Preparation of Compositional Gradient Polymeric Films Based on Gradient Mesh Template

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Gelatin Mesh Template

2.3. Preparation of PDMS-E Grafted Gelatin Colloidal Particles

2.3.1. Synthesis of PDMS-H and PDMS-E

2.3.2. General Procedure for PDMS-E Grafted Gelatin Reaction

2.3.3. Preparation of Colloidal Particles

2.4. Porosity Test

2.5. Filling Colloidal Particles

2.6. Characterization

2.6.1. Scanning Electron Microscope

2.6.2. Energy Dispersive X-ray

2.6.3. Fourier Transform Infrared Spectroscopy

2.6.4. Contact Angle

2.6.5. Thermal Gravimetry Analysis (TGA)

2.6.6. Differential Scanning Calorimetry (DSC)

2.6.7. Dynamic Mechanical Analysis

2.6.8. Particle Size Analysis

2.6.9. Testing of Primary Amino Conversion Rate

2.6.10. Water Vapor Permeability Studies

3. Results and Discussion

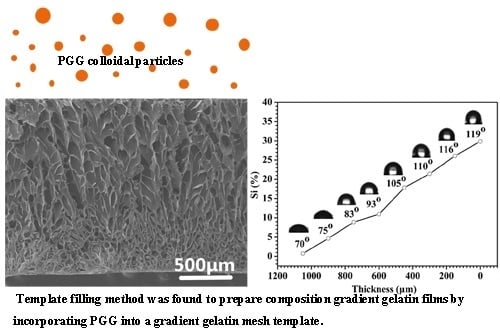

3.1. Pore Structure of Gelatin Mesh Template

3.2. Filling of Colloidal Particles

3.3. Hydrophobicity/Hydrophilicity

3.4. Thermal and Mechanical Properties

3.5. Water Vapor Permeability

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sato, A.K.; Viswanathan, M.; Kent, R.B.; Wood, C.R. Therapeutic peptides: Technological advances driving peptides into development. Curr. Opin. Biotechnol. 2006, 17, 638–642. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Onyeri, S.; Siewe, M.; Moshfeghian, A.; Madihally, S.V. In vitro characterization of chitosan–gelatin scaffolds for tissue engineering. Biomaterials 2005, 26, 7616–7627. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.S.; Zhao, L.G.; Yin, Y.J.; Yao, K.D. Structure and properties of bilayer chitosan–gelatin scaffolds. Biomaterials 2003, 24, 1067–1074. [Google Scholar] [CrossRef]

- Mao, J.; Zhao, L.; De Yao, K.; Shang, Q.; Yang, G.; Cao, Y. Study of novel chitosan–gelatin artificial skin in vitro. J Biomed. Mater. Res. A 2003, 64A, 301–308. [Google Scholar] [CrossRef] [PubMed]

- Pja, S.; Menegalli, F.C.; Hubinger, M.D.; Roques, M.A. Mechanical, water vapor barrier and thermal properties of gelatin based edible films. Food Hydrocoll. 2001, 15, 423–432. [Google Scholar]

- Yakimets, I.; Wellner, N.; Smith, A.C.; Wilson, R.H.; Farhat, I.; Mitchell, J. Mechanical properties with respect to water content of gelatin films in glassy state. Polymer 2005, 46, 12577–12585. [Google Scholar] [CrossRef]

- Xu, J.; Xu, Z.; Qiao, C.D.; Li, T.D. Effect of anionic surfactants on grafting density of gelatin modified with PDMS-E. Colloid Surf. B 2014, 114, 310–315. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Li, T.D.; Jiang, Q.W.; Qiao, C.D.; Chen, J.Y. Microstructure transformation of PDMS-E grafted gelatin polymers induced by SDS and SDBS. Colloid Surf. B 2013, 3, 375–380. [Google Scholar] [CrossRef] [PubMed]

- Karageorgiou, V.; Kaplan, D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 2005, 26, 5474–5491. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.J.; Li, Y.; Zhang, X.H.; Li, H.B. Synthesis of silica microspheres filler for PDMS. Adv. Mater. Res. 2013, 650, 190–193. [Google Scholar] [CrossRef]

- Agari, Y.; Anan, Y.; Nomura, R.; Kawasaki, Y. Estimation of the compositional gradient in a PVC/PMMA graded blend prepared by the dissolution–diffusion method. Polymer 2007, 48, 1139–1147. [Google Scholar] [CrossRef]

- Yu, S.; Sun, Y.D.; Ni, Y.; Zhang, X.F.; Zhou, H. Controlled formation of surface patterns in metal films deposited on elasticity-gradient PDMS substrates. ACS Appl. Mater. Interfaces 2016, 8, 5706–5714. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; You, B.; Gu, G.; Wu, L. A simple approach to fabricate morphological gradient on polymer surfaces. Polymer 2009, 50, 6235–6244. [Google Scholar] [CrossRef]

- Claussen, K.U.; Giesa, R.; Schmidt, H.-W. Longitudinal polymer gradient materials based on crosslinked polymers. Polymer 2014, 55, 29–38. [Google Scholar] [CrossRef]

- Wang, B.; Benitez, A.J.; Lossada, F.; Merindol, R.; Walther, A. Bioinspired mechanical gradients in cellulose nanofibril/polymer nanopapers. Angew. Chem. 2016, 128, 6070–6074. [Google Scholar] [CrossRef]

- Pedron, S.; Peinado, C.; Bosch, P.; Benton, J.A.; Anseth, K.S. Microfluidic approaches for the fabrication of gradient crosslinked networks based on poly(ethylene glycol) and hyperbranched polymers for manipulation of cell interactions. J. Biomed. Mater. Res. 2011, 96, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Davis, R.L.; Jayaraman, S.; Chaikin, P.M.; Register, R.A. Creating controlled thickness gradients in polymer thin films via flowcoating. Langmuir 2014, 30, 5637–5644. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Du, Y.; Guo, Y.; Hancock, M.J.; Wang, B.; Shin, H.; Wu, J.H.; Li, D.; Khademhosseini, A. Microfluidic Synthesis of composite cross–gradient materials for investigating cell–biomaterial interactions. Biotechnol. Bioeng. 2011, 108, 175–185. [Google Scholar] [CrossRef] [PubMed]

- Inagi, S. Fabrication of gradient polymer surfaces using bipolar electrochemistry. Polym. J. 2016, 48, 39–44. [Google Scholar] [CrossRef]

- Marianne, V.; Petit, L.; Mathon-Lagresle, J.; Spano, F.; Rupper, P.; Bernard, L.; Hegemann, D. Formation of lateral chemical gradients in plasma polymer films shielded by an inclined mask. Plasma Process. Polym. 2018, 15, 1700185. [Google Scholar] [CrossRef]

- Gbabode, G.; Delvaux, M.; Schweicher, G.; Andreasen, J.W.; Nielsen, M.M.; Geerts, Y.H. Unique crystal orientation of poly(ethylene oxide) thin films by crystallization using a thermal gradient. Macromolecules 2017, 50, 5877–5891. [Google Scholar] [CrossRef]

- Feng, X.M.; Xing, W.Y.; Yang, H.Y.; Yuan, B.; Song, L.; Hu, Y.; Liew, K.M. High-performance poly(ethylene oxide)/molybdenum disulfide nanocomposite films: Reinforcement of properties based on gradient interface effect. ACS Appl. Mater. Interfaces 2015, 7, 13164–13173. [Google Scholar] [CrossRef] [PubMed]

- Parameswaran, V.; Shukla, A. Dynamic fracture of a functionally gradient material having discrete property variation. J. Mater. Sci. 1998, 33, 3303–3311. [Google Scholar] [CrossRef]

- Bishop, A.; Lin, C.Y.; Navaratnam, M.; Rawlings, R.D.; Mcshane, H.B. A functionally gradient material produced by a powder metallurgical process. J. Mater. Sci. Lett. 1993, 12, 1516–1518. [Google Scholar]

- Li, Y.Y.; Fei, J.; Chen, W.P.; Zhang, W.W.; Shao, M. Preparation of 2024/3003 gradient materials by semi-continuous casting using double-stream-pouring technique. J. Cent. South Univ. 2002, 9, 229–234. [Google Scholar] [CrossRef]

- Narayan, R.J.; Hobbs, L.W.; Jin, C.; Rabiei, A. The use of functionally gradient materials in medicine. JOM 2006, 58, 52–56. [Google Scholar] [CrossRef]

- Li, H.Q.; Xing, D.M.; Shi hu, M.A.; Wang, H.Z.; Wang, S.B. Experiment study of thermal strain field of functionally gradient material. J. Exp. Mech. 2002, 17, 274–278. [Google Scholar]

- Meshkova, A.S.; Liu, Y.G.; Elam, F.M.; Starostin, S.A.; van de Sanden, M.C.M.; de Vries, H.W. The role of the gradient film properties in silica moisture barriers synthesized in a roll-to-roll atmospheric pressure plasma enhanced CVD reactor. Plasma Process. Polym. 2017, 1700093. [Google Scholar] [CrossRef]

- Wang, S.; Guo, L.; Seneviratne, C.J.; Huang, B.; Han, J.; Peng, L.; Liu, X.; Zhang, C. Biofilm formation of salivary microbiota on dental restorative materials analyzed by denaturing gradient gel electrophoresis and sequencing. Dent. Mater. J. 2014, 33, 325–331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Harris, P.C.; Roberts, H.; Al, H. Effect of density gradient material upon ex-vivo neutrophil extracellular trap (NET) formation. Free Radic. Biol. Med. 2012, 53, S168. [Google Scholar] [CrossRef]

- Lother, S.; Hoelscher, U.; Kampf, T.; Jakob, P.; Fidler, F. 3D gradient system for two B0 field directions in earth’s field MRI. Magn. Reson. Mater. Phys. 2013, 26, 565–573. [Google Scholar] [CrossRef] [PubMed]

- Rick, J.; Speck, O.; Maier, S.; Tüscher, O.; Dössel, O.; Hennig, J.; Zaitsev, M. Optimized EPI for fMRI using a slice-dependent template-based gradient compensation method to recover local susceptibility-induced signal loss. Magn. Reson. Mater. Phys. 2010, 23, 165–176. [Google Scholar] [CrossRef] [PubMed]

- Marinov, Y.; Hadjichristov, G.B.; Petrov, A.G. Controllable-gradient microscale PDLC electro-optical materials formed by nanosecond laser photopolymerization. J. Optoelectron. Adv. Mater. 2007, 9, 417–419. [Google Scholar]

- Marinov, Y.G.; Hadjichristov, G.B.; Petrov, A.G. Single-layered microscale linear-gradient PDLC material for electro-optics. Cryst. Res. Technol. 2010, 44, 870–878. [Google Scholar] [CrossRef]

- Vernhes, R.; Zabeida, O.; Klembergsapieha, J.E.; Martinu, L. Single-material inhomogeneous optical filters based on microstructural gradients in plasma-deposited silicon nitride. Appl. Opt. 2004, 43, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Kathuria, N.; Tripathi, A.; Kar, K.K.; Kumar, A. Synthesis and characterization of elastic and macroporous chitosan–gelatin cryogels for tissue engineering. Acta Biomater. 2009, 5, 406–418. [Google Scholar] [CrossRef] [PubMed]

- Vlierberghe, S.V.; Cnudde, V.; Dubruel, P.; Masschaele, B.; Cosijns, A.; Paepe, I.D.; Jacobs, P.J.; Hoorebeke, L.V.; Remon, J.P.; Schacht, E. Porous gelatin hydrogels: 1. cryogenic formation and structure analysis. Biomacromolecules 2007, 8, 331–337. [Google Scholar] [CrossRef] [PubMed]

- Georgopanos, P.; Lo, T.Y.; Ho, R.M.; Apostolos, A. Synthesis, molecular characterization and self-assembly of (PS-b-PDMS)n type linear (n = 1, 2) and star (n = 3, 4) block copolymers. Polym. Chem. 2017, 8, 843–850. [Google Scholar] [CrossRef]

- Li, T.D.; Tang, X.L.; Yang, X.D.; Guo, H.; Cui, Y.Z.; Xu, J. Studies on the reaction of allyl glycidyl ether with gelatin by the Van Slyke method. Asian J. Chem. 2013, 25, 858–860. [Google Scholar] [CrossRef]

- Lin, H.; Erguney, F.; Mattice, W.L. Collapsed chains as models for filler particles in a polymer melt. Polymer 2005, 46, 6154–6162. [Google Scholar] [CrossRef]

- Hou, Z.S.; Qu, W.Q.; Kan, C.Y. Synthesis and properties of triethoxysilane-terminated anionic polyurethane and its waterborne dispersions. J. Polym. Res. 2015, 22, 111–120. [Google Scholar] [CrossRef]

| Sample | Gelatin Film | Gradient Film | Non-Gradient Film |

|---|---|---|---|

| Water vapor permeability (mg/cm2·h) | 1288.1 ± 5 1349.6 ± 5 | 1093.4 ± 5 1078.3 ± 5 | 608.3 ± 5 612.4 ± 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, H.; Li, J.; Hou, Z.; Yan, X.; Han, L.; Xu, J.; Li, T. Preparation of Compositional Gradient Polymeric Films Based on Gradient Mesh Template. Polymers 2018, 10, 677. https://doi.org/10.3390/polym10060677

Teng H, Li J, Hou Z, Yan X, Han L, Xu J, Li T. Preparation of Compositional Gradient Polymeric Films Based on Gradient Mesh Template. Polymers. 2018; 10(6):677. https://doi.org/10.3390/polym10060677

Chicago/Turabian StyleTeng, Honglei, Jing Li, Zhaosheng Hou, Xilu Yan, Linru Han, Jing Xu, and Tianduo Li. 2018. "Preparation of Compositional Gradient Polymeric Films Based on Gradient Mesh Template" Polymers 10, no. 6: 677. https://doi.org/10.3390/polym10060677

APA StyleTeng, H., Li, J., Hou, Z., Yan, X., Han, L., Xu, J., & Li, T. (2018). Preparation of Compositional Gradient Polymeric Films Based on Gradient Mesh Template. Polymers, 10(6), 677. https://doi.org/10.3390/polym10060677