The Effect of Reaction Conditions and Presence of Magnesium on the Crystallization of Nickel Sulfate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up for Crystallization Experiments

2.2. Experimental Methods and Characterization

2.2.1. Preparation of Nickel Sulfate Seeds

2.2.2. Crystallization Experiments

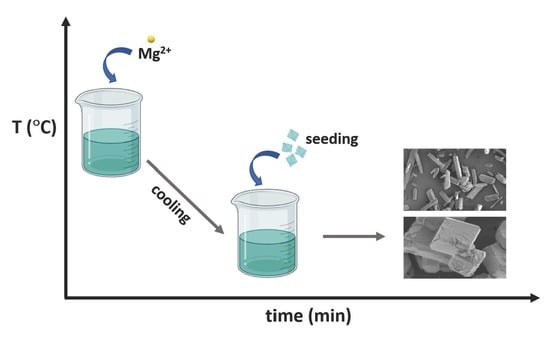

2.2.3. Seeded Experiments

2.2.4. Unseeded Experiments

2.2.5. Magnesium Uptake during Crystallization

2.2.6. Characterization

2.2.7. Phase Transformation in Solution and in Solid-State

3. Results

3.1. Crystallization of Nickel Sulfate

3.1.1. Effect of Temperature

3.1.2. Effect of Seed Amount

3.2. Crystallization of Nickel Sulfate in the Presence of Magnesium

3.2.1. Effect of Initial Mg Content

3.2.2. Effect of Seed Amount

3.3. Phase Transformation of Nickel Sulfate Crystals

3.3.1. Phase Transformation in Suspension

3.3.2. Phase Transformation in the Dry State

4. Discussion

4.1. Effect of Temperature and Seed Amount

4.2. Effect of Magnesium

4.3. Transformation of Nickel Sulfate Hydrates in Solution and Dry State

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| α-NSH6 | α-NiSO4·6H2O |

| β-NSH6 | β-NiSO4·6H2O |

| NSH7 | NiSO4·7H2O |

| EVB | Electric vehicle battery |

| SEM | Scanning electron microscopy |

| XRD | X-ray diffraction |

References

- He, Y.; Su, G.; Yu, X.; Li, Z.; Huang, B.; Jang, R.; Zhao, Q. Growth of α-nickel sulphate hexahydrate for ultraviolet filters. J. Cryst. Growth 1996, 169, 193–195. [Google Scholar] [CrossRef]

- Thirupathy, J.; Dhas, S.S.J.; Jose, M.; Dhas, S.M.B. An investigation on optical, mechanical and thermal properties of nickel sulphate hexahydrate single crystal—A UV band pass filter. Mater. Res. Express 2019, 6, 086206. [Google Scholar] [CrossRef]

- Volkova, E.; Demidov, A. Production of nickel sulfate single crystals in processing of nickel oxide electrodes of alkaline batteries. Russ. J. Appl. Chem. 2010, 83, 1874–1876. [Google Scholar] [CrossRef]

- Han, B.; Bøckman, O.; Wilson, B.P.; Lundström, M.; Louhi-Kultanen, M. Purification of Nickel Sulfate by Batch Cooling Crystallization. Chem. Eng. Technol. 2019, 42, 1475–1480. [Google Scholar] [CrossRef]

- Berckmans, G.; Messagie, M.; Smekens, J.; Omar, N.; Vanhaverbeke, L.; Van Mierlo, J. Cost Projection of State of the Art Lithium-Ion Batteries for Electric Vehicles Up to 2030. Energies 2017, 10, 1314. [Google Scholar] [CrossRef] [Green Version]

- The European Commission. White Paper: European Transport Policy for 2010: Time to Decide; The European Commission: Bruxelles, Belgium, 2001. [Google Scholar]

- Bloomberg Finance. New Energy Finance, Electric Vehicle Outlook 2017—Executive Summary. 2017. Available online: http://data.bloomberglp.com/bnef/sites/14/2017/07/BNEF_EVO_2017_ExecutiveSummary.pdf (accessed on 16 July 2019).

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Coman, V.; Robotin, B.; Ilea, P. Nickel recovery/removal from industrial wastes: A review. Resour. Conserv. Recycl. 2013, 73, 229–238. [Google Scholar] [CrossRef]

- Nyirenda, R.; Phiri, W. The removal of nickel from copper electrorefining bleed-off electrolyte. Miner. Eng. 1998, 11, 23–37. [Google Scholar] [CrossRef]

- Agrawal, A.; Manoj, M.K.; Kumari, S.; Bagchi, D.; Kumar, V.; Pandey, B.D. Extractive separation of copper and nickel from copper bleed stream by solvent extraction route. Miner. Eng. 2008, 21, 1126–1130. [Google Scholar] [CrossRef]

- Roskill. Nickel Sulphate Outlook to 2030. 2021. Available online: https://roskill.com/market-report/nickel-sulphate/ (accessed on 25 October 2021).

- Ma, Y.; Svärd, M.; Xiao, X.; Gardner, J.M.; Olsson, R.T.; Forsberg, K. Precipitation and Crystallization Used in the Production of Metal Salts for Li-Ion Battery Materials: A Review. Metals 2020, 10, 1609. [Google Scholar] [CrossRef]

- Nicholls, D. The Chemistry of Iron, Cobalt and Nickel: Comprehensive Inorganic Chemistry; Elsevier Science: Amsterdam, The Netherlands, 2013; pp. 1109–1159. [Google Scholar]

- Steele, B.D.; Johnson, F. XIII.—The solubility curves of the hydrates of nickel sulphate. J. Chem. Soc. Trans. 1904, 85, 113–120. [Google Scholar] [CrossRef] [Green Version]

- Angel, R.; Finger, L. Polymorphism of nickel sulfate hexahydrate. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1988, 44, 1869–1873. [Google Scholar] [CrossRef] [Green Version]

- Mullin, J.W. Crystallization; Elsevier Science: Amsterdam, The Netherlands, 2001; pp. 280–284. [Google Scholar]

- Sangwal, K. Additives and Crystallization Processes: From Fundamentals to Applications; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Manomenova, V.L.; Rudneva, E.B.; Voloshin, A.E.; Soboleva, L.V.; Vasil’ev, A.B.; Mchedlishvili, B.V. Growth of α-NiSO4·6H2O crystals at high rates. Crystallogr. Rep. 2005, 50, 877–882. [Google Scholar] [CrossRef]

- Friesen, M.; Burt, H.; Mitchell, A. The dehydration of nickel sulfate. Thermochim. Acta 1980, 41, 167–174. [Google Scholar] [CrossRef]

- Svarovsky, L. 2—Characterization of particles suspended in liquids. In Solid-Liquid Separation, 4th ed.; Svarovsky, L., Ed.; Butterworth-Heinemann: Oxford, UK, 2001; pp. 30–65. [Google Scholar]

- Davey, R.; Blagden, N.; Potts, A.G.D.; Docherty, R. Polymorphism in Molecular Crystals: Stabilization of a Metastable Form by Conformational Mimicry. J. Am. Chem. Soc. 1997, 119, 1767–1772. [Google Scholar] [CrossRef]

- Sakata, Y.; Takenouchi, K. Studies on the Behaviors of Impurities on the Crystallization of L-Glutamic Acid—Part III. Influences of Some Factors on the Solubility. Agric. Biol. Chem. 1962, 26, 824–830. [Google Scholar]

- Kul’kov, A.M.; Glikin, A.E. Replacement of nickelhexahydrite with retgersite: Polymorphic-metasomatic structures. Geol. Ore Depos. 2007, 49, 821–826. [Google Scholar] [CrossRef]

- Bourcier, D.; Féraud, J.; Colson, D.; Mandrick, K.; Ode, D.; Brackx, E.; Puel, F. Influence of particle size and shape properties on cake resistance and compressibility during pressure filtration. Chem. Eng. Sci. 2016, 144, 176–187. [Google Scholar] [CrossRef]

- Jenssen, I.B.; Ucar, S.; Bøckman, O.; Dotterud, O.M.; Andreassen, J.-P. Impurity Uptake During Cooling Crystallization of Nickel Sulfate; Springer International Publishing: Cham, Switzerland, 2020; pp. 191–199. [Google Scholar]

- Kathiravan, P.; Balakrishnan, T.; Srinath, C.; Ramamurthi, K.; Thamotharan, S. Growth and characterization of α-nickel sulphate hexahydrate single crystal. Karbala Int. J. Mod. Sci. 2016, 2, 226–238. [Google Scholar] [CrossRef] [Green Version]

- Moldoveanu, G.A.; Demopoulos, G.P. Producing high-grade nickel sulfate with solvent displacement crystallization. JOM 2002, 54, 49–53. [Google Scholar] [CrossRef]

- Kubota, N.; Doki, N.; Yokota, M.; Sato, A. Seeding policy in batch cooling crystallization. Powder Technol. 2001, 121, 31–38. [Google Scholar] [CrossRef]

- Chung, S.H.; Ma, D.L.; Braatz, R.D. Optimal seeding in batch crystallization. Can. J. Chem. Eng. 1999, 77, 590–596. [Google Scholar] [CrossRef]

- Berner, R.A. The role of magnesium in the crystal growth of calcite and aragonite from sea water. Geochim. Cosmochim. Acta 1975, 39, 489–504. [Google Scholar] [CrossRef]

- Kitano, Y. The behavior of various inorganic ions in the separation of calcium carbonate from a bicarbonate solution. Bull. Chem. Soc. Jpn. 1962, 35, 1973–1980. [Google Scholar] [CrossRef]

- Henck, J.O.; Kuhnert-Brandstatter, M. Demonstration of the terms enantiotropy and monotropy in polymorphism research exemplified by flurbiprofen. J. Pharm. Sci. 1999, 88, 103–108. [Google Scholar] [CrossRef] [PubMed]

- Kitamura, M. Strategy for control of crystallization of polymorphs. CrystEngComm 2009, 11, 949–964. [Google Scholar] [CrossRef]

- Frondel, C.; Palache, C. Retgersite, NiSO4·6H2O, a new mineral. Am. Mineral. J. Earth Planet. Mater. 1949, 34, 188–194. [Google Scholar]

- Sinha, S.; Deshpande, N.; Deshpande, D. Thermal dehydration of crystallin NiSO4·6H2O. Thermochim. Acta 1989, 144, 83–93. [Google Scholar] [CrossRef]

| Seed Amount (g) | Mg Content (mg/g tot) |

|---|---|

| T = 25 °C | |

| 0 | 0 |

| 0 | 18 |

| 0.2 | 0 |

| 0.2 | 5 |

| 0.2 | 9 |

| 0.2 | 18 |

| 2 | 0 |

| 2 | 9 |

| T = 70 °C | |

| 0.2 | 0 |

| 2 | 0 |

| Nickel Sulfate Hydrate | Abbreviations | Characteristic Peaks (2θ) |

|---|---|---|

| α-NiSO4·6H2O | α-NSH6 | 19.4° and 20.9° |

| β-NiSO4·6H2O | β-NSH6 | 20.4° and 22.3° |

| NiSO4·7H2O | NSH7 | 16.7° and 21.1° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jenssen, I.B.; Bøckman, O.; Andreassen, J.-P.; Ucar, S. The Effect of Reaction Conditions and Presence of Magnesium on the Crystallization of Nickel Sulfate. Crystals 2021, 11, 1485. https://doi.org/10.3390/cryst11121485

Jenssen IB, Bøckman O, Andreassen J-P, Ucar S. The Effect of Reaction Conditions and Presence of Magnesium on the Crystallization of Nickel Sulfate. Crystals. 2021; 11(12):1485. https://doi.org/10.3390/cryst11121485

Chicago/Turabian StyleJenssen, Ina Beate, Oluf Bøckman, Jens-Petter Andreassen, and Seniz Ucar. 2021. "The Effect of Reaction Conditions and Presence of Magnesium on the Crystallization of Nickel Sulfate" Crystals 11, no. 12: 1485. https://doi.org/10.3390/cryst11121485

APA StyleJenssen, I. B., Bøckman, O., Andreassen, J. -P., & Ucar, S. (2021). The Effect of Reaction Conditions and Presence of Magnesium on the Crystallization of Nickel Sulfate. Crystals, 11(12), 1485. https://doi.org/10.3390/cryst11121485