1. Introduction

Self-avoiding random walks (SAWs) have long been used in polymer science as one of the simplest and most useful descriptions of polymeric chains. The relative simplicity of SAWs has made them an ideal tool to investigate static and dynamic properties of polymers both analytically and computationally [

1,

2,

3,

4,

5,

6,

7] . They have proved particularly useful in the determination of universal behavior and scaling laws for polymer systems ranging from individual chains to melts. The critical behavior of SAWs is also closely related to that of the Ising model and to percolation [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18].

Besides their extensive application in polymer science, SAWs have been a subject of mathematical interest in their own right [

19,

20], mainly because of their close relationship to Brownian motion and stochastic processes in general soft matter physics [

21,

22,

23]. In spite of the very simple idea underlying SAWs, comparatively few results have been rigorously solved in a mathematical sense [

19]. As a consequence, a great deal of computational work has been carried out to complement analytical approaches. From the numerical point of view, a currently active research area is the efficient computation of the number of distinct conformations for an SAW of a given length on a lattice, which is very closely related to the single-chain classical partition function [

24]. Over the last several years, increasingly sophisticated enumeration algorithms [

25,

26,

27] have been continually pushing the upper SAW length limit for which numerical results on enumeration can be obtained within a reasonable computational time.

Detailed knowledge of SAW properties in restricted geometries is an essential ingredient in the study of confined polymeric systems, which can range from single macromolecules to highly entangled melts in pores, slits, narrow gaps and nanocavities. Such properties include the number of distinct SAWs for a given length, mean squared end-to-end vector, distribution of size, etc. Although SAWs in such restricted geometries have also been studied [

11,

12,

28,

29,

30,

31,

32], they have received far less attention than unrestricted SAWs, one of the reasons being the apparent lack of applications in polymer science. The relatively recent [

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47,

48] increased interest in confined polymeric systems, accompanied by significant advances in molecular simulations and the availability of experimental techniques able to probe the behavior of individual macromolecules in channels, slits, etc. [

49,

50,

51,

52,

53] is a strong motivation for the investigation of SAWs in such confined geometries. Recent Monte Carlo (MC) simulations [

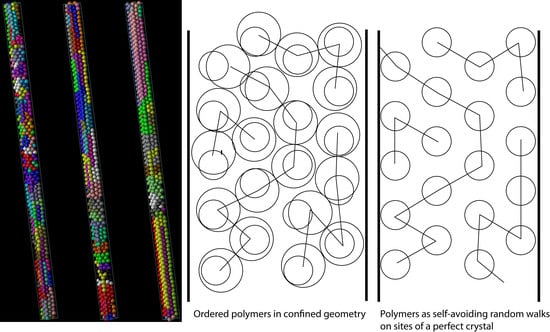

54] of highly confined, dense assemblies of linear, freely jointed chains of strictly tangent hard spheres of uniform size show that such athermal polymer systems display an unexpectedly broad range of morphologies, presumably connected by phase transitions.

In the following, “polymer” will refer to a linear chain of strictly tangent hard spheres, unless explicitly stated otherwise. “Monomer” will refer to each of the hard spheres that make up a chain, and “site” will refer to each of the points of a lattice. We will also refer interchangeably to the cubic P and F lattices and the corresponding simple cubic (SC) and face centered cubic (FCC) crystals obtained by placing a spherical base motif on all lattice points.

As stated earlier, the present work is motivated by the simulation results of Ref. [

54] where linear, freely-jointed chains of tangent hard spheres of uniform size are generated and successively equilibrated under various conditions of confinement. The latter is realized through the presence of flat, impenetrable parallel walls in one or more dimensions. Extreme confinement corresponds to the state where inter-wall distance approaches monomer diameter leading eventually to the formation of quasi 1D (tube-like) and 2D (plate-like) polymer templates. Typical computer-generated polymer configurations can be seen in

Figure 1 and

Figure 2 in lateral and cross-sectional views, respectively. They correspond to systems containing a total of 720 monomers and average number of bonds per chain

, 17 and 35 at a packing density

. In all cases, chains are packed in an approximately 3.11 × 3.11 square tube of length 77.8. All lengths are reported in units of monomer diameter (equal to the SAW step length). Periodic boundary conditions are applied on the long dimension, and hard walls exist in the short ones. More details on the simulation algorithm, the systems studied and the corresponding model parameters can be found in [

54].

Visual inspection of athermal chain configurations confined in square tubes, as the ones shown in

Figure 1 and

Figure 2, reveals the presence of highly ordered regions with crystalline defects. A more precise analysis of the local environment around each sphere monomer identifies such structures as slightly defective, coexisting FCC crystals of different orientations. Entropy is the sole driving force for structural transitions between different ordered morphologies in such athermal systems. Accordingly, an enumeration of all possible chain configurations on a specific regular lattice, subject to spatial restrictions arising from confinement, would allow us to determine the conformational component of entropy and eventually predict the stability of each distinct polymer crystal.

An analysis, based on the Characteristic Crystallographic Element (CCE) norm [

55,

56,

57], of the geometrical environment around the spherical monomers shows the ordered regions in such highly-confined polymer structures to very closely correspond to an FCC crystal. One remarkable aspect of such dense polymer systems in the bulk (i.e., without spatial confinement) is the existence of highly ordered, crystalline phases [

58]. In previous MC work [

57,

58,

59,

60,

61,

62,

63,

64], it was shown that the apparent loss of entropy, caused by the regular organization of monomers in the sites of a crystal lattice, is more than compensated for by the increase of available volume for monomers, and hence translational entropy, as made evident by sharp decreases in asphericity and acylindricity of the Voronoi cells associated with each monomeric site. The resulting crystalline structures strongly resemble those appearing in Molecular Dynamics (MD) and MC simulations of

single (monomeric) spheres, well known since the pioneering work of Alder and Wainwright [

65,

66,

67]. These crystalline

polymer structures can be simplistically viewed as built from crystals of single hard spheres and overlaying on them all possible linear paths of a given length that connect tangent spheres. Vice versa, configurations of single hard spheres can be obtained trivially from available configurations of polymers by deleting all bonds in chains.

As a matter of fact, if chain connectivity is ignored and the monomers are considered as individual spheres, the resulting ordered structures are virtually indistinguishable, except for one main feature, from those appearing in single hard sphere systems [

69,

70,

71]. The distinguishing feature is the absence of twinned structures in polymer systems [

72]. In computer simulations, packings of single hard spheres often form quite perfect tetrahedral clusters which tend to aggregate in pentatwins [

73]. The entropic conformational entropy loss associated with twinning in polymeric systems raises the entropic barrier to the extent that individual crystals with single or multiple stacking directions and abundant defects are observed predominantly in simulations.

Since difference in entropy is the only hindering or driving force for phase transitions in athermal polymeric systems [

6,

74,

75,

76], the entropy calculation in confined geometries is an essential requirement in understanding and predicting their phase behavior. Although all previously described characteristics have been obtained from off-lattice simulations, the appearance of highly ordered crystalline phases in quasi 1D (tube-like) confined polymer systems, such as the ones shown in

Figure 1 and

Figure 2, motivates the calculation of their entropy on crystal lattices under equivalent spatial restrictions.

Figure 3 is a simplified, generic, two-dimensional representation of the ordered structures observed in MC simulations of highly confined polymeric systems [

54]. The left panel represents a typical system configuration (MC-snapshot) confined between parallel walls. The centers of the spherical monomers (circles in solid line) are, on average, close to the sites of the perfect crystal (circles in dashed line). Configuration space is sampled through changes in the positions of the monomers as the MC progresses (such changes being compatible with chain connectivity, packing density, confinement and crystalline morphology; see, for example, the corresponding MC algorithms in [

54,

77]), much as monomer vibrations about the equilibrium position sample configurations in MD simulations. At high densities, monomers remain close to the sites of the crystal lattice (shown in the right panel), so that on-lattice polymer chains, built by joining the corresponding sites of the perfect crystal, closely approximate the original off-lattice system from the conformational point of view. Each of these chains is thus effectively a restricted SAW on the crystal lattice.

In typical classical MC simulations [

78,

79,

80,

81,

82], configurations for off-lattice polymer systems are generated with a probability proportional to their statistical (Boltzmann) weight and correspond to individual points in a configuration space spanned by continuously varying degrees of freedom, e.g., Cartesian coordinates of monomer centers in an MD formulation based on Newton’s equations of motion, or Euler, torsion and bond angles in a Lagrangian formulation, etc. Entropy or free energy calculations require then the evaluation of a high-dimensional integral in configuration space [

78].

On the other hand, configuration space for lattice SAWs (

Figure 3, right panel) is discrete and entropy is evaluated as a sum of Boltzmann probabilities or weights. Since all feasible configurations are equally probable in athermal systems, entropy is proportional to the logarithm of the number of different SAWs. While extensive work on the exact enumeration of SAWs on unrestricted lattices in several dimensions (typically the

d-dimensional hypercubic lattice

) has been carried out, enumeration of SAWs on restricted cubic P and F lattices has not been reported to date. In this contribution, we evaluate, by direct enumeration, the number of SAWs on the cubic P and F lattices subject to geometrical restriction and calculate the SAW size as a function of lattice type, number of bonds and level of confinement.

2. Methods

In the following, an N-step three-dimensional SAW on a lattice is defined as the ordered sequence of sites , where is the position vector of the SAW origin, satisfying the condition for , and such that , where it is assumed that the step length of the SAW is taken as the unit of length, and denotes the usual Euclidean norm.

According to the previous definition of step length, two neighboring sites are 1 length unit apart on both the cubic P and the F lattices. For the cubic P lattice, the edge length of the conventional cell is therefore also a unit, whereas, in the cubic F lattice, the edge length of the conventional cell is .

The individual components of the position vector of the

i-th site of an

N-step SAW are denoted by

with

. The squared end-to-end distance of the SAW

is given by

. With the previous definitions of unit length,

for a fully extended SAW, whereas the minimum SAW length is

. These two values bracket the range over which the distribution of

is defined. If we denote by

the number of distinct

N-step SAWs, the average squared end-to-end distance is given by:

where the sum is over the

SAWs starting at a given lattice point

. For unrestricted SAWs,

can be any one of the countable infinity of lattice points, since the set

of all SAWs starting at all points of a given lattice has the same space group symmetry as the lattice itself. Let us define the following equivalence relation on the set

of all three-dimensional SAWs of a given length

N starting at all points of a given lattice: two SAWs

,

are equivalent, and we write

, if there exists a geometrical transformation

T (group element) in the space group

such that

. The set of all distinct

SAWs is then the set of all equivalent classes

. For confined SAWs, the introduction of geometric restrictions will reduce this trivial multiplicity (which is due to the maximal symmetry of the unconfined lattice).

For unrestricted lattices, the number

and thus the computational effort for the exact enumeration problem for SAWs are believed to grow exponentially with power law corrections as

N increases, instead of the purely exponential growth for simple non-SAWs. More specifically, it is conjectured, and there is strong numerical and nonrigorous evidence, that

and

depend on

N as:

where

A,

D,

,

and

are (dimension dependent) positive constants. The constant

A is known as the amplitude,

as the connective constant, while

(the entropic exponent) and

are critical exponents. For simple non-SAWs,

and

. Estimates and bounds for

,

and

for SAWs are available [

25,

83,

84,

85,

86,

87,

88,

89]. Approximate values in three dimensions are

,

and

.

The value of

has been the object of increasingly refined and extensive calculations. Milestone calculations for the 3D cubic P lattice are: Orr’s

[

24], Fisher and Sykes

[

17,

90,

91], Guttmann

[

83,

88,

91,

92,

93,

94], MacDonald et al.

[

84,

88], Clisby et al.

[

87], Schram et al.

[

25,

26,

27], this latter value being the current record, obtained by the length doubling method. The latter group has also determined the current highest values of

on the BCC (body-centered cubic) (

) and FCC (

) unrestricted lattices. The continual growth of the range of known values of

has made it possible to obtain more accurate numerical estimates of the various parameters appearing in Equations (

1) and (

2). Extrapolation by means of differential approximants and direct fitting to asymptotic expansions yields values for

and

in good agreement with those obtained by the MC renormalization group [

95], conformal bootstrap [

96] and field theory [

97].

In this contribution, we present results for the cubic P (SC) and cubic F (FCC) lattices restricted to a pore or “tube” of square cross section. While the complete set of SAWs on the unrestricted lattice possesses the maximal crystallographic symmetry of space group , the introduction of geometrical restrictions reduces the symmetry on the one hand and, on the other, introduces additional freedom in the definition of the problem. For polymers confined in a pore or tube, the natural correspondence would be to an SAW whose growth is limited in the plane transversal to the tube direction. The new degrees of freedom, which are not meaningful for unrestricted SAWs, are the orientation of the tube axis, the size of its cross-section and the origin of the SAW: the orientation of the tube axis will be defined by direction indices according to crystallographic practice: . The cross section will be assumed to be a square of side L, measured in units of SAW step length. Finally, will be calculated for each distinct origin located on the tube cross section at .

The value of

will of course depend on the choice of the origin and on the doubly countable infinity of degrees of freedom: direction

and tube cross section

L. In the MC simulations of confined polymers that motivate this work, hard-sphere chains confined to tubes of square cross-section are observed to preferentially form quite perfect FCC crystalline domains with their

aligned along the tube axis. For both the SC and FCC lattices, we will thus consider the geometrically restricted lattice

to consist of all the lattice points of coordinates

contained in the square-section “tube” defined by:

where the unit of length is the SAW step length. In Equation (

3), the tube has been assumed to be oriented parallel to one of the three standard cubic crystallographic axes, or, equivalently, to belong to the direction type

. The

(or

x) axis [

98] has been chosen without loss of generality due to the equivalence of all three axes in the cubic system. The sides of the tube are contained in planes of the crystallographic form

.

Unlike in the references cited above, and again motivated by the MC simulations of hard-sphere model polymers confined to tubes, the range of SAW lengths investigated in this work has been kept modest. The reason is twofold: the rich morphological behavior of confined polymers is already clearly observable in MC simulations of comparatively short chains (

5–15). This can be understood by observing the structural similarity of the ordered chain morphologies presented in the panels of

Figure 1 and

Figure 2 and which correspond to systems characterized by different chain lengths (from

to 35). Furthermore, once

in this range is known, it can be used as the basis of reliable approximations for the prediction of entropy-driven phase transitions for much longer chains as well. For these two reasons, we have employed the direct enumeration procedure to determine

.

The introduction of the tube restriction reduces the symmetry of the full cubic lattice to that of tetragonal space group

. As a consequence, lattice sites in the tube cross section are not all identical any more, but split into subsets of SAW origins

, all sites in a subset being crystallographically equivalent. We will refer to the cardinality

of these subsets as their

multiplicity and will label each of the distinct origins by a

type which effectively corresponds to the numerical subindex,

i, of each subset. For example, there are three possible origins for SAWs on an SC lattice restricted by a tube of size

, with multiplicities (

)

, (

)

, (

)

(

Figure 4), and six possible origins for SAWs on an FCC lattice restricted by a tube of size

, with multiplicities

,

,

,

,

and

(

Figure 5).

Figure 4 and

Figure 5 schematically show the definition of tube size and the numbering/labeling scheme for the SC and FCC restricted lattices, respectively. Thus, an

tube has a cross section of the same size as

conventional cubic unit cells arranged in a square array, and its side measures

units of length (SAW step) for the SC lattice, and

for the FCC lattice. In these figures, a number placed at selected lattice points is their label, corresponding to the notation

types in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9. Each different type corresponds to a different origin for the SAW. The number in parentheses corresponds to the multiplicity of that

(number of crystallographically equivalent restricted lattice points) while the subindex in braces refers to the overlap, to be defined and discussed in

Section 4.

As the size of the tube cross section grows, the number of distinct origins (i.e., of different types) increases. The value of

reported below is given separately for all possible distinct (crystallographically non-equivalent) origins: the values of

in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9 correspond to the number of SAWs starting from only one of all equivalent lattice sites of a given type. The value of the multiplicity is a useful piece of information for situations in which the

symmetry of the tube is possibly further reduced by other geometrical considerations. For example, a flat, comb-like array of equidistant, identical parallel tubes joined at one end by a common channel loses (among others) all fourfold rotation and screw axes of symmetry, which lowers its space group symmetry to orthorhombic

. For the estimation of the entropy of polymers confined to such a nanostructure, origins belonging to the same subset for the isolated tube are, at least in principle, no longer equivalent.

For the calculation of for SAWs of the moderate lengths considered in this work, simple enumeration was more than adequate: was obtained by exhaustively testing all possible SAWs of length N for self-intersections or for violation of the geometrical restrictions, and discarding those that fail to fulfill self-avoidance or geometrical constraint. Computations were carried out on Intel i7-8700K CPUs with 16 GB of memory. For benchmark purposes in the case of unconstrained SAWs, the computational (CPU) time required for the full enumeration of a -SAW in the SC lattice and of a -SAW in the FCC lattice reaches approximately 108 and 928 h, respectively.

It must be emphasized that the goal of this work is not to achieve high-accuracy values [

27,

85,

86,

89,

99,

100] in the calculation of the critical exponents or the leading or sub-leading correction-to-scaling exponents, but to obtain correlations for

for chains of moderate length to be used in the understanding of the entropic mechanisms of phase transitions observed in the off-lattice (continuum) simulations of confined and densely-packed polymers.

3. Results

The values of

for SAWs on lattices restricted to a tube of cross section

oriented along the

direction are presented in

Table A1,

Table A2 and

Table A3 for the SC lattice, together with their average squared end-to-end distance. The corresponding results for the FCC lattice can be found in

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9. SAW origin

correspond to the labeling schemes of

Figure 4 and

Figure 5. The coefficients of best fit of the scaling laws in Equations (

1) and (

2) to the data of

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9 are shown in

Table 1 and

Table 2. As expected, the values of all coefficients are specific for each lattice type, tube size and type of origin. Within a given tube size, restricted SAWs starting at more confined lattice sites (lower

) have systematically lower values of

than those further removed from the boundaries. Thus, for SAWs of

restricted to a

tube in the SC lattice,

for the more confined, in the corner of the tube, type 1 (of multiplicity 4),

for the less confined type 2 (on the side wall with multiplicity 8) and

for the least confined type 3 (with multiplicity 4). For comparison, using the same number of steps the number of different SAW configurations is (

)

for the unrestricted SC lattice.

Based on the results presented in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7,

Table A8 and

Table A9 Figure 6 shows the log-log plot of the number of distinct SAWs,

, versus the number of SAW steps,

N, for all SC (left panel) and selected FCC (right panel) lattices for different SAW origins (types) and sizes of the confining tube. Also shown for comparison purposes are the corresponding results for the unrestricted cases. It can be clearly seen that, for a given tube size the closer to the tube surface, the lower the total number of distinct SAWS; for origin types residing in the corner of the tube, the larger the tube size, the larger the SAW population. Compared to the unrestricted case, type 1 (corner) of the smallest tube shows always the largest difference while the type of highest value (farthest from the corner) of the largest tube shows the closest similarity, independently of lattice type.

We should note here that Equation (

1), quantifying the dependence of

on

N, is manifestly valid for the whole range of studied systems, independently of lattice type, tube confinement and SAW origin. However, the same is not true for Equation (

2) which relates SAW size, as quantified by the average square end-to-end distance, with a number of SAW steps. For the unrestricted lattice, Equation (

2) remains accurate in the whole

N-range. In sharp contrast, for the confined lattices, especially for SAW origins near the confining tube, anomalous behavior is clearly observed for small-

N SAWs. This is particularly evident in the results of

Figure 7 showing log-log plots of

versus

N for SC (filled symbols) and FCC (open symbols) unrestricted (black color) and confined (red or green color) lattices. For the latter, we differentiate between SAW origins corresponding to the most (SC: type 1 in

tube; FCC: type 1 in

) and least (SC: type 3 in

tube; FCC: type 6 in

) confined cases. The combination of spatial restrictions along with the anisotropy in cell size leads to this anomalous scaling for early-

N SAWs. Thus, all

D and

coefficients reported in

Table 1 and

Table 2 correspond to fittings applied on data covering the late-

N SAW regime.

In addition to

and

, the discrete probability distribution functions (PDF) and cumulative distribution functions (CDF) of

are available. In

Figure 8 and

Figure 9, the effects of tube size (left panel), for a fixed SAW origin, and of origin type (right panel), for a fixed tube cross section, on the distribution for SAWs of length

are presented for the SC and FCC lattices, respectively. As expected, higher confinement (i.e., smaller tube cross section) leads to more stretched SAWs and a distribution shifted to higher values of

(remarkably higher histogram values above

at and above 50). This shift is particularly evident in the cumulative distributions (left panels of

Figure 10 and

Figure 11). The strong confinement induced by the small tube

definitely leads to significantly more stretched SAWs.

On the other hand, the SAW origin type has little influence on the spread of the distribution, but it does increase or reduce the probability of certain SAW extensions (see, for example, the higher red bars in the right panel of

Figure 8). It is also remarkable that, for a given

N and tube cross section, the most confined SAWs (type 1 in this case) show non-vanishing probabilities for values of

for which the probability for types 2 and 3 is zero (isolated black bars in the plot of

Figure 8 at

). Identical conclusions can be drawn for the effect of origin type and tube length for SAWS on FCC lattices according to the probability distributions presented in

Figure 9. As can be seen in the right panels of

Figure 10 and

Figure 11, there is virtually no difference in the cumulative distributions for the different types of SAW origins.

The effect of chain length on the cumulative distribution of

is shown in

Figure 12 and

Figure 13 for the SC and FCC lattices, respectively. With respect to SC, according to the data in

Figure 12, the four curves corresponding to

(left panel) are noticeably different, as they should be for different values of

N. However, they come much closer together when scaled by

(right panel of the same figure). In other words, the characteristic ratio of the SAWs is fairly constant in this range of

N, with a median value of approx. 1.25. A very similar conclusion can be drawn for the FCC case (

Figure 13), where the characteristic ratio shows little variation with the number of SAW steps.

4. Discussion

An inspection of the tables shows that

is, as expected, lower for the restricted lattices than for the unrestricted ones, the more so, the smaller the restricting tube. The black, solid line in both panels of

Figure 6 represents in log-log scale the growth of

with SAW length

N for the unrestricted case, while all other lines correspond to the value of

for SAWs restricted on confining tubes of specific sizes for all possible different origins, both on the cubic P (left panel) and F (right panel) lattices.

The faster growth of

for unrestricted SAWs is also reflected in the larger values of the connective constant

, which is the dominant term in Equation (

1) for large values of

N:

for the unrestricted SC lattice, against

(multiplicity-based, weighted average over all three types of origin) for the restricted 3 × 3 SC lattice, while the corresponding value drops to just

for the

tube, a decrease of approximately 50% with respect to the bulk case. For the FCC lattice, the analogous numbers are:

(unrestricted),

(weighted average over all six types of origin for the restricted

FCC lattice) and

for the most confined

FCC case, the latter being around 75% less than the value of the unrestricted FCC SAW. This behavior is in agreement with the geometrical meaning of connectivity: restricted SAWs that start close to one of the boundaries have, on average, fewer neighbors than those that start farther from the confining tube.

In addition, the average (weighted by the type multiplicity) connectivity constants in

Table 1 and

Table 2 reflect this trend very clearly: as tube size increases, the values of the average connectivity constant increase and approach the unrestricted values. For FCC lattices of sizes

,

,

,

,

and

, the multiplicity-weighted average values of

are 2.674 (73.4%), 4.742 (52.9%), 6.491 (35.5%), 7.613 (24.3%), 8.344 (17.2%) and 8.751 (13.1%), where numbers in parentheses denote percentage reduction with respect to the connectivity constant of the bulk FCC lattice.

Furthermore, for a given size of the tube, the values of

for different origins tend to converge as

N grows. This is most clearly observed in the left panel of

Figure 6: the curves for the three origin types are already quite close for the moderate value

for all restricted SC lattices. The same is true for the SAWs of length

on confined FCC lattices as seen in the right panel of

Figure 6. For a given lattice type (FCC or SC) and a given spatial restriction (tube cross section), the value of

must approach a common limit as

, independently of the particular type of SAW origin: sufficiently long SAWs lose the “memory” of their starting point so that:

must hold, where

is one of the sets of equivalent SAW origins for a restricted lattice, and

is the number of restricted SAWs of length

N starting at an origin of type

. The rate at which

approaches this common

limit is of course dependent on the lattice. As can be seen in

Figure 6, SAWs on the restricted FCC lattice tend to this limit more slowly than SAWs on the SC one.

In

Figure 14, the ratio

for different SAW origins (i.e., the ratio of the curves represented in

Figure 6 divided by the curve for

of SAW origin of type 1, taken arbitrarily as reference) is seen to indeed approach unity as

N increases for both SC (left panel) and FCC (right panel) lattices. Systematically, the ratio tends faster to unity for SAW origins that lie close in space and for smaller tube cross sections. For example, for an SAW of length

on the

FCC lattice for type of origin

, 4 and 6, the corresponding ratios are 1.026, 1.048 and 1.051. In parallel, for an SAW of

steps on a SC lattice with origin type 2, the ratio increases from 1.007 for a

tube to 1.011 for a

one.

The dependence of

on SAW origin (type) for given

N and tube size can be explained, at least approximately, by a simple geometric argument. Since a higher degree of confinement leads to a greater reduction in

, it seems natural to attempt a scaling of

by means of the following area ratio or

overlap:

where

is the area common to a tube cross section (a square in the present work) centered at the SAW origin of type

i (square in dotted line in

Figure 15), and the tube cross section. The overlap

is the ratio of this area (small square in

Figure 15) to the entire tube cross section. More highly confined SAW origins (i.e., a corner, like type 1 in the

restricted SC lattice) have lower values of

, while those close to the center of the tube have higher

. Taking the SC lattice restricted by a

tube (rightmost panel in

Figure 4) as an illustrative example, the values of the overlap for the three distinct types of origin are:

The overlap values for all SAW origin types in the SC and FCC lattices used in the present work are reported in braces in the schemes of

Figure 4 and

Figure 5. In fact, going back to the sketches, the labeling of the distinct types of SAW origins is based on the overlap value of a given site: the lower the overlap value, the lower the origin index. According to the definition, overlap values for the SC and FCC lattices, confined in tube with direction type

, are bounded between 0.25 (assigned always to origin type 1) and 1. As can be seen in the reported area ratios of

Figure 4 and

Figure 5 for a given tube size, no two distinct origin types have the same overlap value. With respect to the confined

FCC lattice, origin types 1, 2, 3, 4, 5 and 6 are characterized by area ratios (overlaps) of

,

,

,

,

and

, respectively.

Based on the above, it is tempting to study the behavior of the curves

(log-log plots in

Figure 16) versus

N, where now the number of distinct SAW configurations for a given origin type is divided by the corresponding overlap of that type. The comparison of the left panel of

Figure 6 with

Figure 16 strongly suggests that this simple geometric argument does indeed successfully explain to first order the dependence of

on the type of SAW origin. Curves corresponding to different tube cross-sections and origin types seem to be brought closer together when they are scaled by the proper overlap values.