Recent Advances in Fabricating Wurtzite AlN Film on (0001)-Plane Sapphire Substrate

Abstract

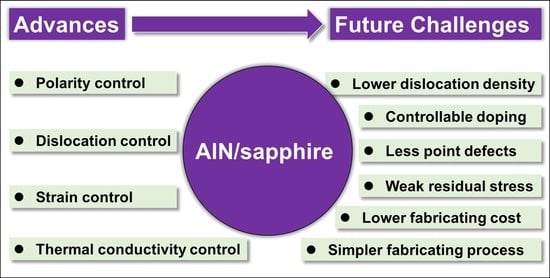

:1. Introduction

2. Polarity Control of AlN/Sapphire Template

3. Dislocation and Strain Control of AlN/Sapphire Template

3.1. Two-Step Growth (TSG)

3.2. Multiple-Step Growth (MSG)

3.3. Epitaxial Lateral Overgrowth (ELOG)

3.4. High Temperature Annealing (HTA)

3.5. Quasi-Van der Waals Epitaxy (QvdWE)

4. The TDD Compilation of AlN Films Grown by Different Techniques

5. Thermal Conductivity Control of AlN

6. Future Challenges

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kneissl, M.; Rass, J. III-Nitride Ultraviolet Emitters; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Yu, R.; Liu, G.; Wang, G.; Chen, C.; Xu, M.; Zhou, H.; Wang, T.; Yu, J.; Zhao, G.; Zhang, L. Ultrawide-bandgap semiconductor AlN crystals: Growth and applications. J. Mater. Chem. C 2021, 9, 1852–1873. [Google Scholar] [CrossRef]

- Tsao, J.; Chowdhury, S.; Hollis, M.; Jena, D.; Johnson, N.; Jones, K.; Kaplar, R.; Rajan, S.; Van de Walle, C.; Bellotti, E. Ultrawide-bandgap semiconductors: Research opportunities and challenges. Adv. Electron. Mater. 2018, 4, 1600501. [Google Scholar] [CrossRef] [Green Version]

- Fei, C.; Liu, X.; Zhu, B.; Li, D.; Yang, X.; Yang, Y.; Zhou, Q. AlN piezoelectric thin films for energy harvesting and acoustic devices. Nano Energy 2018, 51, 146–161. [Google Scholar] [CrossRef]

- Ni, X.; Fan, Q.; Hua, B.; Sun, P.; Cai, Z.; Wang, H.-C.; Huang, C.; Gu, X. Improvement of AlN Material Quality by High-Temperature Annealing Toward Power Diodes. IEEE T. Electron. Dev. 2020, 67, 3988–3991. [Google Scholar] [CrossRef]

- Chu, Y.; Kharel, P.; Yoon, T.; Frunzio, L.; Rakich, P.T.; Schoelkopf, R.J. Creation and control of multi-phonon Fock states in a bulk acoustic-wave resonator. Nature 2018, 563, 666–670. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Mayrhofer, P.M.; He, X.; Gillinger, M.; Ye, Z.; Wang, X.; Bittner, A.; Schmid, U.; Luo, J. High performance AlScN thin film based surface acoustic wave devices with large electromechanical coupling coefficient. Appl. Phys. Lett. 2014, 105, 133502. [Google Scholar] [CrossRef]

- Jung, H.; Xiong, C.; Fong, K.Y.; Zhang, X.; Tang, H.X. Optical frequency comb generation from aluminum nitride microring resonator. Opt. Lett. 2013, 38, 2810–2813. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Bruch, A.W.; Gong, Z.; Lu, J.; Surya, J.B.; Zhang, L.; Wang, J.; Yan, J.; Tang, H.X. Ultra-high-Q UV microring resonators based on a single-crystalline AlN platform. Optica 2018, 5, 1279–1282. [Google Scholar] [CrossRef] [Green Version]

- Kneissl, M.; Seong, T.-Y.; Han, J.; Amano, H. The emergence and prospects of deep-ultraviolet light-emitting diode technologies. Nat. Photonics 2019, 13, 233–244. [Google Scholar] [CrossRef]

- Wu, H.; Wu, W.; Zhang, H.; Chen, Y.; Wu, Z.; Wang, G.; Jiang, H. All AlGaN epitaxial structure solar-blind avalanche photodiodes with high efficiency and high gain. Appl. Phys. Express 2016, 9, 52103. [Google Scholar] [CrossRef]

- Zhang, Z.; Kushimoto, M.; Sakai, T.; Sugiyama, N.; Schowalter, L.J.; Sasaoka, C.; Amano, H. A 271.8 nm deep-ultraviolet laser diode for room temperature operation. Appl. Phys. Express 2019, 12, 124003. [Google Scholar] [CrossRef]

- Mackey, T.K.; Contreras, J.T.; Liang, B.A. The Minamata Convention on Mercury: Attempting to address the global controversy of dental amalgam use and mercury waste disposal. Sci. Total Environ. 2014, 472, 125–129. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Luo, W.; Li, D.; Yuan, Y.; Tong, W.; Kang, J.; Wang, Y.; Li, D.; Rong, X.; Wang, T. Sec-Eliminating the SARS-CoV-2 by AlGaN Based High Power Deep Ultraviolet Light Source. Adv. Funct. Mater. 2021, 31, 2008452. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Jiang, K.; Sun, X.; Guo, C. AlGaN photonics: Recent advances in materials and ultraviolet devices. Adv. Opt. Photonics 2018, 10, 43–110. [Google Scholar] [CrossRef]

- Wang, Q.; Lei, D.; He, G.; Gong, J.; Huang, J.; Wu, J. Characterization of 60 mm AlN Single Crystal Wafers Grown by the Physical Vapor Transport Method. Phys. Status Solidi A 2019, 216, 1900118. [Google Scholar] [CrossRef]

- He, C.; Zhao, W.; Wu, H.; Zhang, S.; Zhang, K.; He, L.; Liu, N.; Chen, Z.; Shen, B. High-quality AlN film grown on sputtered AlN/sapphire via growth-mode modification. Cryst. Growth Des. 2018, 18, 6816–6823. [Google Scholar] [CrossRef]

- Shen, J.; Yang, X.; Liu, D.; Cai, Z.; Wei, L.; Xie, N.; Xu, F.; Tang, N.; Wang, X.; Ge, W. High quality AlN film grown on a nano-concave-circle patterned Si substrate with an AlN seed layer. Appl. Phys. Lett. 2020, 117, 22103. [Google Scholar] [CrossRef]

- Zollner, C.J.; Almogbel, A.; Yao, Y.; SaifAddin, B.K.; Wu, F.; Iza, M.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Reduced dislocation density and residual tension in AlN grown on SiC by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2019, 115, 161101. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.; Weimann, N.; Chu, K.; Murphy, M.; Schaff, W.; Eastman, L.; Dimitrov, R.; Wittmer, L. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N-and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Sun, H.; Torre, B.; Li, J.; Sheikhi, M.; Jiang, J.; Li, H.; Guo, S.; Li, K.H.; Lin, R. Lateral-polarity structure of AlGaN quantum wells: A promising approach to enhancing the ultraviolet luminescence. Adv. Funct. Mater. 2018, 28, 1802395. [Google Scholar] [CrossRef]

- Ito, T.; Sakamoto, R.; Isono, T.; Yao, Y.; Ishikawa, Y.; Okada, N.; Tadatomo, K. Growth and Characterization of Nitrogen-Polar AlGaN/AlN Heterostructure for High-Electron-Mobility Transistor. Phys. Status Solidi. B 2020, 257, 1900589. [Google Scholar] [CrossRef]

- Kirste, R.; Mita, S.; Hussey, L.; Hoffmann, M.P.; Guo, W.; Bryan, I.; Bryan, Z.; Tweedie, J.; Xie, J.; Gerhold, M. Polarity control and growth of lateral polarity structures in AlN. Appl. Phys. Lett. 2013, 102, 181913. [Google Scholar] [CrossRef]

- Lemettinen, J.; Okumura, H.; Kim, I.; Rudzinski, M.; Grzonka, J.; Palacios, T.; Suihkonen, S. MOVPE growth of nitrogen-and aluminum-polar AlN on 4H-SiC. J. Cryst. Growth 2018, 487, 50–56. [Google Scholar] [CrossRef] [Green Version]

- Eom, D.; Kim, J.; Lee, K.; Jeon, M.; Heo, C.; Pyeon, J.; Nam, O. AlN nanostructures fabricated on a vicinal sapphire (0001) substrate. Cryst. Growth Des. 2015, 15, 1242–1248. [Google Scholar] [CrossRef]

- Akiyama, T.; Saito, Y.; Nakamura, K.; Ito, T. Nitridation of Al2O3 surfaces: Chemical and structural change triggered by oxygen desorption. Phys. Rev. Lett. 2013, 110, 26101. [Google Scholar] [CrossRef] [PubMed]

- McCauley, J.W.; Patel, P.; Chen, M.; Gilde, G.; Strassburger, E.; Paliwal, B.; Ramesh, K.; Dandekar, D.P. AlON: A brief history of its emergence and evolution. J. Eur. Ceram. Soc. 2009, 29, 223–236. [Google Scholar] [CrossRef]

- Sun, H.; Wu, F.; Park, Y.J.; Al Tahtamouni, T.; Li, K.-H.; Alfaraj, N.; Detchprohm, T.; Dupuis, R.D.; Li, X. Influence of TMAl preflow on AlN epitaxy on sapphire. Appl. Phys. Lett. 2017, 110, 192106. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Xu, F.; He, C.; Zhang, L.; Lu, L.; Wang, X.; Qin, Z.; Shen, B. High quality AlN epilayers grown on nitrided sapphire by metal organic chemical vapor deposition. Sci. Rep. 2017, 7, 42747. [Google Scholar] [CrossRef] [Green Version]

- Miyagawa, R.; Yang, S.; Miyake, H.; Hiramatsu, K.; Kuwahara, T.; Mitsuhara, M.; Kuwano, N. Microstructure of AlN grown on a nucleation layer on a sapphire substrate. Appl. Phys. Express 2012, 5, 25501. [Google Scholar] [CrossRef]

- Mohn, S.; Stolyarchuk, N.; Markurt, T.; Kirste, R.; Hoffmann, M.P.; Collazo, R.; Courville, A.; Di Felice, R.; Sitar, Z.; Vennéguès, P. Polarity control in group-III nitrides beyond pragmatism. Phys. Rev. Appl. 2016, 5, 54004. [Google Scholar] [CrossRef] [Green Version]

- Funato, M.; Shibaoka, M.; Kawakami, Y. Heteroepitaxy mechanisms of AlN on nitridated c-and a-plane sapphire substrates. J. Appl. Phys. 2017, 121, 85304. [Google Scholar] [CrossRef]

- Ban, K.; Yamamoto, J.-I.; Takeda, K.; Ide, K.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I.; Amano, H. Internal quantum efficiency of whole-composition-range AlGaN multiquantum wells. Appl. Phys. Express 2011, 4, 52101. [Google Scholar] [CrossRef]

- Reddy, P.; Hayden Breckenridge, M.; Guo, Q.; Klump, A.; Khachariya, D.; Pavlidis, S.; Mecouch, W.; Mita, S.; Moody, B.; Tweedie, J. High gain, large area, and solar blind avalanche photodiodes based on Al-rich AlGaN grown on AlN substrates. Appl. Phys. Lett. 2020, 116, 81101. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Sun, W.; Adivarahan, V.; Wu, S.; Chitnis, A.; Chen, C.; Shatalov, M.; Kuokstis, E.; Yang, J. High-quality AlGaN layers over pulsed atomic-layer epitaxially grown AlN templates for deep ultraviolet light-emitting diodes. J. Electron. Mater. 2003, 32, 364–370. [Google Scholar] [CrossRef]

- Banal, R.G.; Funato, M.; Kawakami, Y. Initial nucleation of AlN grown directly on sapphire substrates by metal-organic vapor phase epitaxy. Appl. Phys. Lett. 2008, 92, 241905. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Hu, X.; Lunev, A.; Deng, J.; Bilenko, Y.; Katona, T.M.; Shur, M.S.; Gaska, R.; Khan, M.A. AlGaN deep-ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2005, 44, 7250. [Google Scholar] [CrossRef]

- Tian, W.; Yan, W.; Dai, J.; Li, S.; Tian, Y.; Hui, X.; Zhang, J.; Fang, Y.; Wu, Z.; Chen, C. Effect of growth temperature of an AlN intermediate layer on the growth mode of AlN grown by MOCVD. J. Phys. D Appl. Phys. 2013, 46, 65303. [Google Scholar] [CrossRef]

- Wu, H.; Wang, H.; Chen, Y.; Zhang, L.; Chen, Z.; Wu, Z.; Wang, G.; Jiang, H. Improved crystalline quality of AlN epitaxial layer on sapphire by introducing TMGa pulse flow into the nucleation stage. J. Cryst. Growth 2018, 490, 56–60. [Google Scholar] [CrossRef]

- Shatalov, M.; Sun, W.; Lunev, A.; Hu, X.; Dobrinsky, A.; Bilenko, Y.; Yang, J.; Shur, M.; Gaska, R.; Moe, C. AlGaN deep-ultraviolet light-emitting diodes with external quantum efficiency above 10%. Appl. Phys. Express 2012, 5, 82101. [Google Scholar] [CrossRef]

- Lorenz, K.; Gonsalves, M.; Kim, W.; Narayanan, V.; Mahajan, S. Comparative study of GaN and AlN nucleation layers and their role in growth of GaN on sapphire by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2000, 77, 3391–3393. [Google Scholar] [CrossRef]

- He, C.; Wu, H.; Jia, C.; Zhang, K.; He, L.; Wang, Q.; Li, J.; Liu, N.; Zhang, S.; Zhao, W. Low-Defect-Density Aluminum Nitride (AlN) Thin Films Realized by Zigzag Macrostep-Induced Dislocation Redirection. Cryst. Growth Des. 2021, 21, 3394–3400. [Google Scholar] [CrossRef]

- Hirayama, H.; Maeda, N.; Fujikawa, S.; Toyoda, S.; Kamata, N. Recent progress and future prospects of AlGaN-based high-efficiency deep-ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2014, 53, 100209. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, F.; Wang, J.; He, C.; Zhang, L.; Huang, J.; Cheng, J.; Qin, Z.; Yang, X.; Tang, N. Epitaxial growth of AlN films on sapphire via a multilayer structure adopting a low-and high-temperature alternation technique. CrystEngComm 2015, 17, 7496–7499. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Z.; Jiang, H.; Li, Z.; Miao, G.; Song, H. The optimized growth of AlN templates for back-illuminated AlGaN-based solar-blind ultraviolet photodetectors by MOCVD. J. Mater. Chem. C 2018, 6, 4936–4942. [Google Scholar] [CrossRef]

- Yan, J.; Wang, J.; Zhang, Y.; Cong, P.; Sun, L.; Tian, Y.; Zhao, C.; Li, J. AlGaN-based deep-ultraviolet light-emitting diodes grown on high-quality AlN template using MOVPE. J. Cryst. Growth 2015, 414, 254–257. [Google Scholar] [CrossRef]

- He, C.; Zhao, W.; Zhang, K.; He, L.; Wu, H.; Liu, N.; Zhang, S.; Liu, X.; Chen, Z. High-quality GaN epilayers achieved by facet-controlled epitaxial lateral overgrowth on sputtered AlN/PSS templates. ACS Appl. Mater. Interfaces 2017, 9, 43386–43392. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Xu, F.; Wang, M.; Sun, Y.; Xie, N.; Wang, T.; Dong, B.; Qin, Z.; Wang, X.; Shen, B. High-quality AlN epitaxy on sapphire substrates with sputtered buffer layers. Superlattices Microstruct. 2017, 105, 34–38. [Google Scholar] [CrossRef]

- Wu, H.; Zhao, W.; He, C.; Zhang, K.; He, L.; Chen, Z. Growth of high quality AlN/sapphire templates with high growth rate using a medium-temperature layer. Superlattices Microstruct. 2019, 125, 343–347. [Google Scholar] [CrossRef]

- Bai, J.; Wang, T.; Parbrook, P.; Cullis, A. Mechanisms of dislocation reduction in an Al 0.98 Ga 0.02 N layer grown using a porous AlN buffer. Appl. Phys. Lett. 2006, 89, 131925. [Google Scholar] [CrossRef]

- Wang, T.; Bai, J.; Parbrook, P.; Cullis, A. Air-bridged lateral growth of an Al 0.98 Ga 0.02 N layer by introduction of porosity in an AlN buffer. Appl. Phys. Lett. 2005, 87, 151906. [Google Scholar] [CrossRef]

- He, C.; Zhao, W.; Wu, H.; Liu, N.; Zhang, S.; Li, J.; Jia, C.; Zhang, K.; He, L.; Chen, Z. Fast growth of crack-free thick AlN film on sputtered AlN/sapphire by introducing high-density nano-voids. J. Phys. D Appl. Phys. 2020, 53, 405303. [Google Scholar] [CrossRef]

- Imura, M.; Nakano, K.; Kitano, T.; Fujimoto, N.; Narita, G.; Okada, N.; Balakrishnan, K.; Iwaya, M.; Kamiyama, S.; Amano, H. Microstructure of epitaxial lateral overgrown AlN on trench-patterned AlN template by high-temperature metal-organic vapor phase epitaxy. Appl. Phys. Lett. 2006, 89, 221901. [Google Scholar] [CrossRef]

- Imura, M.; Nakano, K.; Narita, G.; Fujimoto, N.; Okada, N.; Balakrishnan, K.; Iwaya, M.; Kamiyama, S.; Amano, H.; Akasaki, I.; et al. Epitaxial lateral overgrowth of AlN on trench-patterned AlN layers. J. Cryst. Growth 2007, 298, 257–260. [Google Scholar] [CrossRef]

- Nakano, K.; Imura, M.; Narita, G.; Kitano, T.; Hirose, Y.; Fujimoto, N.; Okada, N.; Kawashima, T.; Iida, K.; Balakrishnan, K.; et al. Epitaxial lateral overgrowth of AlN layers on patterned sapphire substrates. Phys. Status Solidi A 2006, 203, 1632–1635. [Google Scholar] [CrossRef]

- Long, H.; Dai, J.; Zhang, Y.; Wang, S.; Tan, B.; Zhang, S.; Xu, L.; Shan, M.; Feng, Z.C.; Kuo, H.-c. High quality 10.6 μ m AlN grown on pyramidal patterned sapphire substrate by MOCVD. Appl. Phys. Lett. 2019, 114, 42101. [Google Scholar] [CrossRef]

- Hirayama, H.; Fujikawa, S.; Norimatsu, J.; Takano, T.; Tsubaki, K.; Kamata, N. Fabrication of a low threading dislocation density ELO-AlN template for application to deep-UV LEDs. Phys. Status Solidi C 2009, 6, S356–S359. [Google Scholar] [CrossRef]

- Zeimer, U.; Kueller, V.; Knauer, A.; Mogilatenko, A.; Weyers, M.; Kneissl, M. High quality AlGaN grown on ELO AlN/sapphire templates. J. Cryst. Growth 2013, 377, 32–36. [Google Scholar] [CrossRef]

- Dong, P.; Yan, J.; Wang, J.; Zhang, Y.; Geng, C.; Wei, T.; Cong, P.; Zhang, Y.; Zeng, J.; Tian, Y.; et al. 282-nm AlGaN-based deep ultraviolet light-emitting diodes with improved performance on nano-patterned sapphire substrates. Appl. Phys. Lett. 2013, 102, 241113. [Google Scholar] [CrossRef]

- Conroy, M.; Zubialevich, V.Z.; Li, H.; Petkov, N.; Holmes, J.D.; Parbrook, P.J. Epitaxial lateral overgrowth of AlN on self-assembled patterned nanorods. J. Mater. Chem. C 2015, 3, 431–437. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Lee, J.W.; Jang, J.; Shin, I.-S.; Jin, L.; Park, J.H.; Kim, J.; Lee, J.; Noh, H.-S.; Kim, Y.-I.; et al. Improved performance of AlGaN-based deep ultraviolet light-emitting diodes with nano-patterned AlN/sapphire substrates. Appl. Phys. Lett. 2017, 110, 191103. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, F.; Wang, J.; He, C.; Guo, W.; Wang, M.; Sheng, B.; Lu, L.; Qin, Z.; Wang, X. High-quality AlN epitaxy on nano-patterned sapphire substrates prepared by nano-imprint lithography. Sci. Rep. 2016, 6, 35934. [Google Scholar] [CrossRef] [Green Version]

- Xu, F.; Zhang, L.; Xie, N.; Wang, M.; Sun, Y.; Liu, B.; Ge, W.; Wang, X.; Shen, B. Realization of low dislocation density AlN on a small-coalescence-area nano-patterned sapphire substrate. CrystEngComm 2019, 21, 2490–2494. [Google Scholar] [CrossRef]

- Xie, N.; Xu, F.; Zhang, N.; Lang, J.; Wang, J.; Wang, M.; Sun, Y.; Liu, B.; Ge, W.; Qin, Z.; et al. Period size effect induced crystalline quality improvement of AlN on a nano-patterned sapphire substrate. Jpn. J. Appl. Phys. 2019, 58, 100912. [Google Scholar] [CrossRef]

- Nagamatsu, K.; Okada, N.; Sugimura, H.; Tsuzuki, H.; Mori, F.; Iida, K.; Bando, A.; Iwaya, M.; Kamiyama, S.; Amano, H.; et al. High-efficiency AlGaN-based UV light-emitting diode on laterally overgrown AlN. J. Cryst. Growth 2008, 310, 2326–2329. [Google Scholar] [CrossRef]

- Hirayama, H.; Norimatsu, J.; Noguchi, N.; Fujikawa, S.; Takano, T.; Tsubaki, K.; Kamata, N. Milliwatt power 270 nm-band AlGaN deep-UV LEDs fabricated on ELO-AlN templates. Phys. Status Sodili. C 2009, 6, S474–S477. [Google Scholar] [CrossRef]

- Susilo, N.; Ziffer, E.; Hagedorn, S.; Cancellara, L.; Netzel, C.; Ploch, N.L.; Wu, S.; Rass, J.; Walde, S.; Sulmoni, L.; et al. Improved performance of UVC-LEDs by combination of high-temperature annealing and epitaxially laterally overgrown AlN/sapphire. Photonics Res. 2020, 8, 589. [Google Scholar] [CrossRef]

- Kar, J.P.; Bose, G.; Tuli, S. Influence of rapid thermal annealing on morphological and electrical properties of RF sputtered AlN films. Mat. Sci. Semicon. Proc. 2005, 8, 646–651. [Google Scholar] [CrossRef]

- Miyake, H.; Nishio, G.; Suzuki, S.; Hiramatsu, K.; Fukuyama, H.; Kaur, J.; Kuwano, N. Annealing of an AlN buffer layer in N2–CO for growth of a high-quality AlN film on sapphire. Appl. Phys. Express 2016, 9, 25501. [Google Scholar] [CrossRef] [Green Version]

- Miyake, H.; Lin, C.-H.; Tokoro, K.; Hiramatsu, K. Preparation of high-quality AlN on sapphire by high-temperature face-to-face annealing. J. Cryst. Growth 2016, 456, 155–159. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.-Y.; Wu, P.-Y.; Chang, K.-S.; Lin, Y.-H.; Peng, W.-C.; Chang, Y.-Y.; Li, J.-P.; Yen, H.-W.; Wu, Y.S.; Miyake, H.; et al. High-quality and highly-transparent AlN template on annealed sputter-deposited AlN buffer layer for deep ultra-violet light-emitting diodes. AIP Adv. 2017, 7, 55110. [Google Scholar] [CrossRef] [Green Version]

- Uesugi, K.; Hayashi, Y.; Shojiki, K.; Miyake, H. Reduction of threading dislocation density and suppression of cracking in sputter-deposited AlN templates annealed at high temperatures. Appl. Phys. Express 2019, 12, 65501. [Google Scholar] [CrossRef]

- Ben, J.; Shi, Z.; Zang, H.; Sun, X.; Liu, X.; Lü, W.; Li, D. The formation mechanism of voids in physical vapor deposited AlN epilayer during high temperature annealing. Appl. Phys. Lett. 2020, 116, 251601. [Google Scholar] [CrossRef]

- Wang, D.; Uesugi, K.; Xiao, S.; Norimatsu, K.; Miyake, H. Low dislocation density AlN on sapphire prepared by double sputtering and annealing. Appl. Phys. Express 2020, 13, 95501. [Google Scholar] [CrossRef]

- Wang, D.; Uesugi, K.; Xiao, S.; Norimatsu, K.; Miyake, H. High-quality AlN/sapphire templates prepared by thermal cycle annealing for high-performance ultraviolet light-emitting diodes. Appl. Phys. Express 2021, 14, 35505. [Google Scholar] [CrossRef]

- Susilo, N.; Hagedorn, S.; Jaeger, D.; Miyake, H.; Zeimer, U.; Reich, C.; Neuschulz, B.; Sulmoni, L.; Guttmann, M.; Mehnke, F.; et al. AlGaN-based deep UV LEDs grown on sputtered and high temperature annealed AlN/sapphire. Appl. Phys. Lett. 2018, 112, 41110. [Google Scholar] [CrossRef]

- Wang, M.X.; Xu, F.J.; Xie, N.; Sun, Y.H.; Liu, B.Y.; Qin, Z.X.; Wang, X.Q.; Shen, B. Crystal quality evolution of AlN films via high-temperature annealing under ambient N2 conditions. CrystEngComm 2018, 20, 6613–6617. [Google Scholar] [CrossRef]

- Wang, M.X.; Xu, F.J.; Wang, J.M.; Xie, N.; Sun, Y.H.; Liu, B.Y.; Lang, J.; Zhang, N.; Ge, W.K.; Kang, X.N.; et al. The sapphire substrate pretreatment effects on high-temperature annealed AlN templates in deep ultraviolet light emitting diodes. CrystEngComm 2019, 21, 4632–4636. [Google Scholar] [CrossRef]

- Wang, J.; Xu, F.; Liu, B.; Lang, J.; Zhang, N.; Kang, X.; Qin, Z.; Yang, X.; Wang, X.; Ge, W.; et al. Control of dislocations in heteroepitaxial AlN films by extrinsic supersaturated vacancies introduced through thermal desorption of heteroatoms. Appl. Phys. Lett. 2021, 118, 162103. [Google Scholar] [CrossRef]

- Akiyma, T.; Uchino, M.; Nakamura, K.; Ito, T.; Xiao, S.; Miyake, H. Structural analysis of polarity inversion boundary in sputtered AlN films annealed under high temperatures. Jpn. J. Appl. Phys. 2019, 58, SCCB30. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, Y.; Yan, J.; Zeng, Y.; Wang, J.; Li, J. Polarity tuning of crystalline AlN films utilizing trace oxygen involved sputtering and post-high-temperature annealing. Appl. Phys. Express 2021, 14, 85501. [Google Scholar] [CrossRef]

- Wang, M.; Xu, F.; Xie, N.; Sun, Y.; Liu, B.; Ge, W.; Kang, X.; Qin, Z.; Yang, X.; Wang, X. High-temperature annealing induced evolution of strain in AlN epitaxial films grown on sapphire substrates. Appl. Phys. Lett. 2019, 114, 112105. [Google Scholar] [CrossRef]

- Ben, J.; Sun, X.; Jia, Y.; Jiang, K.; Shi, Z.; Liu, H.; Wang, Y.; Kai, C.; Wu, Y.; Li, D. Defect evolution in AlN templates on PVD-AlN/sapphire substrates by thermal annealing. CrystEngComm 2018, 20, 4623–4629. [Google Scholar] [CrossRef]

- Won, D.; Weng, X.; Al Balushi, Z.Y.; Redwing, J.M. Influence of growth stress on the surface morphology of N-polar GaN films grown on vicinal C-face SiC substrates. Appl. Phys. Lett. 2013, 103, 241908. [Google Scholar] [CrossRef]

- Nilsson, D.; Janzén, E.; Kakanakova-Georgieva, A. Strain and morphology compliance during the intentional doping of high-Al-content AlGaN layers. Appl. Phys. Lett. 2014, 105, 82106. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Yu, J.; Hao, X.; Wu, Y.; Dai, Y.; Shao, Y.; Zhang, H.; Tian, Y. Influence of stress in GaN crystals grown by HVPE on MOCVD-GaN/6H-SiC substrate. Sci. Rep. 2015, 4, 4179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, C.; Qin, Z.; Xu, F.; Zhang, L.; Wang, J.; Hou, M.; Zhang, S.; Wang, X.; Ge, W.; Shen, B. Effect of stress on the Al composition evolution in AlGaN grown using metal organic vapor phase epitaxy. Appl. Phys. Express 2016, 9, 051001. [Google Scholar] [CrossRef]

- He, C.; Qin, Z.; Xu, F.; Zhang, L.; Wang, J.; Hou, M.; Zhang, S.; Wang, X.; Ge, W.; Shen, B. Mechanism of stress-driven composition evolution during hetero-epitaxy in a ternary AlGaN system. Sci. Rep. 2016, 6, 25124. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Wang, Q.; Li, B.; Wang, J.; Zhang, K.; He, C.; Wang, L.; Song, L.; Cao, X.; Wang, B. Point-defect distribution and transformation near the surfaces of AlGaN films grown by MOCVD. J. Phys. Chem. C 2019, 123, 8865–8870. [Google Scholar] [CrossRef]

- Kim, Y.; Cruz, S.S.; Lee, K.; Alawode, B.O.; Choi, C.; Song, Y.; Johnson, J.M.; Heidelberger, C.; Kong, W.; Choi, S. Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 2017, 544, 340–343. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Kumakura, K.; Akasaka, T.; Makimoto, T. Layered boron nitride as a release layer for mechanical transfer of GaN-based devices. Nature 2012, 484, 223–227. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, Y.; Pang, Z.; Dou, Z.; Wei, T.; Gao, P.; Zhang, S.; Xu, X.; Chang, Z.; Deng, B. Fast growth of strain-free AlN on graphene-buffered sapphire. J. Am. Chem. Soc. 2018, 140, 11935–11941. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Chen, Z.; Li, W.; Yan, J.; Hou, R.; Yang, S.; Liu, Z.; Yuan, G.; Wang, J.; Li, J. Graphene-assisted quasi-van der Waals epitaxy of AlN film for ultraviolet light emitting diodes on nano-patterned sapphire substrate. Appl. Phys. Lett. 2019, 114, 91107. [Google Scholar] [CrossRef] [Green Version]

- Wu, Q.; Yan, J.; Zhang, L.; Chen, X.; Wei, T.; Li, Y.; Liu, Z.; Wei, X.; Zhang, Y.; Wang, J. Growth mechanism of AlN on hexagonal BN/sapphire substrate by metal–organic chemical vapor deposition. CrystEngComm 2017, 19, 5849–5856. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Z.; Wei, T.; Yang, S.; Dou, Z.; Wang, Y.; Ci, H.; Chang, H.; Qi, Y.; Yan, J. Improved epitaxy of AlN film for deep-ultraviolet light-emitting diodes enabled by graphene. Adv. Mater. 2019, 31, 1807345. [Google Scholar] [CrossRef]

- Song, Y.; Gao, Y.; Liu, X.; Ma, J.; Chen, B.; Xie, Q.; Gao, X.; Zheng, L.; Zhang, Y.; Ding, Q. Transfer-Enabled Fabrication of Graphene Wrinkle Arrays for Epitaxial Growth of AlN Films. Adv. Mater. 2021, 2105851. [Google Scholar] [CrossRef]

- Chang, H.; Liu, B.; Liang, D.; Gao, Y.; Yan, J.; Liu, Z.; Liu, Z.; Wang, J.; Li, J.; Gao, P. Graphene-induced crystal-healing of AlN film by thermal annealing for deep ultraviolet light-emitting diodes. Appl. Phys. Lett. 2020, 117, 181103. [Google Scholar] [CrossRef]

- Jain, R.; Sun, W.; Yang, J.; Shatalov, M.; Hu, X.; Sattu, A.; Lunev, A.; Deng, J.; Shturm, I.; Bilenko, Y. Migration enhanced lateral epitaxial overgrowth of AlN and AlGaN for high reliability deep ultraviolet light emitting diodes. Appl. Phys. Lett. 2008, 93, 51113. [Google Scholar] [CrossRef]

- Sun, X.; Li, D.; Chen, Y.; Song, H.; Jiang, H.; Li, Z.; Miao, G.; Zhang, Z. In situ observation of two-step growth of AlN on sapphire using high-temperature metal–organic chemical vapour deposition. CrystEngComm 2013, 15, 6066–6073. [Google Scholar] [CrossRef]

- Li, X.H.; Wang, S.; Xie, H.; Wei, Y.O.; Kao, T.T.; Satter, M.M.; Shen, S.C.; Douglas Yoder, P.; Detchprohm, T.; Dupuis, R.D. Growth of high-quality AlN layers on sapphire substrates at relatively low temperatures by metalorganic chemical vapor deposition. Phys. Status Solidi B 2015, 252, 1089–1095. [Google Scholar] [CrossRef]

- Chen, S.; Li, Y.; Ding, Y.; Li, S.; Zhang, M.; Wu, Z.; Fang, Y.; Dai, J.; Chen, C. Defect reduction in AlN epilayers grown by MOCVD via intermediate-temperature interlayers. J. Electron. Mater. 2015, 44, 217–221. [Google Scholar] [CrossRef]

- Hagedorn, S.; Knauer, A.; Mogilatenko, A.; Richter, E.; Weyers, M. AlN growth on nano-patterned sapphire: A route for cost efficient pseudo substrates for deep UV LEDs. Phys. Status Solidi A 2016, 213, 3178–3185. [Google Scholar] [CrossRef]

- Wang, T.Y.; Liang, J.H.; Fu, G.W.; Wuu, D.S. Defect annihilation mechanism of AlN buffer structures with alternating high and low V/III ratios grown by MOCVD. CrystEngComm 2016, 18, 9152–9159. [Google Scholar] [CrossRef]

- Su, X.; Zhang, J.; Huang, J.; Zhang, J.; Wang, J.; Xu, K. Defect structure of high temperature hydride vapor phase epitaxy-grown epitaxial (0001) AlN/sapphire using growth mode modification process. J. Cryst. Growth 2017, 467, 82–87. [Google Scholar] [CrossRef]

- Hagedorn, S.; Walde, S.; Mogilatenko, A.; Weyers, M.; Cancellara, L.; Albrecht, M.; Jaeger, D. Stabilization of sputtered AlN/sapphire templates during high temperature annealing. J. Cryst. Growth 2019, 512, 142–146. [Google Scholar] [CrossRef]

- Chen, Z.; Hoo, J.; Chen, Y.; Wang, V.; Guo, S. Study of AlN based materials grown on nano-patterned sapphire substrates for deep ultraviolet LED applications. Jpn. J. Appl. Phys. 2019, 58, SC1007. [Google Scholar] [CrossRef]

- Ruschel, J.; Glaab, J.; Susilo, N.; Hagedorn, S.; Walde, S.; Ziffer, E.; Cho, H.K.; Ploch, N.L.; Wernicke, T.; Weyers, M. Reliability of UVC LEDs fabricated on AlN/sapphire templates with different threading dislocation densities. Appl. Phys. Lett. 2020, 117, 241104. [Google Scholar] [CrossRef]

- Tang, B.; Hu, H.; Wan, H.; Zhao, J.; Gong, L.; Lei, Y.; Zhao, Q.; Zhou, S. Growth of high-quality AlN films on sapphire substrate by introducing voids through growth-mode modification. Appl. Surf. Sci. 2020, 518, 146218. [Google Scholar] [CrossRef]

- Moram, M.; Vickers, M. X-ray diffraction of III-nitrides. Rep. Prog. Phys. 2009, 72, 36502. [Google Scholar] [CrossRef]

- Koleske, D.; Figiel, J.; Alliman, D.; Gunning, B.; Kempisty, J.; Creighton, J.; Mishima, A.; Ikenaga, K. Metalorganic vapor phase epitaxy of AlN on sapphire with low etch pit density. Appl. Phys. Lett. 2017, 110, 232102. [Google Scholar] [CrossRef]

- Rounds, R.; Sarkar, B.; Alden, D.; Guo, Q.; Klump, A.; Hartmann, C.; Nagashima, T.; Kirste, R.; Franke, A.; Bickermann, M. The influence of point defects on the thermal conductivity of AlN crystals. J. Appl. Phys. 2018, 123, 185107. [Google Scholar] [CrossRef]

- Cheng, Z.; Koh, Y.R.; Mamun, A.; Shi, J.; Bai, T.; Huynh, K.; Yates, L.; Liu, Z.; Li, R.; Lee, E. Experimental observation of high intrinsic thermal conductivity of AlN. Phys. Rev. Mater. 2020, 4, 44602. [Google Scholar] [CrossRef]

- Koh, Y.R.; Cheng, Z.; Mamun, A.; Bin Hoque, M.S.; Liu, Z.; Bai, T.; Hussain, K.; Liao, M.E.; Li, R.; Gaskins, J.T. Bulk-like Intrinsic Phonon Thermal Conductivity of Micrometer-Thick AlN Films. ACS Appl. Mater. Interfaces 2020, 12, 29443–29450. [Google Scholar] [CrossRef] [PubMed]

- Mamun, A.; Hussain, K.; Jewel, M.U.; Mollah, S.; Huynh, K.; Liao, M.E.; Bai, T.; Koh, Y.R.; Cheng, Z.; Hoque, M.S.B. Thick AlN Templates by MOCVD for the Thermal Management of III-N Electronics. ECS Meet. Abstr. 2021, 33, 1075. [Google Scholar] [CrossRef]

- Hoque, M.S.B.; Koh, Y.R.; Braun, J.L.; Mamun, A.; Liu, Z.; Huynh, K.; Liao, M.E.; Hussain, K.; Cheng, Z.; Hoglund, E.R. High in-plane thermal conductivity of aluminum nitride thin films. ACS Nano 2021, 15, 9588–9599. [Google Scholar] [CrossRef]

- Harris, J.S.; Baker, J.N.; Gaddy, B.E.; Bryan, I.; Bryan, Z.; Mirrielees, K.J.; Reddy, P.; Collazo, R.; Sitar, Z.; Irving, D.L. On compensation in Si-doped AlN. Appl. Phys. Lett. 2018, 112, 152101. [Google Scholar] [CrossRef]

- Lyons, J.L.; Janotti, A.; Van de Walle, C.G. Shallow versus deep nature of Mg acceptors in nitride semiconductors. Phys. Rev. Lett. 2012, 108, 156403. [Google Scholar] [CrossRef] [Green Version]

- Szabo, A.; Son, N.T.; Janzén, E.; Gali, A. Group-II acceptors in wurtzite AlN: A screened hybrid density functional study. Appl. Phys. Lett. 2010, 96, 192110. [Google Scholar] [CrossRef] [Green Version]

- Nam, K.; Nakarmi, M.; Li, J.; Lin, J.; Jiang, H. Mg acceptor level in AlN probed by deep ultraviolet photoluminescence. Appl. Phys. Lett. 2003, 83, 878–880. [Google Scholar] [CrossRef]

- Wu, R.; Shen, L.; Yang, M.; Sha, Z.-D.; Cai, Y.; Feng, Y.P.; Huang, Z.; Wu, Q.Y. Possible efficient p-type doping of AlN using Be: An ab initio study. Appl. Phys. Lett. 2007, 91, 152110. [Google Scholar] [CrossRef]

- Lyons, J.L.; Krishnaswamy, K.; Gordon, L.; Janotti, A.; Van de Walle, C.G. Identification of microscopic hole-trapping mechanisms in nitride semiconductors. IEEE Electron Device Lett. 2015, 37, 154–156. [Google Scholar] [CrossRef]

- Breckenridge, M.H.; Bagheri, P.; Guo, Q.; Sarkar, B.; Khachariya, D.; Pavlidis, S.; Tweedie, J.; Kirste, R.; Mita, S.; Reddy, P. High n-type conductivity and carrier concentration in Si-implanted homoepitaxial AlN. Appl. Phys. Lett. 2021, 118, 112104. [Google Scholar] [CrossRef]

- Ahmad, H.; Lindemuth, J.; Engel, Z.; Matthews, C.M.; McCrone, T.M.; Doolittle, W.A. Substantial P-Type Conductivity of AlN Achieved via Beryllium Doping. Adv. Mater. 2021, 33, 2104497. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Zhang, K.; He, C.; He, L.; Wang, Q.; Zhao, W.; Chen, Z. Recent Advances in Fabricating Wurtzite AlN Film on (0001)-Plane Sapphire Substrate. Crystals 2022, 12, 38. https://doi.org/10.3390/cryst12010038

Wu H, Zhang K, He C, He L, Wang Q, Zhao W, Chen Z. Recent Advances in Fabricating Wurtzite AlN Film on (0001)-Plane Sapphire Substrate. Crystals. 2022; 12(1):38. https://doi.org/10.3390/cryst12010038

Chicago/Turabian StyleWu, Hualong, Kang Zhang, Chenguang He, Longfei He, Qiao Wang, Wei Zhao, and Zhitao Chen. 2022. "Recent Advances in Fabricating Wurtzite AlN Film on (0001)-Plane Sapphire Substrate" Crystals 12, no. 1: 38. https://doi.org/10.3390/cryst12010038

APA StyleWu, H., Zhang, K., He, C., He, L., Wang, Q., Zhao, W., & Chen, Z. (2022). Recent Advances in Fabricating Wurtzite AlN Film on (0001)-Plane Sapphire Substrate. Crystals, 12(1), 38. https://doi.org/10.3390/cryst12010038