Recent Progress of Imprinted Polymer Photonic Waveguide Devices and Applications

Abstract

:1. Introduction

2. Imprinting Techniques

3. Passive Photonic Integrated Waveguide Devices

3.1. Microring Resonators

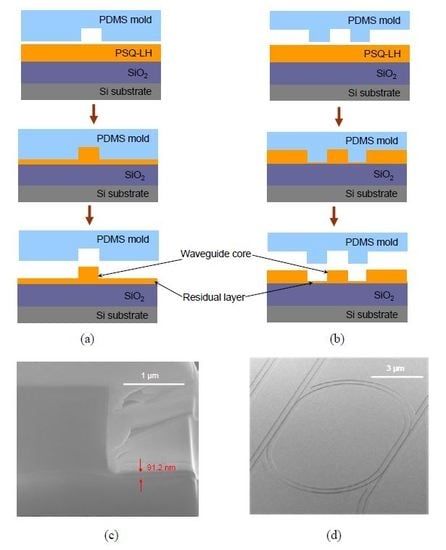

3.1.1. Microring Resonators with Inverted Ridge Waveguide

3.1.2. Microring Resonators with Ridge Waveguide

3.2. Optical Waveguide Splitters

3.3. Arrayed Waveguide Gratings

3.4. Long-Period Waveguide Gratings

3.5. Microlenses

4. Active Photonic Integrated Waveguide Devices

4.1. Tunable Microring Resonator Filters

4.2. Tunable Waveguide Bragg Grating Filters

4.3. Optical Switches

4.4. Variable Optical Attenuators

5. Electro-Optic Modulators

6. Photonic Biosensors

6.1. Microring Based Biosensors

6.2. Young’s Interferometer Based Biosensors

7. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Chiang, K.S. Development of optical polymer waveguide devices. Proc. SPIE 2010, 7605. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Mettbach, N.; Zawadzki, C.; Wang, J.; Schmidt, D.; Brinker, W.; Grote, N.; Schell, M.; Keil, N. Polymer-based photonic toolbox: Passive components, hybrid integration and polarization control. IET Optoelectron. 2011, 5, 226–232. [Google Scholar] [CrossRef]

- Lu, X.J.; Chen, R.T. Polymeric optical code-division multiple-access (CDMA) encoder and decoder modules. Polymers 2011, 3, 1554–1564. [Google Scholar] [CrossRef]

- Chen, C.M.; Niu, X.Y.; Han, C.; Shi, Z.S.; Wang, X.B.; Sun, X.Q.; Wang, F.; Cui, Z.C.; Zhang, D.M. Reconfigurable optical interleaver modules with tunable wavelength transfer matrix function using polymer photonics lightwave circuits. Opt. Express 2014, 22, 19895–19911. [Google Scholar] [CrossRef] [PubMed]

- Oh, M.-C.; Kim, K.-J.; Chu, W.-S.; Kim, J.-W.; Seo, J.-K.; Noh, Y.-O.; Lee, H.-J. Integrated photonic devices incorporating low-loss fluorinated polymer materials. Polymers 2011, 3, 975–997. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, C.; Zhang, H.; Bechtel, J.H.; Dalton, L.R.; Robinson, B.H.; Steier, W.H. Low (sub-1 volt) halfwave voltage electrooptic polymer modulators achieved by controlling chromophore shape. Science 2000, 288, 119–122. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.; Katz, H.E.; Erben, C.; Gill, D.M.; Gopalan, P.; Heber, J.D.; McGee, D.J. Broadband modulation of light by using an electro-optic polymer. Science 2002, 298, 1401–1403. [Google Scholar] [CrossRef] [PubMed]

- Nuccio, S.R.; Dinu, R.; Shamee, B.; Parekh, D.; Chang, H.C.; Willner, A.E. Modulation and chirp characterization of a 100-GHz EO polymer Mach-Zehnder modulator. In Proceedings of the National Fiber Optic Engineers Conference on Optical Fiber Communication Conference and Exposition (OFC/NFOEC), Los Angeles, CA, USA, 6–10 March 2011. [Google Scholar]

- Ren, J.; Wang, L.H.; Han, X.Y.; Cheng, J.F.; Lv, H.L.; Wang, J.Y.; Jian, X.G.; Zhao, M.S.; Jia, L.Y. Organic silicone sol-gel polymer as non-covalent carrier of receptor proteins for label-free optical biosensor application. ACS Appl. Mater. Interfaces 2013, 5, 386–394. [Google Scholar] [CrossRef] [PubMed]

- Hoff, J.D.; Cheng, L.-J.; Meyhöfer, E.; Guo, L.J.; Hun, A.J. Nanoscale protein patterning by imprint lithography. Nano Lett. 2004, 5, 853–857. [Google Scholar] [CrossRef]

- Kim, J.-W.; Kim, K.-J.; Yi, J.-A.; Oh, M.-C. Polymer waveguide label-free biosensors with enhanced sensitivity by incorporating low-refractive-index polymers. IEEE J. Sel. Top. Quantum Electron. 2010, 16, 973–980. [Google Scholar]

- Bañuls, M.J.; Puchades, R.; Maquieira, Á. Chemical surface modifications for the development of silicon-based label-free integrated optical (IO) biosensors: A review. Anal. Chim. Acta 2013, 777, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Y.; Hosseini, A.; Lin, X.H.; Subbaraman, H.; Chen, R.T. Polymer-based hybrid-integrated photonic devices for silicon on-chip modulation and board-level optical interconnects. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 196–210. [Google Scholar] [CrossRef]

- Bettotti, P. Hybrid materials for integrated photonics. Adv. Opt. 2014. [Google Scholar] [CrossRef]

- Kleinert, M.; Felipe, D.; Zawadzki, C.; Brinker, W.; Choi, J.H.; Reinke, P.; Happach, M.; Nellen, S.; Möhrle, M.; Bach, H.-G.; et al. Photonic integrated devices and functions on hybrid polymer platform. Proc. SPIE 2017. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint lithography with 25-nanometer resolution. Science 1996, 272, 85–87. [Google Scholar] [CrossRef]

- Susumu, F. Fine pattern fabrication by the molded mask method (nanoimprint lithography) in the 1970s. Jpn. J. Appl. Phys. 2009, 48. [Google Scholar] [CrossRef]

- Wulff, G. Fourty years of molecular imprinting in synthetic polymers: Origin, features and perspectives. Microchim. Acta 2013, 180, 1359–1370. [Google Scholar] [CrossRef]

- Mosbach, K. Molecular Imprinting. Trends Biochem. Sci. 1994, 19, 9–14. [Google Scholar] [CrossRef]

- Resnick, D.J.; Dauksher, W.J.; Mancini, D.; Nordquist, K.J.; Bailey, T.C.; Johnson, S.; Stacey, N.; Ekerdt, J.G.; Willson, C.G.; Sreenivasan, S.V.; et al. Imprint lithography for integrated circuit fabrication. J. Vac. Sci. Technol. B 2003, 21. [Google Scholar] [CrossRef]

- Sreenivasan, S.V. Nanoimprint lithography steppers for volume fabrication of leading-edge semiconductor integrated circuits. Microsyst. Nanoeng. 2017, 3. [Google Scholar] [CrossRef]

- Guo, L.J. Recent progress in nanoimprint technology and its applications. J. Phys. D 2004, 37, R123–R141. [Google Scholar] [CrossRef]

- Scheer, H.-C. Nanoimprint lithography techniques—An introduction. Proc. SPIE 2006, 6281. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Schift, H. Nanoimprint lithography: 2D or not 2D? A review. Appl. Phys. A 2015, 121, 415–435. [Google Scholar] [CrossRef]

- Zhang, C.; Subbaraman, H.; Li, Q.C.; Pan, Z.Y.; Ok, J.G.; Ling, T.; Chung, C.-J.; Zhang, X.Y.; Lin, X.H.; Chen, R.T.; et al. Printed photonic elements: Nanoimprinting and beyond. J. Mater. Chem. C 2016, 4, 5133–5153. [Google Scholar] [CrossRef]

- Chen, L.X.; Wang, X.Y.; Lu, W.H.; Wu, X.Q.; Li, J.H. Molecular imprinting: Perspectives and applications. Chem. Soc. Rev. 2016, 45, 2137–2211. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Meng, Z.H.; Xue, M.; Shea, K.J. Molecular imprinted photonic crystal for sensing of biomolecules. Mol. Impr. 2016, 4, 1–12. [Google Scholar] [CrossRef]

- Uzun, L.; Turner, A.P.F. Molecularly-imprinted polymer sensors: Realising their potential. Biosens. Bioelectron. 2016, 76, 131–144. [Google Scholar] [CrossRef] [PubMed]

- Schirhagl, R. Bioapplications for molecularly imprinted polymers. Anal. Chem. 2013, 86, 250–261. [Google Scholar] [CrossRef] [PubMed]

- Ye, L. Molecularly imprinted polymers with multi-functionality. Anal. Bioanal. Chem. 2016, 408, 1727–1733. [Google Scholar] [CrossRef] [PubMed]

- Zahedi, P.; Ziaee, M.; Abdouss, M.; Farazin, A.; Mizaikoff, B. Biomacromolecule template-based molecularly imprinted polymers with an emphasis on their synthesis strategies: A review. Polym. Adv. Technol. 2016, 27, 1124–1142. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, W.; Li, M.; Xia, Q.; Wu, W.; Ge, H.; Huang, X.; Chou, S.Y. Electrostatic force-assisted nanoimprint lithography (EFAN). Nano Lett. 2005, 5, 527–530. [Google Scholar] [CrossRef] [PubMed]

- Teng, J.; Scheerlinck, S.; Zhang, H.B.; Jian, X.G.; Morthier, G.; Beats, R.; Han, X.Y.; Zhao, M.S. A PSQ-L polymer microring resonator fabricated by a simple UV-based soft-lithography process. IEEE Photonics Technol. Lett. 2009, 21, 1323–1325. [Google Scholar] [CrossRef]

- Wang, L.H.; Ren, J.; Han, X.Y.; Claes, T.; Jian, X.G.; Bienstman, P.; Baets, R.; Zhao, M.S.; Morthier, G. A label-free optical biosensor built on a low cost polymer platform. IEEE Photonics J. 2012, 4, 920–930. [Google Scholar] [CrossRef] [Green Version]

- Bar-On, O.; Brenner, P.; Gvishi, R.; Siegle, T.; Kalt, H.; Lemmer, U.; Scheuer, J. 3D Integrated Photonics Based on Fast Sol-Gel Technology and Soft Nano Imprint Lithography; Optical Society of America: New Orleans, LA, USA, 2017; p. NoTh1C.5. [Google Scholar]

- Morarescu, R.; Pal, P.K.; Beneitez, N.T.; Missinne, J.; Steenberge, G.V.; Bienstman, P.; Morthier, G. Fabrication and characterization of high-optical-quality-factor hybrid polymer microring resonators operating at very near infrared wavelengths. IEEE Photonics J. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Zhu, Z.D.; Li, Q.Q.; Zhan, L.H.; Chen, M.; Fan, S.S. UV-based nanoimprinting lithography with a fluorinated flexible stamp. J. Vac. Sci. Technol. B 2011, 29. [Google Scholar] [CrossRef]

- Matsukawa, D.; Wakayama, H.; Mitsukura, K.; Okamura, H.; Hirai, Y.; Shirai, M. A UV curable resin with reworkable properties: Application to imprint lithography. J. Mater. Chem. 2009, 19, 4085–4087. [Google Scholar] [CrossRef]

- Pan, Z.Y.; Subbaraman, H.; Zhang, C.; Panday, A.; Li, Q.C.; Zhang, X.Y.; Zou, Y.; Xu, X.C.; Guo, L.J.; Chen, R.T. Reconfigurable thermo-optic polymer switch based true-time-delay network utilizing imprinting and inkjet printing. In Proceedings of the Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 8–13 June 2014. [Google Scholar]

- Schmitt, H.; Rommel, M.; Bauer, A.J.; Frey, L.; Bich, A.; Eisner, M. Full wafer microlens replication by UV imprint lithography. Microelectron. Eng. 2010, 87, 1074–1076. [Google Scholar] [CrossRef]

- Bogaerts, W.; Heyn, P.D.; Van Vaerenbergh, T.; Vos, K.D.; Selvaraja, S.K.; Claes, T.; Dumon, P.; Bienstman, P.; Van Thourhout, D.; Baets, R. Silicon microring resonators. Laser Photonics Rev. 2012, 6, 47–73. [Google Scholar] [CrossRef]

- Chao, C.Y.; Guo, L.J. Polymer microring resonators fabricated by nanoimprint technique. J. Vac. Sci. Technol. B 2002, 20, 2862–2866. [Google Scholar] [CrossRef]

- Zhang, H.B.; Wang, J.Y.; Li, L.K.; Song, Y.; Zhao, M.S.; Jian, X.G. A study on liquid hybrid material for waveguides–Synthesis and property of PSQ-Ls for waveguides. J. Macromol. Sci. Part A 2008, 45, 232–237. [Google Scholar] [CrossRef]

- Lin, X.H.; Ling, T.; Subbaraman, H.; Guo, L.J.; Chen, R.T. Printable thermo-optic polymer switches utilizing imprinting and ink-jet printing. Opt. Express 2013, 21, 2110–2117. [Google Scholar] [CrossRef] [PubMed]

- Flores, A.; Song, S.; Baig, S.; Wang, M.R. Vacuum-assisted microfluidic technique for fabrication of guided wave devices. IEEE Photonics Technol. Lett. 2008, 20, 1246–1248. [Google Scholar] [CrossRef]

- Wang, L.L.; An, J.M.; Wu, Y.D.; Zhang, J.S.; Wang, Y.; Li, J.G.; Wang, H.J.; Zhang, X.G.; Pan, P.; Zhong, F.; et al. Design and fabrication of novel symmetric low-loss 1 × 24 optical power splitter. J. Lightwave Technol. 2014, 32, 3112–3118. [Google Scholar] [CrossRef]

- Fan, G.F.; Li, Y.; Han, B. A wide wavelength range of 1 × 8 optical power splitter with an imbalance of less than ±1.0 dB on silicon-on-insulator technology. IEEE Photonics J. 2017, 9. [Google Scholar] [CrossRef]

- Wu, Z.L.; Liang, Y.X.; Li, C.K.; Han, X.Y.; Gu, Y.Y.; Hu, J.J.; Zhao, M.S. Design and fabrication of polymer-based 1 × 4 Y-branch splitters. Optik 2016, 127, 11427–11432. [Google Scholar] [CrossRef]

- Gilles, S.; Diez, M.; Offenhäusser, A.; Lensen, M.C.; Mayer, D. Deformation of nanostructures on polymer molds during soft UV nanoimprint lithography. Nanotechnology 2010, 21. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.X.; Zhao, M.S.; Luo, Y.Q.; Gu, Y.Y.; Zhang, Y.; Wang, L.H.; Han, X.Y.; Wu, Z.L. Design and fabrication of polymer-based multimode interference optical splitters. Opt. Eng. 2016, 55. [Google Scholar] [CrossRef]

- Lim, J.G.; Lee, S.S.; Lee, K.D. Polymeric arrayed waveguide grating using imprint method incorporating a flexible PDMS stamp. Opt. Commun. 2007, 272, 97–101. [Google Scholar] [CrossRef]

- Kim, W.S.; Lee, J.H.; Shin, S.Y.; Bae, B.S.; Kim, Y.C. Fabrication of ridge waveguides by UV embossing and stamping of sol-gel hybrid materials. IEEE Photonics Technol. Lett. 2004, 16, 1888–1890. [Google Scholar] [CrossRef]

- Rastogi, V.; Chiang, K.S. Long-period gratings in planar optical waveguides. Appl. Opt. 2002, 41, 6351–6355. [Google Scholar] [CrossRef] [PubMed]

- Perentos, A.; Kostovski, G.; Mitchell, A. Polymer long-period raised rib waveguide gratings using nano-imprint lithography. IEEE Photonics Technol. Lett. 2005, 17, 2595–2597. [Google Scholar] [CrossRef]

- Ottevaere, H.; Cox, R.; Herzig, H.P.; Miyashita, T.; Naessens, K.; Taghizadeh, M.; Völkel, R.; Woo, H.J.; Thienpont, H. Comparing glass and plastic refractive microlenses fabricated with different technologies. J. Opt. A 2006, 8, 407–429. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Zhao, P.; Lin, P.; Sun, F.G. Thermo-optic coefficients of polymers for optical waveguide applications. Polymer 2006, 47, 4893–4896. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Keil, N. Thermo-optic devices on polymer platform. Opt. Commun. 2016, 362, 101–114. [Google Scholar] [CrossRef]

- Yariv, A. Universal relations for coupling of optical power between microresonators and dielectric waveguides. Electron. Lett. 2000, 36, 321–322. [Google Scholar] [CrossRef]

- Zhuang, L.M.; Roeloffzen, C.G.H.; Hoekman, M.; Boller, K.-J.; Lowery, A.J. Programmable photonic signal processor chip for radiofrequency applications. Optica 2015, 2, 854–859. [Google Scholar] [CrossRef]

- Han, X.Y.; Wang, L.H.; Wang, Y.; Zou, P.; Teng, J.; Gu, Y.Y.; Wang, J.Y.; Jian, X.G.; Morthier, G.; Zhao, M.S. UV-soft imprinted tunable polymer waveguide ring resonator for microwave photonic filtering. J. Lightwave Technol. 2014, 32, 3924–3932. [Google Scholar] [CrossRef]

- Burla, M.; Marpaung, D.; Zhuang, L.M.; Khan, M.R.; Leinse, A.; Beeker, W.; Hoekman, M.; Heideman, R.G.; Roeloffzen, C. Multiwavelength-integrated optical beamformer based on wavelength division multiplexing for 2-D phased array antennas. J. Lightwave Technol. 2014, 32, 3509–3520. [Google Scholar] [CrossRef]

- Hraimel, B.; Zhang, X.P.; Pei, Q.Q.; Wu, K.; Liu, T.J.; Xu, T.F.; Nie, Q.H. Optical single-sideband modulation with tunable optical carrier to sideband ratio in radio over fiber systems. J. Lightwave Technol. 2011, 29, 775–781. [Google Scholar] [CrossRef]

- Kim, K.-J.; Oh, M.-C.; Moon, S.-R.; Lee, C.-H. Flexible polymeric tunable lasers for WDM passive optical networks. J. Lightwave Technol. 2013, 31, 982–987. [Google Scholar] [CrossRef]

- Wu, X.P.; Park, T.-H.; Park, S.-H.; Seo, J.-K.; Oh, M.-C. Polarization independent polymer waveguide tunable receivers incorporating a micro-optic circulator. Opt. Commun. 2018, 416, 185–189. [Google Scholar]

- Yun, B.F.; Hu, G.H.; Zhang, R.H.; Cui, Y.P. Tunable erbium-doped fiber ring laser based on thermo-optic polymer waveguide Bragg grating. Opt. Commun. 2015, 336, 30–33. [Google Scholar] [CrossRef]

- Han, Y.-T.; Shin, J.-U.; Park, S.-H.; Lee, H.-J.; Hwang, W.-Y.; Park, H.-H.; Baek, Y. N × N polymer matrix switches using thermo-optic total-internal-reflection switch. Opt. Express 2012, 20, 13284–13295. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.M.; Niu, X.Y.; Han, C.; Shi, Z.S.; Wang, X.B.; Sun, X.Q.; Wang, F.; Cui, Z.C.; Zhang, D.M. Monolithic multi-functional integration of ROADM modules based on polymer photonic lightwave circuit. Opt. Express 2014, 22, 10716–10727. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Zhou, L.J.; Li, Z.; Wang, J.; Chen, J.P. Seven-bit reconfigurable optical true time delay line based on silicon integration. Opt. Express 2014, 22, 22707–22715. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.L.; Howley, B.; Chen, M.Y.; Zhou, Q.J.; Chen, R.T.; Basile, P. Polymer based thermo-optic switch for optical true time delay. Proc. SPIE 2005, 5728, 60–67. [Google Scholar]

- Duduś, A.; Blue, R.; Zagnoni, M.; Stewart, G.; Uttamchandani, D. Modeling and characterization of an electro wetting-based single-mode fiber variable optical attenuator. IEEE J. Sel. Top. Quantum Electron. 2015, 21. [Google Scholar] [CrossRef]

- Wang, L.F.; Song, Q.Q.; Wu, J.Y.; Chen, K.X. Low-power variable optical attenuator based on a hybrid SiON–polymer S-bend waveguide. Appl. Opt. 2016, 55, 969–973. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.T.; Choi, C.-G. Polymeric PLC-type thermo-optic optical attenuator fabricated by UV imprint technique. Opt. Commun. 2006, 257, 72–75. [Google Scholar] [CrossRef]

- Enami, Y.; Derose, C.T.; Mathine, D.; Loychik, C.; Greenlee, C.; Norwood, R.A.; Kim, T.D.; Luo, J.; Tian, Y.; Jen, A.K.-Y.; et al. Hybrid polymer sol–gel waveguide modulators with exceptionally large electro–optic coefficients. Nat. Photonics 2007, 1, 180–185. [Google Scholar] [CrossRef]

- Alloatti, L.; Palmer, R.; Diebold, S.; Pahl, K.P.; Chen, B.Q.; Dinu, R.; Fournier, M.; Fedeli, J.-M.; Zwick, T.; Freude, W.; et al. 100 GHz silicon–organic hybrid modulator. Light Sci. Appl. 2014, 3. [Google Scholar] [CrossRef]

- Wu, J.Y.; Peng, C.C.; Xiao, H.Y.; Bo, S.H.; Qiu, L.; Zhen, Z.; Liu, X.H. Donor modification of nonlinear optical chromophores: Synthesis, characterization, and fine-tuning of chromophores’ mobility and steric hindrance to achieve ultra large electro-optic coefficients in guest–host electro-optic materials. Dyes Pigment. 2014, 104, 15–23. [Google Scholar] [CrossRef]

- Wu, J.Y.; Bo, S.H.; Liu, J.L.; Zhou, T.T.; Xiao, H.Y.; Qiu, L.; Zhen, Z.; Liu, X.H. Synthesis of novel nonlinear optical chromophore to achieve ultrahigh electro-optic activity. Chem. Commun. 2012, 48, 9637–9639. [Google Scholar] [CrossRef] [PubMed]

- Paloczi, G.T.; Huang, Y.; Yariv, A.; Luo, J.; Jen, A.K.-Y. Replica-molded electro-optic polymer Mach–Zehnder modulator. Appl. Phys. Lett. 2004, 85, 1662–1664. [Google Scholar] [CrossRef]

- Lin, X.; Ling, T.; Subbaraman, H.; Zhang, X.; Byun, K.; Guo, L.J.; Chen, R.T. Ultraviolet imprinting and aligned ink-jet printing for multilayer patterning of electro-optic polymer modulators. Opt. Lett. 2013, 38, 1597–1599. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; White, I.M.; Shopoua, S.I.; Zhu, H.; Suter, J.D.; Sun, Y. Sensitive optical biosensors for unlabeled targets: A review. Anal. Chim. Acta 2008, 620, 8–26. [Google Scholar] [CrossRef] [PubMed]

- Ciminellin, C.; Campanella, C.M.; Dell’Olio, F.; Campanella, C.E.; Armenise, M.N. Label-free optical resonant sensors for biochemical applications. Prog. Quantum Electron. 2013, 37, 51–107. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Yu, F.; Yang, C.; Song, J.Y.; Tang, L.H.; Li, M.Y.; He, J.J. Label-free biosensing using cascaded double-microring resonators integrated with microfluidic channels. Opt. Commun. 2015, 344, 129–133. [Google Scholar] [CrossRef]

- Iqbal, M.; Gleeson, M.A.; Spaugh, B.; Tybor, F.; Gunn, W.G.; Hochberg, M.; Jones, T.B.; Bailey, R.C.; Gunn, L.C. Label-free biosensor arrays based on silicon ring resonators and high speed optical scanning instrumentation. IEEE J. Sel. Top. Quantum Electron. 2010, 16, 654–661. [Google Scholar] [CrossRef]

- Bastos, A.R.; Vicente, C.M.S.; Silva, R.O.; Silva, N.J.O.; Tacão, M.; Costa, J.P.; Lima, M.; André, P.S.; Ferreira, R.A.S. Integrated optical Mach-Zehnder interferometer based on organic-inorganic hybrids for photonics-on-a-chip biosensing applications. Sensors 2018, 18, 840. [Google Scholar] [CrossRef] [PubMed]

- Satyanarayana, S.; Karnik, R.N.; Majumdar, A. Stamp-and-stick room-temperature bonding technique for microdevices. IEEE J. Microelectromech. Syst. 2005, 14, 392–399. [Google Scholar] [CrossRef]

- Kozma, P.; Kehl, F.; Ehrentreich-Förster, E.; Stamm, C.; Bier, F.F. Integrated planar optical waveguide interferometer biosensors: A comparative review. Biosens. Bioelectron. 2014, 58, 87–307. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Hiltunen, J.; Liedert, C.; Pearce, S.; Charlton, M.; Hakalahti, L.; Karioja, P.; Myllylä, R. Highly sensitive biosensor based on UV-imprinted layered polymeric–inorganic composite waveguides. Opt. Express 2012, 20, 20309–20317. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Hiltunen, J.; Uusitalo, S.; Puustinen, J.; Lappalainen, J.; Karioja, P.; Myllylä, R. Fabrication of optical inverted-rib waveguides using UV-imprinting. Microelectron. Eng. 2011, 88, 175–178. [Google Scholar] [CrossRef]

- Hiltunen, J.; Uusitalo, S.; Karioja, P.; Pearce, S.; Charlton, M.; Wang, M.; Puustinen, J.; Lappalainen, J. Manipulation of optical field distribution in layered composite polymeric-inorganic waveguides. Appl. Phys. Lett. 2011, 98. [Google Scholar] [CrossRef]

- Hiltunen, M.; Hiltunen, J.; Stenberg, P.; Aikio, S.; Kurki, L.; Vahimaa, P.; Karioja, P. Polymeric slot waveguide interferometer for sensor applications. Opt. Express 2014, 22, 7229–7237. [Google Scholar] [CrossRef] [PubMed]

- Aikio, S.; Hiltunen, J.; Hiitola-Keinänen, J.; Hiltunen, M.; Kontturi, V.; Siitonen, S.; Puustinen, J.; Karioja, P. Disposable photonic integrated circuits for evanescent wave sensors by ultra-high volume roll-to-roll method. Opt. Express 2016, 24, 2527–2541. [Google Scholar] [CrossRef] [PubMed]

- Ryu, J.H.; Lee, T.H.; Cho, I.K.; Kim, C.-S.; Jeong, M.Y. Simple fabrication of a double-layer multi-channel optical waveguide using passive alignment. Opt. Express 2011, 19, 1183–1190. [Google Scholar] [CrossRef] [PubMed]

- Wan, L.; Zhu, N.; Zhang, R.Y.; Mei, T. All-polymeric planar waveguide devices based on a gas-assisted thermal imprinting technique. Microsyst. Technol. 2017, 23, 5271–5279. [Google Scholar] [CrossRef]

- Qin, S.J.; Shang, J.T.; Ma, M.Y.; Zhang, L.; Lai, C.M.; Huang, Q.-A.; Wong, C.-P. Fabrication of micro-polymer lenses with spacers using low-cost wafer-level glass-silicon molds. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 2006–2013. [Google Scholar] [CrossRef]

- Bruck, R.; Hainberger, R.; Heer, R.; Kataeva, N.; Köck, A.; Krapf-Günther, M.; Kaiblinger, K.; Pipelka, F. Direct replication of nanostructures from silicon wafers in polymethylpentene by injection molding. Proc. SPIE 2010. [Google Scholar] [CrossRef]

- Lee, W.H.; Park, Y.D. Inkjet etching of polymers and its applications in organic electronic devices. Polymers 2017, 9, 441. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, C.L.; Zhao, Y.; Dong, C.H.; Wei, C.; Wang, H.; Liu, Y.; Guo, G.C.; Yao, J.; Zhao, Y.S. Organic printed photonics: From microring lasers to integrated circuits. Sci. Adv. 2015, 1. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.Y.; Felipe, D.; Katopodis, V.; Groumas, P.; Kouloumentas, C.; Avramopoulos, H.; Dupuy, J.-Y.; Konczykowska, A.; Dede, A.; Beretta, A.; et al. Hybrid photonic integration on a polymer platform. Photonics 2015, 2, 1005–1026. [Google Scholar] [CrossRef]

- Estevez, M.C.; Alvarez, M.; Lechuga, L.M. Integrated optical devices for lab-on-a-chip biosensing applications. Laser Photonics Rev. 2012, 6, 463–487. [Google Scholar] [CrossRef] [Green Version]

- Song, F.C.; Xiao, J.; Seo, S.-W. Heterogeneously integrated optical system for lab-on-a-chip applications. Sens. Actuators A 2013, 195, 148–153. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.-Y.; Wu, Z.-L.; Yang, S.-C.; Shen, F.-F.; Liang, Y.-X.; Wang, L.-H.; Wang, J.-Y.; Ren, J.; Jia, L.-Y.; Zhang, H.; et al. Recent Progress of Imprinted Polymer Photonic Waveguide Devices and Applications. Polymers 2018, 10, 603. https://doi.org/10.3390/polym10060603

Han X-Y, Wu Z-L, Yang S-C, Shen F-F, Liang Y-X, Wang L-H, Wang J-Y, Ren J, Jia L-Y, Zhang H, et al. Recent Progress of Imprinted Polymer Photonic Waveguide Devices and Applications. Polymers. 2018; 10(6):603. https://doi.org/10.3390/polym10060603

Chicago/Turabian StyleHan, Xiu-You, Zhen-Lin Wu, Si-Cheng Yang, Fang-Fang Shen, Yu-Xin Liang, Ling-Hua Wang, Jin-Yan Wang, Jun Ren, Ling-Yun Jia, Hua Zhang, and et al. 2018. "Recent Progress of Imprinted Polymer Photonic Waveguide Devices and Applications" Polymers 10, no. 6: 603. https://doi.org/10.3390/polym10060603

APA StyleHan, X. -Y., Wu, Z. -L., Yang, S. -C., Shen, F. -F., Liang, Y. -X., Wang, L. -H., Wang, J. -Y., Ren, J., Jia, L. -Y., Zhang, H., Bo, S. -H., Morthier, G., & Zhao, M. -S. (2018). Recent Progress of Imprinted Polymer Photonic Waveguide Devices and Applications. Polymers, 10(6), 603. https://doi.org/10.3390/polym10060603