.000064101016 | 0.0016 | 0.000000000033 |

| β5 | 0.00000784 | 0.001120651665 | 0.00018 | 0.001929026774 |

| β6 | 0.000234 | 0.013343148245 | 0.000063 | 0.028016097916 |

| β7 | 0.01959 | 0.000004718638 | 0.000316 | 0.044971587777 |

| β8 | - | - | 0.006228 | 0.000000446349 |

| β9 | - | - | - | - |

| R2 | 0.987 | 0.998 | ||

| R2adjusted | 0.977 | 0.996 | ||

| Heterogeneous Catalytic Reaction | |||||

|---|---|---|---|---|---|

| Source | SS | MS | F0 | Fcritical | DOF |

| Regression | 3.655 | 0.522 | 104.42 | 3.135 (F0.05,7,10) | 7 |

| Residual | 0.050 | 0.00500 | - | - | 10 |

| LOF Error | 0.048 | 0.00689 | 11.476 | 0.035 | 7 |

| Pure Error | 0.002 | 0.00060 | - | - | 3 |

| Total | 3.705 | - | - | - | 17 |

| Homogeneous Catalytic Reaction | |||||

| Source | SS | MS | F0 | Fcritical | DOF |

| Regression | 75.16 | 9.395 | 491.42 | 3.230 (F0.05,8,9) | 8 |

| Residual | 0.172 | 0.01912 | - | - | 9 |

| LOF Error | 0.139 | 0.02311 | 2.0757 | 0.293 | 6 |

| Pure Error | 0.033 | 0.01113 | - | - | 3 |

| Total | 75.33 | - | - | - | 17 |

| Condition, Compositions, Density, Yield, and Residual Methanol | SPO | Esterified Oil Using Amberlyst 15 | Esterified Oil Using Sulfuric Acid | ||

|---|---|---|---|---|---|

| Optimum b | Recommend c | Optimum b | Recommend c | ||

| Condition | |||||

| Methanol (wt.%) | 55.51 | 44.66 | 75.97 | 58.35 | |

| Reaction time (min) | 527.3 | 360.0 | 120.9 | 79.70 | |

| Acid catalyst (wt.%) | 41.21 | 38.57 | 20.37 | 16.81 | |

| Predicted FFA (wt.%) | 0.41 | 1.00 | 0.14 | 1.00 | |

| Composition | |||||

| Free fatty acid (wt.%) | 89.16 | 0.59 | 1.26 | 0.31 | 1.03 |

| Methyl ester (wt.%) | - | 88.94 | 88.20 | 87.48 | 86.93 |

| Triglyceride (wt.%) | 9.79 | 6.24 | 6.62 | 9.30 | 9.42 |

| Diglyceride (wt.%) | 0.80 | 3.50 | 3.33 | 2.46 | 2.22 |

| Monoglyceride (wt.%) | 0.24 | 0.72 | 0.58 | 0.45 | 0.40 |

| Density at 60 °C (kg/L) | 0.865 | 0.850 | 0.851 | 0.850 | 0.851 |

| Viscosity (cSt) | 3.89 d | 5.72 e | 5.70 e | 5.36 e | 5.46 e |

| Cloud point (°C) | 12.0 | 13.0 | 12.0 | 12.0 | |

| Pour point (°C) | 9.0 | 10.0 | 8.0 | 8.0 | |

| Yield a | |||||

| Esterified oil (wt.%) | 92.5 | 89.9 | 92.5 | 90.5 | |

| Residual methanol | |||||

| Esterified oil (wt.%) | 13.9 | 10.8 | 5.17 | 4.15 | |

| Generated wastewater (wt.%) | - | - | 63.33 | 61.05 | |

| Properties | Details |

|---|---|

| Form | Beans |

| Quality | Wet |

| Parameter | 120 °C maximum temperature |

| Moisture | ≤1.6% |

| Matrix | Styrene-divinylbenzene (macroreticular) |

| Matrix active group | Sulfonic acid functional group |

| Particle size | <300 μm |

| Operating pH | 0–14 |

| Capacity | 1.7 meq/mL by wetted bed volume |

| Separation technique | 4.7 meq/g by dry weight |

| Cation exchange |

| Independent Variable | Symbol | Unit | Level of Independent Variable | ||||

|---|---|---|---|---|---|---|---|

| −1.682 | −1 | 0 | +1 | +1.682 | |||

| Heterogeneous catalytic reaction | |||||||

| Methanol | M1 | wt.% | 26.5 | 34.0 | 45.0 | 56.0 | 63.5 |

| Reaction time | T1 | min | 180.0 | 253.0 | 360.0 | 467.0 | 540.0 |

| Amberlyst 15 | C1 | wt.% | 35.0 | 37.0 | 40.0 | 43.0 | 45.0 |

| Homogeneous catalytic reaction | |||||||

| Methanol | M2 | wt.% | 9.50 | 30.0 | 60.0 | 90.0 | 110.5 |

| Reaction time | T2 | min | 12.0 | 40.0 | 80.0 | 120.0 | 147.0 |

| Sulfuric acid | C2 | wt.% | 3.00 | 9.0 | 18.0 | 27.0 | 33.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juera-Ong, P.; Pongraktham, K.; Oo, Y.M.; Somnuk, K. Reduction in Free Fatty Acid Concentration in Sludge Palm Oil Using Heterogeneous and Homogeneous Catalysis: Process Optimization, and Reusable Heterogeneous Catalysts. Catalysts 2022, 12, 1007. https://doi.org/10.3390/catal12091007

Juera-Ong P, Pongraktham K, Oo YM, Somnuk K. Reduction in Free Fatty Acid Concentration in Sludge Palm Oil Using Heterogeneous and Homogeneous Catalysis: Process Optimization, and Reusable Heterogeneous Catalysts. Catalysts. 2022; 12(9):1007. https://doi.org/10.3390/catal12091007

Chicago/Turabian StyleJuera-Ong, Panupong, Kritsakon Pongraktham, Ye Min Oo, and Krit Somnuk. 2022. "Reduction in Free Fatty Acid Concentration in Sludge Palm Oil Using Heterogeneous and Homogeneous Catalysis: Process Optimization, and Reusable Heterogeneous Catalysts" Catalysts 12, no. 9: 1007. https://doi.org/10.3390/catal12091007

APA StyleJuera-Ong, P., Pongraktham, K., Oo, Y. M., & Somnuk, K. (2022). Reduction in Free Fatty Acid Concentration in Sludge Palm Oil Using Heterogeneous and Homogeneous Catalysis: Process Optimization, and Reusable Heterogeneous Catalysts. Catalysts, 12(9), 1007. https://doi.org/10.3390/catal12091007