Woven Fabrics Made of Auxetic Plied Yarns

Abstract

:1. Introduction

2. Experimental Details

2.1. Fabrication of Auxetic Yarn Samples

2.2. Fabrication of Auxetic Fabric Samples

2.3. Testing Method

3. Results and Discussion

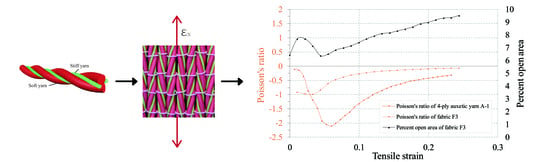

3.1. Typical Tensile Properties of Woven Fabric Made of 4-ply Auxetic Yarn

3.2. Effect of 4-Ply Auxetic Yarn Arrangement

3.3. Effect of Weft Yarn Type

3.4. Effect of 4-Ply Auxetic Yarn Components

3.5. Effect of Weave Structure

3.6. Effect of Yarn Helical Structure

4. Conclusions

- (1)

- The in-plane NPR behavior of a woven fabric can be inherited from its constituent auxetic yarns, but with a significant reduction due to a combination of different factors. These factors include the embedding of auxetic plied yarns during fabric fabrication, the constraint of weft yarns, and the overlapping effect of auxetic yarns upon extension.

- (2)

- The alternative arrangement of S- and Z-twisted auxetic yarns in a woven fabric can generate higher NPR and percent open area to the fabric.

- (3)

- Weft yarns with low modulus and short float over the 4-ply auxetic yarns are favorable for producing high NPR values of the fabric.

- (4)

- Weave structure has significant effect on the NPR behavior of the woven fabric. More intersections help to prevent the auxetic plied yarns from embedding to each other.

- (5)

- Stiff yarns with high tensile modulus in a plied auxetic yarn structure result in a higher NPR effect in the fabric. However, a finer soft yarn does not necessarily produce a higher NPR due to the early onset of fabric contraction.

- (6)

- Weft cover factor plays a significant role in the determination of the open pore properties of the woven fabrics. When the weft cover factor is reduced to certain extent, different variation trends can be identified. Variation in the major diameter and minor diameter of the auxetic plied yarn upon extension induces opposing effects on the percent open area of the auxetic woven fabrics.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ezazshahabi, N.; Saharkhiz, S.; Mohammad Hosseini Varkiyani, S. Effect of fabric structure and weft density on the Poisson’s ratio of worsted fabric. J. Eng. Fiber. Fabr. 2013, 8, 63–71. [Google Scholar]

- Sun, H.; Pan, N.; Postle, R. On the Poisson’s ratios of a woven fabric. Compos. Struct. 2005, 68, 505–510. [Google Scholar] [CrossRef]

- Hosseini, K.; Sadeghi, A.; Jeddi, A.A.A. Characterization of fabric tensile loading curve in nonlinear region related to their structure; Part I: Woven fabric. J. Text. Polym. 2013, 1, 53–59. [Google Scholar]

- Shahabi, N.E.; Mousazadegan, F.; Varkiyani, S.M.H.; Saharkhiz, S. Crimp analysis of worsted fabrics in the terms of fabric extension behaviour. Fibers Polym. 2014, 15, 1211–1220. [Google Scholar] [CrossRef]

- Ajeli, S.; Jeddi, A.A.A. Geometrically Poisson’s ratio of the polyester double-bar warp-knitted structures on the jamming point. J. Text. Polym. 2014, 2, 24–28. [Google Scholar]

- Bhullar, S.K.; Wegner, J.L.; Mioduchowski, A. Strain energy distribution in an auxetic plate with a crack. J. Eng. Technol. Res. 2010, 2, 118–125. [Google Scholar]

- Scarpa, F.; Yates, J.R.; Ciffo, L.G.; Patsias, S. Dynamic crushing of auxetic open-cell polyurethane foam. Proc. Inst. Mech. Eng. Part C 2002, 216, 1153–1156. [Google Scholar] [CrossRef]

- Stott, P.J.; Mitchell, R.; Alderson, K.; Alderson, A. A growing industry. Mater. World 2000, 8, 12–14. [Google Scholar]

- Simkins, V.R.; Alderson, A.; Davies, P.J.; Alderson, K.L. Single fibre pullout tests on auxetic polymeric fibres. J. Mater. Sci. 2005, 40, 4355–4364. [Google Scholar] [CrossRef]

- Alderson, A.; Rasburn, J.; Beg, S.A.; Mullarkey, P.G.; Perrie, W.; Evans, K.E. An auxetic filter: A tuneable filter displaying enhanced size selectivity or defouling properties. Ind. Eng. Chem. Res. 2000, 39, 654–665. [Google Scholar] [CrossRef]

- Alderson, A.; Alderson, K. Expanding materials and applications: exploiting auxetic textiles. Tech. Text. Int. 2005, 14, 29–34. [Google Scholar]

- Wright, J.L.; Burns, M.K.; James, E.; Sloan, M.R.; Evans, K.E. On the design and characterisation of low-stiffness auxetic yarns and fabrics. Text. Res. J. 2012, 82, 645–654. [Google Scholar] [CrossRef]

- Dolla, W.J.; Fricke, B.A.; Becker, B.R. Structural and drug diffusion models of conventional and auxetic drug-eluting stents. J. Med. Devices 2007, 1, 47–55. [Google Scholar] [CrossRef]

- Alderson, A.; Davies, P.J.; Williams, M.R.; Evans, K.E.; Alderson, K.L.; Grima, J.N. Modelling of the mechanical and mass transport properties of auxetic molecular sieves: an idealised organic (polymeric honeycomb) host-guest system. Mol. Simulat. 2005, 31, 897–905. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H.; Lam, J.K.C.; Liu, S. Negative Poisson’s ratio weft-knitted fabrics. Text. Res. J. 2010, 80, 856–863. [Google Scholar]

- Hu, H.; Wang, Z.Y.; Liu, S. Development of auxetic fabrics using flat knitting technology. Text. Res. J. 2011, 81, 1493–1502. [Google Scholar]

- Starbuck, M.; Subhash, C.A.; Ravirala, N.; Alderson, K.L.; Alderson, A. Fabrics having knit structures exhibiting auxetic properties and garments formed thereby. U.S. Patent 20080011021 A1, 17 January 2008. [Google Scholar]

- Ugbolue, S.C.; Kim, Y.K.; Warner, S.B.; Fan, Q.; Yang, C.; Kyzymchuk, O.; Feng, Y. The formation and performance of auxetic textiles. Part I: theoretical and technical considerations. J. Text. Inst. 2010, 101, 660–667. [Google Scholar] [CrossRef]

- Ugbolue, S.C.; Kim, Y.K.; Warner, S.B.; Fan, Q.; Yang, C.; Kyzymchuk, O.; Feng, Y.; Lord, J. The formation and performance of auxetic textiles. Part II: geometry and structural properties. J. Text. Inst. 2011, 102, 424–433. [Google Scholar] [CrossRef]

- Vysanskav, M.; Vintrova, P. Auxetic woven fabrics-Pores’ parameters observation. J. Donghua University 2013, 30, 416–420. [Google Scholar]

- Hook, P.B. Auxetic Mechanisms, Structures & Materials. Ph.D. Thesis, School of Engineering and Computer Science, University of Exeter, Exeter, UK, 2003. [Google Scholar]

- Miller, W.; Hook, P.B.; Smith, C.W.; Wang, X.; Evans, K.E. The manufacture and characterisation of a novel, low modulus, negative Poisson’s ratio composite. Compos. Sci. Technol. 2009, 69, 651–655. [Google Scholar] [CrossRef]

- Ge, Z.Y.; Hu, H.; Liu, S.R. A novel plied yarn structure with negative Poisson’s ratio. J. Text. Inst. 2016, 107, 578–588. [Google Scholar] [CrossRef]

- Ng, W.S.; Hu, H. Tensile and deformation behavior of auxetic plied yarns. Phys. Status Solidi B 2017, 254. [Google Scholar] [CrossRef]

| Sample Code | Yarn Type | Yarn Twist (turns/m) | Yarn Composition | Yarn Cross-Section | |

|---|---|---|---|---|---|

| Soft Yarn | Stiff Yarn | ||||

| A-1 | 4-ply | 51 | 2.18-mm polyester-covered rubber cord | 0.87-mm polyester-covered monofilament cord |  |

| A-3 | 4-ply | 51 | 2.18-mm polyester-covered rubber cord | 0.80-mm 3-ply polyester thread |  |

| A-4 | 4-ply | 51 | 2.18-mm polyester-covered rubber cord | 0.77-mm waxed polyester cord |  |

| B-1 | 4-ply | 51 | 1.56-mm polyester-covered rubber cord | 0.87-mm polyester-covered monofilament cord |  |

| C-1 | 4-ply | 51 | 1.14-mm polyester-covered rubber cord | 0.87-mm polyester-covered monofilament cord |  |

| A-1-D | Double helix | 51 | 2.18-mm polyester-covered rubber cord | 0.87-mm polyester-covered monofilament cord |  |

| A-1-T | 6-ply | 51 | 2.18-mm polyester-covered rubber cord | 0.87-mm polyester-covered monofilament cord |  |

| Parameter Consideration | Fabric Code | Material | Fabric Density | Fabric Structure | ||

|---|---|---|---|---|---|---|

| Warp | Weft | Ends/Inch | Picks/Inch | |||

| Direction of twist | F1 | A-1 (S/Z) | 4 mm flat braided polyester elastic band | 6.35 | 6.46 | Plain |

| F2 | A-1 (S/S) | |||||

| Weft type | F1 | A-1 (S/Z) | 4 mm flat braided polyester elastic band | 6.35 | 6.46 | Plain |

| F3 | 100 D polyester-covered spandex yarn | 6.10* | ||||

| 4-ply auxetic yarn properties: diameter of soft yarn | F3 | A-1 (S/Z) | 100 D polyester-covered spandex yarn | 6.35 | 6.10* | Plain |

| F4 | B-1 (S/Z) | 8.63 | ||||

| F5 | C-1 (S/Z) | 9.03 | ||||

| 4-ply auxetic yarn properties: tensile modulus of stiff yarn | F3 | A-1 (S/Z) | 100 D polyester-covered spandex yarn | 6.35 | 6.10* | Plain |

| F6 | A-3 (S/Z) | 6.35 | ||||

| F7 | A-4 (S/Z) | 6.35 | ||||

| Weave | F1 | A-1 (S/Z) | 4 mm flat braided polyester elastic band | 6.35 | 6.46 | Plain |

| F8 | 6.35 | 2 × 1 Twill | ||||

| F9 | 6.35 | 3 × 1 Twill | ||||

| F10 | 6.35 | 5-end Satin | ||||

| Helical structure of yarn | F11 | A-1-D (S/Z) | 100 D polyester-covered spandex yarn | 9.14 | 6.10* | Plain |

| F3 | A-1 (S/Z) | 6.35 | ||||

| F12 | A-1-T (S/Z) | 5.59 | ||||

|  |  |  |

| F1 | F2 | F3 | F4 |

|  |  |  |

| F5 | F6 | F7 | F8 |

|  |  |  |

| F9 | F10 | F11 | F12 |

| Strain | Fabric Picture | Strain | Fabric Picture | ||

|---|---|---|---|---|---|

|  | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ng, W.S.; Hu, H. Woven Fabrics Made of Auxetic Plied Yarns. Polymers 2018, 10, 226. https://doi.org/10.3390/polym10020226

Ng WS, Hu H. Woven Fabrics Made of Auxetic Plied Yarns. Polymers. 2018; 10(2):226. https://doi.org/10.3390/polym10020226

Chicago/Turabian StyleNg, Wing Sum, and Hong Hu. 2018. "Woven Fabrics Made of Auxetic Plied Yarns" Polymers 10, no. 2: 226. https://doi.org/10.3390/polym10020226

APA StyleNg, W. S., & Hu, H. (2018). Woven Fabrics Made of Auxetic Plied Yarns. Polymers, 10(2), 226. https://doi.org/10.3390/polym10020226