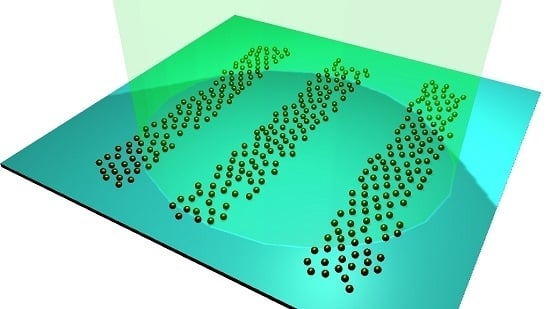

Photo-Thermal Effects in 1D Gratings of Gold Nanoparticles

Abstract

:1. Introduction

2. Results and Discussions

3. Materials and Methods

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zheludev, N. Single nanoparticle as photonic switch and optical memory element. J. Opt. A Pure Appl. Opt. 2006, 8, S1–S9. [Google Scholar] [CrossRef]

- Pelton, M.; Aizpurua, J.; Bryant, G. Metal-nanoparticle plasmonics. Laser Photonics Rev. 2008, 2, 136–159. [Google Scholar] [CrossRef]

- Sonnefraud, Y.; Leen Koh, A.; McComb, D.W.; Maier, S.A. Nanoplasmonics: Engineering and observation of localized plasmon modes. Laser Photonics Rev. 2012, 6, 277–295. [Google Scholar] [CrossRef]

- Jin, Y.; Li, Q.; Li, G.; Chen, M.; Liu, J.; Zou, Y.; Fan, S. Enhanced optical output power of blue light-emitting diodes with quasi-aligned gold nanoparticles. Nanoscale Res. Lett. 2014, 9, 7. [Google Scholar] [CrossRef] [PubMed]

- Halas, N.J. The photonic nanomedicine revolution: Let the human side of nanotechnology emerge. Nanomedicine 2009, 4, 369–371. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, L.C.; Bickford, L.R.; Lewinski, N.A.; Coughlin, A.J.; Hu, Y.; Day, E.S.; Drezek, R.A. A New Era for Cancer Treatment: Gold-Nanoparticle-Mediated Thermal Therapies. Small 2011, 7, 169–183. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Jain, P.K.; El-Sayed, I.H.; El-Sayed, M.A. Plasmonic photothermal therapy (PPTT) using gold nanoparticles. Lasers Med. Sci. 2008, 23, 217–228. [Google Scholar] [CrossRef] [PubMed]

- Pustovalov, V.K.; Smetannikov, A.S.; Zharov, V.P. Photothermal and accompanied phenomena of selective nanophotothermolysis with gold nanoparticles and laser pulses. Laser Phys. Lett. 2008, 5, 775–792. [Google Scholar] [CrossRef]

- Adleman, J.R.; Boyd, D.A.; Goodwin, D.G.; Psaltis, D. Heterogenous catalysis mediated by plasmon heating. Nano Lett. 2009, 9, 4417–4423. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, R.; El-Sayed, M.A. Some aspects of colloidal nanoparticle stability, catalytic activity, and recycling potential. Top. Catal. 2008, 47, 15–21. [Google Scholar] [CrossRef]

- Goia, D.V. Preparation and formation mechanisms of uniform metallic particles in homogeneous solutions. J. Mater. Chem. 2004, 14, 451–458. [Google Scholar] [CrossRef]

- Turkevich, J.; Stevenson, P.T.; Hillier, J. A study of the nucleation and growth processes in the synthesis of colloidal gold. Discuss. Faraday Soc. 1951, 11, 55–75. [Google Scholar] [CrossRef]

- Palpant, B. Photothermal properties of gold nanoparticles. In Gold Nanoparticles for Physics, Biology and Chemistry, 2nd ed.; Louis, C., Pluchery, O., Eds.; Imperial College: London, UK, 2012; Volume 3, pp. 75–102. [Google Scholar]

- Richardson, H.H.; Carlson, M.T.; Tandler, P.J.; Hernandez, P.; Govorov, A.O. Experimental and theoretical studies of light-to-heat conversion and collective heating effects in metal nanoparticle solutions. Nano Lett. 2009, 9, 1139–1146. [Google Scholar] [CrossRef] [PubMed]

- Xiaohua, H.; El-Sayed, M.A. Plasmonic photo-thermal therapy (PPTT). Alex. J. Med. 2011, 47, 1–9. [Google Scholar]

- Abadeer, N.S.; Murphy, C.J. Recent Progress in Cancer Thermal Therapy Using Gold Nanoparticles. J. Phys. Chem. C 2016, 120, 4691–4716. [Google Scholar] [CrossRef]

- Liu, G.L.; Kim, J.; Lu, Y.U.; Lee, L.P. Optofluidic control using photothermal nanoparticles. Nat. Mater. 2006, 5, 27–32. [Google Scholar] [CrossRef] [PubMed]

- Tohmyoh, H.; Imaizumi, T.; Hayashi, H.; Saka, M. Welding of Pt nanowires by Joule heating. Scr. Mater. 2007, 57, 953–956. [Google Scholar] [CrossRef]

- Challener, W.A.; Peng, C.; Itagi, A.V.; Karns, D.; Peng, W.; Peng, Y.; Ju, G. Heat-assisted magnetic recording by a near-field transducer with efficient optical energy transfer. Nat. Photonics 2009, 3, 220–224. [Google Scholar] [CrossRef]

- Jain, P.K.; Lee, K.S.; El-Sayed, I.H.; El-Sayed, M.A. Calculated absorption and scattering properties of gold nanoparticles of different size, shape, and composition: Applications in biological imaging and biomedicine. J. Phys. Chem. B 2006, 110, 7238–7248. [Google Scholar] [CrossRef] [PubMed]

- Pissuwan, D.; Valenzuela, S.M.; Cortie, M.B. Therapeutic possibilities of plasmonically heated gold nanoparticles. Trends Biotechnol. 2006, 24, 62–67. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grzelczak, M.; Perez-Juste, J.; Mulvaney, P.; Liz-Marzan, L.M. Shape control in gold nanoparticle synthesis. Chem. Soc. Rev. 2008, 37, 1783–1791. [Google Scholar] [CrossRef] [PubMed]

- Engelhardt, S. Direct Laser Writing, in Laser Technology in Biomimetics; Schmidt, V., Belegratis, M.R., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 13–56. [Google Scholar]

- Sakamoto, M.; Fujistuka, M.; Majima, T. Light as a construction tool of metal nanoparticles: Synthesis and mechanism. J. Photochem. Photobiol. C 2009, 10, 33–56. [Google Scholar] [CrossRef]

- Pucci, A.; Bernabo, M.; Elvati, P.; Meza, L.I.; Galembeck, F.; de Paula Leite, C.A.; Ruggeri, G. Photoinduced formation of gold nanoparticles into vinyl alcohol based polymers. J. Mater. Chem. 2006, 16, 1058–1066. [Google Scholar] [CrossRef]

- Kaneko, K.; Sun, H.B.; Duan, X.M.; Kawata, S. Two-photon photoreduction of metallic nanoparticle gratings in a polymer matrix. Appl. Phys. Lett. 2003, 83, 1426–1428. [Google Scholar] [CrossRef]

- Ritacco, T.; Ricciardi, L.; La Deda, M.; Giocondo, M. Controlling the optical creation of gold nanoparticles in a PVA matrix by direct laser writing. J. Eur. Opt. Soc. Rapid 2016, 11, 16008. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Kou, X.; Yang, Z.; Ni, W.; Wang, J. Shape-and size-dependent refractive index sensitivity of gold nanoparticles. Langmuir 2008, 24, 5233–5237. [Google Scholar] [CrossRef] [PubMed]

- Passinger, S. Two-Photon Polymerization and Application to Surface Plasmon Polaritons; Cuvillier Verlag: Gottingen, Germany, 2008. [Google Scholar]

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palermo, G.; Ritacco, T.; Aceti, D.M.; Pezzi, L.; Giocondo, M.; De Luca, A. Photo-Thermal Effects in 1D Gratings of Gold Nanoparticles. Crystals 2017, 7, 14. https://doi.org/10.3390/cryst7010014

Palermo G, Ritacco T, Aceti DM, Pezzi L, Giocondo M, De Luca A. Photo-Thermal Effects in 1D Gratings of Gold Nanoparticles. Crystals. 2017; 7(1):14. https://doi.org/10.3390/cryst7010014

Chicago/Turabian StylePalermo, Giovanna, Tiziana Ritacco, Dante Maria Aceti, Luigia Pezzi, Michele Giocondo, and Antonio De Luca. 2017. "Photo-Thermal Effects in 1D Gratings of Gold Nanoparticles" Crystals 7, no. 1: 14. https://doi.org/10.3390/cryst7010014

APA StylePalermo, G., Ritacco, T., Aceti, D. M., Pezzi, L., Giocondo, M., & De Luca, A. (2017). Photo-Thermal Effects in 1D Gratings of Gold Nanoparticles. Crystals, 7(1), 14. https://doi.org/10.3390/cryst7010014