Bond Behavior of Cleaned Corroded Lap Spliced Beams Repaired with Carbon Fiber Reinforced Polymer Sheets and Partial Depth Repairs

Abstract

:1. Introduction

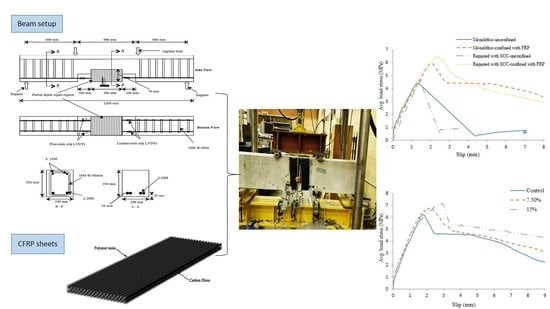

2. Experimental Program

2.1. Test Specimen

2.2. Test Procedure

2.3. Specimen Fabrication

2.4. Material Properties

3. Results and Discussion

3.1. Mode of Failure and Cracking Pattern

3.2. Lap Splice Beam

3.3. Effect of Partial Depth Repair with and without FRP Wrapping

3.4. Effect of Corrosion on Load-Deflection Response

3.5. Bond Stress versus Slip Response

4. Conclusions

- All of the unconfined beams and the beams confined with FRP sheets failed because of splitting bond failure. However, the beams confined with FRP sheets had a more ductile failure than the unconfined beams. At failure, the lap splice beams confined with FRP sheets produced smaller chunks of concrete than those of the unconfined beams.

- The average bond strength increased with increasing bar mass loss level due to the decrease in the cross-sectional area of the rebar. Therefore, as the bar diameter decreases, the bond force at failure decreases more slowly than the decreasing bar area. Also, as the corrosion level increased, the cleaned rebar surface roughness increased, which probably increased the mechanical bond contribution. Repairing the beams with partial depth repair SCC concrete enhanced the average bond strength compared to the monolithic beams.

- The beams confined with FRP sheets had a delayed bond failure related to that of the unconfined beams. The beams wrapped with FRP sheets had a higher maximum load and corresponding deflection than the unwrapped beams by 49% and 191%, respectively.

- The beams confined with FRP sheets showed a rise in the bond strength and the equivalent slip by 34–49%, and 56–260% compared to the unconfined beams, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amaireh, L.; Al-Rousan, R.Z.; Ababneh, A.N.; Alhassan, M. Integration of CFRP strips as an internal shear reinforcement in reinforced concrete beams. Structures 2020, 23, 13–19. [Google Scholar] [CrossRef]

- Junaid, M.T.; Elbana, A.; Altoubat, S. Flexural response of geopolymer and fiber reinforced geopolymer concrete beams reinforced with GFRP bars and strengthened using CFRP sheets. Structures 2020, 24, 666–677. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.P.; Cundy, A.B.; Tsioulou, O.T.; Alrekabi, S. Flexural performance of reinforced concrete beams strengthened with fibre reinforced geopolymer concrete under accelerated corrosion. Structures 2019, 19, 394–410. [Google Scholar] [CrossRef]

- Barris, C.; Sala, P.; Gómez, J.; Torres, L. Flexural behaviour of FRP reinforced concrete beams strengthened with NSM CFRP strips. Compos. Struct. 2020, 241, 112059. [Google Scholar] [CrossRef]

- Hadhood, A.; Agamy, M.H.; Abdelsalam, M.M.; Mohamed, H.M.; El-Sayed, T.A. Shear strengthening of hybrid externally-bonded mechanically-fastened concrete beams using short CFRP strips: Experiments and theoretical evaluation. Eng. Struct. 2019, 201, 109795. [Google Scholar] [CrossRef]

- Zuo, J.; Darwin, D. Splice Strength of Conventional and High Relative Rib Area Bars in Normal and High-strength Concrete. Struct. J. 2000, 97, 630–641. [Google Scholar]

- Azizinamini, A.; Pavel, R.; Hatfield, E.; Ghosh, S. Behavior of lap-spliced reinforcing bars embedded in high strength concrete. Struct. J. 1999, 96, 826–835. [Google Scholar]

- Hamad, B.S.; Najjar, S.S. Evaluation of the Role of Transverse Reinforcement in Confining Tension Lap Splices in High Strength Concrete. Mater. Struct. 2002, 35, 219–228. [Google Scholar] [CrossRef]

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Wang, Z.; Almeida Jr, J.H.S.; St-Pierre, L.; Wang, Z.; Castro, S.G. Reliability-based buckling optimization with an accelerated Kriging metamodel for filament-wound variable angle tow composite cylinders. Compos. Struct. 2020, 254, 112821. [Google Scholar] [CrossRef]

- Masoud, S.; Soudki, K.; Topper, T. Postrepair Fatigue Performance of FRP-Repaired Corroded RC Beams: Experimental and Analytical Investigation. ASCE J. Compos. Constr. 2005, 9, 441–449. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Almusallam, A.; Al-Gahtani, A.; Aziz Rasheeduzzafar, A. Effect of Reinforcement Corrosion on Bond Strength. Constr. Build. Mater. 1996, 10, 123–129. [Google Scholar] [CrossRef]

- Alrshoudi, F.; Mohammadhosseini, H.; Alyousef, R.; Alabduljabbar, H.; Mustafa Mohamed, A. The Impact Resistance and Deformation Performance of Novel Pre-Packed Aggregate Concrete Reinforced with Waste Polypropylene Fibres. Crystals 2020, 10, 788. [Google Scholar] [CrossRef]

- Alyousef, R.; Mohammadhosseini, H.; Alrshoudi, F.; Alabduljabbar, H.; Mohamed, A.M. Enhanced Performance of Concrete Composites Comprising Waste Metalised Polypropylene Fibres Exposed to Aggressive Environments. Crystals 2020, 10, 696. [Google Scholar] [CrossRef]

- El Maadawi, T.; Soudki, K. Carbon-Fibre-Reinforced Polymer Repair to Extend Service Life of Corroded Reinforced Concrete Beams. J. Compos. Constr. ASCE 2005, 9, 187–194. [Google Scholar] [CrossRef]

- Okada, K.; Kobayashi, I.K.; Miyagawa, T. Influence of Longitudinal Cracking Due to Reinforcement Corrosion on Characteristics of Reinforced Concrete Members. Struct. J. 1988, 85, 134–140. [Google Scholar]

- Tahir, M.M.; Mohammadhosseini, H.; Ngian, S.P.; Effendi, M.K. I-beam to square hollow column blind bolted moment connection: Experimental and numerical study. J. Constr. St. Rese. 2018, 148, 383–398. [Google Scholar] [CrossRef]

- Cabrera, J.G. Deterioration of Concrete Due to Reinforcement Steel Corrosion. Cem. Concr. Compos. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- ACI (American Concrete Institute). Protection of Metals in Concrete against Corrosion; ACI 222-01: Farmington Hills, MI, USA, 2001. [Google Scholar]

- ACI (American Concrete Institute). Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI 440.2R-08: Farmington Hills, MI, USA, 2008. [Google Scholar]

- Garcia, R.; Helal, Y.; Pilakoutas, K.; Guadagnini, M. Bond Strength of Short Lap Splices in RC Beams Confined with Steel Stirrups or External CFRP. Mater. Struct. 2015, 48, 277–293. [Google Scholar] [CrossRef]

- Alyousef, R.; Topper, T.; Al-Mayah, A. Effect of FRP Wrapping on Fatigue Bond Behavior of Spliced Concrete Beams. J. Compos. Constr. 2015, 20, 04015030. [Google Scholar] [CrossRef]

- 24. Shihata, Ayman. 2011CFRP Strengthening of RC Beams with Corroded Lap Spliced Steel Bars. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2011.

- Almeida, J.H.S.; Souza, S.D.; Botelho, E.C.; Amico, S.C. Carbon fiber-reinforced epoxy filament-wound composite laminates exposed to hygrothermal conditioning. J. Mater. Sci. 2016, 51, 4697–4708. [Google Scholar] [CrossRef] [Green Version]

- Antunes, M.B.; Almeida, J.H.S., Jr.; Amico, S.C. Curing and seawater aging effects on mechanical, thermal, and physical properties of glass/epoxy filament wound composite cylinders. Compos. Commun. 2020, 22, 100517. [Google Scholar] [CrossRef]

- Malumbela, G.; Alexander, M.; Moyo, P. Serviceability of Corrosion-Affected RC Beams after Patch Repairs and FRPs under Load. Mater. Struct. 2011, 44, 331–349. [Google Scholar] [CrossRef]

- Emberson, N.K.; Mays, G.C. Significance of Property Mismatch in the Patch Repair of Structural Concrete. Part 3: Reinforced concrete members in flexure. Mag. Concr. Res. 1996, 48, 45–57. [Google Scholar] [CrossRef]

- Fang, C.; Lundgren, K.; Chen, L.; Zhu, C. Corrosion Influence on Bond in Reinforced Concrete. Cem. Concr. Res. 2004, 34, 2159–2167. [Google Scholar] [CrossRef]

- ACI (American Concrete Institute). Bond and Development of Straight Reinforcing Bars in Tension; ACI 408R-03: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Alrshoudi, F.; Mohammadhosseini, H.; Tahir, M.M.; Alyousef, R.; Alghamdi, H.; Alharbi, Y.R.; Alsaif, A. Sustainable use of waste polypropylene fibers and palm oil fuel ash in the production of novel prepacked aggregate fiber-reinforced concrete. Sustainability 2020, 12, 4871. [Google Scholar] [CrossRef]

| Concrete Type | CA * (kg/m3) | FA * (kg/m3) | Cement (kg/m3) | WR * (%C) | AEA * (%C) | W * (kg/m3) | W/C | CA% |

|---|---|---|---|---|---|---|---|---|

| M | 1110 | 865 | 280 | 0.29 | 0.003 | 155 | 0.55 | 46 |

| Concrete Mechanical Properties | M | SCC |

|---|---|---|

| Compressive strength, f’c (MPa) | 42 | 48 |

| Splitting strength, ft (MPa) | 4.1 | 4.1 |

| Fracture energy, Gf (N/m) | 135 | 137 |

| Property | Typical Properties of SikaWrap Hex 103C | Cured Laminated Properties of SikaWrap Hex 103C |

|---|---|---|

| Tensile strength (MPa) | 3.7 | 1.055 |

| Tensile modulus (MPa) | 234,500 | 64,828 |

| Elongation (%) | 1.5 | 0.89 |

| Thickness (mm) | 0.34 | 1.016 |

| Property | Sikadur 330 | Sikadur 300 |

|---|---|---|

| Tensile strength (MPa) | 30 | 55 |

| Tensile modulus (MPa) | 4500 | 1724 |

| Flexural modulus (MPa) | 3800 | 3450 |

| Elongation (%) | 0.9 | 3 |

| Specimen | Corrosion Level (%) | Load on Beam at Failure (kN) | fs (MPa) | Bond Strength τb (MPa) | Bar Slip at Failure (mm) | Failure Mode * |

|---|---|---|---|---|---|---|

| LS-M-UN-C | 0 | 172.3 | 269 | 4.42 | 1.30 | S |

| LS-M-F-C | - | 231.0 | 361 | 5.91 | 2.04 | S |

| LS-SCC-UN-C | - | 186.4 | 291 | 4.78 | 1.44 | S |

| LS-SCC-F-C | - | 250.2 | 391 | 6.41 | 2.52 | S |

| LS-M-UN-7.5 | 7.5 | 173.9 | 294 | 4.63 | 1.41 | S |

| LS-M-F-7.5 | - | 245.0 | 414 | 6.51 | 2.42 | S |

| LS-SCC-UN-7.5 | - | 192.5 | 325 | 5.13 | 1.59 | S |

| LS-SCC-F-7.5 | - | 261.7 | 442 | 6.97 | 2.81 | S |

| LS-M-UN-15 | 15 | 176.8 | 324 | 4.91 | 1.52 | S |

| LS-M-F-15 | - | 258.1 | 473 | 7.16 | 2.93 | S |

| LS-SCC-UN-15 | - | 191.8 | 352 | 5.32 | 1.71 | S |

| LS-SCC-F-15 | - | 285.7 | 524 | 7.93 | 6.25 | Y + S |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alabduljabbar, H.; Alyousef, R.; Mohammadhosseini, H.; Topper, T. Bond Behavior of Cleaned Corroded Lap Spliced Beams Repaired with Carbon Fiber Reinforced Polymer Sheets and Partial Depth Repairs. Crystals 2020, 10, 1014. https://doi.org/10.3390/cryst10111014

Alabduljabbar H, Alyousef R, Mohammadhosseini H, Topper T. Bond Behavior of Cleaned Corroded Lap Spliced Beams Repaired with Carbon Fiber Reinforced Polymer Sheets and Partial Depth Repairs. Crystals. 2020; 10(11):1014. https://doi.org/10.3390/cryst10111014

Chicago/Turabian StyleAlabduljabbar, Hisham, Rayed Alyousef, Hossein Mohammadhosseini, and Tim Topper. 2020. "Bond Behavior of Cleaned Corroded Lap Spliced Beams Repaired with Carbon Fiber Reinforced Polymer Sheets and Partial Depth Repairs" Crystals 10, no. 11: 1014. https://doi.org/10.3390/cryst10111014

APA StyleAlabduljabbar, H., Alyousef, R., Mohammadhosseini, H., & Topper, T. (2020). Bond Behavior of Cleaned Corroded Lap Spliced Beams Repaired with Carbon Fiber Reinforced Polymer Sheets and Partial Depth Repairs. Crystals, 10(11), 1014. https://doi.org/10.3390/cryst10111014