Effects of Al Composition and High-Temperature Atomic Layer-Deposited Al2O3 Layer on the Leakage Current Characteristics of AlGaN/GaN Schottky Barrier Diodes

Abstract

:1. Introduction

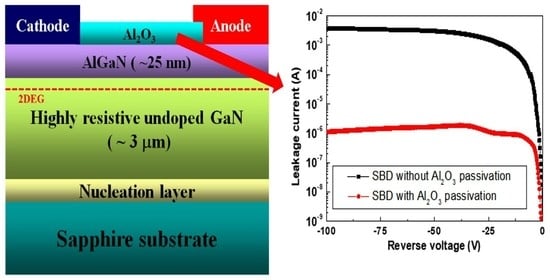

2. Experiments

3. Results and Discussion

3.1. Effect of Al Composition on Characteristics of AlGaN/GaN SBDs

3.2. High Temperature Al2O3 Dielectric Layers

3.3. I–V Curves of the Fabricated AlGaN/GaN SBDs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Mat-sushita, T.; Sugimoto, Y.; Kiyoku, H. High-Power, Long-Lifetime InGaN Multi-Quantum-Well-Structure Laser Diodes. Jpn. J. Appl. Phys. 1997, 36, L1059. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, D.Y.; Oh, B.W.; Lee, J.H. Comparison of InGaN-based LEDs grown on conventional sapphire and cone-shape-patterned sapphire substrate. IEEE Trans. Electron Dev. 2010, 57, 157. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Schaff, W.J.; Eastman, L.F.; Dimitrov, R.; Wittmer, L.; et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.-F.; Kapolnek, D.; Ibbetson, J.P.; Parikh, P.; Keller, B.P.; Mishra, U.K. Very-high power density AlGaN/GaN HEMTs. IEEE Electron Dev. Lett. 2001, 48, 586. [Google Scholar]

- Uemoto, Y.; Hikita, M.; Ueno, H.; Matsuo, H.; Ishida, H.; Yanagihara, M.; Ueda, T.; Tanaka, T.; Ueda, D. Gate injection transistor (GIT)-A normally-off AlGaN/GaN power transistor using conductivity modulation. IEEE Trans. Electron Dev. 2007, 54, 3393. [Google Scholar] [CrossRef]

- Lee, J.-H.; Im, K.-S.; Kim, J.K.; Lee, J.-H. Performance of recessed anode AlGaN/GaN Schottky barrier diode passivated with high-temperature atomic layer-deposited Al2O3 layer. IEEE Trans. Electron Dev. 2019, 66, 324. [Google Scholar] [CrossRef]

- Hasegawa, H.; Oyama, S. Mechanism of anomalous current transport in n-type GaN Schottky contacts. J. Vac. Sci. Technol. B 2002, 20, 1647. [Google Scholar] [CrossRef]

- Klein, P.B.; Binari, S.C.; Ikossi, K.; Wickenden, A.E.; Koleske, D.D.; Henry, R.L. Current collapse and the role of carbon in AlGaN/GaN high electron mobility transistors grown by metalorganic vapor-phase epitaxy. Appl. Phys. Lett. 2001, 79, 3527. [Google Scholar] [CrossRef]

- Vetury, R.; Zhang, N.Q.; Keller, S.; Mishra, U.K. The impact of surface states on the DC and RF characteristics of AlGaN/GaN HFETs. IEEE Trans. Electron Dev. 2001, 48, 560. [Google Scholar] [CrossRef]

- Hasegawa, H.; Inagaki, T.; Ootomo, S.; Hashizume, T. Mechanisms of current collapse and gate leakage currents in AlGaN/GaN heterostructure field effect transistors. J. Vac. Sci. Technol. B 2003, 21, 1844. [Google Scholar] [CrossRef] [Green Version]

- Simin, G.; Koudymov, A.; Fatima, H.; Zhang, J.; Yang, J.; Khan, M.A.; Hu, X.; Tarakji, A.; Gaska, R.; Shur, M. SiO2/AlGaN/InGaN/GaN MOSDHFETs. IEEE Electron Dev. Lett. 2002, 23, 458. [Google Scholar] [CrossRef]

- Onojima, N.; Higashiwaki, M.; Suda, J.; Kimoto, T.; Mimura, T.; Matsui, T. Reduction in potential barrier height of AlGaN/GaN heterostructures by SiN passivation. J. Appl. Phys. 2007, 101, 043703. [Google Scholar] [CrossRef]

- Wang, C.; Maeda, N.; Hiroki, M.; Yokoyama, H.; Watanabe, N.; Makimoto, T.; Enoki, T.; Kobayashi, T. Mechanism of superior suppression effect on gate current leakage in ultrathin Al2O3/Si3N4 bilayer-based AlGaN/GaN insulated gate heterostructure field-effect transistors. Jpn. J. Appl. Phys. 2006, 45, 40. [Google Scholar] [CrossRef]

- Lee, J.-H.; Jeong, J.-H.; Lee, J.-H. Enhanced Electrical Characteristics of AlGaN-Based SBD With In Situ Deposited Silicon Carbon Nitride Cap Layer. IEEE Electron Dev. Lett. 2012, 33, 492. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, M.-B.; Hahm, S.-H.; Lee, Y.-H.; Lee, J.-H.; Bae, Y.-H.; Cho, H.K. Growth of Semi-insulating GaN Layer by Controlling Size of Nucleation Sites for SAW Device Applications. MRS Internet J. Nitride Semicond. Res. 2003, 8, 5. [Google Scholar] [CrossRef]

- Kim, J.K.; Jang, H.W.; Lee, J.L. Current conduction mechanism of Pt/GaN and Pt/Al0.35 Ga0.65N Schottky diodes. J. Appl. Phys. 2003, 94, 7201. [Google Scholar] [CrossRef] [Green Version]

- Kotani, J.; Kaneko, M.; Hasegawa, H.; Hashizume, T. Large reduction of leakage currents in AlGaN Schottky diodes by a surface control process and its mechanism. J. Vac. Sci. Technol. B 2006, 24, 2148. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Lu, X.; Jiang, H.; Liu, C.; Lau, K.M. In situ growth of SiNx as gate dielectric and surface passivation for AlN/GaN heterostructures by metalorganic chemical vapor deposition. Appl. Phys. Exp. 2014, 7, 091002. [Google Scholar] [CrossRef]

- Pakula, K.; Bozek, R.; Baranowski, J.M.; Jasinski, J.; Liliental-Weber, Z. Reduction of dislocation density in heteroepitaxial GaN: Role of SiH4 treatment. J. Cryst. Growth 2004, 267, 1. [Google Scholar] [CrossRef]

- Miller, E.J.; Schaadt, D.M.; Yu, E.T. Origin and microscopic mechanism for suppression of leakage currents in Schottky contacts to GaN grown by molecular-beam epitaxy. J. Appl. Phys. 2003, 94, 7611. [Google Scholar] [CrossRef] [Green Version]

- Faraci, G.; Rosa, S.; Hwu, Y.; Margaritondo, G. Al intermediate oxidation states observed by core level photoemission spectroscopy. J. Appl. Phys. 1995, 78, 4091. [Google Scholar] [CrossRef]

- Kang, H.-S.; Reddy, M.S.P.; Kim, D.-S.; Kim, K.-W.; Ha, J.-B.; Lee, Y.S.; Choi, H.-C.; Lee, J.-H. Effect of oxygen species on the positive flat-band voltage shift in Al2O3/GaN metal–insulator–semiconductor capacitors with post-deposition annealing. J. Phys. D Appl. Phys. 2013, 46, 155101. [Google Scholar] [CrossRef]

- Terman, L.M. An investigation of surface states at a silicon/silicon oxide interface employing metal-oxide-silicon diodes. Solid-State Electron. 1962, 5, 285. [Google Scholar] [CrossRef]

- Lee, J.-H.; Park, C.; Im, K.-S.; Lee, J.-H. AlGaN/GaN-based lateral-type schottky barrier diode with very low reverse recovery charge at high temperature. IEEE Trans. Electron Dev. 2013, 60, 3032. [Google Scholar] [CrossRef]

- Cheung, S.K.; Cheung, N.W. Extraction of Schottky diode parameters from forward current–voltage characteristics. Appl. Phys. Lett. 1986, 49, 85. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-H.; Lee, J.-H.; Im, K.-S. Effects of Al Composition and High-Temperature Atomic Layer-Deposited Al2O3 Layer on the Leakage Current Characteristics of AlGaN/GaN Schottky Barrier Diodes. Crystals 2021, 11, 87. https://doi.org/10.3390/cryst11020087

Lee J-H, Lee J-H, Im K-S. Effects of Al Composition and High-Temperature Atomic Layer-Deposited Al2O3 Layer on the Leakage Current Characteristics of AlGaN/GaN Schottky Barrier Diodes. Crystals. 2021; 11(2):87. https://doi.org/10.3390/cryst11020087

Chicago/Turabian StyleLee, Jae-Hoon, Jung-Hee Lee, and Ki-Sik Im. 2021. "Effects of Al Composition and High-Temperature Atomic Layer-Deposited Al2O3 Layer on the Leakage Current Characteristics of AlGaN/GaN Schottky Barrier Diodes" Crystals 11, no. 2: 87. https://doi.org/10.3390/cryst11020087

APA StyleLee, J. -H., Lee, J. -H., & Im, K. -S. (2021). Effects of Al Composition and High-Temperature Atomic Layer-Deposited Al2O3 Layer on the Leakage Current Characteristics of AlGaN/GaN Schottky Barrier Diodes. Crystals, 11(2), 87. https://doi.org/10.3390/cryst11020087