A Stable and Efficient Pt/n-Type Ge Schottky Contact That Uses Low-Cost Carbon Paste Interlayers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization

3. Results and Discussion

3.1. I–V Characteristics

3.2. C–V Characteristics

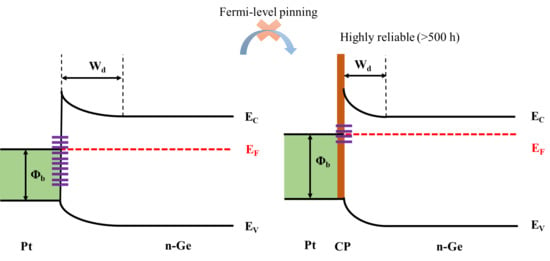

3.3. Energy Band Diagrams

3.4. Long-Term Reliability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chawanda, A.; Coelho, S.M.M.; Auret, F.D.; Mtangi, W.; Nyamhere, C.; Nel, J.M.; Diale, M. Effect of thermal treatment on the characteristics of iridium Schottky barrier diodes on n-Ge (100). J. Alloy. Compd. 2012, 513, 44–49. [Google Scholar] [CrossRef] [Green Version]

- Ruan, D.-B.; Chang-Liao, K.-S.; Hong, Z.-Q.; Huang, J.; Yi, S.-H.; Liu, G.-T.; Chiu, P.-C.; Li, Y.-L. Radiation effects and reliability characteristics of Ge pMOSFETs. Microelectron. Eng. 2019, 216. [Google Scholar] [CrossRef]

- Pfeiffer, U.R.; Mishra, C.; Rassel, R.M.; Pinkett, S.; Reynolds, S.K. Schottky Barrier Diode Circuits in Silicon for Future Millimeter-Wave and Terahertz Applications. IEEE Trans. Microw. Theory Tech. 2008, 56, 364–371. [Google Scholar] [CrossRef]

- Lou, X.; Zhang, W.; Xie, Z.; Yang, L.; Yu, X.; Liu, Y.; Chang, H. Solution-processed high-k dielectrics for improving the performance of flexible intrinsic Ge nanowire transistors: Dielectrics screening, interface engineering and electrical properties. J. Phys. D Appl. Phys. 2019, 52. [Google Scholar] [CrossRef]

- Khurelbaatar, Z.; Kil, Y.-H.; Shim, K.-H.; Cho, H.; Kim, M.-J.; Kim, Y.-T.; Choi, C.-J. Temperature Dependent Current Transport Mechanism in Graphene/Germanium Schottky Barrier Diode. JSTS J. Semicond. Technol. Sci. 2015, 15, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Chawanda, A.; Nyamhere, C.; Auret, F.D.; Mtangi, W.; Diale, M.; Nel, J.M. Thermal annealing behaviour of platinum, nickel and titanium Schottky barrier diodes on n-Ge (100). J. Alloy. Compd. 2010, 492, 649–655. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, S.; Li, J.; Zhang, R. Thermal Stability Enhancement of NiGe Metal Source/Drain and Ge pMOSFETs by Dopant Segregation. IEEE Trans. Electron Devices 2019, 66, 5284–5288. [Google Scholar] [CrossRef]

- Lee, H.-K.; Jyothi, I.; Janardhanam, V.; Shim, K.-H.; Yun, H.-J.; Lee, S.-N.; Hong, H.; Jeong, J.-C.; Choi, C.-J. Effects of Ta-oxide interlayer on the Schottky barrier parameters of Ni/n-type Ge Schottky barrier diode. Microelectron. Eng. 2016, 163, 26–31. [Google Scholar] [CrossRef]

- Zhou, Y.; Ogawa, M.; Han, X.; Wang, K.L. Alleviation of Fermi-level pinning effect on metal/germanium interface by insertion of an ultrathin aluminum oxide. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- Zhou, Y.; Han, W.; Wang, Y.; Xiu, F.; Zou, J.; Kawakami, R.K.; Wang, K.L. Investigating the origin of Fermi level pinning in Ge Schottky junctions using epitaxially grown ultrathin MgO films. Appl. Phys. Lett. 2010, 96. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.A.; Reddy, V.R.; Janardhanam, V.; Seo, M.-W.; Hong, H.; Shin, K.-S.; Choi, C.-J. Electrical Properties of Pt/n-Ge Schottky Contact Modified Using Copper Phthalocyanine (CuPc) Interlayer. J. Electrochem. Soc. 2011, 159, H33–H37. [Google Scholar] [CrossRef]

- Jyothi, I.; Janardhanam, V.; Rajagopal Reddy, V.; Choi, C.-J. Modified electrical characteristics of Pt/n-type Ge Schottky diode with a pyronine-B interlayer. Superlattices Microstruct. 2014, 75, 806–817. [Google Scholar] [CrossRef]

- Ashok Kumar, A.; Rajagopal Reddy, V.; Janardhanam, V.; Yang, H.-D.; Yun, H.-J.; Choi, C.-J. Electrical properties of Pt/n-type Ge Schottky contact with PEDOT:PSS interlayer. J. Alloy. Compd. 2013, 549, 18–21. [Google Scholar] [CrossRef]

- Enver Aydin, M.; Yakuphanoglu, F. Electrical characterization of inorganic-on-organic diode based InP and poly(3,4-ethylenedioxithiophene)/poly(styrenesulfonate) (PEDOT:PSS). Microelectron. Reliab. 2012, 52, 1350–1354. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, P.-T.; Cheng, H.-C.; Lo, F.-C.; Lee, P.-S.; Huang, Y.-W.; Huang, Q.-Y.; Kuo, Y.-C.; Lin, S.-W.; Liu, Y.-R. Rectified Schottky diodes that use low-cost carbon paste/InGaZnO junctions. Org. Electron. 2019, 68, 212–217. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, G.-Y.; Lin, P.-T.; Chen, J.-W.; Chen, C.-H.; Chien, F.S.-S. Influences of sintering temperature on low-cost carbon paste based counter electrodes for dye-sensitized solar cells. Jpn. J. Appl. Phys. 2017, 56. [Google Scholar] [CrossRef]

- Gao, Y.; Chu, L.; Wu, M.; Wang, L.; Guo, W.; Ma, T. Improvement of adhesion of Pt-free counter electrodes for low-cost dye-sensitized solar cells. J. Photochem. Photobiol. A Chem. 2012, 245, 66–71. [Google Scholar] [CrossRef]

- Mishraa, A.; Ahmadb, Z.; Zimmermannc, I.; Martineaud, D.; Shakoorb, R.A.; Touatia, F.; Riaze, K.; Al-Muhtasebf, S.A.; Nazeeruddinc, M.K. Effect of annealing temperature on the performance of printable carbon electrodes for perovskite solar cells. Org. Electron. 2019, 65, 375–380. [Google Scholar] [CrossRef]

- Chasin, A.; Steudel, S.; Myny, K.; Nag, M.; Ke, T.-H.; Schols, S.; Genoe, J.; Gielen, G.; Heremans, P. High-performance a-In-Ga-Zn-O Schottky diode with oxygen-treated metal contacts. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Sreenu, K.; Venkata Prasad, C.; Rajagopal Reddy, V. Barrier Parameters and Current Transport Characteristics of Ti/p-InP Schottky Junction Modified Using Orange G (OG) Organic Interlayer. J. Electron. Mater. 2017, 46, 5746–5754. [Google Scholar] [CrossRef]

- Tan, S.O.; Tecimer, H.; Cicek, O. Comparative Investigation on the Effects of Organic and Inorganic Interlayers in Au/n-GaAs Schottky Diodes. IEEE Trans. Electron Devices 2017, 64, 984–990. [Google Scholar] [CrossRef]

- Tan, S.O. Comparison of Graphene and Zinc Dopant Materials for Organic Polymer Interfacial Layer Between Metal Semiconductor Structure. IEEE Trans. Electron Devices 2017, 64, 5121–5127. [Google Scholar] [CrossRef]

- Winfried, M. Barrier heights of real Schottky contacts explained by metal-induced gap states and lateral inhomogeneities. J. Vac. Sci. Technol. B 1999, 17. [Google Scholar] [CrossRef]

- Lonergan, M.C.; Jones, F.E. Calculation of transmission coefficients at nonideal semiconductor interfaces characterized by a spatial distribution of barrier heights. J. Chem. Phys. 2001, 115, 433. [Google Scholar] [CrossRef]

- Gullu, O.; Cankaya, M.; Baris, O.; Biber, M.; Ozdemir, H.; Gulluce, M.; Turut, A. DNA-based organic-on-inorganic semiconductor Schottky structures. Appl. Surf. Sci. 2008, 254, 5175–5180. [Google Scholar] [CrossRef]

- Gullu, O.; Aydogan, S.; Turut, A. High barrier Schottky diode with organic interlayer. Solid State Commun. 2012, 152, 381–385. [Google Scholar] [CrossRef]

- Cheung, S.K.; Cheung, N.W. Extraction of Schottky diode parameters from forward current-voltage characteristics. Appl. Phys. Lett. 1986, 49, 85–87. [Google Scholar] [CrossRef]

- Aubry, V.; Meyer, F. Schottky diodes with high series resistance: Limitations of forwardI-Vmethods. J. Appl. Phys. 1994, 76, 7973–7984. [Google Scholar] [CrossRef]

- Norde, H. A modified forward I-V plot for Schottky diodes with high series resistance. J. Appl. Phys. 1979, 50, 5052–5053. [Google Scholar] [CrossRef]

- Ocak, Y.S.; Guven, R.G.; Tombak, A.; Kilicoglu, T.; Guven, K.; Dogru, M. Barrier height enhancement of metal/semiconductor contact by an enzyme biofilm interlayer. Philos. Mag. 2013, 93, 2172–2181. [Google Scholar] [CrossRef]

- Du, L.; Li, H.; Yan, L.; Zhang, J.; Xin, Q.; Wang, Q.; Song, A. Effects of substrate and anode metal annealing on InGaZnO Schottky diodes. Appl. Phys. Lett. 2017, 110. [Google Scholar] [CrossRef] [Green Version]

- Xin, Q.; Yan, L.; Luo, Y.; Song, A. Study of breakdown voltage of indium-gallium-zinc-oxide-based Schottky diode. Appl. Phys. Lett. 2015, 106. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Wilson, J.; Ma, X.; Jin, J.; Song, A. Room Temperature Processed Ultrahigh-Frequency Indium-Gallium–Zinc-Oxide Schottky Diode. IEEE Electron Device Lett. 2016, 37, 389–392. [Google Scholar] [CrossRef]

- Xin, Q.; Yan, L.; Du, L.; Zhang, J.; Luo, Y.; Wang, Q.; Song, A. Influence of sputtering conditions on room-temperature fabricated InGaZnO-based Schottky diodes. Thin Solid Film. 2016, 616, 569–572. [Google Scholar] [CrossRef]

- Zou, C.; Huang, C.Y.; Sanehira, E.M.; Luther, J.M.; Lin, L.Y. Highly stable cesium lead iodide perovskite quantum dot light-emitting diodes. Nanotechnology 2017, 28, 455201. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.-Y.; Zou, C.; Mao, C.; Corp, K.L.; Yao, Y.-C.; Lee, Y.-J.; Schlenker, C.W.; Jen, A.K.Y.; Lin, L.Y. CsPbBr3 Perovskite Quantum Dot Vertical Cavity Lasers with Low Threshold and High Stability. ACS Photonics 2017, 4, 2281–2289. [Google Scholar] [CrossRef]

- Qian, H.; Wu, C.; Lu, H.; Xu, W.; Zhou, D.; Ren, F.; Chen, D.; Zhang, R.; Zheng, Y. Bias stress instability involving subgap state transitions in a-IGZO Schottky barrier diodes. J. Phys. D Appl. Phys. 2016, 49. [Google Scholar] [CrossRef]

- Kim, S.; Sanyoto, B.; Park, W.-T.; Kim, S.; Mandal, S.; Lim, J.-C.; Noh, Y.-Y.; Kim, J.-H. Purification of PEDOT:PSS by Ultrafiltration for Highly Conductive Transparent Electrode of All-Printed Organic Devices. Adv. Mater. 2016, 46. [Google Scholar] [CrossRef]

- Williamson, J.B.P.; Allen, N. Thermal stability in graphite contacts. Wear 1982, 78, 38–49. [Google Scholar] [CrossRef]

| I–V | dV/d(lnI) vs. I | H(I) vs. I | Norde | C–V | |||||

|---|---|---|---|---|---|---|---|---|---|

| ΦB (eV) | n | RS(Ω) | n | RS(Ω) | ΦB (eV) | RS(Ω) | ΦB (eV) | ΦB (eV) | |

| w/o CP | 0.57 | 1.08 | 4.37 | 1.01 | 8.93 | 0.57 | 12.14 | 0.58 | 0.82 |

| w/i CP | 0.65 | 1.95 | 376 | 1.28 | 459 | 0.65 | 2735 | 0.72 | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, P.-T.; Chang, J.-W.; Chang, S.-R.; Li, Z.-K.; Chen, W.-Z.; Huang, J.-H.; Ji, Y.-Z.; Hsueh, W.-J.; Huang, C.-Y. A Stable and Efficient Pt/n-Type Ge Schottky Contact That Uses Low-Cost Carbon Paste Interlayers. Crystals 2021, 11, 259. https://doi.org/10.3390/cryst11030259

Lin P-T, Chang J-W, Chang S-R, Li Z-K, Chen W-Z, Huang J-H, Ji Y-Z, Hsueh W-J, Huang C-Y. A Stable and Efficient Pt/n-Type Ge Schottky Contact That Uses Low-Cost Carbon Paste Interlayers. Crystals. 2021; 11(3):259. https://doi.org/10.3390/cryst11030259

Chicago/Turabian StyleLin, Pei-Te, Jia-Wei Chang, Syuan-Ruei Chang, Zhong-Kai Li, Wei-Zhi Chen, Jui-Hsuan Huang, Yu-Zhen Ji, Wen-Jeng Hsueh, and Chun-Ying Huang. 2021. "A Stable and Efficient Pt/n-Type Ge Schottky Contact That Uses Low-Cost Carbon Paste Interlayers" Crystals 11, no. 3: 259. https://doi.org/10.3390/cryst11030259

APA StyleLin, P. -T., Chang, J. -W., Chang, S. -R., Li, Z. -K., Chen, W. -Z., Huang, J. -H., Ji, Y. -Z., Hsueh, W. -J., & Huang, C. -Y. (2021). A Stable and Efficient Pt/n-Type Ge Schottky Contact That Uses Low-Cost Carbon Paste Interlayers. Crystals, 11(3), 259. https://doi.org/10.3390/cryst11030259