Multifunctional Polymer Nanocomposites Reinforced by Aligned Carbon Nanomaterials

Abstract

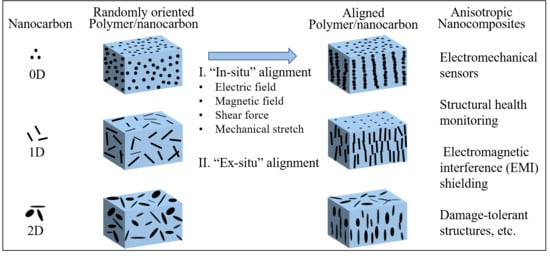

:1. Introduction

2. Alignment Techniques

2.1. Overview of Different Alignment Techniques

2.1.1. “Ex Situ” Alignment

2.1.2. “In Situ” Alignment

2.2. Electric Field-Induced Alignment: Mechanisms and Modeling

2.3. Magnetic Field-Induced Alignment: Mechanisms and Modeling

3. Properties of Polymer Nanocomposites Containing Aligned Carbon Nanofillers

3.1. Electrical Properties

3.2. Thermal Properties

3.3. Mechanical Properties

4. Applications

4.1. Electromechanical Sensors

4.2. Structural Health Monitoring

4.3. Electromagnetic Interference (EMI) Shielding

4.4. Damage-Tolerant Structures

5. Challenges and Opportunities

- Each of the established alignment techniques have both advantages and disadvantages, as discussed in the early sections of this review and summarized in a previous study [23]. For instance, as discussed in Section 2.1.1, polymer infiltration process may cause structural damage to the vertical aligned CNTs and the polymer must be highly compatible with CNTs to ensure the complete infusion. Other techniques based on shear force, mechanical stretching, or electrospinning may damage the structure of carbon nanomaterials. For alignment by external fields (electric field or magnetic field), high field strength is usually required for preparing bulk composites. Due to the relatively low magnetic susceptibility, carbon nanomaterials may need functionalization by introducing magnetic particles so that they can be aligned under a low-strength magnetic field.

- Large scale production remains a great challenge. Cakmak et al. [48] recently developed a large scale manufacturing platform to align nanoparticles in the through-the-thickness direction by a new roll-to-toll processing line. Meanwhile, to prepare a large-scale nanocomposite film with nanofillers aligning in the in-plane direction, Sun and coworkers [128] proposed an array of parallel wire electrodes instead of a single pair of parallel plate electrodes. Apart from these attempts, very few reports could be located in the literature on the translation of lab-scale alignment techniques to practical applications for processing large size nanocomposites. Therefore, further studies and investigations are needed to scale-up the alignment process.

- The effects of alignment on some properties such as piezoresistive sensitivity of polymer nanocomposites are not conclusive and further detailed investigations, both experimentally and/or numerically, are needed. It is anticipated that significant improvement in the design and fabrication of electromechanical sensors is possible by manipulating the orientation of nanomaterials.

- The type of polymer matrix investigated to date is limited and more studies are needed to understand how alignment will affect the properties of other polymer matrix composites. Moreover, very few studies have been reported on the alignment of hybrid nanofillers. The different structures and properties of the nanofillers may result in multiscale aligned structures, which will be of great interest for designing new functional nanocomposites.

- The different alignment techniques may be combined to create new composites materials. For instance, shear forced-induced alignment during 3D printing of polymer nanocomposites may be combined with other techniques (e.g., applying electric or magnetic fields) to develop nanocomposites with well-aligned microstructures.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Rong, M.Z.; Zhang, M.Q.; Pan, S.L.; Friedrich, K. Interfacial effects in polypropylene–silica nanocomposites. J. Appl. Polym. Sci. 2004, 92, 1771–1781. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Tang, L.-C.; Yan, D.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. Improved dispersion and interface in the graphene/epoxy composites via a facile surfactant-assisted process. Compos. Sci. Technol. 2013, 82, 60–68. [Google Scholar] [CrossRef]

- Xie, X.-L.; Mai, Y.-W.; Zhou, X.-P. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Zaman, I.; Kuan, H.-C.; Dai, J.; Kawashima, N.; Michelmore, A.; Sovi, A.; Dong, S.; Luong, L.; Ma, J. From carbon nanotubes and silicate layers to graphene platelets for polymer nanocomposites. Nanoscale 2012, 4, 4578–4586. [Google Scholar] [CrossRef] [PubMed]

- King, J.A.; Klimek, D.R.; Miskioglu, I.; Odegard, G.M. Mechanical properties of graphene nanoplatelet/epoxy composites. J. Appl. Polym. Sci. 2013, 128, 4217–4223. [Google Scholar] [CrossRef]

- Wagner, H.D.; Lourie, O.; Feldman, Y.; Tenne, R. Stress-induced fragmentation of multiwall carbon nanotubes in a polymer matrix. Appl. Phys. Lett. 1998, 72, 188–190. [Google Scholar] [CrossRef]

- Xing, W.; Yang, W.; Yang, W.; Hu, Q.; Si, J.; Lu, H.; Yang, B.; Song, L.; Hu, Y.; Yuen, R.K.K. Functionalized Carbon Nanotubes with Phosphorus- and Nitrogen-Containing Agents: Effective Reinforcer for Thermal, Mechanical, and Flame-Retardant Properties of Polystyrene Nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 26266–26274. [Google Scholar] [CrossRef] [PubMed]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Yang, Y.H.; Bolling, L.; Priolo, M.A.; Grunlan, J.C. Super Gas Barrier and Selectivity of Graphene Oxide-Polymer Multilayer Thin Films. Adv. Mater. 2013, 25, 503–508. [Google Scholar] [CrossRef] [PubMed]

- Al-Saleh, M.H.; Sundararaj, U. A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon 2009, 47, 2–22. [Google Scholar] [CrossRef]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Wajid, A.S.; Das, S.; Irin, F.; Ahmed, H.S.T.; Shelburne, J.L.; Parviz, D.; Fullerton, R.J.; Jankowski, A.F.; Hedden, R.C.; Green, M.J. Polymer-stabilized graphene dispersions at high concentrations in organic solvents for composite production. Carbon 2012, 50, 526–534. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Morales-Teyssier, O.; Sánchez-Valdes, S.; Ramos-de Valle, L.F. Effect of Carbon Nanofiber Functionalization on the Dispersion and Physical and Mechanical Properties of Polystyrene Nanocomposites. Macromol. Mater. Eng. 2006, 291, 1547–1555. [Google Scholar] [CrossRef]

- Kim, S.W.; Kim, T.; Kim, Y.S.; Choi, H.S.; Lim, H.J.; Yang, S.J.; Park, C.R. Surface modifications for the effective dispersion of carbon nanotubes in solvents and polymers. Carbon 2012, 50, 3–33. [Google Scholar] [CrossRef]

- Haggenmueller, R.; Du, F.; Fischer, J.E.; Winey, K.I. Interfacial in situ polymerization of single wall carbon nanotube/nylon 6,6 nanocomposites. Polymer 2006, 47, 2381–2388. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Bafekrpour, E.; Ghorbani, K.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 2015, 94, 607–618. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Improving the toughness and electrical conductivity of epoxy nanocomposites by using aligned carbon nanofibres. Compos. Sci. Technol. 2015, 117, 146–158. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Multifunctional properties of epoxy nanocomposites reinforced by aligned nanoscale carbon. Mater. Des. 2016, 94, 554–564. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Ladani, R.B.; Ghorbani, K.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. A novel route for tethering graphene with iron oxide and its magnetic field alignment in polymer nanocomposites. Polymer 2016, 97, 273–284. [Google Scholar] [CrossRef]

- Ajayan, P.M.; Stephan, O.; Colliex, C.; Trauth, D. Aligned carbon nanotube arrays formed by cutting a polymer resin-nanotube composite. Science 1994, 265, 1212–1214. [Google Scholar] [CrossRef] [PubMed]

- Ahir, S.V.; Huang, Y.Y.; Terentjev, E.M. Polymers with aligned carbon nanotubes: Active composite materials. Polymer 2008, 49, 3841–3854. [Google Scholar] [CrossRef]

- Goh, P.S.; Ismail, A.F.; Ng, B.C. Directional alignment of carbon nanotubes in polymer matrices: Contemporary approaches and future advances. Compos. Part A 2014, 56, 103–126. [Google Scholar] [CrossRef]

- Sun, X.M.; Chen, T.; Yang, Z.B.; Peng, H.S. The Alignment of Carbon Nanotubes: An Effective Route to Extend Their Excellent Properties to Macroscopic Scale. Acc. Chem. Res. 2013, 46, 539–549. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Yang, Z.; Gao, H.; Zhang, H.; Ren, J.; Sun, X.; Chen, T.; Kia, H.G.; Peng, H. Vertically Aligned and Penetrated Carbon Nanotube/Polymer Composite Film and Promising Electronic Applications. Adv. Mater. 2011, 23, 3730–3735. [Google Scholar] [CrossRef] [PubMed]

- Shin, M.K.; Oh, J.; Lima, M.; Kozlov, M.E.; Kim, S.J.; Baughman, R.H. Elastomeric Conductive Composites Based on Carbon Nanotube Forests. Adv. Mater. 2010, 22, 2663–2667. [Google Scholar] [CrossRef] [PubMed]

- Shoukat, R.; Khan, M.I. Synthesis of vertically aligned carbon nanofibers using inductively coupled plasma-enhanced chemical vapor deposition. Electr. Eng. 2017, 100, 997–1002. [Google Scholar] [CrossRef]

- Jakob, B.; Hyung Gyu, P. Failure mechanism of the polymer infiltration of carbon nanotube forests. Nanotechnology 2016, 27, 464002. [Google Scholar]

- Lian, G.; Tuan, C.-C.; Li, L.; Jiao, S.; Wang, Q.; Moon, K.-S.; Cui, D.; Wong, C.-P. Vertically Aligned and Interconnected Graphene Networks for High Thermal Conductivity of Epoxy Composites with Ultralow Loading. Chem. Mater. 2016, 28, 6096–6104. [Google Scholar] [CrossRef]

- Dong, R.-Y.; Cao, B.-Y. Anomalous orientations of a rigid carbon nanotube in a sheared fluid. Sci. Rep. 2014, 4, 6120. [Google Scholar] [CrossRef] [PubMed]

- Arjmand, M.; Apperley, T.; Okoniewski, M.; Sundararaj, U. Comparative study of electromagnetic interference shielding properties of injection molded versus compression molded multi-walled carbon nanotube/polystyrene composites. Carbon 2012, 50, 5126–5134. [Google Scholar] [CrossRef]

- Arjmand, M.; Mahmoodi, M.; Gelves, G.A.; Park, S.; Sundararaj, U. Electrical and electromagnetic interference shielding properties of flow-induced oriented carbon nanotubes in polycarbonate. Carbon 2011, 49, 3430–3440. [Google Scholar] [CrossRef]

- Abbasi, S.; Carreau, P.J.; Derdouri, A. Flow induced orientation of multiwalled carbon nanotubes in polycarbonate nanocomposites: Rheology, conductivity and mechanical properties. Polymer 2010, 51, 922–935. [Google Scholar] [CrossRef]

- Eken, A.E.; Tozzi, E.J.; Klingenberg, D.J.; Bauhofer, W. A simulation study on the effects of shear flow on the microstructure and electrical properties of carbon nanotube/polymer composites. Polymer 2011, 52, 5178–5185. [Google Scholar] [CrossRef]

- Tao, F.; Bonnaud, L.; Auhl, D.; Struth, B.; Dubois, P.; Bailly, C. Influence of shear-induced crystallization on the electrical conductivity of high density polyethylene carbon nanotube nanocomposites. Polymer 2012, 53, 5909–5916. [Google Scholar] [CrossRef]

- Eken, A.E.; Tozzi, E.J.; Klingenberg, D.J.; Bauhofer, W. Combined effects of nanotube aspect ratio and shear rate on the carbon nanotube/polymer composites. Polymer 2012, 53, 4493–4500. [Google Scholar] [CrossRef]

- Sulong, A.B.; Park, J. Alignment of multi-walled carbon nanotubes in a polyethylene matrix by extrusion shear flow: Mechanical properties enhancement. J. Compos. Mater. 2011, 45, 931–941. [Google Scholar] [CrossRef]

- Skipa, T.; Lellinger, D.; Böhm, W.; Saphiannikova, M.; Alig, I. Influence of shear deformation on carbon nanotube networks in polycarbonate melts: Interplay between build-up and destruction of agglomerates. Polymer 2010, 51, 201–210. [Google Scholar] [CrossRef]

- Alig, I.; Skipa, T.; Lellinger, D.; Pötschke, P. Destruction and formation of a carbon nanotube network in polymer melts: Rheology and conductivity spectroscopy. Polymer 2008, 49, 3524–3532. [Google Scholar] [CrossRef]

- Fan, Z.; Advani, S.G. Characterization of orientation state of carbon nanotubes in shear flow. Polymer 2005, 46, 5232–5240. [Google Scholar] [CrossRef]

- Fan, Z.; Advani, S.G. Rheology of multiwall carbon nanotube suspensions. J. Rheol. 2007, 51, 585–604. [Google Scholar] [CrossRef]

- Zhang, W.; Ning, N.; Gao, Y.; Xu, F.; Fu, Q. Stretching induced interfacial crystallization and property enhancement of poly(L-lactide)/single-walled carbon nanotubes fibers. Compos. Sci. Technol. 2013, 83, 47–53. [Google Scholar] [CrossRef]

- Chatterjee, T.; Mitchell, C.A.; Hadjiev, V.G.; Krishnamoorti, R. Oriented Single-Walled Carbon Nanotubes–Poly(ethylene oxide) Nanocomposites. Macromolecules 2012, 45, 9357–9363. [Google Scholar] [CrossRef]

- Arras, M.M.L.; Schillai, C.; Keller, T.F.; Schulze, R.; Jandt, K.D. Alignment of multi-wall carbon nanotubes by disentanglement in ultra-thin melt-drawn polymer films. Carbon 2013, 60, 366–378. [Google Scholar] [CrossRef]

- Salalha, W.; Dror, Y.; Khalfin, R.L.; Cohen, Y.; Yarin, A.L.; Zussman, E. Single-walled carbon nanotubes embedded in oriented polymeric nanofibers by electrospinning. Langmuir 2004, 20, 9852–9855. [Google Scholar] [CrossRef] [PubMed]

- Dror, Y.; Salalha, W.; Khalfin, R.L.; Cohen, Y.; Yarin, A.L.; Zussman, E. Carbon Nanotubes Embedded in Oriented Polymer Nanofibers by Electrospinning. Langmuir 2003, 19, 7012–7020. [Google Scholar] [CrossRef]

- Ko, F.; Gogotsi, Y.; Ali, A.; Naguib, N.; Ye, H.; Yang, G.L.; Li, C.; Willis, P. Electrospinning of Continuous Carbon Nanotube-Filled Nanofiber Yarns. Adv. Mater. 2003, 15, 1161–1165. [Google Scholar] [CrossRef]

- Cakmak, M.; Batra, S.; Yalcin, B. Field assisted self-assembly for preferential through thickness (“z-direction”) alignment of particles and phases by electric, magnetic, and thermal fields using a novel roll-to-roll processing line. Polym. Eng. Sci. 2014, 55, 34–46. [Google Scholar] [CrossRef]

- Kunitoshi, Y.; Seiji, A.; Yoshikazu, N. Orientation of Carbon Nanotubes Using Electrophoresis. Jpn. J. Appl. Phys. 1996, 35, L917. [Google Scholar]

- Yamamoto, K.; Akita, S.; Nakayama, Y. Orientation and purification of carbon nanotubes using ac electrophoresis. J. Phys. D Appl. Phys. 1998, 31, L34. [Google Scholar] [CrossRef]

- Schwarz, M.-K.; Bauhofer, W.; Schulte, K. Alternating electric field induced agglomeration of carbon black filled resins. Polymer 2002, 43, 3079–3082. [Google Scholar] [CrossRef]

- Prasse, T.; Cavaille, J.Y.; Bauhofer, W. Electric anisotropy of carbon nanofibre/epoxy resin composites due to electric field induced alignment. Compos. Sci. Technol. 2003, 63, 1835–1841. [Google Scholar] [CrossRef]

- Kim, G.; Shkel, Y.M. Polymeric Composites Tailored by Electric Field. J. Mater. Res. 2004, 19, 1164–1174. [Google Scholar] [CrossRef]

- Arp, P.A.; Foister, R.T.; Mason, S.G. Some electrohydrodynamic effects in fluid dispersions. Adv. Colloid Interface Sci. 1980, 12, 295–356. [Google Scholar] [CrossRef]

- Monti, M.; Natali, M.; Torre, L.; Kenny, J.M. The alignment of single walled carbon nanotubes in an epoxy resin by applying a DC electric field. Carbon 2012, 50, 2453–2464. [Google Scholar] [CrossRef]

- Kozinsky, B.; Marzari, N. Static dielectric properties of carbon nanotubes from first principles. Phys. Rev. Lett. 2006, 96, 166801. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.Q.; Saito, T.; Yamada, H.; Matsushige, K. Aligning single-wall carbon nanotubes with an alternating-current electric field. Appl. Phys. Lett. 2001, 78, 3714–3716. [Google Scholar] [CrossRef] [Green Version]

- Oliva-Aviles, A.I.; Aviles, F.; Sosa, V.; Oliva, A.I.; Gamboa, F. Dynamics of carbon nanotube alignment by electric fields. Nanotechnology 2012, 23, 465710. [Google Scholar] [CrossRef] [PubMed]

- Pang, H.A.; Chen, C.; Zhang, Y.C.; Ren, P.G.; Yan, D.X.; Li, Z.M. The effect of electric field, annealing temperature and filler loading on the percolation threshold of polystyrene containing carbon nanotubes and graphene nanosheets. Carbon 2011, 49, 1980–1988. [Google Scholar] [CrossRef]

- Su, C.; Xu, L.; Yan, R.-J.; Chen, M.-Q.; Zhan, C. Electric field induced conductive network formation of MWNTs and MWNTs-COOH in polycarbonate composites. Mater. Chem. Phys. 2012, 133, 1034–1039. [Google Scholar] [CrossRef]

- Bao, Y.; Pang, H.; Xu, L.; Cui, C.H.; Jiang, X.; Yan, D.X.; Li, Z.M. Influence of surface polarity of carbon nanotubes on electric field induced aligned conductive network formation in a polymer melt. RSC Adv. 2013, 3, 24185–24192. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, W.; Zhu, Y.F.; Ji, L.J.; Zhang, R.P.; Koratkar, N.; Liang, J. Alignment and dispersion of functionalized carbon nanotubes in polymer composites induced by an electric field. Carbon 2008, 46, 706–710. [Google Scholar] [CrossRef]

- Lim, C.S.; Rodriguez, A.J.; Guzman, M.E.; Schaefer, J.D.; Minaie, B. Processing and properties of polymer composites containing aligned functionalized carbon nanofibers. Carbon 2011, 49, 1873–1883. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wu, S.; Kinloch, A.J.; Wang, C.H.; Mouritz, A.P. The electric field alignment of short carbon fibres to enhance the toughness of epoxy composites. Compos. Part A 2018, 106, 11–23. [Google Scholar] [CrossRef]

- Martin, C.A.; Sandler, J.K.W.; Windle, A.H.; Schwarz, M.K.; Bauhofer, W.; Schulte, K.; Shaffer, M.S.P. Electric field-induced aligned multi-wall carbon nanotube networks in epoxy composites. Polymer 2005, 46, 877–886. [Google Scholar] [CrossRef]

- De Rango, P.; Lees, M.; Lejay, P.; Sulpice, A.; Tournier, R.; Ingold, M.; Germi, P.; Pernet, M. Texturing of magnetic materials at high temperature by solidification in a magnetic field. Nature 1991, 349, 770. [Google Scholar] [CrossRef]

- Fujiwara, M.; Chidiwa, T.; Tokunaga, R.; Tanimoto, Y. Crystal Growth of trans-Azobenzene in a Magnetic Field of 80 kOe. J. Phys. Chem. B 1998, 102, 3417–3419. [Google Scholar] [CrossRef]

- Fujiwara, M.; Oki, E.; Hamada, M.; Tanimoto, Y.; Mukouda, I.; Shimomura, Y. Magnetic Orientation and Magnetic Properties of a Single Carbon Nanotube. J. Phys. Chem. A 2001, 105, 4383–4386. [Google Scholar] [CrossRef]

- Ajiki, H.; Ando, T. Magnetic Properties of Carbon Nanotubes. J. Phys. Soc. Jpn. 1993, 62, 2470–2480. [Google Scholar] [CrossRef]

- Kimura, T.; Ago, H.; Tobita, M.; Ohshima, S.; Kyotani, M.; Yumura, M. Polymer composites of carbon nanotubes aligned by a magnetic field. Adv. Mater. 2002, 14, 1380–1383. [Google Scholar] [CrossRef]

- Choi, E.S.; Brooks, J.S.; Eaton, D.L.; Al-Haik, M.S.; Hussaini, M.Y.; Garmestani, H.; Li, D.; Dahmen, K. Enhancement of thermal and electrical properties of carbon nanotube polymer composites by magnetic field processing. J. Appl. Phys. 2003, 94, 6034–6039. [Google Scholar] [CrossRef]

- Camponeschi, E.; Vance, R.; Al-Haik, M.; Garmestani, H.; Tannenbaum, R. Properties of carbon nanotube–polymer composites aligned in a magnetic field. Carbon 2007, 45, 2037–2046. [Google Scholar] [CrossRef]

- Mahfuz, H.; Zainuddin, S.; Parker, M.; Al-Saadi, T.; Rangari, V.; Jeelani, S. Reinforcement of SC-15 epoxy with CNT/CNF under high magnetic field: An investigation of mechanical and thermal response. J. Mater. Sci. 2009, 44, 1113–1120. [Google Scholar] [CrossRef]

- Steinert, B.W.; Dean, D.R. Magnetic field alignment and electrical properties of solution cast PET–carbon nanotube composite films. Polymer 2009, 50, 898–904. [Google Scholar] [CrossRef]

- Abdalla, M.; Dean, D.; Theodore, M.; Fielding, J.; Nyairo, E.; Price, G. Magnetically processed carbon nanotube/epoxy nanocomposites: Morphology, thermal, and mechanical properties. Polymer 2010, 51, 1614–1620. [Google Scholar] [CrossRef]

- Correa-Duarte, M.A.; Grzelczak, M.; Salgueirino-Maceira, V.; Giersig, M.; Liz-Marzan, L.M.; Farle, M.; Sierazdki, K.; Diaz, R. Alignment of carbon nanotubes under low magnetic fields through attachment of magnetic nanoparticles. J. Phys. Chem. B 2005, 109, 19060–19063. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.T.; Nunnery, G.A.; Jacob, K.; Schwartz, J.; Liu, X.T.; Tannenbaum, R. Synthesis, Characterization, and Alignment of Magnetic Carbon Nanotubes Tethered with Maghemite Nanoparticles. J. Phys. Chem. C 2010, 114, 6944–6951. [Google Scholar] [CrossRef]

- Shi, D.; He, P.; Zhao, P.; Guo, F.F.; Wang, F.; Huth, C.; Chaud, X.; Bud’ko, S.L.; Lian, J. Magnetic alignment of Ni/Co-coated carbon nanotubes in polystyrene composites. Compos. Part B 2011, 42, 1532–1538. [Google Scholar] [CrossRef]

- Malkina, O.; Mahfuz, H.; Sorge, K.; Rondinone, A.; Chen, J.; More, K.; Reeves, S.; Rangari, V. Magnetic alignment of SWCNTs decorated with Fe3O4 to enhance mechanical properties of SC-15 epoxy. AIP Adv. 2013, 3, 042104. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Meliton, B.G.; Del Rosario, G.; Urena, A. New alignment procedure of magnetite-CNT hybrid nanofillers on epoxy bulk resin with permanent magnets. Compos. Part B 2013, 46, 166–172. [Google Scholar] [CrossRef]

- Zhang, X.; Alloul, O.; He, Q.L.; Zhu, J.H.; Verde, M.J.; Li, Y.T.; Wei, S.Y.; Guo, Z.H. Strengthened magnetic epoxy nanocomposites with protruding nanoparticles on the graphene nanosheets. Polymer 2013, 54, 3594–3604. [Google Scholar] [CrossRef]

- Yan, H.Y.; Tang, Y.X.; Long, W.; Li, Y.F. Enhanced thermal conductivity in polymer composites with aligned graphene nanosheets. J. Mater. Sci. 2014, 49, 5256–5264. [Google Scholar] [CrossRef]

- Ma, C.; Liu, H.-Y.; Du, X.; Mach, L.; Xu, F.; Mai, Y.-W. Fracture resistance, thermal and electrical properties of epoxy composites containing aligned carbon nanotubes by low magnetic field. Compos. Sci. Technol. 2015, 114, 126–135. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Kinloch, A.J.; Zhao, Z.; Ma, J.; Zhang, X.; Mouritz, A.P.; Ghorbani, K.; Wang, C.H. Epoxy nanocomposites containing magnetite-carbon nanofibers aligned using a weak magnetic field. Polymer 2015, 68, 25–34. [Google Scholar] [CrossRef]

- Liu, C.; Yan, H.; Lv, Q.; Li, S.; Niu, S. Enhanced tribological properties of aligned reduced graphene oxide-Fe3O4@polyphosphazene/bismaleimides composites. Carbon 2016, 102, 145–153. [Google Scholar] [CrossRef]

- Fragouli, D.; Das, A.; Innocenti, C.; Guttikonda, Y.; Rahman, S.; Liu, L.; Caramia, V.; Megaridis, C.M.; Athanassiou, A. Polymeric Films with Electric and Magnetic Anisotropy Due to Magnetically Assembled Functional Nanofibers. ACS Appl. Mater. Interfaces 2014, 6, 4535–4541. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.M.; Sun, H.; Li, H.P.; Peng, H.S. Developing Polymer Composite Materials: Carbon Nanotubes or Graphene? Adv. Mater. 2013, 25, 5153–5176. [Google Scholar] [CrossRef] [PubMed]

- Baur, J.; Silverman, E. Challenges and Opportunities in Multifunctional Nanocomposite Structures for Aerospace Applications. MRS Bull. 2011, 32, 328–334. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Ladani, R.B.; Ravindran, A.R.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Novel Electrically Conductive Porous PDMS/Carbon Nanofiber Composites for Deformable Strain Sensors and Conductors. ACS Appl. Mater. Interfaces 2017, 9, 14207–14215. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Ladani, R.B.; Zhang, J.; Ghorbani, K.; Zhang, X.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Strain Sensors with Adjustable Sensitivity by Tailoring the Microstructure of Graphene Aerogel/PDMS Nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 24853–24861. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Ladani, R.B.; Ravindran, A.R.; Zhang, J.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Aligning carbon nanofibres in glass-fibre/epoxy composites to improve interlaminar toughness and crack-detection capability. Compos. Sci. Technol. 2017, 152, 46–56. [Google Scholar] [CrossRef]

- Yu, C.; Masarapu, C.; Rong, J.; Wei, B.; Jiang, H. Stretchable supercapacitors based on buckled single-walled carbon nanotube macrofilms. Adv. Mater. 2009, 21, 4793–4797. [Google Scholar] [CrossRef] [PubMed]

- Feng, C.; Jiang, L. Micromechanics modeling of the electrical conductivity of carbon nanotube (CNT)–polymer nanocomposites. Compos. Part A 2013, 47, 143–149. [Google Scholar] [CrossRef]

- Alamusi; Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.L.; Li, J.H. Piezoresistive Strain Sensors Made from Carbon Nanotubes Based Polymer Nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar] [CrossRef] [PubMed]

- Lanticse, L.J.; Tanabe, Y.; Matsui, K.; Kaburagi, Y.; Suda, K.; Hoteida, M.; Endo, M.; Yasuda, E. Shear-induced preferential alignment of carbon nanotubes resulted in anisotropic electrical conductivity of polymer composites. Carbon 2006, 44, 3078–3086. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, X.; Han, N.M.; Liu, X.; Wu, Y.; Ye, W.; Kim, J.-K. Ultralow Electrical Percolation in Graphene Aerogel/Epoxy Composites. Chem. Mater. 2016, 28, 6731–6741. [Google Scholar] [CrossRef]

- Bao, W.S.; Meguid, S.A.; Zhu, Z.H.; Meguid, M.J. Modeling electrical conductivities of nanocomposites with aligned carbon nanotubes. Nanotechnology 2011, 22, 485704. [Google Scholar] [CrossRef] [PubMed]

- Fangjun, L.; Weijie, S.; Zhendong, S.; Yeow, J.T.W. Effect of CNTs alignment on electrical conductivity of PDMS/MWCNTs composites. In Proceedings of the 14th IEEE International Conference on Nanotechnology, Toronto, ON, Canada, 18–21 August 2014; pp. 711–714. [Google Scholar]

- Xiaodong, X.; Jia, H.; Yang, W.; Zheng, Z.; George, J.W. Theory of electrical conductivity and dielectric permittivity of highly aligned graphene-based nanocomposites. J. Phys. Cond. Matter 2017, 29, 205702. [Google Scholar]

- Song, S.H.; Park, K.H.; Kim, B.H.; Choi, Y.W.; Jun, G.H.; Lee, D.J.; Kong, B.-S.; Paik, K.-W.; Jeon, S. Enhanced Thermal Conductivity of Epoxy–Graphene Composites by Using Non-Oxidized Graphene Flakes with Non-Covalent Functionalization. Adv. Mater. 2013, 25, 732–737. [Google Scholar] [CrossRef] [PubMed]

- Teng, C.C.; Ma, C.C.M.; Lu, C.H.; Yang, S.Y.; Lee, S.H.; Hsiao, M.C.; Yen, M.Y.; Chiou, K.C.; Lee, T.M. Thermal conductivity and structure of non-covalent functionalized graphene/epoxy composites. Carbon 2011, 49, 5107–5116. [Google Scholar] [CrossRef]

- Marconnet, A.M.; Yamamoto, N.; Panzer, M.A.; Wardle, B.L.; Goodson, K.E. Thermal Conduction in Aligned Carbon Nanotube–Polymer Nanocomposites with High Packing Density. ACS Nano 2011, 5, 4818–4825. [Google Scholar] [CrossRef] [PubMed]

- Du, C.; Li, M.; Cao, M.; Feng, S.; Guo, H.; Li, B. Enhanced thermal and mechanical properties of polyvinlydene fluoride composites with magnetic oriented carbon nanotube. Carbon 2018, 126, 197–207. [Google Scholar] [CrossRef]

- Gaska, K.; Kádár, R.; Rybak, A.; Siwek, A.; Gubanski, S. Gas Barrier, Thermal, mechanical and rheological properties of highly aligned graphene-LDPE nanocomposites. Polymers 2017, 9, 294. [Google Scholar] [CrossRef]

- Shi, D.; He, P.; Lian, J.; Chaud, X.; Bud’ko, S.L.; Beaugnon, E.; Wang, L.M.; Ewing, R.C.; Tournier, R. Magnetic alignment of carbon nanofibers in polymer composites and anisotropy of mechanical properties. J. Appl. Phys. 2005, 97, 064312. [Google Scholar] [CrossRef]

- Khan, S.U.; Pothnis, J.R.; Kim, J.-K. Effects of carbon nanotube alignment on electrical and mechanical properties of epoxy nanocomposites. Compos. Part A 2013, 49, 26–34. [Google Scholar] [CrossRef]

- Cai, Z.; Meng, X.; Ye, H.; Cong, C.; Wang, Y.; Cui, L.; Zhou, Q. Reinforcing polyamide 1212 nanocomposites with aligned carbon nanofibers. Mater. Des. 2014, 63, 691–698. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Shen, X.; Garakani, M.A.; Lin, X.Y.; Wu, Y.; Liu, X.; Sun, X.Y.; Kim, J.K. Graphene Aerogel/Epoxy Composites with Exceptional Anisotropic Structure and Properties. ACS Appl. Mater. Interfaces 2015, 7, 5538–5549. [Google Scholar] [CrossRef] [PubMed]

- Thostenson, E.T.; Chou, T.-W. Aligned multi-walled carbon nanotube-reinforced composites: Processing and mechanical characterization. J. Phys. D Appl. Phys. 2002, 35, L77. [Google Scholar] [CrossRef]

- Erik, T.T.; Tsu-Wei, C. On the elastic properties of carbon nanotube-based composites: Modelling and characterization. J. Phys. D Appl. Phys. 2003, 36, 573. [Google Scholar]

- Hoyer, H.; Knaapila, M.; Kjelstrup-Hansen, J.; Liu, X.; Helgesen, G. A strain sensor based on an aligned carbon particle string in a UV-cured polymer matrix. Appl. Phys. Lett. 2011, 99, 3. [Google Scholar] [CrossRef]

- Oliva-Avilés, A.I.; Avilés, F.; Sosa, V. Electrical and piezoresistive properties of multi-walled carbon nanotube/polymer composite films aligned by an electric field. Carbon 2011, 49, 2989–2997. [Google Scholar] [CrossRef]

- Engin, C.S.; Gary, D.S.; Robert, J.B. Anisotropic piezoresistivity characteristics of aligned carbon nanotube-polymer nanocomposites. Smart Mater. Struct. 2017, 26, 095027. [Google Scholar]

- Miao, Y.; Yang, Q.Q.; Sammynaiken, R.; Zhang, W.J.; Maley, J.; Schatte, G. Influence of aligned carbon nanotube networks on piezoresistive response in carbon nanotube films under in-plane straining. Appl. Phys. Lett. 2013, 102, 233106. [Google Scholar] [CrossRef]

- Rubaiya, R.; Peyman, S. Effects of inter-tube distance and alignment on tunnelling resistance and strain sensitivity of nanotube/polymer composite films. Nanotechnology 2012, 23, 055703. [Google Scholar]

- Theodosiou, T.C.; Saravanos, D.A. Numerical investigation of mechanisms affecting the piezoresistive properties of CNT-doped polymers using multi-scale models. Compos. Sci. Technol. 2010, 70, 1312–1320. [Google Scholar] [CrossRef]

- Sebastian, J.; Schehl, N.; Bouchard, M.; Boehle, M.; Li, L.; Lagounov, A.; Lafdi, K. Health monitoring of structural composites with embedded carbon nanotube coated glass fiber sensors. Carbon 2014, 66, 191–200. [Google Scholar] [CrossRef]

- Akira, T.; Masahito, U. Low-cost delamination monitoring of CFRP beams using electrical resistance changes with neural networks. Smart Mater. Struct. 2006, 15, N75. [Google Scholar]

- Thostenson, E.T.; Chou, T.W. Carbon Nanotube Networks: Sensing of Distributed Strain and Damage for Life Prediction and Self Healing. Adv. Mater. 2006, 18, 2837–2841. [Google Scholar] [CrossRef]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T.-W. Sensing of Damage Mechanisms in Fiber-Reinforced Composites under Cyclic Loading using Carbon Nanotubes. Adv. Funct. Mater. 2009, 19, 123–130. [Google Scholar] [CrossRef]

- Yousefi, N.; Sun, X.; Lin, X.; Shen, X.; Jia, J.; Zhang, B.; Tang, B.; Chan, M.; Kim, J.-K. Highly aligned graphene/polymer nanocomposites with excellent dielectric properties for high-performance electromagnetic interference shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef] [PubMed]

- Dhakate, S.R.; Subhedar, K.M.; Singh, B.P. Polymer nanocomposite foam filled with carbon nanomaterials as an efficient electromagnetic interference shielding material. RSC Adv. 2015, 5, 43036–43057. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, A.; Cho, K.Y.; Das, T.K.; Sudarsan, V. An asymmetric electrically conducting self-aligned graphene/polymer composite thin film for efficient electromagnetic interference shielding. AIP Adv. 2017, 7, 015103. [Google Scholar] [CrossRef]

- Wicks, S.S.; Wang, W.N.; Williams, M.R.; Wardle, B.L. Multi-scale interlaminar fracture mechanisms in woven composite laminates reinforced with aligned carbon nanotubes. Compos. Sci. Technol. 2014, 100, 128–135. [Google Scholar] [CrossRef]

- Gungor, S.; Bakis, C.E. Anisotropic networking of carbon black in glass/epoxy composites using electric field. J. Compos. Mater. 2014, 49, 535–544. [Google Scholar] [CrossRef]

- Arguin, M.; Sirois, F.; Therriault, D. Electric field induced alignment of multiwalled carbon nanotubes in polymers and multiscale composites. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 16–25. [Google Scholar] [CrossRef]

- Domingues, D.; Logakis, E.; Skordos, A.A. The use of an electric field in the preparation of glass fibre/epoxy composites containing carbon nanotubes. Carbon 2012, 50, 2493–2503. [Google Scholar] [CrossRef]

- Sun, W.; Tomita, H.; Hasegawa, S.; Kitamura, Y.; Nakano, M.; Suehiro, J. An array of interdigitated parallel wire electrodes for preparing a large-scale nanocomposite film with aligned carbon nanotubes. J. Phys. D Appl. Phys. 2011, 44, 445303. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Peng, S.; Wang, C.H. Multifunctional Polymer Nanocomposites Reinforced by Aligned Carbon Nanomaterials. Polymers 2018, 10, 542. https://doi.org/10.3390/polym10050542

Wu S, Peng S, Wang CH. Multifunctional Polymer Nanocomposites Reinforced by Aligned Carbon Nanomaterials. Polymers. 2018; 10(5):542. https://doi.org/10.3390/polym10050542

Chicago/Turabian StyleWu, Shuying, Shuhua Peng, and Chun H. Wang. 2018. "Multifunctional Polymer Nanocomposites Reinforced by Aligned Carbon Nanomaterials" Polymers 10, no. 5: 542. https://doi.org/10.3390/polym10050542

APA StyleWu, S., Peng, S., & Wang, C. H. (2018). Multifunctional Polymer Nanocomposites Reinforced by Aligned Carbon Nanomaterials. Polymers, 10(5), 542. https://doi.org/10.3390/polym10050542