1. Introduction

Ammonium nitrate (AN) is an inorganic salt that contains 35 wt % N in the form of ammonium and nitrate ions. It is highly hygroscopic and easily dissolves in water, absorbing heat from the environment in the process. It does not form hydrates and is characterized by good solubility in alcohols, such as methanol and ethanol, along with acetone and some organic and inorganic acids, such as nitric and formic acid [

1,

2].

AN is a chemical of a great practical importance due to its high nitrogen content. It is widely used in agriculture and horticulture as a mineral fertilizer. It has a few unfavorable properties, the most important of which are its tendency to cake, mainly caused by a high hygroscopicity of the salt and an absorption of moisture from the air, and a possibility to explosively decompose, which is a real threat that was proven by numerous, well-documented accidents that have occurred in the past, the most recent being the explosions in Beirut, Lebanon [

3,

4,

5,

6,

7,

8].

Ammonium nitrate can exist in several different crystal structures depending on temperature, pressure and other factors. It has six known crystalline phases at standard pressure conditions, which are stable within specific temperature ranges [

9].

Table 1 shows the temperature ranges of five ammonium nitrate phases that have a well-documented structure in the literature [

10,

11]. These phase transitions result in a volume change of the solid ammonium nitrate phase. Available literature data also indicate the existence of phase VII at temperatures below −170 °C [

10,

12].

Crystalline phases listed in

Table 1 are not the only existing ammonium nitrate crystal structures. Phase VI, the high-pressure structure of ammonium nitrate, occurs in the pressure range of 0.9–1.9 GPa at temperatures above 168 °C, and its exact structure, similarly to phase VII, is not yet known [

13].

Current research on phase transformations of ammonium nitrate suggests the existence of a high-pressure, distorted equivalent of phase IV, which occurs at pressure above 17 GPa—it is defined as phase IV [

10]. The same study also confirmed a significant influence of water in the occurrence of phase III. Some researchers suggest that dry ammonium nitrate (less than 0.1 wt % of water content) does not exist in the form of phase III and undergoes a phase transition from IV to II crystalline phase at a temperature of approximately 51 °C. At low moisture contents, simultaneous IV → III and IV → II phase transformations are observed in the temperature range from 32 to 55 °C [

10,

14].

Tests carried out with the use of X-ray diffraction (XRD) showed that, under certain conditions, it is possible for several phases of ammonium nitrate to coexist in one system. Most often, cases of this phenomenon are coexisting phases II with IV, and IV with V [

15]. If the sample is subjected to several heating and cooling cycles, the course of phase transformations may change [

16,

17].

Phase transformations of ammonium nitrate, occurring as a result of temperature increase, are accompanied by an endothermic effect and a change in the specific volume, caused by different packing of ions in the crystal structure (

Table 2). Multiple transitions from phase IV to III above 32 °C are most unfavorable, as they cause cracking of fertilizer granules, increased porosity and a greater tendency to cake during the production, transport and storage of fertilizers containing ammonium nitrate. The transformation of phase IV into phase III, with a completely different, deformed structure, is possible only in the presence of water. This is probably due to the participation of water in dissolving phase IV crystals, followed by a recrystallization of ammonium nitrate in the form of phase III [

9,

15,

18].

The nitrogen fertilizer granulation process is usually carried out at temperatures above 100 °C, what creates the possibility of changes between crystalline phase II and I of ammonium nitrate. Maintaining the temperature close to 125 °C causes cyclical phase transitions and changes of the volume of produced fertilizer granules by about 2%, which may result in a decrease in mechanical strength and an increase in porosity, which increases the susceptibility of ammonium nitrate to exothermally decompose [

9,

20,

21].

During the production of nitrogen fertilizers, various additives are used in order to change the temperature range of undesirable phase transitions beyond the range typical for conditions of transport and storage of fertilizers. Properly selected chemical compounds allow for the elimination of some phase transitions or reduction in the unfavorable impact of said transformations between crystal structures on properties of the final product [

22].

Additives with a stabilizing effect on ammonium nitrate may fulfill various functions. Some of them act by stabilizing the crystalline structure of ammonium nitrate, limiting its phase transitions. This effect is considered to be a physical stabilization. Other additives increase the temperature of the onset of thermal decomposition of ammonium nitrate and limit the occurrence of undesirable phenomena accompanying this process, e.g., the release of significant amounts of heat or gaseous products. They can also reduce the possibility of ammonium nitrate to explosively decompose. Carbonate minerals are often used for this purpose, such as dolomite, limestone and anhydrite [

14,

23]. All these interactions are considered as a chemical stabilization.

Properties of carbonates that inhibit the exothermic decomposition of ammonium nitrate have been confirmed by numerous scientific studies. It was proven that 20 wt % of calcium, magnesium, sodium, ammonium and potassium carbonates in systems with ammonium nitrate increased the temperature of obtaining the maximum exothermic effect of the decomposition process in comparison to pure ammonium nitrate [

24]. Studies with dolomites and limestones have shown that carbonate minerals are highly effective in inhibiting the exothermic decomposition of ammonium nitrate [

25].

Potassium salts have the ability to form solid phase solutions with ammonium nitrate, in which the NH

4+ ion is exchanged with the K

+ ion, stabilizing its crystal structure. Such a substitution is made possible by the similarity of the potassium ion (with an ion radius of 1.38 Å) with the ammonium ion (1.48 Å) [

26,

27,

28]. The similarity of these two ions causes the formation of a double salt in which its salts crystallize as one substance and dissociate independently of each other after dissolving in water [

29].

Both potassium and carbonate salts have a positive influence on thermal stability of AN. Systems containing potassium carbonate salts together with ammonium nitrate have not yet been studied in temperature ranges typical for fertilizer production processes and their influence on phase transitions of AN is not yet properly defined. It is important to understand phenomena occurring in such systems and it might be useful to know how they compare to pure AN or mixtures of ammonium nitrate and calcium carbonate.

2. Materials and Methods

2.1. Materials

Ammonium nitrate (POCH, Gliwice, Poland, purity ≥ 99.0 wt %), calcium carbonate (POCH, Gliwice, Poland, purity ≥ 99.0 wt %), potassium carbonate (POCH, Gliwice, Poland, purity ≥ 99.0 wt %) and potassium hydrogen carbonate (POCH, Gliwice, Poland, purity ≥ 99.0 wt %) were used without any further purification. Synthetic air (Air Liquide) was used as a purge gas during DTA-TG-MS measurements.

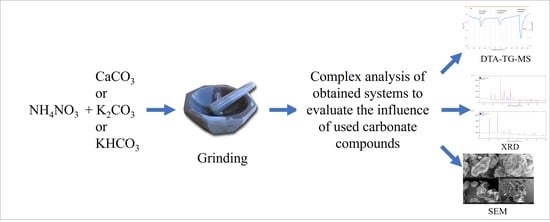

Every tested sample was prepared with the use of agate mortar and pestle. Appropriate amounts of each compound, necessary to acquire a desired mass ratio in a sample (AN:carbonate salt equal to 1:1), were ground together in order to obtain a homogenic mixture.

2.2. Methodology

Thermal analysis measurements were performed with the use of differential thermal analysis coupled with thermogravimetry and mass spectrometry (DTA–TG–MS). A thermal analyzer STA 449 F3 with a thermobalance and a mass spectrometer QMS 403 C, Netzsch, Selb, Germany, were used. The equipment was previously calibrated to ensure that correct results were obtained.

Next, a sample of a mixture containing approximately 40.0 mg of AN was weighted and placed in a 0.3 cm

3 alumina crucible and closed with a pierced lid. Each sample was heated up to 140 °C at the rate of 3 °C/min in synthetic air with a 30 cm

3/min total flow of the purge gas. Every measurement was preceded by heating an empty crucible to 400 °C in order to remove any impurities and a correction to 200 °C for a compensation of thermal effects associated with characteristics of the crucible. Before each measurement, the furnace chamber was evacuated three times and filled with synthetic air. Each mixture was analyzed three times in order to ensure that obtained thermograms are correct and mean values with corrected standard deviation for each sample are presented in

Table 3. In the same way, for comparison purposes, a 40.0 mg sample of ammonium nitrate without the addition of any carbonate was also examined with the use of an empty crucible as a reference material. Obtained results were analyzed with the use of a professional software supplied by the manufacturer of the measuring equipment. The selected ion monitoring for mass-to-charge ratios (

m/z) consisted of following signals: 12 (CO, CO

2), 15 (NH

3), 18 (H

2O), 30 (NO, NO

2), 44 (N

2O, CO

2), 46 (NO

2). MS analyses for every sample are also presented in order to show changes in gaseous products resulting from the addition of each compound.

The scanning electron microscopy (SEM) analysis was performed on Quanta 650 FEG (Thermo Fisher Scientific, Waltham, MA, USA) device equipped with a heating stage in extended vacuum mode (ESEM). Samples were heated up to temperatures of 130–180 °C. Obtained results were presented in the form of images of samples at room temperature and at approximately 130–180 °C. The heating rate was set to 10 °C/min up to 120 °C and then lowered to 5 °C/min afterwards.

Prepared mixtures were characterized by powder X-ray diffraction (XRD) analysis. The XRD patterns were recorded on Empyrean X-ray powder diffraction diffractometer (PANalytical, Malvern, UK). Work parameters of the instrument were as follows: 40 kV, 40 mA, CuKα radiation (α = 1.5406 Å). Samples analyzed at an elevated temperature (130 °C) were studied in a temperature chamber HTK1200 with nitrogen used as a purge gas (5 dm3/h) and a heating rate of 10 °C/min. Obtained results were analyzed with the use of a PDF 4+ 2019 database and presented as diffractograms for each tested sample at room temperature and at 130 °C.

3. Results and Discussion

Results obtained from thermal analysis of prepared samples are presented in the form of figures located in appropriate subsections and are summarized in

Table 3. Temperatures of phase transitions and other observed thermal effects were determined as onset temperatures due to their relatively “sharp” beginnings. Prepared samples were assigned symbols as follows: P1—pure ammonium nitrate, P2—ammonium nitrate and calcium carbonate, P3—ammonium nitrate and potassium hydrogen carbonate, P4—ammonium nitrate and potassium carbonate.

3.1. Characteristics of Pure Ammonium Nitrate (P1)

The results of the thermal analysis of the 40.0 mg ammonium nitrate sample are shown in

Figure 1. During the heating of the sample, ammonium nitrate underwent a sequence of endothermic phase transitions that are specific to this compound and were described in the introduction. Simultaneous IV → III and IV → II phase transitions were recorded at average temperature of 50.8 °C. The III → II transition occurred at 86.0 °C and II → I at 124.8 °C. No evolved gaseous products nor a decrease in mass were recorded during performed analyses of pure AN. Obtained MS signals are presented in

Figure 2.

The ammonium nitrate sample was also analyzed with the use of XRD and SEM in order to obtain reference results that could improve the understanding of phenomena occurring in AN:carbonates mixtures and to verify the purity of used material. XRD measurements (

Figure 3) clearly showed that ammonium nitrate had an orthorhombic crystal system at room temperature (phase IV) and changed fully into phase I, which is characterized as a cubic system, after being heated to 130 °C. SEM analysis allowed for further differentiation between studied phases of ammonium nitrate, showing visible changes in the structure of the sample as it was heated up to 130 °C. It was also possible to notice that ammonium nitrate started to slowly decompose after reaching the desired temperature. Obtained images are shown in

Figure 4.

3.2. Characteristics of Ammonium Nitrate and Calcium Carbonate System (P2)

A thermogram containing results of DTA-TG measurement of 80.0 mg P2 sample is presented in

Figure 5. During the heating program, the studied mixture showed similarity in its thermal properties to the pure ammonium nitrate with the exception of an absent endothermic phase transition at around 86 °C that vas visible during the analysis of the P1 sample. It was indicative that the first endothermic signal registered on the DTA curve represented only the IV → II phase transition of AN, explaining the absence of a thermal effect at the temperature typical for the III → II transformation. The II → I change was observed at an average temperature of 125.0 °C and was connected with a slight mass decrease that resulted in the creation of N

2O and H

2O (

Figure 6). Evacuated gaseous products were probably created during a partial decomposition of ammonium nitrate, according to reaction 1. Trace amounts of NH

3 and CO

2 were also detected, suggesting that a simultaneous reaction 2 might have also started to occur, but to a significantly lesser extent.

The XRD measurement of the P2 sample (

Figure 7) allowed us to determine that crystalline phases of ammonium nitrate at 25 and 130 °C were the same as in the P1 sample. CaCO

3 was in the form of calcite at both temperatures. There was not enough calcium nitrate in the studied system at 130 °C for the measurement to record its presence during the analysis. The SEM measurement revealed visible structural differences between the studied system at room temperature and at temperatures above 130 °C. Obtained images are presented in

Figure 8.

Performed analyses show that the pure calcium carbonate is too reactive to be considered suitable for the main filler in fertilizer production since it should not react with ammonium nitrate at such low temperatures.

3.3. Characteristics of Ammonium Nitrate and Potassium Hydrogen Carbonate System (P3)

The sample containing ammonium nitrate and potassium hydrogen carbonate in a 1:1 mass ratio had vastly different thermal properties than the previous two samples, P1 and P2. During the sample preparation in a mortar, there was a noticeable smell of ammonia, suggesting that a partial reaction between two salts began even before the measurement. Thermal analysis of the mixture revealed the appearance of an endothermic effect at around 40.6 ± 0.1 °C. Since the presence of potassium is known to stop the low temperature transition of ammonium nitrate, the endothermic effect may have been caused by a reaction taking place in the studied sample. The next thermal effect was difficult to define, as it occurred in a wide temperature range and was connected with a slow decrease in mass up until a temperature of approximately 86 °C was reached. After that, the mass drop slowed down and continued with an increasing rate until the end of the heating program. The last phase transition of ammonium nitrate was not influenced by the presence of the potassium salt in the system (

Figure 9). The MS measurements, preformed during the thermal analysis, made it possible to observe a creation of all monitored gaseous products. Their quantities varied with the process progression and first peaked at the temperature of III → II phase transition and then continued to increase with heating. Obtained MS results are shown in

Figure 10.

The P3 sample was analyzed with the use of XRD (

Figure 11) at both 25 and 130 °C. The presence of potassium nitrate and ammonium hydrogen carbonate was determined during the measurement at room temperature, indicating that reaction 3 occurred.

However, there was not enough potassium hydrogen carbonate to allow for total conversion of ammonium nitrate, so there must have been some AN remaining in the studied system. Reaction 3 may also explain the decrease in mass during the thermal analysis of the P3 sample, as ammonium hydrogen carbonate is not thermally stable and should decompose at elevated temperatures. The XRD measurement at 130 °C showed that only potassium nitrate and ammonium nitrate remained in the analyzed mixture, further proving the hypothesis.

SEM analysis showed very minor changes in the structure of analyzed powder after heating it to 141 and then to 160 °C. Observed images are presented as

Figure 12.

Performed measurements prove a high reactivity of potassium hydrogen carbonate in relation to ammonium nitrate.

3.4. Characteristics of Ammonium Nitrate and Potassium Carbonate System (P4)

The ammonia smell, noticed during the preparation of ammonium nitrate and potassium hydrogen carbonate, was more intense during the grinding process of the P4 sample. DTA-TG measurements of the P4 sample recorded a similar, low-temperature endothermic effect as the one observed for the P3 sample. It began at approximately 38 °C and was followed by an accelerating decrease in mass. Unlike in the P3 sample, the decrease did not slow down after the temperature reached 86 °C. The decrease in mass might have been a result of the release of moisture from the potassium carbonate and of reactions occurring between AN and the carbonate salt. The assumed reaction 4 was expected to occur between these two compounds. Obtained results are presented in

Figure 13. MS signals, acquired during the measurement, are shown in

Figure 14. Gaseous products evolved from the analyzer initially consisted of mostly H

2O and small amounts of N

2O, CO

2 and NH

3. After the sample heated up to 125 °C, additional amounts of previous gasses were generated together with NO and NO

2.

XRD results at 25 °C, shown in

Figure 15, indicated the presence of potassium nitrate, ammonium hydrogen carbonate, potassium hydrogen carbonate and small amounts of ammonium nitrate, while the XRD performed at 130 °C revealed crystal structures of potassium nitrate, potassium carbonate and ammonium nitrate. These analyses could suggest that the above-mentioned reaction 4 might only be a simplified, general chemical reaction. To explain the presence of detected crystalline phases, multiple reactions would have to occur, such as:

Reaction 5 presents the formation of potassium hydrogen carbonate in the studied system. Reaction 6 could be defined as reaction 4 with the decomposition of ammonium carbonate. The last one, reaction 7, represents the formation of potassium carbonate from potassium hydrogen carbonate at temperatures above 120 °C. The high reactivity of the system may also cause ammonium nitrate to decompose at temperatures that are not usual for the pure compound.

SEM analysis made it possible to observe substantial structural differences between the studied system at room temperature and at 130–160 °C. Obtained images are shown in

Figure 16.