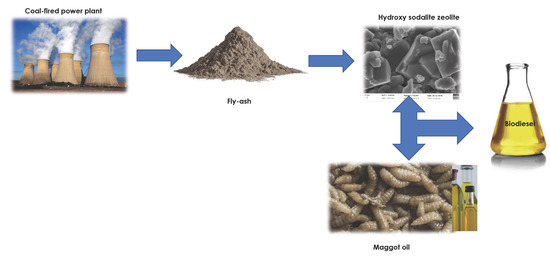

Synthesis of Hydroxy Sodalite from Coal Fly Ash for Biodiesel Production from Waste-Derived Maggot Oil

Abstract

:1. Introduction

2. Results and Discussion

2.1. Effect of Hydrothermal Synthesis Time on HS Formation

2.1.1. XRD Results

2.1.2. Effect of Hydrothermal Synthesis Time on Catalyst Morphology

2.2. Elemental Composition and Si/Al Ratio of the Synthesised Catalysts

2.3. Fourier Transform Infrared (FTIR) of Synthesised Samples

2.4. Transesterification of Maggot Oil

The Quality of Biodiesel Produced

3. Materials and Methods

3.1. Materials

3.2. Catalyst Preparation

3.3. Catalyst Characterisation

3.4. Biodiesel Production and Characterisation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Weitkamp, J. Zeolites and catalysis. Solid State Ion. 2000, 131, 175–188. [Google Scholar] [CrossRef]

- Golbad, S.; Khoshnoud, P.; Abu-Zahra, N. Hydrothermal synthesis of hydroxy sodalite from fly ash for the removal of lead ions from water. Int. J. Environ. Sci. Technol. 2017, 14, 135–142. [Google Scholar] [CrossRef]

- Shumba, M.; Chigondo, M.; Guyo, U.; Chigondo, F.; Moyo, M.; Nharingo, T.; Sebata, E. Synthesis of zeolites and their applications in heavy metals removal: A review. Eng. Sci. Technol. 2011. [Google Scholar]

- Frising, T.; Leflaive, P. Extraframework cation distributions in X and Y faujasite zeolites: A review. Microporous Mesoporous Mater. 2008, 114, 27–63. [Google Scholar] [CrossRef]

- Musyoka, N.M.; Missengue, R.; Kusisakana, M.; Petrik, L.F. Conversion of South African clays into high quality zeolites. Appl. Clay Sci. 2014, 97–98, 182–186. [Google Scholar] [CrossRef]

- Mezni, M.; Hamzaoui, A.; Hamdi, N.; Srasra, E. Synthesis of zeolites from the low-grade Tunisian natural illite by two different methods. Appl. Clay Sci. 2011, 52, 209–218. [Google Scholar] [CrossRef]

- Zielke-Olivier, J.; Vermeulen, D. Fine Ash Leaching in Tailings Dams—An Impact on the Underlying Aquifers? In Proceedings of the IMWA 2016—Mining Meets Water—Conflicts and Solutions, Leipzig, Germany, 11–15 July 2016. [Google Scholar]

- Dwivedi, A.; Jain, M.K. Fly ash waste management and overview: A Review. Recent Res. Sci. Technol. 2014, 6, 30–35. [Google Scholar]

- Makgaba, C.P.; Daramola, M.O. Transesterification of Waste Cooking Oil to Biodiesel over Calcined Hydroxy Sodalite (HS) Catalyst: A preliminary investigation. In Proceedings of the 2015 International Conference on Sustainable Energy and Environmental Engineering (SEEE 2015), Bangkok, Thailand, 25–26 October 2015. [Google Scholar]

- Murayama, N.; Yamamoto, H.; Shibata, J. Mechanism of zeolite synthesis from coal fly ash by alkali hydrothermal reaction. Int. J. Miner. Process. 2002, 64, 1–17. [Google Scholar] [CrossRef]

- Querol, X.; Moreno, N.; Umaña, J.t.; Alastuey, A.; Hernández, E.; Lopez-Soler, A.; Plana, F. Synthesis of zeolites from coal fly ash: An overview. Int. J. Coal Geol. 2002, 50, 413–423. [Google Scholar] [CrossRef]

- Leung, D.Y.; Wu, X.; Leung, M.K.H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef] [PubMed]

- Chouhan, A.P.S.; Sarma, A.K. Modern heterogeneous catalysts for biodiesel production: A comprehensive review. Renew. Sustain. Energy Rev. 2011, 15, 4378–4399. [Google Scholar] [CrossRef]

- Nabavi, M.S.; Mohammadi, T.; Kazemimoghadam, M. Hydrothermal synthesis of hydroxy sodalite zeolite membrane: Separation of H2/CH4. Ceram. Int. 2014, 40, 5889–5896. [Google Scholar] [CrossRef]

- Musyoka, N.M.; Petrik, L.F.; Balfour, G.; Gitari, W.M.; Hums, E. Synthesis of hydroxy sodalite from coal fly ash using waste industrial brine solution. J. Environ. Sci. Health Part A 2011, 46, 1699–1707. [Google Scholar] [CrossRef]

- Volli, V.; Purkait, M.K. Selective preparation of zeolite X and A from flyash and its use as catalyst for biodiesel production. J. Hazard. Mater. 2015, 297, 101–111. [Google Scholar] [CrossRef]

- Belviso, C.; Cavalcante, F.; Lettino, A.; Fiore, S. Zeolite Synthesized from Fused Coal Fly Ash at Low Temperature Using Seawater for Crystallization. Coal Combust. Gasif. Prod. 2009, 1, 8–13. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, D.; Zhang, M.; Yang, R. Synthesis of NaX zeolite: Influence of crystallization time, temperature and batch molar ratio SiO2/Al2O3 on the particulate properties of zeolite crystals. Powder Technol. 2013, 235, 322–328. [Google Scholar] [CrossRef]

- Leong, S.Y.; Kutty, S.R.M.; Malakahmad, A.; Tan, C.K. Feasibility study of biodiesel production using lipids of Hermetia illucens larva fed with organic waste. Waste Manag. 2016, 47, 84–90. [Google Scholar] [CrossRef]

- Ushakova, N.A.; Brodskii, E.S.; Kovalenko, A.A.; Bastrakov, A.I.; Kozlova, A.A.; Pavlov, D.S. Characteristics of lipid fractions of larvae of the black soldier fly Hermetia illucens. Dokl. Biochem. Biophys. 2016, 468, 209–212. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, L.; Cai, H.; Garza, E.; Yu, Z.; Zhou, S. From organic waste to biodiesel: Black soldier fly, Hermetia illucens, makes it feasible. Fuel 2011, 90, 1545–1548. [Google Scholar] [CrossRef]

- Nanganoa, L.T.; Mbadcam, K.J.; Kang, S. Synthesis of Hydroxy-sodalite from Fine Fractions of Sandy Clay Loam Soil (Natural Aluminosilicate). Int. J. Chem. Tech. Res. 2016, 9, 725–732. [Google Scholar]

- Surendra, K.C.; Olivier, R.; Tomberlin, J.K.; Jha, R.; Khanal, S.K. Bioconversion of organic wastes into biodiesel and animal feed via insect farming. Renew. Energy 2016, 98, 197–202. [Google Scholar] [CrossRef] [Green Version]

- Ferreira Madeira, F.; Ben Tayeb, K.; Pinard, L.; Vezin, H.; Maury, S.; Cadran, N. Ethanol transformation into hydrocarbons on ZSM-5 zeolites: Influence of Si/Al ratio on catalytic performances and deactivation rate. Study of the radical species role. Appl. Catal. A General 2012, 443–444, 171–180. [Google Scholar] [CrossRef]

- Treacy, M.M.; Higgins, J.B. Collection of Simulated XRD Powder Patterns for Zeolites; Fifth (5th) Revised Edition; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- ResearchGate. How do I determine the Free Fatty Acid (FFA) Percentage in non-edible oils? Available online: https://www.researchgate.net/post/how_do_i_determine_the_Free_Fatty_Acid_FFA_Percentage_in_non-edible_oils (accessed on 26 February 2019).

- Japir, A.A.-W.; Salimon, J.; Derawi, D.; Bahadi, M.; Al-Shuja’a, S.; Yusop, M.R. Physicochemical characteristics of high free fatty acid crude palm oil. OCL 2017, 24, D506. [Google Scholar] [CrossRef]

| Sample | Synthesis Time (Hour) | HS Crystallinity (%) a | Crystal Size (nm) |

|---|---|---|---|

| S-12 | 12 | 11 | 43.6 |

| S-24 | 24 | 18 | 21.1 |

| S-48 | 48 | 98 | 32.4 |

| S-72 b | 72 | 100 | 31.9 |

| S-144 | 144 | 85 | 38.1 |

| Sample | Element (Atomic, w/w%) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O | Al | Si | Na | Mg | K | Ca | Ti | Fe | P | Total | Si/Al Ratio | Na/Al Ratio | |

| CFA | 65.15 | 11.23 | 14.86 | - | 1.54 | 0.23 | 4.32 | 0.30 | 1.13 | 1.25 | 100.0 | 1.32 | - |

| S-12 | 58.63 | 17.08 | 17.49 | 3.04 | 0.58 | 0.37 | 1.30 | 0.90 | 0.62 | - | 100.0 | 1.02 | 0.18 |

| S-24 | 59.35 | 16.50 | 13.33 | 4.89 | 0.99 | 0.38 | 2.69 | 0.78 | 1.09 | - | 100.0 | 0.81 | 0.30 |

| S-48 | 45.09 | 14.32 | 19.5 | 14.62 | 0.65 | - | 3.57 | 0.93 | 1.33 | - | 100.0 | 1.36 | 1.02 |

| S-72 | 44.77 | 13.97 | 19.07 | 15.24 | 0.96 | - | 3.78 | 0.79 | 1.43 | - | 100.0 | 1.37 | 1.09 |

| S-144 | 43.47 | 13.76 | 17.42 | 20.67 | - | - | 2.16 | 1.23 | 1.29 | - | 100.0 | 1.27 | 1.50 |

| Maggot Oil Properties | |

|---|---|

| Acid value (mg KOH/g) | 7.2 |

| Saponification value (mg KOH/g) | 176.43 |

| Iodine value (g of /100 g) | 44.27 |

| Density at 40 °C (g/mL) | 0.883 |

| Kinematics viscosity at 40 °C (mm2/s) | 43.16 |

| Fatty acid (wt.%) | |

| C12:0 | 37.14 |

| C14:0 | 7.1 |

| C16:0 | 23.84 |

| C16:1 | 3.16 |

| C18:0 | 2.52 |

| C18:1 | 17.81 |

| C18:2 | 8.44 |

| C18:3 | - |

| C20:0 | - |

| Biodiesel Properties | Obtained from Current Study for Respective SYNTHESISED CAtalysts | B-STANDARD a | ||||

| HS-12 | S-24 | S-48 | S-72 | S-144 | ENS b/ASTM c | |

| Acid value (mg KOH/g) | 0.56 | 0.60 | 0.53 | 0.49 | 0.47 | 0.5–0.8 Max |

| Saponification value (mg KOH/g) | - | - | - | - | 148.59 | - |

| Ester content d (% m/m) | 35.83 | 42.49 | 59.56 | 62.64 | 97.50 | 96.5 |

| Iodine value (g of /100 g) | - | - | 59.02 | 56.86 | 50.17 | 130 |

| Density at 40 °C (g/mL) | 0.975 | 0.905 | 0.931 | 0.897 | 0.907 | 0.86–0.90 |

| Kinematics viscosity at 40 °C (mm2/s) | 6.18 | 4.90 | 5.73 | 5.70 | 5.73 | 3.5–5.0 1.9–6.0 |

| Refractive index e | 1.4450 | 1.4443 | 1.4454 | 1.4450 | 1.4461 | 1.479 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malonda Shabani, J.; Babajide, O.; Oyekola, O.; Petrik, L. Synthesis of Hydroxy Sodalite from Coal Fly Ash for Biodiesel Production from Waste-Derived Maggot Oil. Catalysts 2019, 9, 1052. https://doi.org/10.3390/catal9121052

Malonda Shabani J, Babajide O, Oyekola O, Petrik L. Synthesis of Hydroxy Sodalite from Coal Fly Ash for Biodiesel Production from Waste-Derived Maggot Oil. Catalysts. 2019; 9(12):1052. https://doi.org/10.3390/catal9121052

Chicago/Turabian StyleMalonda Shabani, Juvet, Omotola Babajide, Oluwaseun Oyekola, and Leslie Petrik. 2019. "Synthesis of Hydroxy Sodalite from Coal Fly Ash for Biodiesel Production from Waste-Derived Maggot Oil" Catalysts 9, no. 12: 1052. https://doi.org/10.3390/catal9121052

APA StyleMalonda Shabani, J., Babajide, O., Oyekola, O., & Petrik, L. (2019). Synthesis of Hydroxy Sodalite from Coal Fly Ash for Biodiesel Production from Waste-Derived Maggot Oil. Catalysts, 9(12), 1052. https://doi.org/10.3390/catal9121052