Lignin Valorizations with Ni Catalysts for Renewable Chemicals and Fuels Productions

Abstract

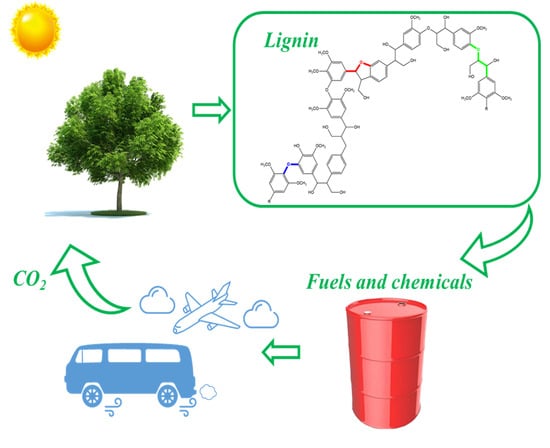

:1. Introduction & Scope of Study

2. Ni-Based Catalysts for Pyrolysis of Lignin

2.1. Pyrolysis of Lignin to Oil over Ni-Based Catalysts

2.2. Pyrolysis of Lignin to Gas over Ni-Based Catalysts

3. Hydrodeoxygenation

3.1. Monometallic Ni-Based Catalysts for HDO of Lignin

3.2. Ni-Based Bimetallic Catalysts for HDO of Lignin

3.3. Ni-Based Catalysts for HDO of Real Lignin Feedstock

4. Hydrogenolysis

4.1. Monometallic Ni-Based Catalysts for Hydrogenolysis of Lignin

4.2. Ni-Based Bimetallic Catalysts for Hydrogenolysis of Lignin

5. Conclusions & Future Prospect

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| W/F | weight of catalyst: feedgas flowrate |

| CEL | cellulolytic enzyme lignin |

| HL | hydrolysis lignin |

| BTEX | benzene, toluene, ethylbenzene & xylene |

| IS | iron slag |

| DFT | density functional theory |

| SD lignin | soda pulping |

| SAQ lignin | soda anthraquinone pulping |

| SEH lignin | steam explosion pre-treatment followed by enzymatic hydrolysis |

| SCW | supercritical water |

| WGS | water gas shift reaction |

| OSR | oxidative steam reforming |

| CB | carbon black |

| AC | activated carbon |

| GGGE | guaiacyl glycerol-β-guaiacyl ether |

| NDC | nitrogen doped carbon |

| LDH | layered double hydroxides |

| ASA | amorphous silica-alumina |

| HDO | hydrodeoxygenation |

| HYD | hydrogenation |

| CTH | catalytic transfer hydrogenation |

| MOF | metal organic framework |

References

- Rada, E.C.; Ragazzi, M.; Torretta, V.; Castagna, G.; Adami, L.; Cioca, L.I. Circular economy and waste to energy. AIP Conf. Proc. 2018, 1968, 030050. [Google Scholar]

- Vandecasteele, C. The role of Waste-to-energy in the circular economy. In Proceedings of the 18th ERSCP (European Round table on Sustainable Consumption and Production) Conference, Skiathos, Greece, 1–5 October 2017. [Google Scholar]

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Metal Prices Per Kilogram. 2019. Available online: https://www.dailymetalprice.com/ (accessed on 25 April 2019).

- Nuss, P.; Eckelman, M.J. Life cycle assessment of metals: a scientific synthesis. PLoS ONE 2014, 9, e101298. [Google Scholar] [CrossRef] [PubMed]

- Zakzeski, J.; Bruijnincx, P.C.A.; Jongerius, A.L.; Weckhuysen, B.M. The Catalytic Valorization of Lignin for the Production of Renewable Chemicals. Chem. Rev. 2010, 110, 3552–3599. [Google Scholar] [CrossRef] [PubMed]

- Pandey, M.P.; Kim, C.S. Lignin Depolymerization and Conversion: A Review of Thermochemical Methods. Chem. Eng. Technol. 2011, 34, 29–41. [Google Scholar] [CrossRef]

- Mu, W.; Ben, H.; Ragauskas, A.; Deng, Y. Lignin Pyrolysis Components and Upgrading—Technology Review. Bioenergy Res. 2013, 6, 1183–1204. [Google Scholar] [CrossRef]

- Ben, H.; Ragauskas, A.J. Pyrolysis of Kraft lignin with additives. Energy Fuels 2011, 25, 4662–4668. [Google Scholar] [CrossRef]

- Collard, F.-X.; Blin, J.; Bensakhria, A.; Valette, J. Influence of impregnated metal on the pyrolysis conversion of biomass constituents. J. Anal. Appl. Pyrol. 2012, 95, 213–226. [Google Scholar] [CrossRef]

- Geng, J.; Wang, W.L.; Yu, Y.X.; Chang, J.M.; Cai, L.P.; Shi, S.Q. Adding nickel formate in alkali lignin to increase contents of alkylphenols and aromatics during fast pyrolysis. Bioresour. Technol. 2017, 227, 1–6. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, F.; Yang, X.; Huang, Y.; Liu, C.; Zheng, Z.; Gu, J. Study on aromatics production via the catalytic pyrolysis vapor upgrading of biomass using metal-loaded modified H-ZSM-5. J. Anal. Appl. Pyrol. 2017, 126, 169–179. [Google Scholar] [CrossRef]

- Milovanovic, J.; Stensrød, R.; Myhrvold, E.; Tschentscher, R.; Stöcker, M.; Lazarevic, S.; Rajic, N. Modification of natural clinoptilolite and ZSM-5 with different oxides and studying of the obtained products in lignin pyrolysis. J. Serb. Chem. Soc. 2015, 80, 717–729. [Google Scholar] [CrossRef]

- Paysepar, H.; Rao, K.T.V.; Yuan, Z.; Shui, H.; Xu, C. Improving activity of ZSM-5 zeolite catalyst for the production of monomeric aromatics/phenolics from hydrolysis lignin via catalytic fast pyrolysis. Appl. Catal. A 2018, 563, 154–162. [Google Scholar] [CrossRef]

- Ma, T.; Liu, Y.; Yu, H. Catalytic characteristics of pyrolysis volatile matter from biomass/biomass components on a novel Ni-based catalyst supported by iron slag. J. Renew. Sustain. Ener. 2017, 9, 063101. [Google Scholar] [CrossRef]

- Naron, D.R.; Collard, F.X.; Tyhoda, L.; Görgens, J.F. Production of phenols from pyrolysis of sugarcane bagasse lignin: Catalyst screening using thermogravimetric analysis–Thermal desorption–Gas chromatography–Mass spectroscopy. J. Anal. Appl. Pyrol. 2019, 138, 120–131. [Google Scholar] [CrossRef]

- Lee, H.; Cha, J.; Park, Y.-K. Catalytic co-pyrolysis of Kraft lignin with refuse-derived fuels using Ni-loaded ZSM-5 type catalysts. Catalysts 2018, 8, 506. [Google Scholar] [CrossRef]

- Shafaghat, H.; Jae, J.; Jung, S.-C.; Jeon, J.-K.; Ko, C.H.; Park, Y.-K. Effect of methane co-feeding on product selectivity of catalytic pyrolysis of biomass. Catal. Today 2018, 303, 200–206. [Google Scholar] [CrossRef]

- Jiang, Y.T.; Li, Z.; Tang, X.; Sun, Y.; Zeng, X.H.; Liu, S.J.; Lin, L. Depolymerization of cellulolytic enzyme lignin for the production of monomeric phenols over Raney ni and acidic zeolite catalysts. Energy Fuels 2015, 29, 1662–1668. [Google Scholar] [CrossRef]

- Wu, C.; Wang, Z.; Dupont, V.; Huang, J.; Williams, P.T. Nickel-catalysed pyrolysis/gasification of biomass components. J. Anal. Appl. Pyrol. 2013, 99, 143–148. [Google Scholar] [CrossRef]

- Wu, C.; Wang, Z.; Huang, J.; Williams, P.T. Pyrolysis/gasification of cellulose, hemicellulose and lignin for hydrogen production in the presence of various nickel-based catalysts. Fuel 2013, 106, 697–706. [Google Scholar] [CrossRef] [Green Version]

- Ryczkowski, R.; Ruppert, A.M.; Przybysz, P.; Chałupka, K.; Grams, J. Hydrogen production from biomass woodchips using Ni/CaO–ZrO2 catalysts. React. Kinet. Mech. Catal. 2017, 121, 97–107. [Google Scholar] [CrossRef]

- Furusawa, T.; Sato, T.; Sugito, H.; Miura, Y.; Ishiyama, Y.; Sato, M.; Itoh, N.; Suzuki, N. Hydrogen production from the gasification of lignin with nickel catalysts in supercritical water. Int. J. Hydrog. Energy 2007, 32, 699–704. [Google Scholar] [CrossRef]

- Valle, B.; Remiro, A.; Aguayo, A.T.; Bilbao, J.; Gayubo, A.G. Catalysts of Ni/α-Al2O3 and Ni/La2O3-αAl2O3 for hydrogen production by steam reforming of bio-oil aqueous fraction with pyrolytic lignin retention. Int. J. Hydrog. Energy 2013, 38, 1307–1318. [Google Scholar] [CrossRef]

- Remiro, A.; Valle, B.; Aramburu, B.; Aguayo, A.T.; Bilbao, J.; Gayubo, A.G. Steam reforming of the bio-oil aqueous fraction in a fluidized bed reactor with in situ CO2 capture. Ind. Eng. Chem. Res. 2013, 52, 17087–17098. [Google Scholar] [CrossRef]

- Ochoa, A.; Aramburu, B.; Valle, B.; Resasco, D.E.; Bilbao, J.; Gayubo, A.G.; Castaño, P. Role of oxygenates and effect of operating conditions in the deactivation of a Ni supported catalyst during the steam reforming of bio-oil. Green Chem. 2017, 19, 4315–4333. [Google Scholar] [CrossRef]

- Remiro, A.; Valle, B.; Aguayo, A.T.; Bilbao, J.; Gayubo, A.G. Steam Reforming of Raw Bio-oil in a Fluidized Bed Reactor with Prior Separation of Pyrolytic Lignin. Energy Fuels 2013, 27, 7549–7559. [Google Scholar] [CrossRef]

- Remiro, A.; Arandia, A.; Bilbao, J.; Gayubo, A.G. Comparison of Ni based and Rh based catalyst performance in the oxidative steam reforming of raw bio-oil. Energy Fuels 2017, 31, 7147–7156. [Google Scholar] [CrossRef]

- Remiro, A.; Valle, B.; Oar-Arteta, L.; Aguayo, A.T.; Bilbao, J.; Gayubo, A.G. Hydrogen production by steam reforming of bio-oil/bio-ethanol mixtures in a continuous thermal-catalytic process. Int. J. Hydrog. Energy 2014, 39, 6889–6898. [Google Scholar] [CrossRef]

- Valle, B.; Aramburu, B.; Remiro, A.; Bilbao, J.; Gayubo, A.G. Effect of calcination/reduction conditions of Ni/La2O3–αAl2O3 catalyst on its activity and stability for hydrogen production by steam reforming of raw bio-oil/ethanol. Appl. Catal. B 2014, 147, 402–410. [Google Scholar] [CrossRef]

- Nie, R.; Yang, H.; Zhang, H.; Yu, X.; Lu, X.; Zhou, D.; Xia, Q. Mild-temperature hydrodeoxygenation of vanillin over porous nitrogen-doped carbon black supported nickel nanoparticles. Green Chem. 2017, 19, 3126–3134. [Google Scholar] [CrossRef]

- Phongpreecha, T.; Liu, J.; Hodge, D.B.; Qi, Y. Adsorption of Lignin β-O-4 Dimers on Metal Surfaces in Vacuum and Solvated Environments. ACS Sustain. Chem. Eng. 2019, 7, 2667–2678. [Google Scholar] [CrossRef]

- Wang, X.; Rinaldi, R. Bifunctional Ni catalysts for the one-pot conversion of organosolv lignin into cycloalkanes. Catal. Today 2016, 269, 48–55. [Google Scholar] [CrossRef]

- Jin, S.; Xiao, Z.; Li, C.; Chen, X.; Wang, L.; Xing, J.; Li, W.; Liang, C. Catalytic hydrodeoxygenation of anisole as lignin model compound over supported nickel catalysts. Catal. Today 2014, 234, 125–132. [Google Scholar] [CrossRef]

- Jin, S.; Xiao, Z.; Chen, X.; Wang, L.; Guo, J.; Zhang, M.; Liang, C. Cleavage of lignin-derived 4-O-5 aryl ethers over nickel nanoparticles supported on niobic acid-activated carbon composites. Ind. Eng. Chem. Res. 2015, 54, 2302–2310. [Google Scholar] [CrossRef]

- Wang, W.; Yang, Y.; Luo, H.; Peng, H.; Wang, F. Effect of La on Ni–W–B amorphous catalysts in hydrodeoxygenation of phenol. Ind. Eng. Chem. Res. 2011, 50, 10936–10942. [Google Scholar] [CrossRef]

- Zuliani, A.; Balu, A.M.; Luque, R. Efficient and Environmentally Friendly Microwave-Assisted Synthesis of Catalytically Active Magnetic Metallic Ni Nanoparticles. ACS Sustain. Chem. Eng. 2017, 5, 11584–11587. [Google Scholar] [CrossRef]

- Sankaranarayanan, T.M.; Berenguer, A.; Ochoa-Hernández, C.; Moreno, I.; Jana, P.; Coronado, J.M.; Serrano, D.P.; Pizarro, P. Hydrodeoxygenation of anisole as bio-oil model compound over supported Ni and Co catalysts: Effect of metal and support properties. Catal. Today 2015, 243, 163–172. [Google Scholar] [CrossRef]

- Zhao, C.; Kou, Y.; Lemonidou, A.A.; Li, X.; Lercher, J.A. Hydrodeoxygenation of bio-derived phenols to hydrocarbons using Raney Ni and Nafion/SiO2 catalysts. Chem. Commun. 2010, 46, 412–414. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, Q.; Wang, T.; Ma, L.; Yu, Y.; Chen, L. Hydrodeoxygenation of lignin-derived phenolic compounds to hydrocarbons over Ni/SiO2-ZrO2 catalysts. Bioresour. Technol. 2013, 134, 73–80. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Zhao, C.; Lercher, J.A. Ni-catalyzed cleavage of aryl ethers in the aqueous phase. J. Am. Chem. Soc. 2012, 134, 20768–20775. [Google Scholar] [CrossRef]

- Xu, C.; Tang, S.-F.; Sun, X.; Sun, Y.; Li, G.; Qi, J.; Li, X.; Li, X. Investigation on the cleavage of β-O-4 linkage in dimeric lignin model compound over nickel catalysts supported on ZnO-Al2O3 composite oxides with varying Zn/Al ratios. Catal. Today 2017, 298, 89–98. [Google Scholar] [CrossRef]

- Yang, L.; Seshan, K.; Li, Y. A review on thermal chemical reactions of lignin model compounds. Catal. Today 2017, 298, 276–297. [Google Scholar] [CrossRef]

- Dongil, A.B.; Pastor-Pérez, L.; Sepúlveda-Escribano, A.; García, R.; Escalona, N. Hydrodeoxygenation of guaiacol: Tuning the selectivity to cyclohexene by introducing Ni nanoparticles inside carbon nanotubes. Fuel 2016, 172, 65–69. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, W.; Zhang, Q.; Wang, T.; Ma, L. Hydrodeoxygenation of lignin-derived phenoic compounds to hydrocarbon fuel over supported Ni-based catalysts. Appl. Energy 2018, 227, 73–79. [Google Scholar] [CrossRef]

- Barton, R.R.; Carrier, M.; Segura, C.; Fierro, J.L.G.; Park, S.; Lamb, H.H.; Escalona, N.; Peretti, S.W. Ni/HZSM-5 catalyst preparation by deposition-precipitation. Part 2. Catalytic hydrodeoxygenation reactions of lignin model compounds in organic and aqueous systems. Appl. Catal. A 2018, 562, 294–309. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.; Lercher, J.A. Upgrading pyrolysis oil over Ni/HZSM-5 by cascade reactions. Angew Chem. Int. Ed. Engl. 2012, 51, 5935–5940. [Google Scholar] [CrossRef] [PubMed]

- Shu, R.; Xu, Y.; Ma, L.; Zhang, Q.; Chen, P.; Wang, T. Synergistic effects of highly active Ni and acid site on the hydrodeoxygenation of syringol. Catal. Commun. 2017, 91, 1–5. [Google Scholar] [CrossRef]

- Tran, N.T.T.; Uemura, Y.; Chowdhury, S.; Ramli, A. Vapor-phase hydrodeoxygenation of guaiacol on Al-MCM-41 supported Ni and Co catalysts. Appl. Catal. A 2016, 512, 93–100. [Google Scholar] [CrossRef]

- Long, J.; Shu, S.; Wu, Q.; Yuan, Z.; Wang, T.; Xu, Y.; Zhang, X.; Zhang, Q.; Ma, L. Selective cyclohexanol production from the renewable lignin derived phenolic chemicals catalyzed by Ni/MgO. Energy Convers. Manag. 2015, 105, 570–577. [Google Scholar] [CrossRef]

- Dongil, A.B.; Ghampson, I.T.; García, R.; Fierro, J.L.G.; Escalona, N. Hydrodeoxygenation of guaiacol over Ni/carbon catalysts: effect of the support and Ni loading. RSC Adv. 2016, 6, 2611–2623. [Google Scholar] [CrossRef]

- Yang, Y.; Ochoa-Hernández, C.; de la Peña O’Shea, V.A.; Pizarro, P.; Coronado, J.M.; Serrano, D.P. Effect of metal–support interaction on the selective hydrodeoxygenation of anisole to aromatics over Ni-based catalysts. Appl. Catal. B 2014, 145, 91–100. [Google Scholar] [CrossRef]

- Jin, S.; Chen, X.; Li, C.; Tsang, C.-W.; Lafaye, G.; Liang, C. Hydrodeoxygenation of lignin-derived diaryl ethers to aromatics and alkanes using nickel on Zr-doped niobium phosphate. ChemistrySelect 2016, 1, 4949–4956. [Google Scholar] [CrossRef]

- Berenguer, A.; Bennett, J.A.; Hunns, J.; Moreno, I.; Coronado, J.M.; Lee, A.F.; Pizarro, P.; Wilson, K.; Serrano, D.P. Catalytic hydrodeoxygenation of m-cresol over Ni2P/hierarchical ZSM-5. Catal. Today 2018, 304, 72–79. [Google Scholar] [CrossRef]

- Feitosa, L.F.; Berhault, G.; Laurenti, D.; Davies, T.E.; Teixeira da Silva, V. Synthesis and hydrodeoxygenation activity of Ni 2 P/C – Effect of the palladium salt on lowering the nickel phosphide synthesis temperature. J. Catal. 2016, 340, 154–165. [Google Scholar] [CrossRef]

- Gonçalves, V.O.O.; de Souza, P.M.; da Silva, V.T.; Noronha, F.B.; Richard, F. Kinetics of the hydrodeoxygenation of cresol isomers over Ni2P/SiO2: Proposals of nature of deoxygenation active sites based on an experimental study. Appl. Catal. B 2017, 205, 357–367. [Google Scholar] [CrossRef]

- Lan, X.; Hensen, E.J.M.; Weber, T. Hydrodeoxygenation of guaiacol over Ni2P/SiO2–reaction mechanism and catalyst deactivation. Appl. Catal. A 2018, 550, 57–66. [Google Scholar] [CrossRef]

- Shu, R.; Zhang, Q.; Xu, Y.; Long, J.; Ma, L.; Wang, T.; Chen, P.; Wu, Q. Hydrogenation of lignin-derived phenolic compounds over step by step precipitated Ni/SiO2. RSC Adv. 2016, 6, 5214–5222. [Google Scholar] [CrossRef]

- Forchheim, D.; Hornung, U.; Kempe, P.; Kruse, A.; Steinbach, D. Influence of Raney nickel on the formation of intermediates in the degradation of lignin. Int. J. Chem. Eng. 2012, 2012, 1–8. [Google Scholar] [CrossRef]

- Schutyser, W.; Van den Bosch, S.; Dijkmans, J.; Turner, S.; Meledina, M.; van Tendeloo, G.; Debecker, D.; Sels, B. Selective Ni-catalyzed conversion of model and lignin-derived phenoli compounds to cyclohexanone-based polymer building blocks. ChemSusChem 2015, 8, 1805–1818. [Google Scholar] [CrossRef]

- Song, W.; Liu, Y.; Baráth, E.; Zhao, C.; Lercher, J.A. Synergistic effects of Ni and acid sites for hydrogenation and C–O bond cleavage of substituted phenols. Green Chem. 2015, 17, 1204–1218. [Google Scholar] [CrossRef]

- Wang, X.; Rinaldi, R. Solvent effects on the hydrogenolysis of diphenyl ether with Raney nickel and their implications for the conversion of lignin. ChemSusChem 2012, 5, 1455–1466. [Google Scholar] [CrossRef]

- Li, C.; Zhao, X.; Wang, A.; Huber, G.W.; Zhang, T. Catalytic Transformation of Lignin for the Production of Chemicals and Fuels. Chem. Rev. 2015, 115, 11559–11624. [Google Scholar] [CrossRef]

- Kong, J.; He, M.; Lercher, J.A.; Zhao, C. Direct production of naphthenes and paraffins from lignin. Chem. Commun. 2015, 51, 17580–17583. [Google Scholar] [CrossRef] [PubMed]

- Kong, J.; Li, B.; Zhao, C. Tuning Ni nanoparticles and the acid sites of silica-alumina for liquefaction and hydrodeoxygenation of lignin to cyclic alkanes. RSC Adv. 2016, 6, 71940–71951. [Google Scholar] [CrossRef]

- Feng, B.; Kobayashi, H.; Ohta, H.; Fukuoka, A. Aqueous-phase hydrodeoxygenation of 4-propylphenol as a lignin model to n-propylbenzene over Re-Ni/ZrO2 catalysts. J. Mol. Catal. A Chem. 2014, 388, 41–46. [Google Scholar] [CrossRef]

- Do, P.T.M.; Foster, A.J.; Chen, J.; Lobo, R.F. Bimetallic effects in the hydrodeoxygenation of meta-cresol on γ-Al2O3 supported Pt–Ni and Pt–Co catalysts. Green Chem. 2012, 14, 1388. [Google Scholar] [CrossRef]

- Reddy Kannapu, H.P.; Mullen, C.A.; Elkasabi, Y.; Boateng, A.A. Catalytic transfer hydrogenation for stabilization of bio-oil oxygenates: Reduction of p-cresol and furfural over bimetallic Ni–Cu catalysts using isopropanol. Fuel Process. Technol. 2015, 137, 220–228. [Google Scholar] [CrossRef]

- Mauriello, F.; Paone, E.; Pietropaolo, R.; Balu, A.M.; Luque, R. Catalytic transfer hydrogenolysis of lignin-derived aromatic ethers promoted by bimetallic Pd/Ni systems. ACS Sustain. Chem. Eng. 2018, 6, 9269–9276. [Google Scholar] [CrossRef]

- Yang, F.; Liu, D.; Wang, H.; Liu, X.; Han, J.; Ge, Q.; Zhu, X. Geometric and electronic effects of bimetallic Ni–Re catalysts for selective deoxygenation of m-cresol to toluene. J. Catal. 2017, 349, 84–97. [Google Scholar] [CrossRef]

- Zhang, J.; Asakura, H.; van Rijn, J.; Yang, J.; Duchesne, P.; Zhang, B.; Chen, X.; Zhang, P.; Saeys, M.; Yan, N. Highly efficient, NiAu-catalyzed hydrogenolysis of lignin into phenolic chemicals. Green Chem. 2014, 16, 2432–2437. [Google Scholar] [CrossRef]

- Joshi, N.; Lawal, A. Hydrodeoxygenation of 4-Propylguaiacol (2-Methoxy-4-propylphenol) in a microreactor: Performance and kinetic studies. Ind. Eng. Chem. Res. 2013, 52, 4049–4058. [Google Scholar] [CrossRef]

- Sangnikul, P.; Phanpa, C.; Xiao, R.; Zhang, H.; Reubroycharoen, P.; Kuchonthara, P.; Vitidsant, T.; Pattiya, A.; Hinchiranan, N. Role of copper- or cerium-promoters on NiMo/γ-Al2O3 catalysts in hydrodeoxygenation of guaiacol and bio-oil. Appl. Catal. A 2019, 574, 151–160. [Google Scholar] [CrossRef]

- Wang, H.; Ruan, H.; Feng, M.; Qin, Y.; Job, H.; Luo, L.; Wang, C.; Engelhard, M.H.; Kuhn, E.; Chen, X.; et al. One-pot process for hydrodeoxygenation of lignin to alkanes using Ru-based bimetallic and bifunctional catalysts supported on zeolite y. ChemSusChem 2017, 10, 1846–1856. [Google Scholar] [CrossRef] [PubMed]

- Echeandia, S.; Arias, P.L.; Barrio, V.L.; Pawelec, B.; Fierro, J.L.G. Synergy effect in the HDO of phenol over Ni–W catalysts supported on active carbon: Effect of tungsten precursors. Appl. Catal. B 2010, 101, 1–12. [Google Scholar] [CrossRef]

- Jin, S.; Guan, W.; Tsang, C.-W.; Yan, D.Y.S.; Chan, C.-Y.; Liang, C. Enhanced hydroconversion of lignin-derived oxygen-containing compounds over bulk nickel catalysts though Nb2O5 modification. Catal. Lett. 2017, 147, 2215–2224. [Google Scholar] [CrossRef]

- Li, C.; Jin, S.; Guan, W.; Tsang, C.-W.; Chu, W.-K.; Lau, W.K.; Liang, C. Chemical precipitation method for the synthesis of Nb2O5 modified bulk nickel catalysts with high specific surface area. J. Vis. Exp. 2018, 10, e56987. [Google Scholar] [CrossRef]

- Luo, Z.; Zheng, Z.; Li, L.; Cui, Y.-T.; Zhao, C. Bimetallic Ru–Ni catalyzed aqueous-phase guaiacol hydrogenolysis at low H2 pressures. ACS Catal. 2017, 7, 8304–8313. [Google Scholar] [CrossRef]

- Narani, A.; Chowdari, R.K.; Cannilla, C.; Bonura, G.; Frusteri, F.; Heeres, H.J.; Barta, K. Efficient catalytic hydrotreatment of Kraft lignin to alkylphenolics using supported NiW and NiMo catalysts in supercritical methanol. Green Chem. 2015, 17, 5046–5057. [Google Scholar] [CrossRef] [Green Version]

- Meier, D.; Ante, R.; Faix, O. Catalytic hydropyrolysis of lignin - influence of reaction conditions on the formation and composition of liquid products. Bioresour. Technol. 1992, 40, 171–177. [Google Scholar] [CrossRef]

- Oasmaa, A.; Alen, R.; Meier, D. Catalytic hydrotreatment of some technical lignins. Bioresour. Technol. 1993, 45, 189–194. [Google Scholar] [CrossRef]

- Meier, D.; Berns, J.; Grunwald, C.; Faix, O. Analytical pyrolysis and semicontinuous catalytic hydropyrolysis of organocell lignin. J. Anal. Appl. Pyrol. 1993, 25, 335–347. [Google Scholar] [CrossRef]

- Kumar, C.R.; Anand, N.; Kloekhorst, A.; Cannilla, C.; Bonura, G.; Frusteri, F.; Barta, K.; Heeres, H.J. Solvent free depolymerization of Kraft lignin to alkyl-phenolics using supported NiMo and CoMo catalysts. Green Chem. 2015, 17, 4921–4930. [Google Scholar] [CrossRef]

- Harris, E.E.; D’ianni, J.; Adkin, H. Reaction of hardwood lignin with hydrogen. J. Am. Chem. Soc. 1938, 60, 1467–1470. [Google Scholar] [CrossRef]

- Duzee, E.M.V.; Adkins, H. Hydrogenation and hydrogenolysis of ethers. J. Am. Chem. Soc. 1935, 57, 147–151. [Google Scholar] [CrossRef]

- Chandler, G.S.; Sass, W.H.F. Synthetical applications of activated metal catalysts xvii. The hydrogenolysis of aromatic ethers by Raney nickel. Aust. J. Chem. 1963, 16, 20–30. [Google Scholar] [CrossRef]

- Liang, S.; Wan, C. Biorefinery Lignin to Renewable Chemicals via Sequential Fractionation and Depolymerization. Waste Biomass Valorization 2017, 8, 393–400. [Google Scholar] [CrossRef]

- Strueven, J.O.; Meier, D. Hydrocracking of organosolv lignin in subcritical water to useful phenols employing various Raney nickel catalysts. ACS Sustain. Chem. Eng. 2016, 4, 3712–3721. [Google Scholar] [CrossRef]

- Lam, C.H.; Lowe, C.B.; Li, Z.; Longe, K.N.; Rayburn, J.T.; Caldwell, M.A.; Houdek, C.E.; Maguire, J.B.; Saffron, C.M.; Miller, D.J.; et al. Electrocatalytic upgrading of model lignin monomers with earth abundant metal electrodes. Green Chem. 2015, 17, 601–609. [Google Scholar] [CrossRef]

- Gomez-Monedero, B.; Ruiz, M.P.; Bimbela, F.; Faria, J. Selective hydrogenolysis of α-O-4, β-O-4, 4-O-5 C-O bonds of lignin-model compounds and lignin-containing stillage derived from cellulosic bioethanol processing. Appl. Catal. A 2017, 541, 60–76. [Google Scholar] [CrossRef]

- Song, Q.; Wang, F.; Cai, J.; Wang, Y.; Zhang, J.; Yu, W.; Xu, J. Lignin depolymerization (LDP) in alcohol over nickel-based catalysts via a fragmentation-hydrogenolysis process. Energy Environ. Sci. 2013, 6, 994–1007. [Google Scholar] [CrossRef]

- Song, Q.; Wang, F.; Xu, J. Hydrogenolysis of lignosulfonate into phenols over heterogeneous nickel catalysts. Chem. Commun. 2012, 48, 7019–7021. [Google Scholar] [CrossRef]

- Matsagar, B.M.; Kang, T.-C.; Wang, Z.-Y.; Yoshikawa, T.; Nakasaka, Y.; Masuda, T.; Chuang, L.-C.; Wu, K.C.W. Efficient liquid-phase hydrogenolysis of a lignin model compound (benzyl phenyl ether) using a Ni/carbon catalyst. React. Chem. Eng. 2019, 4, 618–626. [Google Scholar] [CrossRef]

- Wang, S.Z.; Gao, W.; Xiao, L.P.; Shi, J.; Sun, R.C.; Song, G.Y. Hydrogenolysis of biorefinery corncob lignin into aromatic phenols over activated carbon-supported nickel. Sustain. Energ. Fuels 2019, 3, 401–408. [Google Scholar] [CrossRef]

- Chen, J.; Lu, F.; Si, X.; Nie, X.; Chen, J.; Lu, R.; Xu, J. High yield production of natural phenolic alcohols from woody biomass using a Nickel-based catalyst. ChemSusChem 2016, 9, 3353–3360. [Google Scholar] [CrossRef] [PubMed]

- Anderson, E.M.; Katahira, R.; Reed, M.; Resch, M.G.; Karp, E.M.; Beckham, G.T.; Román-Leshkov, Y. Reductive Catalytic Fractionation of Corn Stover Lignin. ACS Sustain. Chem. Eng. 2016, 4, 6940–6950. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Sun, H.; Liu, J.-x.; Zhang, J.-j.; Li, Z.-x.; Fu, Y. Selective reductive cleavage of C-O bond in lignin model compounds over nitrogen-doped carbon-supported iron catalysts. Mol. Catal. 2018, 452, 36–45. [Google Scholar] [CrossRef]

- Lama, S.M.G.; Pampel, J.; Fellinger, T.-P.; Beskoski, V.P.; Slavkovic-Beskoski, L.; Antonietti, M.; Molinari, V. Efficiency of Ni nanoparticles supported on hierarchical porous nitrogen-doped carbon for hydrogenolysis of Kraft lignin in flow and batch systems. ACS Sustain. Chem. Eng. 2017, 5, 2415–2420. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, X.; Li, H.; Lu, J.; Liu, M.; Wang, F. Carbon Modification of Nickel Catalyst for Depolymerization of Oxidized Lignin to Aromatics. ACS Catal. 2018, 8, 1614–1620. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, Q.; Shu, R.; Xu, Y.; Ma, L.; Wang, T. Catalytic depolymerization of the hydrolyzed lignin over mesoporous catalysts. Bioresour. Technol. 2017, 226, 125–131. [Google Scholar] [CrossRef]

- Toledano, A.; Serrano, L.; Pineda, A.; Romero, A.A.; Luque, R.; Labidi, J. Microwave-assisted depolymerisation of organosolv lignin via mild hydrogen-free hydrogenolysis: Catalyst screening. Appl. Catal. B 2014, 145, 43–55. [Google Scholar] [CrossRef]

- Toledano, A.; Serrano, L.; Labidi, J.; Pineda, A.; Balu, A.M.; Luque, R. Heterogeneously catalysed mild hydrogenolytic depolymerisation of lignin under microwave irradiation with hydrogen-donating solvents. ChemCatChem 2013, 5, 977–985. [Google Scholar] [CrossRef]

- Toledano, A.; Serrano, L.; Balu, A.M.; Luque, R.; Pineda, A.; Labidi, J. Fractionation of Organosolv Lignin from Olive Tree Clippings and its Valorization to Simple Phenolic Compounds. Chemsuschem 2013, 6, 529–536. [Google Scholar] [CrossRef]

- Zhou, L.; Wu, Q.; Xu, Y.; Wang, C.; Ma, L.; Li, W.; Chen, P. Depolymerization of the alkali lignin for aromatic compounds over Ni/SiO2-Al2O3 solid acid catalysts. Chem. J. Chin. Univ. 2018, 39, 735–742. [Google Scholar] [CrossRef]

- Kasakov, S.; Shi, H.; Camaioni, D.M.; Zhao, C.; Barath, E.; Jentys, A.; Lercher, J.A. Reductive deconstruction of organosolv lignin catalyzed by zeolite supported nickel nanoparticles. Green Chem. 2015, 17, 5079–5090. [Google Scholar] [CrossRef] [Green Version]

- Zaheer, M.; Hermannsdoerfer, J.; Kretschmer, W.P.; Motz, G.; Kempe, R. Robust Heterogeneous Nickel Catalysts with Tailored Porosity for the Selective Hydrogenolysis of Aryl Ethers. ChemCatChem 2014, 6, 91–95. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, P.; Wolcott, M.P.; Zhang, X.; Zhang, J. Partial depolymerization of enzymolysis lignin via mild hydrogenolysis over Raney nickel. Bioresour. Technol. 2014, 155, 422–426. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zheng, M.; Wang, A.; Zhang, T. One-pot catalytic hydrocracking of raw woody biomass into chemicals over supported carbide catalysts: simultaneous conversion of cellulose, hemicellulose and lignin. Energy Environ. Sci. 2012, 5, 6383–6390. [Google Scholar] [CrossRef]

- Ma, X.; Tian, Y.; Hao, W.; Ma, R.; Li, Y. Production of phenols from catalytic conversion of lignin over a tungsten phosphide catalyst. Appl. Catal. A 2014, 481, 64–70. [Google Scholar] [CrossRef]

- Molinari, V.; Giordano, C.; Antonietti, M.; Esposito, D. Titanium nitride-nickel nanocomposite as heterogeneous catalyst for the hydrogenolysis of aryl ethers. J. Am. Chem. Soc. 2014, 136, 1758–1761. [Google Scholar] [CrossRef] [PubMed]

- Molinari, V.; Clavel, G.; Graglia, M.; Antonietti, M.; Esposito, D. Mild continuous hydrogenolysis of Kraft lignin over titanium nitride-nickel catalyst. ACS Catal. 2016, 6, 1663–1670. [Google Scholar] [CrossRef]

- Yang, X.; Feng, M.; Choi, J.-S.; Meyer, H.M.; Yang, B. Depolymerization of corn stover lignin with bulk molybdenum carbide catalysts. Fuel 2019, 244, 528–535. [Google Scholar] [CrossRef]

- Li, R.; Li, B.; Yang, T.; Kai, X.; Zhang, W. Hydrogenation of rice stalk in situ in supercritical ethanol–water co-solvent via catalytic ethanol steam reforming. J. Supercrit. Fluids 2018, 133, 309–317. [Google Scholar] [CrossRef]

- Loefstedt, J.; Dahlstrand, C.; Orebom, A.; Meuzelaar, G.; Sawadjoon, S.; Galkin, M.V.; Agback, P.; Wimby, M.; Corresa, E.; Mathieu, Y.; et al. Green diesel from Kraft lignin in three steps. ChemSusChem 2016, 9, 1392–1396. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Li, C.; Xu, G.; Ma, Y.; Liu, X.; Zhang, Y. Depolymerization of lignin via a non-precious Ni–Fe alloy catalyst supported on activated carbon. Green Chem. 2017, 19, 1895–1903. [Google Scholar] [CrossRef]

- Regmi, Y.N.; Mann, J.K.; McBride, J.R.; Tao, J.; Barnes, C.E.; Labbé, N.; Chmely, S.C. Catalytic transfer hydrogenolysis of organosolv lignin using B-containing FeNi alloyed catalysts. Catal. Today 2018, 302, 190–195. [Google Scholar] [CrossRef]

- Kong, L.; Liu, C.; Gao, J.; Wang, Y.; Dai, L. Efficient and controllable alcoholysis of Kraft lignin catalyzed by porous zeolite-supported nickel-copper catalyst. Bioresour. Technol. 2019, 276, 310–317. [Google Scholar] [CrossRef] [PubMed]

- Ambursa, M.M.; Sudarsanam, P.; Voon, L.H.; Hamid, S.B.A.; Bhargava, S.K. Bimetallic Cu-Ni catalysts supported on MCM-41 and Ti-MCM-41 porous materials for hydrodeoxygenation of lignin model compound into transportation fuels. Fuel Process. Technol. 2017, 162, 87–97. [Google Scholar] [CrossRef]

- Chen, B.; Li, F.; Yuan, G. Highly Stable and Recyclable Graphene Layers Protected Nickel-Cobalt Bimetallic Nanoparticles as Tunable Hydrotreating Catalysts for Phenylpropane Linkages in Lignin. Catal. Lett. 2017, 147, 2877–2885. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Li, X.; Chen, L.; Li, G.; Li, X. Lignin Valorization: A Novel in Situ Catalytic Hydrogenolysis Method in Alkaline Aqueous Solution. Energy Fuels 2018, 32, 7643–7651. [Google Scholar] [CrossRef]

- Zhang, J.-w.; Lu, G.-p.; Cai, C. Self-hydrogen transfer hydrogenolysis of β-O-4 linkages in lignin catalyzed by MIL-100(Fe) supported Pd-Ni BMNPs. Green Chem. 2017, 19, 4538–4543. [Google Scholar] [CrossRef]

- Sun, K.-k.; Lu, G.-p.; Zhang, J.-w.; Cai, C. The selective hydrogenolysis of C-O bonds in lignin model compounds by Pd-Ni bimetallic nanoparticles in ionic liquids. Dalton Trans. 2017, 46, 11884–11889. [Google Scholar] [CrossRef]

- Zhang, J.-w.; Cai, Y.; Lu, G.-p.; Cai, C. Facile and selective hydrogenolysis of β-O-4 linkages in lignin catalyzed by Pd-Ni bimetallic nanoparticles supported on ZrO2. Green Chem. 2016, 18, 6229–6235. [Google Scholar] [CrossRef]

- Zhang, J.; Ibrahim, M.; Colliere, V.; Asakura, H.; Tanaka, T.; Teramura, K.; Philippot, K.; Yan, N. Rh nanoparticles with NiOx surface decoration for selective hydrogenolysis of C-O bond over arene hydrogenation. J. Mol. Catal. A Chem. 2016, 422, 188–197. [Google Scholar] [CrossRef]

- Hu, Y.; Jiang, G.; Xu, G.; Mu, X. Hydrogenolysis of lignin model compounds into aromatics with bimetallic Ru-Ni supported onto nitrogen-doped activated carbon catalyst. Mol. Catal. 2018, 445, 316–326. [Google Scholar] [CrossRef]

- Verziu, M.; Tirsoaga, A.; Cojocaru, B.; Bucur, C.; Tudora, B.; Richel, A.; Aguedo, M.; Samikannu, A.; Mikkola, J.P. Hydrogenolysis of lignin over Ru-based catalysts: The role of the ruthenium in a lignin fragmentation process. Mol. Catal. 2018, 450, 65–76. [Google Scholar] [CrossRef]

- Zhang, J.; Teo, J.; Chen, X.; Asakura, H.; Tanaka, T.; Teramura, K.; Yan, N. A series of NiM (M = Ru, Rh, and Pd) bimetallic catalysts for effective lignin hydrogenolysis in water. ACS Catal. 2014, 4, 1574–1583. [Google Scholar] [CrossRef]

- Konnerth, H.; Zhang, J.; Ma, D.; Prechtl, M.H.G.; Yan, N. Base promoted hydrogenolysis of lignin model compounds and organosolv lignin over metal catalysts in water. Chem. Eng. Sci. 2015, 123, 155–163. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, N. NiAg catalysts for selective hydrogenolysis of the lignin C-O bond. Part. Part. Syst. Charact. 2016, 33, 610–619. [Google Scholar] [CrossRef]

- Sergeev, A.G.; Hartwig, J.F. Selective nickel-catalyzed hydrogenolysis of aryl ethers. Science 2011, 332, 439–443. [Google Scholar] [CrossRef]

- Sankar, M.; Dimitratos, N.; Miedziak, P.J.; Wells, P.P.; Kiely, C.J.; Hutchings, G.J. Designing bimetallic catalysts for a green and sustainable future. Chem. Soc. Rev. 2012, 41, 8099–8139. [Google Scholar] [CrossRef]

- Wang, W.; Wu, K.; Liu, P.; Li, L.; Yang, Y.; Wang, Y. Hydrodeoxygenation of p-Cresol over Pt/Al2O3 catalyst promoted by ZrO2, CeO2, and CeO2−ZrO2. Ind. Eng. Chem. Res. 2016, 55, 7598–7603. [Google Scholar] [CrossRef]

- Shao, Y.; Xia, Q.; Dong, L.; Liu, X.; Han, X.; Parker, S.F.; Cheng, Y.; Daemen, L.L.; Ramirez-Cuesta, A.J.; Yang, S.; et al. Selective production of arenes via direct lignin upgrading over a niobium-based catalyst. Nat. Commun. 2017, 8, 16104. [Google Scholar] [CrossRef]

- Li, X.H.; Antonietti, M. Metal nanoparticles at mesoporous N-doped carbons and carbon nitrides: functional Mott-Schottky heterojunctions for catalysis. Chem. Soc. Rev. 2013, 42, 6593–6604. [Google Scholar] [CrossRef] [PubMed]

- Ji, N.; Zhang, T.; Zheng, M.; Wang, A.; Wang, H.; Wang, X.; Chen, J.G. Direct catalytic conversion of cellulose into ethylene glycol using nickel-promoted tungsten carbide catalysts. Angew Chem. Int. Ed. Engl. 2008, 47, 8510–8513. [Google Scholar] [CrossRef] [PubMed]

- Mathey, F. Phospha-organic chemistry: panorama and perspectives. Angew Chem. Int. Ed. Engl. 2003, 42, 1578–1604. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Ruan, H.; Pei, H.; Wang, H.; Chen, X.; Tucker, M.P.; Cort, J.R.; Yang, B. Biomass-derived lignin to jet fuel range hydrocarbons via aqueous phase hydrodeoxygenation. Green Chem. 2015, 17, 5131–5135. [Google Scholar] [CrossRef]

- Chin, Y.; King, D.; Roh, H.; Wang, Y.; Heald, S. Structure and reactivity investigations on supported bimetallic AuNi catalysts used for hydrocarbon steam reforming. J. Catal. 2006, 244, 153–162. [Google Scholar] [CrossRef]

- Wang, X.; Perret, N.; Delgado, J.J.; Blanco, G.; Chen, X.; Olmos, C.M.; Bernal, S.; Keane, M.A. Reducible support effects in the gas phase hydrogenation of p-chloronitrobenzene over gold. J. Phys. Chem. C 2013, 117, 994–1005. [Google Scholar] [CrossRef]

- Jin, G.-P.; Baron, R.; Rees, N.V.; Xiao, L.; Compton, R.G. Magnetically moveable bimetallic (nickel/silver) nanoparticle/carbon nanotube composites for methanol oxidation. New J. Chem. 2009, 33, 107–111. [Google Scholar] [CrossRef]

- Yang, L.; Luo, W.; Cheng, G. Graphene-supported Ag-based core-shell nanoparticles for hydrogen generation in hydrolysis of ammonia borane and methylamine borane. ACS Appl. Mater. Interfaces 2013, 5, 8231–8240. [Google Scholar] [CrossRef]

- Pepper, J.M.; Steck, W.F.; Swoboda, R.; Karapall, J.C. Hydrogenation of lignin using nickel and palladium catalysts. Adv. Chem. Ser. 1966, 59, 238–248. [Google Scholar]

- Pepper, J.M.; Lee, Y.W. Lignin and related compounds.2. Studies using ruthenium and raney nickel as catalysts for lignin hydrogenolysis. Can. J. Chem. 1970, 48, 477–479. [Google Scholar] [CrossRef]

- Pepper, J.M.; Lee, Y.W. Lignin and related compounds.I. A comparative study of catalysts for lignin hydrogenolysis. Can. J. Chem. 1969, 47, 723–727. [Google Scholar] [CrossRef]

- Chesi, C.; de Castro, I.B.D.; Clough, M.T.; Ferrini, P.; Rinaldi, R. The influence of hemicellulose sugars on product distribution of early-stage conversion of lignin oligomers catalysed by Raney nickel. ChemCatChem 2016, 8, 2079–2088. [Google Scholar] [CrossRef]

- Van den Bosch, S.; Renders, T.; Kennis, S.; Koelewijn, S.F.; Van den Bossche, G.; Vangeel, T.; Deneyer, A.; Depuydt, D.; Courtin, C.M.; Thevelein, J.M.; et al. Integrating lignin valorization and bio-ethanol production: on the role of Ni-Al2O3 catalyst pellets during lignin-first fractionation. Green Chem. 2017, 19, 3313–3326. [Google Scholar] [CrossRef]

- Klein, I.; Saha, B.; Abu-Omar, M.M. Lignin depolymerization over Ni/C catalyst in methanol, a continuation: effect of substrate and catalyst loading. Catal. Sci. Technol. 2015, 5, 3242–3245. [Google Scholar] [CrossRef]

- Luo, H.; Klein, I.M.; Jiang, Y.; Zhu, H.Y.; Liu, B.Y.; Kenttamaa, H.I.; Abu-Omar, M.M. Total utilization of Miscanthus biomass, lignin and carbohydrates, using earth abundant nickel catalyst. ACS Sustain. Chem. Eng. 2016, 4, 2316–2322. [Google Scholar] [CrossRef]

- Yang, K.X.; Chen, X.; Lafaye, G.; Especel, C.; Epron, F.; Liang, C.H. One-step modification of active sites and support in Ni/Al2O3 catalyst for hydrodeoxygenation of lignin-derived diphenyl ether. ChemistrySelect 2018, 3, 11398–11405. [Google Scholar] [CrossRef]

| Cat. | Reaction Conditions | Substrate | Major Oil Products yield/ (wt %) | Reactor | ref | |||

|---|---|---|---|---|---|---|---|---|

| Loading(wt %) | Temperature(°C) | Time (min) | Atmosphere | |||||

| NiCl2-ZSM-5 | 10 | 700 | 10 | N2 | Kraft lignin | heavy oil (34.5) light oil (11.5) | Quartz pyrolysis tube | [9] |

| Ni(NO3)2·6H2O (W-Ni0.1) | - | 600 | 12 | N2 | wood | tar (38.4) water (18.3) | Tubular heatedreactor | [10] |

| Nickel formate | - | 600 | 1.0 s | N2 | alkali lignin | phenols (59.19) HCs (16.15) alcohols (17.2) | Fixed-bed reactor | [11] |

| Ni-HZSM-5 | 5 | 500 | 30 | N2 | Pine wood | aromatic (41.3) | Fixed-bed reactor | [12] |

| NiO/ZSM-5 | 34.8 | 500 | 15 | N2 | Hardwood lignin | 34.8 with sel. to phenol (68.7) HC (12.2) | Fixed-bed reactor | [13] |

| Ni-ZSM-5 | 5 | 450 | < 0.5 s | N2 | hydrolysis lignin | 85 mg/g-HL | Drop-tube/fixed bed reactor | [14] |

| Ni/IS | 1.8 | 900 | 1.9 s | N2 | lignin | 92.71% conv. with sel. to benzene (80.1) | Fixed-bed quartz tube reactor | [15] |

| Ni/Al2O3-SiO2 | 1.0 | 30-600 | 10 °C/min | Ar | soda pulping lignin | phenol (18.0) char (38.5) | TGA-TD-GC-MS | [16] |

| Soda-anthraquinone pulping lignin | phenol (35.0) char (38.6) | |||||||

| Enzymatic hydrolysis lignin | phenol (4.0) char (37.9) | |||||||

| Ni/DHZSM-5 | 5 | 600 | - | - | Kraft lignin & refuse-derived fuels | aromatic hydrocarbon | Conventional Pyrolyzer | [17] |

| Ni/HZSM-5 | 3 | 600 | - | CH4/He (100 ml/min) | Lignin + methane | oil 27.0 with sel. to total HCs (77) | Horizontal quartz reactor | [18] |

| Cat. | Reaction Conditions | Substrate | Gas Concentration/ (vol %) | Reactor | Ref | |||

|---|---|---|---|---|---|---|---|---|

| Loading(wt %) | Temperature(°C) | Steam (g min−1) | Atmosphere | |||||

| Ni-Mg-Al | 20 mol % | 800 | H2O (0.05) | N2 (80 mL min−1) | lignin | gas yield (42.7) H2 (14.0 mmol g−1) | two-stage reaction system | [20] |

| Ni-Ca-Al | 20 mol % | 900 | H2O (0.02) | N2 (80 mL min−1) | lignin | gas yield (48.0) H2 (17.8 mmol g−1) | two-stage reaction system | [20] |

| Ni-Zn-Al | 20 mol % | 800 | H2O (0.05) | N2 (80 mL min−1) | lignin | gas yield (50.0) H2 (19.4 mmol g−1) | Fixed-bed, two-stage reaction system | [21] |

| Ni/CaO-ZrO2 | 20 | 700 | - | Ar (15 mL min−1) | Pine A | H2 (13.7 mmol g−1) | Quartz fixed bed two step reactor | [22] |

| Beech | H2 (10.1 mmol g−1) | |||||||

| Birch | H2 (9.8 mmol g−1) | |||||||

| Ni/MgO | 10 | 600 (1.5 MPa) | Reaction time (2 h) | Ar (SCW) | organosolv lignin | Carbon yield (30) | Stainless steel tube bomb reactor | [23] |

| Ni/α-Al2O3 | 10 | 700 | 0.1 ml min−1 S/C = 12 | space time 0.22 gcat. H (gbio-oil)−1 | bio-oil | Sel. H2 (63.5) | Fluidized bed reactor | [24] |

| Ni/La2O3-α-Al2O3 | 10 | H2 yield (96) Sel. H2 (68.3) | ||||||

| Ni/La2O3-α-Al2O3 | 10 | 600 | - | space time 0.45 gcat. H (gbio-oil)−1 | bio-oil with in situ CO2 capture | full conversion H2 yield (99) | Fluidized bed reactor | [25] |

| Ni/La2O3-α-Al2O3 | 10 | 700 | S/C = 6 | space time 0.19 gcat. H (gbio-oil)−1 | remaining oxygenates in bio-oil | Conv. (100) H2 yield (95) | Fluidized bed reactor | [26,27] |

| Ni/La2O3-α-Al2O3 | 10 | 700 | Time on stream (1 h) S/C = 6 O/C = 0.67 | space time 0.3 gcat. H (gbio-oil)−1 | raw bio-oil | Xbio-oil (100) H2 yield (58) | Fluidized bed reactor | [28] |

| Ni/α-Al2O3 | 10 | 700 | S/C = 10 | space time 0.23 gcat. H (gbio-oil)−1 | bio-oil/bio-ethanol (50 wt % of ethanol) | Xoxygenates (100) H2 yield (93) | Fluidized bed reactor | [29] |

| Ni/La2O3-α-Al2O3 | 10 | 700 | Time on stream (100 min) S/C = 6 | space time 0.27 gcat. H (gbio-oil)−1 | bio-oil/bio-ethanol (20 wt % of ethanol) | Xoxygenates (100) H2 yield (94) | Fluidized bed reactor | [30] |

| Cat. | Reaction Conditions | Substrate | Major products | Conv. (%) | Reactor | Ref | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ni Loading (wt %) | Support | T (°C) | P (MPa) | Solvent | ||||||

| Ni | 5 | Al-SBA-15 | 200 | 5.0 | methylcyclohexane | diphenyl ether | cyclohexane | 100 | Batch | [33] |

| Ni | 10 | SiO2 | 220 | 3.0 | n-decane | anisole | cyclohexane | 100 | Batch | [34] |

| Ni | 30 | Nb2O5/AC | 200 | 3.0 | n-decane | diphenyl ether | cyclohexane | ~ 90 | Fixed-bed | [35] |

| Ni-W-B | - | - | 250 | 4.0 | dodecane | phenol | cyclohexanone, cyclohexane | 100 | Batch | [36] |

| Ni | 95.65 | - | 230 | - | i-PrOH | benzyl phenyl ether | phenol and toluene | 24 | Microwave | [37] |

| Ni | 5 | Al-SBA-15 | 220 | 5.0 | decalin | anisole | cyclohexane | 99.8 | Batch | [38] |

| Raney Ni | - | Nafion/SiO2 | 300 | 4.0 | H2O | 2-methoxy-4-n-propylphenol | cyclohexanes | 80 | Batch | [39] |

| Ni | 15 | CNTs | 300 | 5.0 | n-dodecane | guaiacol | cyclohexane | 100 | Batch | [44] |

| Ni | 10 | Al2O3 | 300 | 5.0 | n-octane | phenol | cyclohexane | >90 | Batch | [45] |

| Ni | 10 | SiO2 | 300 | 5.0 | n-octane | phenol | cyclohexane | 99.1 | Batch | [45] |

| Ni | 10 | ZnO-Al2O3 | 250 | 2.0 | n-hexane | 2-phenoxy-1-phenylethanone | ethylcyclohexane | 100 | Batch | [42] |

| Ni | 7.41 | NCB-900 | 150 | 0.5 | H2O | vanillin | 2-methoxy-4-methylphenol | 74.4 | Batch | [31] |

| Ni | 14.3 | HZSM-5 | 250 | 5.0 | dodecane | guaiacol | cyclohexane | 100 | Batch | [46] |

| Ni | 14.3 | HZSM-5 | 250 | 5.0 | 0.1M NaOH solution | 2-phenoxy-1-phenylethanol | ethylbenzene | 100 | Batch | [46] |

| Ni | 20.2 | HZSM-5 | 250 | 5.0 | H2O | benzyl phenyl ether | cyclohexane, methylcyclohexane | 100 | Batch | [47] |

| Ni | 20 | SiO2-Al2O3 | 200 | 2.0 | decalin | syringol | cyclohexane | 98.4 | Batch | [48] |

| Ni | 10 | Al-MCM-41 | 400 | 0.1 | guaiacol | guaiacol | phenol | >90 | Fixed-bed | [49] |

| Ni | 20 | MgO | 160 | 3.0 | decahydronaphthalene | guaiacol | cyclohexanol | 97.7 | Batch | [50] |

| Ni | 15 | CNTs | 300 | 5.0 | n-dodecane | guaiacol | cyclohexanol | 100 | Batch | [51] |

| Ni | 20 | Al2O3 | 290 | 0.3 | heptane | anisole | cyclohexane | 98 | Fixed-bed | [52] |

| Ni | 20 | TiO2 | 290 | 0.3 | heptane | anisole | cyclohexane | 47 | Fixed-bed | [52] |

| Ni | 10 | ZrNbPO4 | 220 | 0.5 | n-dodecane | diphenyl ether | benzene & cyclohexane | 83.7 | Batch | [53] |

| Ni2P | 5 | HZSM-5 | 200 | 2.5 | n-dodecane | m-cresol | methylcyclohexane | 91 | Batch | [54] |

| Ni2P | 30 | C | 300 | 3.0 | n-dodecane | guaiacol | cyclohexane, methanol | 4.18 × 10−6 mol gcat −1s−1 | Batch | [55] |

| Ni2P | 10 | SiO2 | 340 | 4.0 | n-dodecane | cresols | methylcyclohexane | ~20 | Fixed-bed | [56] |

| Ni2P | 5.6 | SiO2 | 350 | 0.1 | - | Guaiacol | benzene | 98 | Fixed-bed | [57] |

| Cat. | Reaction Conditions | Substrate | Major Products | Conv.(%) | Reactor | Ref | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ni Loading (wt %) | Support | T (°C) | P (MPa) | Solvent | ||||||

| Re-Ni | 10 | ZrO2 | 300 | 4.0 | H2O | 4-propylphenol | n-propylbenzene | 91.0 | Batch | [66] |

| Pt-Ni | 5 | Al2O3 | 260 | 0.1 | - | m-Cresol | toluene | 62.7 | Fixed-bed | [67] |

| Ni-Cu | 10 | Al2O3 | 300 | 4.5 N2 | isopropanol | p-cresol | 4-methyl-cyclohexanol | 100.0 | Batch | [68] |

| Pd/Ni | - | - | 240 | 1.0 N2 | 2-propanol | diphenyl ether | benzene | 96.0 | Batch | [69] |

| Ni-Re | 5 | SiO2 | 300 | 0.1 | - | m-Cresol | toluene | 47.6 | Fixed-bed | [70] |

| Ni-Au | - | - | 130 | 1.0 | H2O | 2-Phenoxy-1-phenylethanol | monomers | ~60.0 | Batch | [71] |

| Ni-Mo | 1-5 | Al2O3 | 450 | 2.07 | - | 4-Propylguaiacol | 4-propylphenol | >90.0 | Fixed-bed | [72] |

| Ni-Mo-4Ce | 6.2 | - | 300 | 1.0 | - | guaiacol | phenol, 1,2-benzenediol | 56.7 | Fixed-bed | [73] |

| Ru-Ni | 2.5 | HY | 250 | 4.0 | H2O | guaiacol | cyclohexane | 95.0 | Batch | [74] |

| Ni-W | 2.3 | AC | 150 | 1.5 | n-octane | phenol | cyclohexane | 56.2 | Fixed-bed | [75] |

| Ru-Ni | 2.5 | HY | 250 | 4.0 | H2O | soft wood lignin | hydrocarbons | >80.0 | Batch | [74] |

| Ni-Nb | - | bulk | 160 | 3 | n-dodecane | anisole | cyclohexane, cyclohexanol | 95.3 | Batch | [76,77] |

| Cat. | Reaction Conditions | Substrate | Major Products | Max. Performance Obtained (%) | Reactor Type | Ref | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ni Loading (wt %) | Support | T (°C) & Time (h) | Pressure (MPa) | Solvent | ||||||

| Ni | 5 | AC | 150 | 0.7-0.8 | CH3OH | phenyl ether | aromatic alcohol, benzene | conv. (18%) select. (75%) | Batch | [90] |

| Ni | 10 | AC | 200, 6 | 0.1 | hydrogen donor solvents | birch sawdust | aromatic products | phenol selectivity (97%), conv. (50%) | Batch | [91] |

| Ni | 10 | AC | 200 | 5 | ethylene glycol | lignosulfonate | 4-ethyl-guaiacol, 4-propyl-guaiacol and dimers | conv. (91%) | Batch | [92] |

| Ni | 5 | CB | 80 | 0.2 | NaBH4, EtOH/H2O, liquid phase | benzyl phenyl ether | phenol, toluene | conv. (99%) select. to toluene (46%) select. to phenol (45%) | Batch | [93] |

| Ni | 5 | AC | 240, 4 | 3 | alcohol | corncob lignin | aromatic phenols | monomer yield: 12% (MeOH as solvent) | Batch | [94] |

| Ni | 10 | AC | 200, 5 | 2 | methanol-H2O co-solvent | raw beech sawdust | phenolic alcohols | conv. (51.4 wt %) | Batch | [95] |

| Ni | 5 | C | 200-250, 1-6 | 3 | acid co-catalysts | corn stover lignin | phenolic monomers | lignin bio-oil yield: 55% | Batch | [96] |

| Ni | 5 | NDC | 240, 12 | 2 | H2O/THF | β-O-4 lignin model compound | aromatic monomers | conv. (86%) | Batch | [97] |

| Ni | 32 | NDC | 150, 24 | 0.8 | ethanol | Kraft lignin | aromatic monomers | most ether linkage cleaved | Batch and flow | [98] |

| Ni | 10 | MgAlO-C | 200, 6 | 1 | methanol | β-O-4 ketones oxidized birch lignin | aromatic monomers | β-O-4 ketones: conv. (>99%) monomer from birch lignin: 22 wt % yield | Batch | [99] |

| Ni | 20 | Al-SBA-15 | 300, 4 | 1 | ethanol | organosolv hydrolyzed lignin | aromatic monomers | conv. (~90%) monomer yield: 21.9 wt % | Batch | [100] |

| Ni | 10 | Al-SBA-15 | 140, 0.5 | 400 W (Microwave) | tetralin | organosolv olive tree pruning lignin | bio-oil | bio-oil yield: 16.94% | Micro-wave vessel | [101,102,103] |

| Ni | 15 | SiO2-Al2O3 | 260-320 | 2 | ethanol | alkaline lignin | aromatics monomer, naphthalene, phenolic monomer | conv. (60%) at 300 °C monomer yield: 26.54% | Batch | [104] |

| Ni | 20 | HZSM-5, HBEA | 250, 6 | 2 | n-hexadecane | organosolv lignin | mono- and bi-cyclic naphthenes, mono-cyclic alcohols | 42 ± 4 wt % | Batch | [105] |

| Ni | 1.17 x 10−5 mol Ni | @SiC | 90, 20 | 0.6 | H2O, TBAB | benzyl phenyl ether | phenol and toluene | 99% conversion | Batch | [106] |

| Raney Ni | - | - | 300, 8 | 7 | various protic, aprotic polar, aprotic nonpolar solvents | organosolv lignin | various aromatic & naphthene monomers | 91% conversion (in 2-propanol) 86% conversion (in methanol) 81% conversion (in methylcyclohexane) | [62] | |

| Raney Ni | - | - | 120, 20 | - | formic acid | enzymolysis lignin | bio-oil | bio-oil yield: 58.11% | Batch | [87] |

| Raney Ni | - | - | 360, 3 | 7.5 | supercritical H2O | organosolv lignin | phenolic compounds | yield: 1.3−8.0 wt % | Batch | [88] |

| Raney Ni | - | - | 160–180, 3.5 | 2.0 | dioxane/H2O, NaOH | enzymolysis lignin | oligomers | conv. (82.3%) | Batch | [107] |

| Raney Ni | - | - | 75, 6 | 0.1 | aq. buffer solution | guaiacol | cyclohexanol | 91% selectivity | Batch | [89] |

| Ni-W2C | 4 | AC | 235, 4 | 6 | ethylene glycol | birch wood | phenols (guaiacyl propanol, syringyl propanol, guaiacyl propane, syringyl propane) | 46.5 wt % (5.0 wt %, 9.6 wt %, 5.4 wt %, 18.2 wt %) | Batch | [108] |

| Ni-WP | 2 | AC | 280, 2 | 2 | water–ethanol | alkaline lignin | phenols | yield: 48.8 mg/g lignin | Batch | [109] |

| Ni | 0.5 mol ratio | TiN | 125 | 1.2 | alcohol | phenyl ether | aromatic monomer, phenol | conv. (>99%) | Batch | [110] |

| Ni | 6 mmol Ni | TiN | 125 | 2.5 | alcohol, THF | benzyl phenyl ether Kraft lignin | phenol & toluene aromatic fragments | conv. (60 %) yield: (71% max.) | Continuous | [111] |

| Ni-Mo2C | 0.3 | HY | 250, 4 | 4 | H2O/ethanol (v/v = 1/1) | corn stover lignin | phenolic monomers | yield: 37.3% | Batch | [112] |

| NiMoS | 3 wt % NiO | Al2O3 | 320–340 | ethanol steam reforming | ethanol | rice stalk | bio-oil | yield: 36% | Batch | [113] |

| NiMoS | 3.9 wt % NiO | - | 340 | 6.5 | 2-PrOH | Kraft lignin | depolymerized aromatics | monomer yield: 15% | Continuous | [114] |

| Ni–Fe | 5 | AC | 200, 6 | 2 | methanol | organosolv lignin | aromatic monomers | monomer yield: 23.2 wt % | Batch | [115] |

| FeNiB | equal molar ratio of Fe & Ni | - | 320, 2 | - | ethanol (supercritical) | acetophenone, lignin (Poplar) | ethylbenzene bio-oil | conv. (74%) select. (84%) | Batch | [116] |

| Ni-Cu | 20 wt % Ni, 20 wt % Cu | H-Beta | 330, 3 | - | isopropanol | Kraft lignin | paraffins, naphthenes, phenolic naphthenes, aromatics monomers | bio-oil yield: 98.80 wt % monomer yield: 50.83 wt % | Batch | [117] |

| Ni-Cu | Cu:Ni = 3:1, 10 mol % on support | Ti-MCM-41 | 260, 6 | 10 | heptane | guaiacol | cyclohexane | conv. (90.2%) select. (51.2%) | Batch | [118] |

| Ni-Co | Ni:Co = 1:3 | - | 170, 6 | 2 | ethanol/H2O | 2-phenoxy-1-phenylethanol | deoxygenated and hydrolysis products | conv. (85%) | Batch | [119] |

| Ni-Al | 50 | - | 220, 3 | 2 (Ar) | NaOH (aq) | lignin (Poplar) | cyclohexanol, aromatics monomers and oligomers | conv. (86.8%) monomer yield: 18.9% | Batch | [120] |

| Pd1Ni4 | Pd:Ni = 1:4 mol ratio, 4 mol % on support | MIL-100(Fe) | 130, 6 | - | H2O | β-O-4 lignin model compound | aromatic monomers | conv. (99%) | Batch | [121] |

| Pd1Ni7 | Pd:Ni = 1:7 mol ratio | - | 100 or 130, 16 | 1 atm | ionic liquid [bmim]OTf | ɑ-O-4 & β-O-4 lignin model compound | phenolic and aromatics monomers | conv. (99%) | Batch | [122] |

| Pd-Ni | Pd:Ni = 1:1 mol ratio, 2.5 mol % on support | ZrO2 | 80, 6 | NaBH4 | ethanol | β-O-4 lignin model compound | phenyl alcohol, phenol, dehydroxylated products | yield: (>99%) | Batch | [123] |

| Rh | Rh:Ni = 1:1 (mol), Ni = 4.4 wt % | masked with NiOx | max 60, 40 | 1 | H2O | 1-benzoxy-2-methoxy-benzene | hydrodeoxygenated and hydrolysis products | conv. (100%) | Batch | [124] |

| Ru-Ni | Ni (5), Ru (1) | NDC | 230, 4 | 1 | H2O | guaiacol | aromatics and naphthene monomers | conv. (69%) select. to benzene (24%); phenol (59%); cyclohexane (1%); cyclohexanol (10%) | Batch | [125] |

| Ru-Ni | Ni (5), Ru (5) | HZSM-5 | 240 | 0.2 | H2O | guaiacol | phenol | conv. (~90%) | Batch | [78] |

| (RuNiAlO)x | 5 wt % Ru on NiAlO | - | 180, 6 | 7 | methanol | Lignin (Miscanthus x giganteus) | aromatic monomers and dimers | conv. (~85%) | Batch | [126] |

| NiRuNiRhNiPd | Ni (85 mol %) | - | 130, 1/12 | 1 | H2O | organosolv lignin | aromatic monomers | yield: 6.8 wt % (NiRu) 3.6 wt % (NiRh) 4.6 wt % (NiPd) | Batch | [127] |

| Ni7Au3 | Ni:Au = 7:3 (mol) | - | 130/170, 1/12 | 1 | H2O | 2-phenoxy-1-phenylethanol & organosolv lignin | aromatic monomers | conv. (96%) select. (76.4%) | Batch | [71] |

| Ni7Au3 | Ni:Au = 7:3 (mol) | - | 100, 0.5 | 1 | H2O, NaOH | 2-phenoxy-1-phenylethanol | phenol and cyclohexanol | conv. (>95%) | Batch | [128] |

| NiAg | Ni:Ag = 8:2 (pre’ion ratio), 0.022 mol on support | SiO2 | 130, 1 | 1 | H2O | 2-phenoxy-1-phenylethanol | phenol and cyclohexanol | conv. (95%) | Batch | [129] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Guan, W.; Tsang, C.-W.; Hu, H.; Liang, C. Lignin Valorizations with Ni Catalysts for Renewable Chemicals and Fuels Productions. Catalysts 2019, 9, 488. https://doi.org/10.3390/catal9060488

Chen X, Guan W, Tsang C-W, Hu H, Liang C. Lignin Valorizations with Ni Catalysts for Renewable Chemicals and Fuels Productions. Catalysts. 2019; 9(6):488. https://doi.org/10.3390/catal9060488

Chicago/Turabian StyleChen, Xiao, Weixiang Guan, Chi-Wing Tsang, Haoquan Hu, and Changhai Liang. 2019. "Lignin Valorizations with Ni Catalysts for Renewable Chemicals and Fuels Productions" Catalysts 9, no. 6: 488. https://doi.org/10.3390/catal9060488

APA StyleChen, X., Guan, W., Tsang, C. -W., Hu, H., & Liang, C. (2019). Lignin Valorizations with Ni Catalysts for Renewable Chemicals and Fuels Productions. Catalysts, 9(6), 488. https://doi.org/10.3390/catal9060488