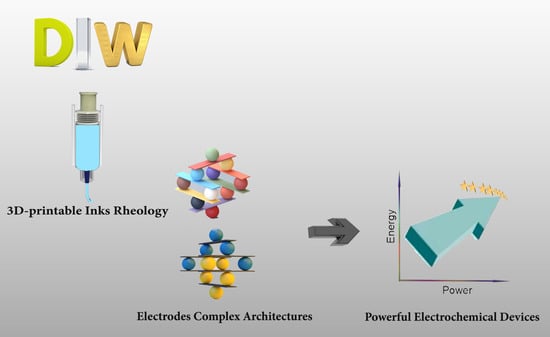

Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology

Abstract

:1. Introduction

2. Rheology of 3D-Printable Inks

2.1. Rheological Properties

2.2. An Overview of the Literature on 3D-Printable Inks’ Rheological Properties for Electrochemical Devices

| Catalyst/Electrochemical Device | Storage Modulus, G′ (Pa) | Yield Stress (τy) from Plot of G′ and G″ vs. τ | Herschel–Bulkley Parameters | 3iTT or G′(t), G″(t) | Rheometer | Reference | |||

|---|---|---|---|---|---|---|---|---|---|

| το (Pa) | k (Pa∙sn) | n | |||||||

| Value | Evaluation Method | ||||||||

| GO suspensions-general | ~2 × 104–3 × 105 | 20~400 | LVE | - | - | Rotational | [33] | ||

| Printability maps of complex fluids | 9 × 103–9 × 104 | 270–840 | cross-over | - | - | [36] | |||

| PEDOT:PSS conductive polymer mesh micro-structures | ~1.5 × 103–3 × 103 | ~150 | cross-over | - | - | [54] | |||

| Hydrogel formulations | ~105 | 343 | cross-over | 215 | 150 | 0.09 | Multi-iTT | Parallel-plate | [60] |

| Supported electrode architectures | |||||||||

| LiNi0.815Co0.15Al0.035O2 (NCA)/Li-based batteries | ~2 × 104–105 | ~100–1000 | cross-over | - | - | Rotational | [53] | ||

| PEDOT:PSS-based MXene inks/Micro-supercapacitors | ~2 × 104 | - | 24 | 1.07 | 0.73 | - | Parallel-plate, cone-and-plate | [57] | |

| NiO-YSZ/Solid oxide fuel cell | - | - | 224.11 | 150.05 | 0.46 | - | Double-coaxial cylinder | [59] | |

| Li|Cu@LATP@Cu|Li (CU-3D-printed scaffold)/Li-battery | ~105–7 × 105 | - | 741–1502 | 456–1358 | 0.15–0.29 | - | Parallel-plate | [56] | |

| LiFePO4-PEDOT:PSS/Li-battery | ~6 × 103 | ~1000 | Cross-over | - | - | Rotational | [63] | ||

| PEDOT:PSS/MXene/micro-supercapacitor electrode | ~104 | - | - | - | Multi-iTT | Parallel-plate | [30] | ||

| Free-standing electrode architectures | |||||||||

| Zn/rechargeable alkaline battery anode | ~104–105 | 30~100 | G′ 90% of LVE plateau | - | G′(t), G″(t) | Rotational | [31] | ||

| Supercapacitor | ~2 × 105 | 1700 | Sharp drop iin G′ | - | - | Rotational | [52] | ||

| Graphene/PEDOT:PSS/supercapacitors | ~700–9 × 103 | 20~200 | Cross-over | - | - | Rotational | [55] | ||

| Graphene oxide/micro-supercapacitor | ~2 × 104 | - | 91.5 | 39.75 | 0.421 | 3iTT | Parallel-plate | [58] | |

| Graphene pristine/micro-supercapacitor | ~105 | 58 | Cross-over | 491 | 94.82 | 0.43 | 3iTT, G′(t) | Parallel-plate | [61] |

| MXene/micro-supercapacitor | ~2 × 105 | 80 | LVE | 271 | 5.25 | 0.71 | 3iTT | Parallel-plate | [62] |

| 274 | Cross-over | ||||||||

| rGO/CNT aerogel/quasi-solid state nickel-iron battery | 6 × 103 | 100 | - | - | - | Rotational | [64] | ||

| MXene/supercapacitors | 3.65 × 104 | 206 | Cross-over | - | 3iTT | [65] | |||

| MXene/supercapacitor | 5.1 × 103 | 191.56 | Cross-over | - | 3iTT | [66] | |||

| Reduced graphene oxide (rGO)-Super-P aerogel/Vanadium redox flow battery | ~7 × 104 | 689 | Cross-over | - | - | [67] | |||

| E-ReSe2@INC/hybrid-(Na+) capacitor | ~2 × 104 | ~250 | Cross-over | - | - | [68] | |||

| NiCo2O4 nanosheets (not in the ink)/pseudo-capacitive electrode | ~104 | ~200 | Cross-over | - | - | [69] | |||

3. Ink Synthesis Strategies for 3D Printing via DIW, Electrode Structures, and Electrochemical Performance

3.1. Printable Inks for Supported Electrode Architectures

3.1.1. PVdF and Other Polymer-Based Inks

3.1.2. MXene-Based Inks

3.1.3. Ceramic-Based Inks

3.2. Printable Inks for Free-Standing Electrode Architectures

3.2.1. Hybrid Polymer-Based Inks

3.2.2. MXene-Based Inks

3.2.3. Graphene- and Graphene Oxide-Based Inks

3.2.4. Aqueous-Based (Capillary) Inks

4. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shah, S.S.; Najam, T.; Brouzgou, A.; Tsiakaras, P. Alkaline Oxygen Electrocatalysis for Fuel Cells and Metal–Air Batteries. Encycl. Electrochem. Online 2007, 9, 1–28. [Google Scholar]

- Medvedev, D.; Brouzgou, A.; Demin, A.; Tsiakaras, P. Proton-conducting electrolytes for solid oxide fuel cell applications. In Advances in Medium and High Temperature Solid Oxide Fuel Cell Technology; Springer: Cham, Switzerland, 2017; Volume 574, pp. 77–118. [Google Scholar]

- Brouzgou, A.; Demin, A.; Tsiakaras, P. Interconnects for Solid Oxide Fuel Cells. Advances in Medium and High Temperature Solid Oxide Fuel Cell Technology; Springer: Cham, Switzerland, 2017; pp. 119–153. [Google Scholar]

- Vignesh, M.; Ranjith Kumar, G.; Sathishkumar, M.; Manikandan, M.; Rajyalakshmi, G.; Ramanujam, R.; Arivazhagan, N. Development of biomedical implants through additive manufacturing: A review. J. Mater. Eng. Perform. 2021, 30, 4735–4744. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D.; Fuh, J.Y.; Hong, G.S. An overview of 3D printing technologies for food fabrication. Food Bioprocess Technol. 2015, 8, 1605–1615. [Google Scholar] [CrossRef]

- Ambrosi, A.; Pumera, M. 3D-printing technologies for electrochemical applications. Chem. Soc. Rev. 2016, 45, 2740–2755. [Google Scholar] [CrossRef]

- Das, A.; Gilmer, E.L.; Biria, S.; Bortner, M.J. Importance of polymer rheology on material extrusion additive manufacturing: Correlating process physics to print properties. ACS Appl. Polym. Mater. 2021, 3, 1218–1249. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y. Vat-Photopolymerization-based ceramic manufacturing. J. Mater. Eng. Perform. 2021, 30, 4819–4836. [Google Scholar] [CrossRef]

- Hossain, S.S.; Lu, K. Recent progress of alumina ceramics by direct ink writing: Ink design, printing and post-processing. Ceram. Int. 2023, 49, 10199–10212. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- a Baer, T.; Cesarano, J., III; Calvert, P.; Cesarano, J.; Baer, T.A.; Calvert, P. Recent developments in freeform fabrication of dense ceramics from slurry deposition. In Proceedings of the 1997 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 11–13 August 1997. [Google Scholar]

- Smay, J.E.; Nadkarni, S.S.; Xu, J. Direct Writing of Dielectric Ceramics and Base Metal Electrodes. Int. J. Appl. Ceram. Technol. 2007, 4, 47–52. [Google Scholar] [CrossRef]

- Sun, K.; Wei, T.-S.; Ahn, B.Y.; Seo, J.Y.; Dillon, S.J.; Lewis, J.A. 3D Printing of Interdigitated Li-Ion Microbattery Architectures. Adv. Mater. 2013, 25, 4539–4543. [Google Scholar] [CrossRef]

- Lamnini, S.; Elsayed, H.; Lakhdar, Y.; Baino, F.; Smeacetto, F.; Bernardo, E. Robocasting of advanced ceramics: Ink optimization and protocol to predict the printing parameters—A review. Heliyon 2022, 8, e10651. [Google Scholar] [CrossRef]

- Guo, C.-F.; Zhang, M.; Bhandari, B. A comparative study between syringe-based and screw-based 3D food printers by computational simulation. Comput. Electron. Agric. 2019, 162, 397–404. [Google Scholar] [CrossRef]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th Anniversary Article: Engineering Hydrogels for Biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef]

- Balani, S.B.; Ghaffar, S.H.; Chougan, M.; Pei, E.; Şahin, E. Processes and materials used for direct writing technologies: A review. Results Eng. 2021, 11, 100257. [Google Scholar] [CrossRef]

- Tan, J.Z.Y.; Ávila-López, M.A.; Jahanbakhsh, A.; Lu, X.; Bonilla-Cruz, J.; Lara-Ceniceros, T.E.; Andresen, J.M.; Maroto-Valer, M.M. 3D direct ink printed materials for chemical conversion and environmental remediation applications: A review. J. Mater. Chem. A 2023, 11, 5408–5426. [Google Scholar] [CrossRef]

- Li, L.; Tan, H.; Yuan, X.; Ma, H.; Ma, Z.; Zhao, Y.; Zhao, J.; Wang, X.; Chen, D.; Dong, Y. Direct ink writing preparation of LiFePO4/MWCNTs electrodes with high-areal Li-ion capacity. Ceram. Int. 2021, 47, 21161–21166. [Google Scholar] [CrossRef]

- Tagliaferri, S.; Panagiotopoulos, A.; Mattevi, C. Direct ink writing of energy materials. Mater. Adv. 2021, 2, 540–563. [Google Scholar] [CrossRef]

- Browne, M.P.; Redondo, E.; Pumera, M. 3D printing for electrochemical energy applications. Chem. Rev. 2020, 120, 2783–2810. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Liu, W.; Su, C.; Li, Y.-Y.; Sun, J. Direct ink writing of conductive materials for emerging energy storage systems. Nano Res. 2022, 15, 6091–6111. [Google Scholar] [CrossRef]

- Yao, B.; Chandrasekaran, S.; Zhang, H.; Ma, A.; Kang, J.; Zhang, L.; Lu, X.; Qian, F.; Zhu, C.; Duoss, E.B. 3D-printed structure boosts the kinetics and intrinsic capacitance of pseudocapacitive graphene aerogels. Adv. Mater. 2020, 32, 1906652. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, W.; Cao, Y.; Wang, W.; Teng, D.; Huang, Y.; Fan, G. 3D graphene-based active electrodes with large areal capacitance by modified direct ink writing method. Colloids Surf. A Phys. Eng. Asp. 2023, 671, 131603. [Google Scholar] [CrossRef]

- Goh, G.L.; Tay, M.F.; Lee, J.M.; Ho, J.S.; Sim, L.N.; Yeong, W.Y.; Chong, T.H. Potential of printed electrodes for electrochemical impedance spectroscopy (EIS): Toward membrane fouling detection. Adv. Electron. Mater. 2021, 7, 2100043. [Google Scholar] [CrossRef]

- Amorim, P.; d’Ávila, M.; Anand, R.; Moldenaers, P.; Van Puyvelde, P.; Bloemen, V. Insights on shear rheology of inks for extrusion-based 3D bioprinting. Bioprinting 2021, 22, e00129. [Google Scholar] [CrossRef]

- Rau, D.A.; Williams, C.B.; Bortner, M.J. Rheology and Printability: A Survey of Critical Relationships for Direct Ink Write Materials Design. Prog. Mater Sci. 2023, 140, 101188. [Google Scholar] [CrossRef]

- Li, L.; Meng, J.; Bao, X.; Huang, Y.; Yan, X.P.; Qian, H.L.; Zhang, C.; Liu, T. Direct-Ink-Write 3D Printing of Programmable Micro-Supercapacitors from MXene-Regulating Conducting Polymer Inks. Adv. Energy Mater. 2023, 13, 2203683. [Google Scholar] [CrossRef]

- Zhu, C.; Schorr, N.B.; Qi, Z.; Wygant, B.R.; Turney, D.E.; Yadav, G.G.; Worsley, M.A.; Duoss, E.B.; Banerjee, S.; Spoerke, E.D. Direct ink writing of 3D Zn structures as high-capacity anodes for rechargeable alkaline batteries. Small Struct. 2023, 4, 2200323. [Google Scholar] [CrossRef]

- M’barki, A.; Bocquet, L.; Stevenson, A. Linking rheology and printability for dense and strong ceramics by direct ink writing. Sci. Rep. 2017, 7, 6017. [Google Scholar] [CrossRef]

- Corker, A.; Ng, H.C.-H.; Poole, R.J.; García-Tuñón, E. 3D printing with 2D colloids: Designing rheology protocols to predict ‘printability’of soft-materials. Soft Matter 2019, 15, 1444–1456. [Google Scholar] [CrossRef]

- Liu, Y.; Hildner, M.; Roy, O.; Van den Bogert, W.A.; Lorenz, J.; Desroches, M.; Koppi, K.; Shih, A.; Larson, R.G. On the selection of rheological tests for the prediction of 3D printability. J. Rheol. 2023, 67, 791–791. [Google Scholar] [CrossRef]

- Cipriani, C.E.; Shu, Y.; Pentzer, E.B.; Benjamin, C.C. Viscoelastic and thixotropic characterization of paraffin/photopolymer composites for extrusion-based printing. Phys. Fluids 2022, 34, 093106. [Google Scholar] [CrossRef]

- García-Tuñón, E.; Agrawal, R.; Ling, B.; Dennis, D.J. Fourier-transform rheology and printability maps of complex fluids for three-dimensional printing. Phys. Fluids 2023, 35, 017113. [Google Scholar] [CrossRef]

- Barnes, H.A. The yield stress—A review or ‘παντα ρει’—Everything flows? J. Non-Newton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Bonn, D.; Denn, M.M.; Berthier, L.; Divoux, T.; Manneville, S. Yield stress materials in soft condensed matter. Rev. Mod. Phys. 2017, 89, 035005. [Google Scholar] [CrossRef]

- De Kee, D. Yield stress measurement techniques: A review. Phys. Fluids 2021, 33, 111301. [Google Scholar] [CrossRef]

- Dinkgreve, M.; Paredes, J.; Denn, M.M.; Bonn, D. On different ways of measuring “the” yield stress. J. Non-Newton. Fluid Mech. 2016, 238, 233–241. [Google Scholar] [CrossRef]

- Chauhan, G.; Verma, A.; Das, A.; Ojha, K. Rheological studies and optimization of Herschel–Bulkley flow parameters of viscous karaya polymer suspensions using GA and PSO algorithms. Rheol. Acta 2018, 57, 267–285. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press; Michigan State University: East Lansing, MI, USA, 1996. [Google Scholar]

- Vlachopoulos, J.; Polychronopoulos, N.D. Understanding Rheology and Technology of Polymer Extrusion. Chemical Engineering, Publications, Ed.; Polydynamics Inc.: Dundas, ON, Canada, 2019. [Google Scholar]

- Rueb, C.; Zukoski, C. Viscoelastic properties of colloidal gels. J. Rheol. 1997, 41, 197–218. [Google Scholar] [CrossRef]

- Smay, J.E.; Gratson, G.M.; Shepherd, R.F.; Cesarano, J., III; Lewis, J.A. Directed colloidal assembly of 3D periodic structures. Adv. Mater. 2002, 14, 1279–1283. [Google Scholar] [CrossRef]

- Wereley, N.; Chaudhuri, A.; Yoo, J.-H.; John, S.; Kotha, S.; Suggs, A.; Radhakrishnan, R.; Love, B.; Sudarshan, T. Bidisperse magnetorheological fluids using Fe particles at nanometer and micron scale. J. Intell. Mater. Syst. Struct. 2006, 17, 393–401. [Google Scholar] [CrossRef]

- Rouyer, F.; Cohen-Addad, S.; Höhler, R. Is the yield stress of aqueous foam a well-defined quantity? Colloids Surf. A Phys. Eng. Asp. 2005, 263, 111–116. [Google Scholar] [CrossRef]

- De Graef, V.; Depypere, F.; Minnaert, M.; Dewettinck, K. Chocolate yield stress as measured by oscillatory rheology. Food Res. Int. 2011, 44, 2660–2665. [Google Scholar] [CrossRef]

- Mewis, J.; Wagner, N.J. Thixotropy. Adv. Colloid Interface Sci. 2009, 147, 214–227. [Google Scholar] [CrossRef] [PubMed]

- Del-Mazo-Barbara, L.; Ginebra, M.-P. Rheological characterisation of ceramic inks for 3D direct ink writing: A review. J. Eur. Ceram. Soc. 2021, 41, 18–33. [Google Scholar] [CrossRef]

- Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomater. 2020, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Zhou, Z.; Yu, J.; Zhao, J.; Wang, G.; Cao, D.; Ding, B.; Li, Y. 3D printing of tunable energy storage devices with both high areal and volumetric energy densities. Adv. Energy Mater. 2019, 9, 1802578. [Google Scholar] [CrossRef]

- Ao, S.; Guo, Z.; Song, Y.; Fang, D.; Bao, Y. Clog-Free, Low-Cost, and Uniform Electrode Inks for 3D Printed Lithium-Ion Batteries. ACS Appl. Energy Mater. 2022, 5, 6970–6979. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D printing of conducting polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.S.; Balu, R.; Mata, J.; Dutta, N.K.; Choudhury, N.R. 3D printed graphene aerogels using conductive nanofibrillar network formulation. Nano Trends 2023, 2, 100011. [Google Scholar] [CrossRef]

- Cipollone, D.; Yang, H.; Yang, F.; Bright, J.; Liu, B.; Winch, N.; Wu, N.; Sierros, K.A. 3D printing of an anode scaffold for lithium batteries guided by mixture design-based sequential learning. J. Mater. Process. Technol. 2021, 295, 117159. [Google Scholar] [CrossRef]

- Orangi, J.; Hamade, F.; Davis, V.A.; Beidaghi, M. 3D printing of additive-free 2D Ti3C2Tx (MXene) ink for fabrication of micro-supercapacitors with ultra-high energy densities. ACS Nano 2019, 14, 640–650. [Google Scholar] [CrossRef] [PubMed]

- Yun, X.; Lu, B.; Xiong, Z.; Jia, B.; Tang, B.; Mao, H.; Zhang, T.; Wang, X. Direct 3D printing of a graphene oxide hydrogel for fabrication of a high areal specific capacitance microsupercapacitor. RSC Adv. 2019, 9, 29384–29395. [Google Scholar] [CrossRef]

- Seo, H.; Iwai, H.; Kishimoto, M.; Ding, C.; Saito, M.; Yoshida, H. Microextrusion printing for increasing electrode–electrolyte interface in anode-supported solid oxide fuel cells. J. Power Sources 2020, 450, 227682. [Google Scholar] [CrossRef]

- Ghodhbane, M.; Beneventi, D.; Zebda, A.; Dubois, L.; Alcaraz, J.-P.; Boucher, F.; Boutonnat, J.; Menassol, G.; Chaussy, D.; Belgacem, N. 3D printed cathodes for implantable abiotic biofuel cells. J. Power Sources 2023, 580, 233356. [Google Scholar] [CrossRef]

- Tagliaferri, S.; Nagaraju, G.; Panagiotopoulos, A.; Och, M.; Cheng, G.; Iacoviello, F.; Mattevi, C. Aqueous inks of pristine graphene for 3D printed microsupercapacitors with high capacitance. ACS Nano 2021, 15, 15342–15353. [Google Scholar] [CrossRef]

- Shi, G.; Zhu, Y.; Batmunkh, M.; Ingram, M.; Huang, Y.; Chen, Z.; Wei, Y.; Zhong, L.; Peng, X.; Zhong, Y.L. Cytomembrane-inspired MXene ink with amphiphilic surfactant for 3D printed microsupercapacitors. ACS Nano 2022, 16, 14723–14736. [Google Scholar] [CrossRef]

- Gao, C.; Cui, X.; Wang, C.; Wang, M.; Wu, S.; Quan, Y.; Wang, P.; Zhao, D.; Li, S. 3D-printed hierarchical porous and multidimensional conductive network based on conducting polymer/graphene oxide. J. Mater. 2023, 10, 234–244. [Google Scholar] [CrossRef]

- Kong, D.; Wang, Y.; Huang, S.; Zhang, B.; Lim, Y.V.; Sim, G.J.; Valdivia y Alvarado, P.; Ge, Q.; Yang, H.Y. 3D printed compressible quasi-solid-state nickel–iron battery. ACS Nano 2020, 14, 9675–9686. [Google Scholar] [CrossRef]

- Yang, W.; Yang, J.; Byun, J.J.; Moissinac, F.P.; Xu, J.; Haigh, S.J.; Domingos, M.; Bissett, M.A.; Dryfe, R.A.; Barg, S. 3D printing of freestanding MXene architectures for current-collector-free supercapacitors. Adv. Mater. 2019, 31, 1902725. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Li, M.C.; Liu, C.; Wu, Q.; Mei, C. 3D printed Ti3C2Tx MXene/cellulose nanofiber architectures for solid-state supercapacitors: Ink rheology, 3D printability, and electrochemical performance. Adv. Funct. Mater. 2022, 32, 2109593. [Google Scholar] [CrossRef]

- Li, Q.; Dong, Q.; Wang, J.; Xue, Z.; Li, J.; Yu, M.; Zhang, T.; Wan, Y.; Sun, H. Direct ink writing (DIW) of graphene aerogel composite electrode for vanadium redox flow battery. J. Power Sources 2022, 542, 231810. [Google Scholar] [CrossRef]

- Zong, W.; Guo, H.; Ouyang, Y.; Mo, L.; Zhou, C.; Chao, G.; Hofkens, J.; Xu, Y.; Wang, W.; Miao, Y.E. Topochemistry-driven synthesis of transition-metal selenides with weakened van der Waals force to enable 3D-printed Na-ion hybrid capacitors. Adv. Funct. Mater. 2022, 32, 2110016. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, X.; Yang, T.; Cao, Y.; Zhang, C.; Zhang, Y.; Li, P.; Yang, J.; Ma, Y.; Li, Q. 3D printing of carbon tile-modulated well-interconnected hierarchically porous pseudocapacitive electrode. Energy Storage Mater. 2023, 54, 51–59. [Google Scholar] [CrossRef]

- Hatzikiriakos, S.G.; Mitsoulis, E. Slip effects in tapered dies. Polym. Eng. Sci. 2009, 49, 1960–1969. [Google Scholar] [CrossRef]

- Fusi, L.; Housiadas, K.D.; Georgiou, G.C. Flow of a Bingham fluid in a pipe of variable radius. J. Non-Newton. Fluid Mech. 2020, 285, 104393. [Google Scholar] [CrossRef]

- Taylor-West, J.J.; Hogg, A.J. The converging flow of viscoplastic fluid in a wedge or cone. J. Fluid Mech. 2021, 915, A69. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Sarris, I.E.; Benos, L.; Vlachopoulos, J. Pressure drop in converging flows in three-dimensional printing of concrete. Phys. Fluids 2023, 35, 093104. [Google Scholar] [CrossRef]

- Mollah, M.T.; Comminal, R.; Serdeczny, M.P.; Šeta, B.; Spangenberg, J. Computational analysis of yield stress buildup and stability of deposited layers in material extrusion additive manufacturing. Addit. Manuf. 2023, 71, 103605. [Google Scholar]

- Comminal, R.; da Silva, W.R.L.; Andersen, T.J.; Stang, H.; Spangenberg, J. Modelling of 3D concrete printing based on computational fluid dynamics. Cem. Concr. Res. 2020, 138, 106256. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Vlachopoulos, J. The role of heating and cooling in viscous sintering of pairs of spheres and pairs of cylinders. Rapid Prototyp. J. 2020, 26, 719–726. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Vlachopoulos, J. Mathematical modeling of sintering of two cylinders in fused filament fabrication. In Proceedings of the PPS2019 Europe-Africa Regional Conference of the Polymer Processing Society, Pretoria, South Africa, 18–22 November 2019. [Google Scholar]

- Polychronopoulos, N.D.; Sarris, I.E.; Vlachopoulos, J. A viscous sintering model for pore shrinkage in packings of cylinders. Rheol. Acta 2021, 60, 397–408. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Benos, L.T.; Stergiou, C.I.; Sarris, I.E.; Vlachopoulos, J. Viscous coalescence of unequally sized spherical and cylindrical doublets. Soft Matter 2022, 18, 4017–4029. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Benos, L.; Vlachopoulos, J. Mathematical modelling of coalescence of viscous particles: An overview. Can. J. Chem. Eng. 2023, 101, 5231. [Google Scholar] [CrossRef]

- Singh, M.; Kaiser, J.; Hahn, H. Effect of Porosity on the Thick Electrodes for High Energy Density Lithium Ion Batteries for Stationary Applications. Batteries 2016, 2, 35. [Google Scholar] [CrossRef]

- Banti, A.; Charalampakis, M.; Pardalis, P.; Prochaska, C.; Sotiropoulos, S.; Binas, V. Electrochemical Studies of Inkjet Printed Semi-Transparent NiCo2O4/ITO Supercapacitor Electrodes. Catalysts 2023, 13, 1110. [Google Scholar] [CrossRef]

- Pandey, S.; Pathak, M.; Karakoti, M.; Tatrari, G.; Shantibhusan, B.; Dhapola, P.S.; Dhali, S.; Srivastava, A.; Rana, S.; Sahoo, N.G. Binder-Free Supercapacitors Based on Thin Films of MWCNT/GO Nanohybrids: Computational and Experimental Analysis. Catalysts 2023, 13, 235. [Google Scholar] [CrossRef]

- Rahimi, M. Lithium-Ion Batteries: Latest Advances and Prospects. Batteries 2021, 7, 8. [Google Scholar] [CrossRef]

- Kim, M.-C.; Song, J.H.; Lee, Y.-W.; Sohn, J.I. Redox-Mediated Polymer Catalyst for Lithium-Air Batteries with High Round-Trip Efficiency. Catalysts 2020, 10, 1479. [Google Scholar] [CrossRef]

- Mok, J.; Choi, D.; Bhang, S.H. Environmentally Friendly Route for Fabricating Conductive Agent for Lithium-Ion Batteries: Carbon Nanoparticles Derived from Polyethylene. Catalysts 2021, 11, 424. [Google Scholar] [CrossRef]

- Fu, W.; Wang, Y.; Kong, K.; Kim, D.; Wang, F.; Yushin, G. Materials and Processing of Lithium-Ion Battery Cathodes. Nanoenergy Adv. 2023, 3, 138–154. [Google Scholar] [CrossRef]

- Martí-Florences, M.; Cecilia, A.; Costa-Castelló, R. Modelling and Estimation in Lithium-Ion Batteries: A Literature Review. Energies 2023, 16, 6846. [Google Scholar] [CrossRef]

- Machín, A.; Márquez, F. The Next Frontier in Energy Storage: A Game-Changing Guide to Advances in Solid-State Battery Cathodes. Batteries 2024, 10, 13. [Google Scholar] [CrossRef]

- Zhao, Y.; Cheng, W.; Wu, J.; Hu, Z.; Liu, F.; Wang, L.; Peng, H. Recent advances in charge mechanism of noble metal-based cathodes for Li-O2 batteries. Chin. Chem. Lett. 2023, 34, 107413. [Google Scholar] [CrossRef]

- Kumar, Y.; Mooste, M.; Tammeveski, K. Recent progress of transition metal-based bifunctional electrocatalysts for rechargeable zinc-air battery application. Curr. Opin. Electrochem. 2023, 38, 101229. [Google Scholar] [CrossRef]

- Jian, C.; Chen, X.-Y.; Liu, Y.; Qiao, Y.; Guan, S.; Li, L.; Chou, S. Recent Progress of Transition Metal-Based Catalysts as Cathodes in O2/H2O-Involved and Pure Li-CO2 batteries. Energy Environ. Sci. 2023, 16, 792–829. [Google Scholar]

- Sico, G.; Montanino, M.; Loffredo, F.; Borriello, C.; Miscioscia, R. Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture. Coatings 2022, 12, 1020. [Google Scholar] [CrossRef]

- Rasul, M.G.; Cheng, M.; Jiang, Y.; Pan, Y.; Shahbazian-Yassar, R. Direct ink printing of PVdF composite polymer electrolytes with aligned BN Nanosheets for lithium-metal batteries. ACS Nanosci. Au 2022, 2, 297–306. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.; Jiang, Y.; Yao, W.; Yuan, Y.; Deivanayagam, R.; Foroozan, T.; Huang, Z.; Song, B.; Rojaee, R.; Shokuhfar, T. Elevated-temperature 3D printing of hybrid solid-state electrolyte for Li-ion batteries. Adv. Mater. 2018, 30, 1800615. [Google Scholar] [CrossRef]

- Cheng, M.; Ramasubramanian, A.; Rasul, M.G.; Jiang, Y.; Yuan, Y.; Foroozan, T.; Deivanayagam, R.; Tamadoni Saray, M.; Rojaee, R.; Song, B. Direct ink writing of polymer composite electrolytes with enhanced thermal conductivities. Adv. Funct. Mater. 2021, 31, 2006683. [Google Scholar] [CrossRef]

- Pinto, R.S.; Serra, J.P.; Barbosa, J.C.; Gonçalves, R.; Silva, M.M.; Lanceros-Méndez, S.; Costa, C.M. Direct-Ink-Writing of Electroactive Polymers for Sensing and Energy Storage Applications. Macromol. Mater. Eng. 2021, 306, 2100372. [Google Scholar] [CrossRef]

- Qiu, M.; Wang, D.; Tawiah, B.; Jia, H.; Fei, B.; Fu, S. Constructing PEDOT: PSS/Graphene sheet nanofluidic channels to achieve dendrite-free Zn anode. Compos. B Eng. 2021, 215, 108798. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Y.; Liu, H.; Wang, Z.; Ling, H.; Wang, C.; Ni, J.; Çelebi-Saltik, B.; Wang, X.; Meng, X. Room-temperature-formed PEDOT: PSS hydrogels enable injectable, soft, and healable organic bioelectronics. Adv. Mater. 2020, 32, 1904752. [Google Scholar] [CrossRef] [PubMed]

- Şahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Comprehensive Review on Supercapacitor Applications and Developments. Energies 2022, 15, 674. [Google Scholar] [CrossRef]

- Ma, N.; Yang, D.; Riaz, S.; Wang, L.; Wang, K. Aging Mechanism and Models of Supercapacitors: A Review. Technologies 2023, 11, 38. [Google Scholar] [CrossRef]

- Forouzandeh, P.; Kumaravel, V.; Pillai, S.C. Electrode Materials for Supercapacitors: A Review of Recent Advances. Catalysts 2020, 10, 969. [Google Scholar] [CrossRef]

- Kannan, K.; Sadasivuni, K.K.; Abdullah, A.M.; Kumar, B. Current Trends in MXene-Based Nanomaterials for Energy Storage and Conversion System: A Mini Review. Catalysts 2020, 10, 495. [Google Scholar] [CrossRef]

- Najam, T.; Shah, S.S.A.; Peng, L.; Javed, M.S.; Imran, M.; Zhao, M.-Q.; Tsiakaras, P. Synthesis and nano-engineering of MXenes for energy conversion and storage applications: Recent advances and perspectives. Coord. Chem. Rev. 2022, 454, 214339. [Google Scholar] [CrossRef]

- Liu, D.; Barbar, A.; Najam, T.; Javed, M.S.; Shen, J.; Tsiakaras, P.; Cai, X. Single noble metal atoms doped 2D materials for catalysis. Appl. Catal. B Environ. 2021, 297, 120389. [Google Scholar] [CrossRef]

- Pandya, K.S.; Shindalkar, S.S.; Kandasubramanian, B. Breakthrough to the pragmatic evolution of direct ink writing: Progression, challenges, and future. Prog. Add. Manuf. 2023, 8, 1303–1328. [Google Scholar] [CrossRef]

- Li, K.; Liang, M.; Wang, H.; Wang, X.; Huang, Y.; Coelho, J.; Pinilla, S.; Zhang, Y.; Qi, F.; Nicolosi, V. 3D MXene architectures for efficient energy storage and conversion. Adv. Funct. Mater. 2020, 30, 2000842. [Google Scholar] [CrossRef]

- Sreenilayam, S.P.; Ahad, I.U.; Nicolosi, V.; Brabazon, D. MXene materials based printed flexible devices for healthcare, biomedical and energy storage applications. Mater. Today 2021, 43, 99–131. [Google Scholar] [CrossRef]

- Ovhal, M.M.; Kumar, N.; Kang, J.-W. 3D direct ink writing fabrication of high-performance all-solid-state micro-supercapacitors. Mol. Cryst. Liq. Cryst. 2020, 705, 105–111. [Google Scholar] [CrossRef]

- Zhang, C.; McKeon, L.; Kremer, M.P.; Park, S.-H.; Ronan, O.; Seral-Ascaso, A.; Barwich, S.; Coileáin, C.Ó.; McEvoy, N.; Nerl, H.C.; et al. Additive-free MXene inks and direct printing of micro-supercapacitors. Nat. Commun. 2019, 10, 1795. [Google Scholar] [CrossRef]

- Prioriello, A.; Duranti, L.; Luisetto, I.; Sanna, F.; Larosa, C.; Grilli, M.L.; Di Bartolomeo, E. Structured Catalyst for Indirect Internal Reforming (IIR) of Biogas in Solid Oxide Fuel Cell (SOFC). Catalysts 2023, 13, 1129. [Google Scholar] [CrossRef]

- Bianchi, F.R.; Bosio, B. Operating Principles, Performance and Technology Readiness Level of Reversible Solid Oxide Cells. Sustainability 2021, 13, 4777. [Google Scholar] [CrossRef]

- Choolaei, M.; Vostakola, M.F.; Horri, B.A. Recent Advances and Challenges in Thin-Film Fabrication Techniques for Low-Temperature Solid Oxide Fuel Cells. Crystals 2023, 13, 1008. [Google Scholar] [CrossRef]

- Zhang, J.; Pang, X.; Yang, N. Materials and Applications of 3D Print for Solid Oxide Fuel Cells. Ιn 3D Printing: Fundamentals to Emerging Applications; CRC Press: Boca Raton, FL, USA, 2023; pp. 115–126. [Google Scholar]

- Yuan, J.; Chen, Y.; Sun, J.; Wang, Y.; Lin, M.; Wang, M.; Wang, H.; Bai, J. 3D Printing of Robust 8YSZ Electrolytes with a Hyperfine Structure for Solid Oxide Fuel Cells. ACS Appl. Energy Mater. 2023, 6, 4133–4143. [Google Scholar] [CrossRef]

- Ye, H.; Ma, Y.; Wang, C.; Liu, J.; Liu, Y.; Liu, Y.; Xu, X.; Chen, Z.; Zhao, X.; Tao, T. A 3D printed redox-stable interconnector for bamboo-like tubular solid oxide fuel cells. Int. J. Hydrog. Energy 2023, 48, 34979–34986. [Google Scholar] [CrossRef]

- Demin, A.; Gorbova, E.; Brouzgou, A.; Volkov, A.; Tsiakaras, P. Sensors based on solid oxide electrolytes. Ιn Solid Oxide-Based Electrochemical Devices; Lo Faro, M., Ed.; Academic Press: Cambridge, MA, USA, 2020; pp. 167–215. [Google Scholar] [CrossRef]

- Pikalova, E.; Bogdanovich, N.; Kolchugin, A.; Brouzgou, A.; Bronin, D.; Plaksin, S.V.; Khasanov, A.; Tsiakaras, P. Effect of Nature of the Ceramic Component of the Composite Electrodes Based on La1.7Ca(Sr)0.3NiO4+δ on Their Electrochemical Performance. ECS Trans. 2015, 68, 809. [Google Scholar] [CrossRef]

- Yang, L.; Zeng, X.; Ditta, A.; Feng, B.; Su, L.; Zhang, Y. Preliminary 3D printing of large inclined-shaped alumina ceramic parts by direct ink writing. J. Adv. Ceram. 2020, 9, 312–319. [Google Scholar] [CrossRef]

- Liu, Q.; Zhai, W. Hierarchical Porous Ceramics with Distinctive Microstructures by Emulsion-Based Direct Ink Writing. ACS Appl. Mater. Interfaces 2022, 14, 32196–32205. [Google Scholar] [CrossRef]

- Fan, J.; Guan, R.; Ou, K.; Fu, Q.; Liu, Q.; Li, D.-S.; Zheng, H.; Sun, Y. Direct Ink Writing 3D Printing of Graphene/Al2O3 Composite Ceramics with Gradient Mechanics. Adv. Eng. Mater. 2023, 25, 2201414. [Google Scholar] [CrossRef]

- Jin, H.; Jia, D.; Yang, Z.; Zhou, Y. Fabrication and properties of embedded dense coating on direct ink writing Si2N2O porous ceramics. Surf. Coat. Technol. 2020, 394, 125801. [Google Scholar] [CrossRef]

- Amini Horri, B. Special Issue “Emerging Materials and Fabrication Methods for Solid Oxide Fuel Cells (SOFCs)”. Energies 2022, 15, 3182. [Google Scholar] [CrossRef]

- Ye, Z.; Chu, C.; Zhang, D.; Ma, S.; Guo, J.; Cheng, Y.; Xu, G.; Li, Z.; Sun, A. Study on 3D-Direct Ink Writing based on adding silica submicron-particles to improve the rheological properties of alumina ceramic ink. Mater. Today Commun. 2021, 28, 102534. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, J.; Jiang, P.; Liu, D.; Jia, X.; Wang, X.; Zhou, F. Direct ink writing of aluminum-phosphate-bonded Al2O3 ceramic with ultra-low dimensional shrinkage. Ceram. Int. 2022, 48, 864–871. [Google Scholar] [CrossRef]

- Shao, H.; Yang, X.; He, Y.; Fu, J.; Liu, L.; Ma, L.; Zhang, L.; Yang, G.; Gao, C.; Gou, Z. Bioactive glass-reinforced bioceramic ink writing scaffolds: Sintering, microstructure and mechanical behavior. Biofabrication 2015, 7, 035010. [Google Scholar] [CrossRef] [PubMed]

- Rosental, T.; Magdassi, S. A new approach to 3D printing dense ceramics by ceramic precursor binders. Adv. Eng. Mater. 2019, 21, 1900604. [Google Scholar] [CrossRef]

- Rath, M.K.; Kossenko, A.; Danchuk, V.; Shatalov, M.; Rahumi, O.; Borodianskiy, K.; Zinigrad, M.; Sahoo, T.; Mishra, S. Development of highly efficient and durable large-area solid oxide fuel cell by a direct-ink-writing three-dimensional printer. J. Power Sources 2022, 552, 232225. [Google Scholar] [CrossRef]

- Seo, H.; Kishimoto, M.; Ding, C.; Iwai, H.; Saito, M.; Yoshida, H. Improvement in the Electrochemical Performance of Anode-supported Solid Oxide Fuel Cells by Meso- and Nanoscale Structural Modifications. Fuel Cells 2020, 20, 570–579. [Google Scholar] [CrossRef]

- Yan, J.; Huang, S.; Von Lim, Y.; Xu, T.; Kong, D.; Li, X.; Yang, H.Y.; Wang, Y. Direct-ink writing 3D printed energy storage devices: From material selectivity, design and optimization strategies to diverse applications. Mater. Today 2022, 54, 110–152. [Google Scholar] [CrossRef]

- Brouzgou, A. Graphene-based Nanomaterials as Organocatalyst. Ιn Graphene-Based Nanomaterial Catalysis; Singh, M., Rai, V.K., Rai, A., Eds.; Bentham Science Publisher: Sharjah, United Arab Emirates, 2022; p. 24. [Google Scholar]

- Pierin, G.; Grotta, C.; Colombo, P.; Mattevi, C. Direct Ink Writing of micrometric SiOC ceramic structures using a preceramic polymer. J. Eur. Ceram. Soc. 2016, 36, 1589–1594. [Google Scholar] [CrossRef]

- Shi, G.; Lowe, S.E.; Teo, A.J.; Dinh, T.K.; Tan, S.H.; Qin, J.; Zhang, Y.; Zhong, Y.L.; Zhao, H. A versatile PDMS submicrobead/graphene oxide nanocomposite ink for the direct ink writing of wearable micron-scale tactile sensors. Appl. Mater. Today 2019, 16, 482–492. [Google Scholar] [CrossRef]

- Tandel, R.; Gozen, B.A. Direct-Ink-writing of liquid metal-graphene-based polymer composites: Composition-processing-property relationships. J. Mater. Process. Technol. 2022, 302, 117470. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, F.; Zhao, Z.; Bai, P.; Ma, Y.; Alhadhrami, A.; Mersal, G.A.; Lin, Z.; Ibrahim, M.M.; El-Bahy, Z.M. Direct ink printing reduced graphene oxide/KCu7S4 electrodes for high-performance supercapacitors. Adv. Compos. Hybrid Mater. 2022, 5, 1516–1526. [Google Scholar] [CrossRef]

- Raj, R.; Dixit, A.R. Direct ink writing of carbon-doped polymeric composite ink: A review on its requirements and applications. 3D Print Addit. Manuf. 2023, 10, 828–854. [Google Scholar] [CrossRef] [PubMed]

- Alam, A.; Saeed, G.; Kim, K.-W.; Kim, J.K.; Park, H.S.; Lim, S. Direct ink writing (DIW) printed high-performance asymmetric supercapacitor based on 0D@2D silver-nanoparticles@MXene as anode and 0D@2DMnO2-nanoparticles@ MXene as cathode materials. J. Energy Storage 2023, 72, 108227. [Google Scholar] [CrossRef]

- Saadi, M.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct ink writing: A 3D printing technology for diverse materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Ravichandran, D.; Xu, W.; Kakarla, M.; Jambhulkar, S.; Zhu, Y.; Song, K. Multiphase direct ink writing (MDIW) for multilayered polymer/nanoparticle composites. Addit. Manuf. 2021, 47, 102322. [Google Scholar] [CrossRef]

- Ding, H.; Barg, S.; Derby, B. Direct 3D printing of graphene using capillary suspensions. Nanoscale 2020, 12, 11440–11447. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ling, S.; Cao, W.; Zeng, L.; Yuan, R.; Zhang, C. Surface-Adaptive Capillarity Enabling Densified 3D Printing for Ultra-High Areal and Volumetric Energy Density Supercapacitors. Angew. Chem. 2022, 134, e202202663. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polychronopoulos, N.D.; Brouzgou, A. Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology. Catalysts 2024, 14, 110. https://doi.org/10.3390/catal14020110

Polychronopoulos ND, Brouzgou A. Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology. Catalysts. 2024; 14(2):110. https://doi.org/10.3390/catal14020110

Chicago/Turabian StylePolychronopoulos, Nickolas D., and Angeliki Brouzgou. 2024. "Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology" Catalysts 14, no. 2: 110. https://doi.org/10.3390/catal14020110

APA StylePolychronopoulos, N. D., & Brouzgou, A. (2024). Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology. Catalysts, 14(2), 110. https://doi.org/10.3390/catal14020110