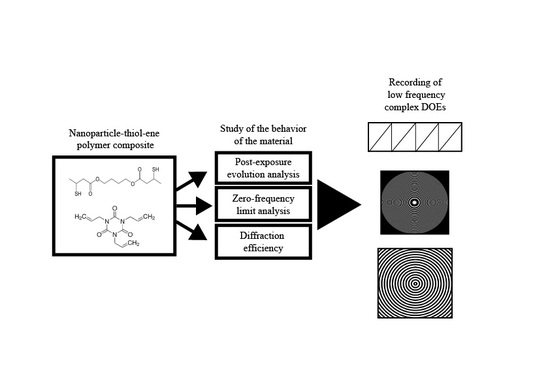

Diffractive and Interferometric Characterization of Nanostructured Photopolymer for Sharp Diffractive Optical Elements Recording

Abstract

:1. Introduction

2. Experimental Setup

3. Results and Discussion

3.1. Post-Exposure Evolution

3.2. Phase Shift and Diffraction Efficency

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Tomita, Y.; Hata, E.; Momose, K.; Takayama, S.; Liu, X.; Chikama, K.; Klepp, J.; Pruner, C.; Fally, M. Photopolymerizable nanocomposite photonic materials and their holographic applications in light and neutron optics. J. Mod. Opt. 2016, 63, S1–S31. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, N.; Tomita, Y. Holographic recording in TiO2 nanoparticle-dispersed methacrylate photopolymer films. Appl. Phys. Lett. 2002, 81, 4121–4123. [Google Scholar] [CrossRef]

- Sakhno, O.V.; Goldenberg, L.M.; Stumpe, J.; Smirnova, T.T. Surface modified ZrO2 and TiO2 nanoparticles embedded in organic photopolymers for highly effective and UV-stable volume holograms. Nanotechnology 2007, 18, 105704. [Google Scholar] [CrossRef]

- Kim, W.S.; Jeong, Y.-C.; Park, J. Nanoparticle-induced refractive index modulation of organic-inorganic hybrid photopolymer. Opt. Express 2006, 14, 8967–8973. [Google Scholar] [CrossRef] [PubMed]

- Moothanchery, M.; Naydenova, I.; Mintova, S.; Toal, V. Nanozeolites doped photopolymer layers with reduced shrinkage. Opt. Express 2011, 19, 25786–25791. [Google Scholar] [CrossRef] [PubMed]

- Tomita, Y.; Furushima, K.; Ochi, K.; Ishizu, K.; Tanaka, A.; Ozawa, M.; Hidaka, M.; Chikama, K. Organic nanoparticle (hyperbranched polymer)-dispersed photopolymers for volume holographic storage. Appl. Phys. Lett. 2006, 88, 071103. [Google Scholar] [CrossRef]

- Chikama, K.; Mastubara, K.; Oyama, S.; Tomita, Y. Three-dimensional confocal Raman imaging of volume holograms formed in ZrO2 nanoparticle-photopolymer composite materials. J. Appl. Phys. 2005, 103, 113108. [Google Scholar] [CrossRef]

- Kalathi, J.T.; Yamamoto, U.; Schweizer, K.S.; Grest, G.S.; Kumar, S.K. Nanoparticle diffusion in polymer nanocomposites. Phys. Rev. Lett. 2014, 112, 108301. [Google Scholar] [CrossRef] [PubMed]

- Tomita, Y.; Nakamura, T.; Tago, A. Improved thermal stability of volume holograms recorded in nanoparticle-polymer composite films. Opt. Lett. 2008, 33, 1750–1752. [Google Scholar] [CrossRef] [PubMed]

- Li, M.S.; Fuh, A.Y.-G.; Liu, J.-H.; Wu, S.-T. Bichromatic optical switch of diffractive light from a BCT photonic crystal based on an azo component-doped HPDLC. Opt. Express 2012, 20, 25545–25553. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Fan, Y.-H.; Lin, Y.-H.; Wu, S.-T. Tunable-focus microlens arrays using nanosized polymer-dispersed liquid crystal droplets. Opt. Commun. 2005, 247, 101–106. [Google Scholar] [CrossRef]

- Li, M.S.; Wu, S.T.; Fuh, A.Y.G. Sensor for monitoring the vibration of a laser beam based on holographic polymer dispersed liquid crystal films. Opt. Express 2010, 18, 26300–26306. [Google Scholar] [CrossRef] [PubMed]

- Fernández, R.; Gallego, S.; Márquez, A.; Francés, J.; Martínez, F.J.; Pascual, I.; Beléndez, A. Analysis of holographic polymer-dispersed liquid crystals (HPDLCs) for tunable low frequency diffractive optical elements recording. Opt. Mater. 2018, 76, 295–301. [Google Scholar] [CrossRef]

- Hata, E.; Tomita, Y. Order-of-magnitude polymerization-shrinkage suppression of volume gratings recorded in nanoparticle-polymer composites. Opt. Lett. 2010, 35, 396–398. [Google Scholar] [CrossRef] [PubMed]

- Hata, E.; Mitsube, K.; Momose, K.; Tomita, Y. Holographic nanoparticle-polymer composites based on step-growth thiol-ene photopolymerization. Opt. Mater. Express 2011, 1, 207–222. [Google Scholar] [CrossRef]

- Hata, E.; Tomita, Y. Stoichiometric thiol-to-ene ratio dependences of refractive index modulation and shrinkage of volume gratings recorded in photopolymerizable nanoparticle-polymer composites based onstep-growth polymerization. Opt. Mater. Express 2011, 1, 1113–1120. [Google Scholar] [CrossRef]

- Mitsube, K.; Nishimura, Y.; Nagaya, K.; Takayama, S.; Tomita, Y. Holographic nanoparticle-polymer composites based on radical-mediated thiol-yne photopolymerizations: Characterization and shift-multiplexed holographic digital data page storage. Opt. Mater. Express 2014, 4, 982–996. [Google Scholar] [CrossRef]

- Peng, H.; Nair, D.P.; Kowalski, B.A.; Xi, W.; Gong, T.; Wang, C.; Cole, M.; Cramer, N.B.; Xie, X.; McLeod, R.R.; et al. High Performance Graded Rainbow Holograms via Two-Stage Sequential Orthogonal Thiol-Click Chemistry. Macromolecules 2014, 47, 2306–2315. [Google Scholar] [CrossRef]

- Alim, M.D.; Glugla, D.J.; Mavila, S.; Wang, C.; Nystrom, P.D.; Sullivan, A.C.; McLeod, R.R.; Bowman, C.N. High Dynamic Range (Δn) Two-Stage Photopolymers via Enhanced Solubility of a High Refractive Index Acrylate Writing Monomer. ACS Appl. Mater. Interfaces 2018, 10, 1217–1224. [Google Scholar] [CrossRef] [PubMed]

- Gallego, S.; Márquez, A.; Martínez, F.J.; Riquelme, M.; Fernández, R.; Pascual, I.; Beléndez, A. Linearity in the response of photopolymers as optical recording media. Opt. Express 2013, 21, 10995–11008. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernández, R.; Gallego, S.; Márquez, A.; Francés, J.; Martínez, F.J.; Beléndez, A. Influence of index matching on AA/PVA photopolymers for low spatial frequency recording. Appl. Opt. 2015, 54, 3132–3140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernández, R.; Gallego, S.; Francés, J.; Pascual, I.; Beléndez, A. Characterization and comparison of different photopolymers for low spatial frequency recording. Opt. Mater. 2015, 44, 18–24. [Google Scholar] [CrossRef]

- Ortuño, M.; Gallego, S.; Márquez, A.; Neipp, C.; Pascual, I.; Beléndez, A. Biophotopol: A Sustainable Photopolymer for Holographic Data Storage Applications. Materials 2012, 5, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Fernández, R.; Gallego, S.; Márquez, A.; Francés, J.; Navarro-Fuster, V.; Beléndez, A. Blazed gratings recorded in absorbent photopolymers. Materials 2016, 9, 195. [Google Scholar] [CrossRef] [PubMed]

- Fernández, R.; Gallego, S.; Márquez, A.; Francés, J.; Navarro, V.; Pascual, I. Diffractive lenses recorded in absorbent photopolymers. Opt. Express 2016, 24, 1559–1572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gallego, S.; Márquez, A.; Méndez, D.; Ortuño, M.; Neipp, C.; Fernández, E.; Pascual, I.; Beléndez, A. Analysis of PVA/AA based photopolymers at the zero spatial frequency limit using interferometric methods. Appl. Opt. 2008, 47, 2557–2563. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gallego, S.; Márquez, A.; Neipp, C.; Fernández, R.; Guardiola, J.M.; Francés, J.; Ortuño, M.; Pascual, I.; Beléndez, A. Model of low spatial frequency diffractive elements recorded in photopolymers during and after recording. Opt. Mater. 2014, 38, 46–52. [Google Scholar] [CrossRef]

- Gallego, S.; Márquez, A.; Marini, S.; Fernández, E.; Ortuño, M.; Pascual, I. In dark analysis of PVA/AA materials at very low spatial frequencies: Phase modulation evolution and diffusion estimation. Opt. Express 2009, 17, 18279–18291. [Google Scholar] [CrossRef] [PubMed]

- Goodman, J.W. Introduction to Fourier Optics, 3rd ed.; Roberts & Company: Englewood, NJ, USA, 2005. [Google Scholar]

- Hariharan, P. Optical Holography: Principles, Techniques, and Applications, 2nd ed.; Cambridge Studies in Modern Optics; Cambridge University: Cambridge, UK, 1996; p. 47. [Google Scholar]

- Babeva, T.; Naydenova, I.; Martin, S.; Toal, V. Method for characterization of diffusion properties of photopolymerisable systems. Opt. Express 2008, 16, 8487–8497. [Google Scholar] [CrossRef] [PubMed]

- Gallego, S.; Márquez, A.; Ortuño, M.; Marini, S.; Francés, J. High environmental compatibility photopolymers compared to PVA/AA based materials at zero spatial frequency limit. Opt. Mater. 2011, 33, 531–537. [Google Scholar] [CrossRef]

- Cramer, N.B.; Bowman, C.N. Kinetics of thiol-ene and thiol-acrylate photopolymerizations with real-time fourier transform infrared. J. Polym. Sci. A Polym. Chem. 2001, 39, 3311–3319. [Google Scholar] [CrossRef]

- Cramer, N.B.; Reddy, S.K.; O’Brien, A.K.; Bowman, C.N. Thiol-Ene Photopolymerization Mechanism and Rate Limiting Step Changes for Various Vinyl Functional Group Chemistries. Macromolecules 2003, 36, 7964–7969. [Google Scholar] [CrossRef]

- Malallah, R.; Li, H.; Kelly, D.P.; Healy, J.J.; Sheridan, J.T. A Review of Hologram Storage and Self-Written Waveguides Formation in Photopolymer Media. Polymers 2017, 9, 337. [Google Scholar] [CrossRef]

- Sabel, T.; Zschocher, M. Transition of refractive index contrast in course of grating growth. Sci. Rep. 2013, 3, 2552. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández, R.; Gallego, S.; Tomita, Y.; Pascual, I.; Beléndez, A. Diffractive and Interferometric Characterization of Nanostructured Photopolymer for Sharp Diffractive Optical Elements Recording. Polymers 2018, 10, 518. https://doi.org/10.3390/polym10050518

Fernández R, Gallego S, Tomita Y, Pascual I, Beléndez A. Diffractive and Interferometric Characterization of Nanostructured Photopolymer for Sharp Diffractive Optical Elements Recording. Polymers. 2018; 10(5):518. https://doi.org/10.3390/polym10050518

Chicago/Turabian StyleFernández, Roberto, Sergi Gallego, Yasuo Tomita, Inmaculada Pascual, and Augusto Beléndez. 2018. "Diffractive and Interferometric Characterization of Nanostructured Photopolymer for Sharp Diffractive Optical Elements Recording" Polymers 10, no. 5: 518. https://doi.org/10.3390/polym10050518

APA StyleFernández, R., Gallego, S., Tomita, Y., Pascual, I., & Beléndez, A. (2018). Diffractive and Interferometric Characterization of Nanostructured Photopolymer for Sharp Diffractive Optical Elements Recording. Polymers, 10(5), 518. https://doi.org/10.3390/polym10050518