Effect of Annealing on Anisotropic Tensile Properties of Al–12%Si Alloy Fabricated by Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. Microstructure

3.2. Mechanical Properties

4. Conclusions

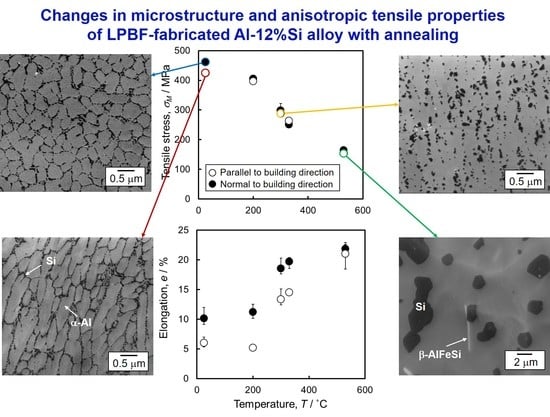

- The as-fabricated sample shows the characteristic microstructure composed of a number of melt pools. Inside the melt pools, a cellular microstructure consists of columnar α-Al phase surrounded by fine particles of eutectic Si phase. The columnar α-Al grains are elongated along their preferred <001> orientation along the z axis.

- After annealing at 200 °C, the cellular microstructure was observed, whereas Si eutectic phase became relatively coarser and fine Si phase locally precipitated within the columnar α-Al phase. After the annealing at 300 °C or 330 °C, the eutectic Si phase appeared to agglutinate, resulting in a coarsened Si phase. The initial cellular microstructure completely disappeared and many coarsened Si phases and plate-shaped Fe-rich intermetallic (β-AlFeSi) phases were formed at annealing temperature of 530 °C. However, the grain morphology of the α-Al matrix remained after annealing.

- The as-fabricated specimen showed a relatively high strength above 400 MPa and a low ductility of below 10% in total elongation. A different tensile ductility depending on the tensile direction was observed. The annealed specimens exhibited lower tensile strength and larger elongation, whereas the direction dependence of the tensile properties was not found in the specimen annealed at a high temperature of 530 °C. The change in tensile ductility was rationalized by the microstructural development during the annealing at various temperatures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014; pp. 1–140. [Google Scholar]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Milewski, J.O.; Elmer, J.W.; Ribic, B.; Blecher, J.J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef] [PubMed]

- Apparatus for Production of Three-Dimensional Objects by Stereolithography. Available online: https://patents.google.com/patent/US4575330A/en (accessed on 19 October 2020).

- Patent and Litigation Trends for 3D Printing Technologies. Available online: https://www.iam-media.com/patent-and-litigation-trends-3d-printing-technologies (accessed on 19 October 2020).

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchi, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. App. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Fores, F.H. Advanced metals for aerospace and automotive use. Mater. Sci. Eng. A 1994, 184, 119–133. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, D.A., Jr. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Lihui, L.; Kangning, L.; Cai, G.; Yang, X.; Guo, C.; Bu, G. A critical review on special forming processes and associated research for lightweight components based on sheet and tube materials. Manuf. Rev. 2014, 1, 9. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [Green Version]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Influence of process-induced microstructure and imperfections on mechanical properties of AlSi12 processed by selective laser melting. J. Mater. Process. Technol. 2015, 221, 205–213. [Google Scholar] [CrossRef]

- Liu, M.; Takata, N.; Suzuki, A.; Kobashi, M. Microstructural characterization of cellular AlSi10Mg alloy fabricated by selective laser melting. Mater. Des. 2018, 157, 478–491. [Google Scholar] [CrossRef]

- Kempf, A.; Hilgenberg, K. Influence of sub-cell structure on the mechanical properties of AlSi10Mg manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2020, 776, 138976. [Google Scholar] [CrossRef]

- Zavala-Arredondo, M.; London, T.; Allen, M.; Maccio, T.; Ward, S.; Griffiths, D.; Allison, A.; Goodwin, P.; Hauser, C. Use of power factor and specific point energy as design parameters in laser powder-bed-fusion (L-PBF) of AlSi10Mg alloy. Mater. Des. 2019, 182, 108018. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloys Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Microstructure and mechanical properties of Al–10Si–0.4Mg alloy fabricated by selective laser melting. J. Jpn. Inst. Light Met. 2017, 67, 582–588. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Takata, N.; Suzuki, A.; Kobashi, M. Development of Gradient Microstructure in the Lattice Structure of AlSi10Mg Alloy Fabricated by Selective Laser Melting. J. Mater. Sci. Technol. 2020, 36, 106–107. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selectively laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Odeshi, A.; Li, J.; Mohammadi, M. Role of hierarchical microstructure of additively manufactured AlSi10Mg on dynamic loading behavior. Addit. Manuf. 2019, 28, 1–13. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M. Contribution of Mg2Si precipitates to the strength of direct metal laser sintered AlSi10Mg. Mater. Sci. Eng. A 2019, 739, 295–300. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Lober, L.; Wang, Z.; Chaubey, A.K.; Kuhn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Fousova, M.; Dvorsky, D.; Michalcova, A.; Vojtech, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Hitzler, L.; Merkel, M.; Hall, W.; Ochsner, A. A Review of Metal Fabricated with Laser- and Powder-Bed Based Additive Manufacturing Techniques: Process, Nomenclature, Materials, Achievable Properties, and its Utilization in the Medical Sector. Adv. Eng. Mater. 2018, 20, 1700658. [Google Scholar] [CrossRef] [Green Version]

- Marola, S.; Manfredi, D.; Fiore, G.; Poletti, M.G.; Lombardi, M.; Fino, P.; Battezzati, L. A comparison of Selective Laser Melting with bulk rapid solidification of AlSi10Mg alloy. J. Alloys Compd. 2018, 742, 271–279. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, C.; Zhou, X.; Shen, Z.; Liu, W. Microstructure of selective laser melted AlSi10Mg alloy. Mater. Des. 2019, 168, 107677. [Google Scholar] [CrossRef]

- Takata, N.; Liu, M.; Kodaira, H.; Suzuki, A.; Kobashi, M. Anomalous strengthening by supersaturated solid solutions of selectively laser melted Al–Si-based alloys. Addit. Manuf. 2020, 33, 101152. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Eckert, J. Defining the tensile properties of Al-12Si parts produced by selective laser melting. Acta Mater. 2017, 126, 25–35. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Echert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Hirata, T.; Kimura, T.; Nakamoto, T. Effects of hot isostatic pressing and internal porosity on the performance of selective laser melted AlSi10Mg alloys. Mater. Sci. Eng. A 2020, 772, 138713. [Google Scholar] [CrossRef]

- Li, X.P.; Wang, X.J.; Saunders, M.; Suvorova, A.; Zhang, L.C.; Liu, Y.J.; Fang, M.H.; Huang, Z.H.; Sercombe, T.B. A selective laser melting and solution heat treatment refined Al–12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater. 2015, 95, 74–82. [Google Scholar] [CrossRef]

- Takata, N.; Nishida, R.; Suzuki, A.; Kobashi, M.; Kato, M. Crystallographic Features of Microstructure in Maraging Steel Fabricated by Selective Laser Melting. Metals 2018, 8, 440. [Google Scholar] [CrossRef] [Green Version]

- CompuTherm LLC, PanAluminum. Thermodynamic Database for Multi-Component Aluminum-Rich Casting and Wrought Alloys. Available online: https://computherm.com/?docs=pandat-database-manual/database-overview (accessed on 1 May 2020).

- Romming, C.; Hansen, V.; Gjonnes, J. Crystal structure of β-Al4.5FeSi. Acta Cystallogr. B 1994, 40, 307–312. [Google Scholar] [CrossRef]

- Marker, M.C.J.; Skolyszewska-Kuhberger, B.; Effenberger, H.S.; Schmetterer, C.; Richter, K.W. Phase equilibria and structural investigations in the system Al-Fe-Si. Intermetallics 2011, 19, 1919–1929. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Xiang, D.D.; Wang, P.; Tan, X.P.; Chandra, S.; Wang, C.; Nai, M.L.S.; Tor, S.B.; Liu, W.Q.; Liu, E. Anisotropic microstructure and mechanical properties of additively manufactured Co–Cr–Mo alloy using selective electron beam melting for orthopedic implants. Mater. Sci. Eng. A 2019, 765, 138270. [Google Scholar] [CrossRef]

- Fan, Z.; Mingzhi, H.; Deke, S. The relationship between the strain-hardening exponent n and the microstructure of metals. Mater. Sci. Eng. A 1989, 122, 211–213. [Google Scholar] [CrossRef]

- Mo, D.; He, G.; Hu, Z.; Liu, X.; Zhang, W. Effect of Microstructures on Strain Hardening Exponent Prediction of Cast Aluminum Alloy. Acta Metall. Sin. 2010, 46, 184–188. [Google Scholar] [CrossRef]

| Al | Si | Cu | Fe | Mg | Zn | Cr | Ni | Mn | Ti | |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | Bal. | 10.5~13.5 | ≤0.1 | ≤1.0 | ≤1.0 | ≤0.15 | – | – | ≤0.55 | ≤0.15 |

| ICP-AES Analyzed | Bal. | 11.87 | – | 0.07 | <0.01 | – | – | – | – | – |

| Tensile Direction | Tensile Stress (σM/MPa) | Anisotropy in Stress (%) | Elongation (e/%) | Anisotropy in Elongation (%) | Yield Stress (σYS/MPa) | Strain Hardening Exponent (n) | |

|---|---|---|---|---|---|---|---|

| as-fabricated | Normal to z axiz | 463 ± 8 | 8.2 | 10 ± 2 | 40.0 | 313 ± 3 | 0.22 ± 0.02 |

| Parallel to z axiz | 425 ± 8 | 6 ± 1 | 275 ± 10 | 0.25 ± 0.01 | |||

| 200 °C/2 h | Normal to z axiz | 406 ± 3 | 2.2 | 11 ± 1 | 54.5 | 289 ± 3 | 0.22 ± 0.06 |

| Parallel to z axiz | 397 ± 1 | 5 ± 1 | 269 ± 4 | 0.23 ± 0.01 | |||

| 300 °C/2 h | Normal to z axiz | 299 ± 21 | 3.7 | 19 ± 1 | 31.6 | 199 ± 12 | 0.22 ± 0.01 |

| Parallel to z axiz | 288 ± 7 | 13 ± 1 | 183 ± 10 | 0.22 ± 0.01 | |||

| 330 °C/2 h | Normal to z axiz | 251 ± 11 | −5.2 | 20 ± 1 | 25.0 | 174 ± 13 | 0.20 ± 0.01 |

| Parallel to z axiz | 264 ± 1 | 15 ± 1 | 178 ± 4 | 0.21 ± 0.01 | |||

| 530 °C/6 h | Normal to z axiz | 164 ± 2 | 6.7 | 22 ± 1 | 4.5 | 104 ± 4 | 0.19 ± 0.01 |

| Parallel to z axiz | 153 ± 3 | 21 ± 2 | 99 ± 4 | 0.20 ± 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Wada, T.; Suzuki, A.; Takata, N.; Kobashi, M.; Kato, M. Effect of Annealing on Anisotropic Tensile Properties of Al–12%Si Alloy Fabricated by Laser Powder Bed Fusion. Crystals 2020, 10, 1007. https://doi.org/10.3390/cryst10111007

Liu M, Wada T, Suzuki A, Takata N, Kobashi M, Kato M. Effect of Annealing on Anisotropic Tensile Properties of Al–12%Si Alloy Fabricated by Laser Powder Bed Fusion. Crystals. 2020; 10(11):1007. https://doi.org/10.3390/cryst10111007

Chicago/Turabian StyleLiu, Mulin, Takafumi Wada, Asuka Suzuki, Naoki Takata, Makoto Kobashi, and Masaki Kato. 2020. "Effect of Annealing on Anisotropic Tensile Properties of Al–12%Si Alloy Fabricated by Laser Powder Bed Fusion" Crystals 10, no. 11: 1007. https://doi.org/10.3390/cryst10111007

APA StyleLiu, M., Wada, T., Suzuki, A., Takata, N., Kobashi, M., & Kato, M. (2020). Effect of Annealing on Anisotropic Tensile Properties of Al–12%Si Alloy Fabricated by Laser Powder Bed Fusion. Crystals, 10(11), 1007. https://doi.org/10.3390/cryst10111007