Deactivation of Cu/SSZ-13 NH3-SCR Catalyst by Exposure to CO, H2, and C3H6

Abstract

:1. Introduction

2. Results and Discussion

2.1. SCR Activity of Degreened and Rich-Aged Catalysts

2.2. NH3-TPD Analysis

2.3. NH3 Oxidation Activity

2.4. DRIFT Spectroscopy Study of NH3 Adsorption

2.5. NO Adsorption on Oxidized Cu/SSZ-13

3. Materials and Methods

3.1. Catalyst Preparation

3.2. Activity Test (SCR, NH3 Oxidation, and NH3-TPD)

3.3. Aging

3.4. DRIFT Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Fickel, D.W.; D’Addio, E.; Lauterbach, J.A.; Lobo, R.F. The ammonia selective catalytic reduction activity of copper-exchanged small-pore zeolites. Appl. Catal. B 2011, 102, 441–448. [Google Scholar] [CrossRef]

- Kwak, J.H.; Tonkyn, R.G.; Kim, D.H.; Szanyi, J.; Peden, C.H.F. Excellent activity and selectivity of Cu-SSZ-13 in the selective catalytic reduction of NOx with NH3. J. Catal. 2010, 275, 187–190. [Google Scholar] [CrossRef]

- Xu, L.; McCabe, R.W. LNT in situ SCR catalyst system for diesel emissions control. Catal. Today 2012, 184, 83–94. [Google Scholar] [CrossRef]

- Liu, Y.; Harold, M.P.; Luss, D. Coupled NOx storage and reduction and selective catalytic reduction using dual-layer monolithic catalysts. Appl. Catal. B 2012, 121–122, 239–251. [Google Scholar] [CrossRef]

- Chatterjee, D.; Kočí, P.; Schmeißer, V.; Marek, M.; Weibel, M.; Krutzsch, B. Modelling of a combined NOx storage and NH3-SCR catalytic system for Diesel exhaust gas aftertreatment. Catal. Today 2010, 151, 395–409. [Google Scholar] [CrossRef]

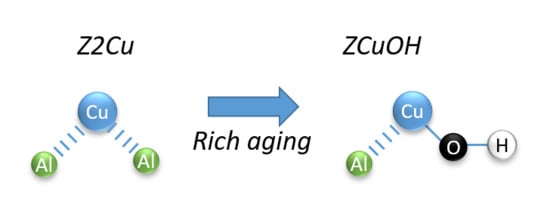

- Auvray, X.; Grant, A.; Lundberg, B.; Olsson, L. Lean and rich aging of a Cu/SSZ-13 catalyst for combined lean NOx trap (LNT) and selective catalytic reduction (SCR) concept. Catal. Sci. Technol. 2019, 9, 2152–2162. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Cheng, Y.; Lambert, C. Deactivation of Cu/Zeolite SCR Catalyst Due To Reductive Hydrothermal Aging. SAE Int. J. Fuels Lubr. 2008, 1, 466–470. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, P.S.; Kim, C.H. Deactivation mechanism of Cu/Zeolite SCR catalyst under high-temperature rich operation condition. Appl. Catal. A 2019, 569, 175–180. [Google Scholar] [CrossRef]

- Partridge, W.P.; Joshi, S.Y.; Pihl, J.A. Currier, N.W. New operando method for quantifying the relative half-cycle rates of the NO SCR redox cycle over Cu-exchanged zeolites. Appl. Catal. B 2018, 236, 195–204. [Google Scholar] [CrossRef]

- Paolucci, C.; Khurana, I.; Parekh, A.A.; Li, S.; Shih, A.J.; Li, H.; Di Iorio, J.R.; Albarracin-Caballero, J.D.; Yezerets, A.; Miller, J.T.; et al. Dynamic multinuclear sites formed by mobilized copper ions in NOx selective catalytic reduction. Science 2017, 357, 898–903. [Google Scholar] [CrossRef]

- Luo, J.; Gao, F.; Kamasamudram, K.; Currier, N.; Peden, C.H.F.; Yezerets, A. New insights into Cu/SSZ-13 SCR catalyst acidity. Part I: Nature of acidic sites probed by NH3 titration. J. Catal. 2017, 348, 291–299. [Google Scholar] [CrossRef] [Green Version]

- Paolucci, C.; Parekh, A.A.; Khurana, I.; Di Iorio, J.R.; Li, H.; Albarracin Caballero, J.D.; Shih, A.J.; Anggara, T.; Delgass, W.N.; Miller, J.T.; et al. Catalysis in a Cage: Condition-Dependent Speciation and Dynamics of Exchanged Cu Cations in SSZ-13 Zeolites. J. Am. Chem. Soc. 2016, 138, 6028–6048. [Google Scholar] [CrossRef] [PubMed]

- Kwak, J.H.; Zhu, H.; Lee, J.H.; Peden, C.H.F.; Szanyi, J. Two different cationic positions in Cu-SSZ-13? Chem. Commun. 2012, 48, 4758–4760. [Google Scholar] [CrossRef] [PubMed]

- Borfecchia, E.; Lomachenko, K.A.; Giordanino, F.; Falsig, H.; Beato, P.; Soldatov, A.V.; Bordiga, S.; Lamberti, C. Revisiting the nature of Cu sites in the activated Cu-SSZ-13 catalyst for SCR reaction. Chem. Sci. 2015, 6, 548–563. [Google Scholar] [CrossRef]

- Valyon, J.; Hall, K. Studies of the surface species formed from NO on copper zeolites. J. Phys. Chem. 1993, 97, 1204–1212. [Google Scholar] [CrossRef]

- Giordanino, F.; Vennestrøm, P.N.R.; Lundegaard, L.F.; Stappen, F.N.; Mossin, S.; Beato, P.; Bordiga, S.; Lamberti, C. Characterization of Cu-exchanged SSZ-13: A comparative FTIR, UV-Vis, and EPR study with Cu-ZSM-5 and Cu-β with similar Si/Al and Cu/Al ratios. Dalton. Trans. 2013, 42, 12741–12761. [Google Scholar] [CrossRef]

- Concepción, P.; Boronat, M.; Millán, R.; Moliner, M.; Corma, A. Identification of Distinct Copper Species in Cu-CHA Samples Using NO as Probe Molecule. A Combined IR Spectroscopic and DFT Study. Top. Catal. 2017, 60, 1–11. [Google Scholar] [CrossRef]

- Lezcano-Gonzalez, I.; Deka, U.; Arstad, B.; Van Yperen-De Deyne, A.; Hemelsoet, K.; Waroquier, M.; Van Speybroeck, V.; Weckhuysen, B.M.; Beale, A.M. Determining the storage, availability and reactivity of NH3 within Cu-Chabazite-based Ammonia Selective Catalytic Reduction systems. Phys. Chem. Chem. Phys. 2014, 16, 1639–1650. [Google Scholar] [CrossRef]

- Chen, L.; Falsig, H.; Janssens, T.V.W.; Jansson, J.; Skoglundh, M.; Grönbeck, H. Effect of Al-distribution on oxygen activation over Cu–CHA. Catal. Sci. Technol. 2018, 8, 2131–2136. [Google Scholar] [CrossRef]

- Han, S.; Cheng, J.; Zheng, C.; Ye, Q.; Cheng, S.; Kang, T.; Dai, H. Effect of Si/Al ratio on catalytic performance of hydrothermally aged Cu-SSZ-13 for the NH3-SCR of NO in simulated diesel exhaust. Appl. Surf. Sci. 2017, 419, 382–392. [Google Scholar] [CrossRef]

- Kim, Y.J.; Lee, J.K.; Min, K.M.; Hong, S.B.; Nam, I.S.; Cho, B.K. Hydrothermal stability of Cu/SSZ-13 for reducing NOx by NH3. J. Catal. 2014, 311, 447–457. [Google Scholar] [CrossRef]

- Kwak, J.H.; Tran, D.; Burton, S.D.; Szanyi, J.; Lee, J.H.; Peden, C.H.F. Effects of hydrothermal aging on NH 3-SCR reaction over Cu/zeolites. J. Catal. 2012, 287, 203–209. [Google Scholar] [CrossRef]

- Leistner, K.; Kumar, A.; Kamasamudram, K.; Olsson, L. Mechanistic study of hydrothermally aged Cu/SSZ-13 catalysts for ammonia-SCR. Catal. Today 2018, 307, 55–64. [Google Scholar] [CrossRef]

- Luo, J.; Wang, D.; Kumar, A.; Li, J.; Kamasamudram, K.; Currier, N.; Yezerets, A. Identification of two types of Cu sites in Cu/SSZ-13 and their unique responses to hydrothermal aging and sulfur poisoning. Catal. Today 2016, 267, 3–9. [Google Scholar] [CrossRef]

- Schmieg, S.J.; Oh, S.H.; Kim, C.H.; Brown, D.B.; Lee, J.H.; Peden, C.H.F.; Kim, D.H. Thermal durability of Cu-CHA NH3-SCR catalysts for diesel NOx reduction. Catal. Today 2012, 184, 252–261. [Google Scholar] [CrossRef]

- Wang, J.; Peng, Z.; Qiao, H.; Han, L.; Bao, W.; Chang, L.; Feng, G.; Liu, W. Influence of aging on in situ hydrothermally synthesized Cu-SSZ-13 catalyst for NH3-SCR reaction. RSC Adv. 2014, 4, 42403–42411. [Google Scholar] [CrossRef]

- Rizzotto, V.; Chen, P.; Simon, U. Mobility of NH3-Solvated CuII Ions in Cu-SSZ-13 and Cu-ZSM-5 NH3-SCR Catalysts: A Comparative Impedance Spectroscopy Study. Catalysts 2018, 8, 162. [Google Scholar] [CrossRef]

- De-La-Torre, U.; Pereda-Ayo, B.; Moliner, M.; González-Velasco, J.R.; Corma, A. Cu-zeolite catalysts for NOx removal by selective catalytic reduction with NH3 and coupled to NO storage/reduction monolith in diesel engine exhaust aftertreatment systems. Appl. Catal. B 2016, 187, 419–427. [Google Scholar] [CrossRef]

- Leistner, K.; Xie, K.; Kumar, A.; Kamasamudram, K.; Olsson, L. Ammonia Desorption Peaks Can Be Assigned to Different Copper Sites in Cu/SSZ-13. Catal. Lett. 2017, 147, 1882–1890. [Google Scholar] [CrossRef]

- Song, J.; Wang, Y.; Walter, E.D.; Washton, N.M.; Mei, D.; Kovarik, L.; Engelhard, M.H.; Prodinger, S.; Wang, Y.; Peden, C.H.F.; et al. Toward Rational Design of Cu/SSZ-13 Selective Catalytic Reduction Catalysts: Implications from Atomic-Level Understanding of Hydrothermal Stability. ACS Catal. 2017, 7, 8214–8227. [Google Scholar] [CrossRef]

- Shan, Y.; Shi, X.; Yan, Z.; Liu, J.; Yu, Y.; He, H. Deactivation of Cu-SSZ-13 in the presence of SO2 during hydrothermal aging. Catal. Today 2019, 320, 84–90. [Google Scholar] [CrossRef]

- Niwa, M.; Nishikawa, S.; Katada, N. IRMS–TPD of ammonia for characterization of acid site in β-zeolite. Microporous Mesoporous Mater. 2005, 82, 105–112. [Google Scholar] [CrossRef]

- Ma, L.; Cheng, Y.; Cavataio, G.; McCabe, R.W.; Fu, L.; Li, J. In situ DRIFTS and temperature-programmed technology study on NH3-SCR of NOx over Cu-SSZ-13 and Cu-SAPO-34 catalysts. Appl. Catal. B 2014, 156-157, 428–437. [Google Scholar] [CrossRef]

- Brookshear, D.W.; Nam, J.G.; Nguyen, K.; Toops, T.J.; Binder, A. Impact of sulfation and desulfation on NOx reduction using Cu-chabazite SCR catalysts. Catal. Today 2015, 258, 359–366. [Google Scholar] [CrossRef]

- Ruggeri, M.P.; Nova, I.; Tronconi, E.; Pihl, J.A.; Toops, T.J.; Partridge, W.P. In-situ DRIFTS measurements for the mechanistic study of NO oxidation over a commercial Cu-CHA catalyst. Appl. Catal. B 2015, 166, 181–192. [Google Scholar] [CrossRef]

- Szanyi, J.; Kwak, J.H.; Zhu, H.; Peden, C.H.F. Characterization of Cu-SSZ-13 NH3 SCR catalysts: An in situ FTIR study. Phys. Chem. Chem. Phys. 2013, 15, 2368–2380. [Google Scholar] [CrossRef]

- Zhang, R.; McEwen, J.-S.; Kollár, M.; Gao, F.; Wang, Y.; Szanyi, J.; Peden, C.H.F. NO Chemisorption on Cu/SSZ-13: A Comparative Study from Infrared Spectroscopy and DFT Calculations. ACS Catal. 2014, 4, 4093–4105. [Google Scholar] [CrossRef]

- Cheung, T.; Bhargava, S.K.; Hobday, M.; Foger, K. Adsorption of NO on Cu exchanged zeolites, an FTIR study: Effects of Cu levels, NO pressure, and catalyst pretreatment. J. Catal. 1996, 158, 301–310. [Google Scholar] [CrossRef]

- Zones, S.I. Conversion of faujasites to high-silica chabazite SSZ-13 in the presence of N,N,N-trimethyl-1-adamantammonium iodide. J. Chem. Soc. Faraday Trans. 1991, 87, 3709–3716. [Google Scholar] [CrossRef]

| Sample | Reductant | Aging Temperature (°C) |

|---|---|---|

| 1 | 2000 ppm CO | 600 |

| 2 | 2000 ppm CO | 700 |

| 3 | 2000 ppm CO | 800 |

| 4 | 2000 ppm H2 | 700 |

| 5 | 2000 ppm H2 | 800 |

| 6 | 2000 ppm H2 + 2000 ppm CO | 700 |

| 7 | 2000 ppm H2 + 2000 ppm CO | 800 |

| 8 | 222 ppm C3H6 | 700 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Auvray, X.; Mihai, O.; Lundberg, B.; Olsson, L. Deactivation of Cu/SSZ-13 NH3-SCR Catalyst by Exposure to CO, H2, and C3H6. Catalysts 2019, 9, 929. https://doi.org/10.3390/catal9110929

Auvray X, Mihai O, Lundberg B, Olsson L. Deactivation of Cu/SSZ-13 NH3-SCR Catalyst by Exposure to CO, H2, and C3H6. Catalysts. 2019; 9(11):929. https://doi.org/10.3390/catal9110929

Chicago/Turabian StyleAuvray, Xavier, Oana Mihai, Björn Lundberg, and Louise Olsson. 2019. "Deactivation of Cu/SSZ-13 NH3-SCR Catalyst by Exposure to CO, H2, and C3H6" Catalysts 9, no. 11: 929. https://doi.org/10.3390/catal9110929

APA StyleAuvray, X., Mihai, O., Lundberg, B., & Olsson, L. (2019). Deactivation of Cu/SSZ-13 NH3-SCR Catalyst by Exposure to CO, H2, and C3H6. Catalysts, 9(11), 929. https://doi.org/10.3390/catal9110929