Microwave Devulcanized Crumb Rubbers in Polypropylene Based Thermoplastic Dynamic Vulcanizates

Abstract

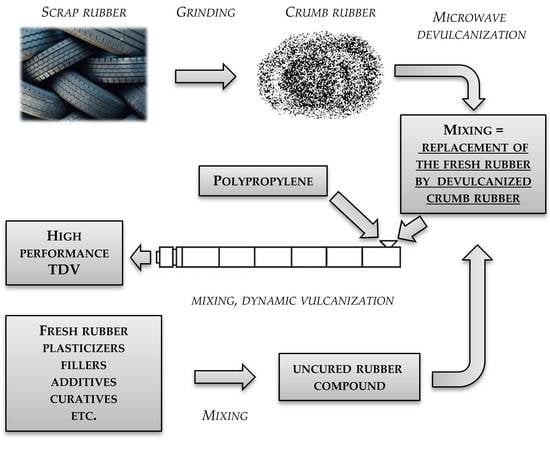

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing Techniques and Parameters

2.3. Testing Methods and Parameters

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Effects of Screw Configurations and MR Content

3.1.2. Effects of the Compounding Temperature Profile

3.1.3. Effects of the Feeding Method of PP

3.1.4. Effects of dCR Content

3.2. Morphology

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Karabork, F.; Tipirdamaz, S.T. Influence of pyrolytic carbon black and pyrolytic oil made from used tires on the curing and (dynamic) mechanical properties of natural rubber (NR)/styrene-butadiene rubber (SBR) blends. Express Polym. Lett. 2016, 10, 72–82. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- De Sousa, F.D.B.; Scuracchio, C.H.; Hu, G.H.; Hoppe, S. Devulcanization of waste tire rubber by microwaves. Polym. Degrad. Stabil. 2017, 138, 169–181. [Google Scholar] [CrossRef]

- De Sousa, F.D.B.; Zanchet, A.; Scuracchio, C.H. Influence of reversion in compounds containing recycled natural rubber: In search of sustainable processing. J. Appl. Polym. Sci. 2017, 134, 45325. [Google Scholar] [CrossRef]

- Diao, B.; Isayev, A.I.; Levin, V.Y. Basic study of continuous ultrasonic devulcanization of unfilled silicone rubber. Rubber. Chem. Technol. 1999, 72, 152–164. [Google Scholar] [CrossRef]

- Luo, M.C.; Liao, X.X.; Liao, S.Q.; Zhao, Y.F. Mechanical and dynamic mechanical properties of natural rubber blended with waste rubber powder modified by both microwave and solgel method. J. Appl. Polym. Sci. 2013, 129, 2313–2320. [Google Scholar] [CrossRef]

- Magioli, M.; Sirqueira, A.S.; Soares, B.G. The effect of dynamic vulcanization on the mechanical, dynamic mechanical and fatigue properties of TPV based on polypropylene and ground tire rubber. Polym. Test. 2010, 29, 840–848. [Google Scholar] [CrossRef]

- De Sousa, F.D.B.; Scuracchio, C.H.; Hu, G.H.; Hoppe, S. Effects of processing parameters on the properties of microwave-devulcanized ground tire rubber/polyethylene dynamically revulcanized blends. J. Appl. Polym. Sci. 2016, 133, 43503. [Google Scholar]

- Anandhan, S.; De, P.P.; Bhowmick, A.K.; De, S.K.; Bandyopadhyay, S. Thermoplastic elastomeric blend of nitrile rubber and poly(styrene-co-acrylonitrile). II. Replacement of nitrile rubber by its vulcanizate powder. J. Appl. Polym. Sci. 2003, 90, 2348–2357. [Google Scholar] [CrossRef]

- Anandhan, S.; De, P.P.; De, S.K.; Bhowmick, A.K. Thermoplastic elastomeric blend of nitrile rubber and poly(styrene-co-acrylonitrile). I. Effect of mixing sequence and dynamic vulcanization on mechanical properties. J. Appl. Polym. Sci. 2003, 88, 1976–1987. [Google Scholar] [CrossRef]

- Naskar, K. Thermoplastic elastomers based on PP/EPDM blends by dynamic vulcanization. Rubber Chem. Technol. 2007, 80, 504–519. [Google Scholar] [CrossRef]

- Coran, A.Y.; Patel, R.P. Thermoplastic elastomers by blending and dynamic vulcanization. In Polypropylene Structure, Blends and Composites: Volume 2 Copolymers and Blends; Karger-Kocsis, J., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 162–201. [Google Scholar]

- Karger-Kocsis, J.; Felhős, D.; Xu, D.; Schlarb, A.K. Unlubricated sliding and rolling wear of thermoplastic dynamic vulcanizates (Santoprene (R)) against steel. Wear 2008, 265, 292–300. [Google Scholar] [CrossRef]

- Oderkerk, J.; de Schaetzen, G.; Goderis, B.; Hellemans, L.; Groeninckx, G. Micromechanical deformation and recovery processes of nylon-6/rubber thermoplastic vulcanizates as studied by atomic force microscopy and transmission electron microscopy. Macromolecules 2002, 35, 6623–6629. [Google Scholar] [CrossRef]

- Radheshkumar, C.; Karger-Kocsis, J. Thermoplastic dynamic vulcanisates containing LDPE, rubber, and thermochemically reclaimed ground tyre rubber. Plast. Rubber Compos. 2002, 31, 99–105. [Google Scholar] [CrossRef]

- Radheshkumar, C.; Fuhrmann, I.; Karger-Kocsis, J. LDPE-based thermoplastic elastomers containing ground tire rubber with and without dynamic curing. Polym. Degrad. Stabil. 2002, 76, 137–144. [Google Scholar]

- Rezaei Abadchi, M.; Jalali Arani, A.; Nazockdast, H. Partial replacement of NR by GTR in thermoplastic elastomer based on LLDPE/NR through using reactive blending: Its effects on morphology, rheological, and mechanical properties. J. Appl. Polym. Sci. 2009, 115, 2416–2422. [Google Scholar] [CrossRef]

- Cañavate, J.; Casas, P.; Colom, X.; Nogués, F. Formulations for thermoplastic vulcanizates based on high density polyethylene, ethylene-propylene-diene monomer, and ground tyre rubber. J. Compos. Mater. 2011, 45, 1189–1200. [Google Scholar] [CrossRef]

- Hernández Gámez José, F.; Hernández Ernesto, H.; Narro Céspedes Rosa, I.; Neira Velázquez María, G.; Solís Rosales Silvia, G.; Soriano Corral, F.; González Morones, P.; Fernández Tavizón, S.; Díaz de Leon, R.; Farías Cepeda, L. Mechanical reinforcement of thermoplastic vulcanizates using ground tyre rubber modified with sulfuric acid. Polym. Compos. 2016, 39, 229–237. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.L.; Xin, Z.X.; Zhang, Z.X.; Kim, J.K. Characterization of the properties of thermoplastic elastomers containing waste rubber tire powder. Waste Manag. 2009, 29, 1480–1485. [Google Scholar] [CrossRef] [PubMed]

- Awang, M.; Ismail, H.; Hazizan, M.A. Polypropylene-based blends containing waste tire dust: Effects of trans-polyoctylene rubber (TOR) and dynamic vulcanization. Polym. Test. 2007, 26, 779–787. [Google Scholar] [CrossRef]

- Luo, T.; Isayev, A.I. Rubber/plastic blends based on devulcanized ground tire rubber. J. Elastom. Plast. 1998, 30, 133–160. [Google Scholar] [CrossRef]

- Naskar, A.K.; Bhowmick, A.K.; De, S.K. Thermoplastic elastomeric composition based on ground rubber tire. Polym. Eng. Sci. 2001, 41, 1087–1098. [Google Scholar] [CrossRef]

- Grigoryeva, O.P.; Fainleib, A.M.; Tolstov, A.L.; Starostenko, O.M.; Lievana, E.; Karger-Kocsis, J. Thermoplastic elastomers based on recycled high-density polyethylene, ethylene-propylene-diene monomer rubber, and ground tire rubber. J. Appl. Polym. Sci. 2005, 95, 659–671. [Google Scholar] [CrossRef]

| Abbreviation | CR | SBR | NR | PP |

|---|---|---|---|---|

| Type, Manufacturer, | Aquajet Ltd., Budapest, Hungary | SBR 1502, SKS-30 ARKPN, JSC Sterlitamak Petrochemical Plant Sterlitamak, Russia | NR TSR 10 Sud Comoe Caoutchuc, Aboisso, Ivory Coast | TIPPLEN R 959 A MOL Petrochemicals Co. Ltd., Budapest, Hungary |

| Main properties | Waterjet-milled truck tire tread, particle size between 200 and 400 μm | Mooney viscosity (ML, 1 + 4, 100 °C): 48–58 Bound styrene content: 22–25 wt % | N/A | Random copolymer for injection molding, MFR (230 °C, 2.16 kg): 45 g/10 min, Tensile strength at yield: 30 MPa, Tensile strain at yield: 12% |

| Designation | ML (dNm) | MH (dNm) | t10 (min) | t70 (min) | t90 (min) |

|---|---|---|---|---|---|

| 160 °C | 1.36 | 34.35 | 1.53 | 2.57 | 5.37 |

| 170 °C | 1.29 | 34.08 | 0.98 | 1.58 | 2.85 |

| 180 °C | 1.20 | 30.01 | 0.54 | 0.83 | 1.33 |

| Designation | 60 MR | 50 MR | 45 MR/5 dCR | 40 MR/10 dCR | 35 MR/15 dCR |

|---|---|---|---|---|---|

| PP | 40 | 50 | 50 | 50 | 50 |

| MR | 60 | 50 | 45 | 40 | 35 |

| dCR | 0 | 0 | 5 | 10 | 15 |

| Designation | Zones | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Die | |

| L | 160 | 160 | 160 | 165 | 165 | 170 | 170 | 170 | 175 | 175 | 180 |

| H | 170 | 170 | 170 | 175 | 175 | 175 | 180 | 180 | 180 | 180 | 180 |

| Designation | Zones | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | Adapter | |

| 1 | 140 | 145 | 155 | 160 | 160 |

| 2 | 165 | 170 | 175 | 108 | 180 |

| 3 | 185 | 190 | 195 | 200 | 200 |

| Abbreviation | Screw configuration | PP feeding method | Compounding extruder temperature profile | PP feeding side extruder temperature profile | TDV formulation |

|---|---|---|---|---|---|

| A_S_L_1_50 MR | A | side, melt | L | 1 | 50 MR |

| A_S_L_1_60 MR | A | side, melt | L | 1 | 60 MR |

| B_S_L_1_50 MR | B | side, melt | L | 1 | 50 MR |

| B_S_L_1_60 MR | B | side, melt | L | 1 | 60 MR |

| A_S_L_1_50 MR | A | side, melt | L | 1 | 50 MR |

| A_S_H_1_50 MR | A | side, melt | H | 1 | 50 MR |

| A_H_H_0_50 MR | A | hopper, granules | H | (PP was fed at the hopper) | 50 MR |

| A_S_H_1_50 MR | A | side, melt | H | 1 | 50 MR |

| A_S_H_2_50 MR | A | side, melt | H | 2 | 50 MR |

| A_S_H_3_50 MR | A | side, melt | H | 3 | 50 MR |

| B_H_H_0_50 MR | B | side, melt | L | 1 | 50 MR |

| B_H_H_0_45 MR/5 dCR | B | side, melt | L | 1 | 45 MR/5 dCR |

| B_H_H_0_40 MR/10 dCR | B | side, melt | L | 1 | 40 MR/10 dCR |

| B_H_H_0_35 MR/15 CR | B | side, melt | L | 1 | 35 MR/15 dCR |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simon, D.Á.; Halász, I.Z.; Karger-Kocsis, J.; Bárány, T. Microwave Devulcanized Crumb Rubbers in Polypropylene Based Thermoplastic Dynamic Vulcanizates. Polymers 2018, 10, 767. https://doi.org/10.3390/polym10070767

Simon DÁ, Halász IZ, Karger-Kocsis J, Bárány T. Microwave Devulcanized Crumb Rubbers in Polypropylene Based Thermoplastic Dynamic Vulcanizates. Polymers. 2018; 10(7):767. https://doi.org/10.3390/polym10070767

Chicago/Turabian StyleSimon, Dániel Ábel, István Zoltán Halász, József Karger-Kocsis, and Tamás Bárány. 2018. "Microwave Devulcanized Crumb Rubbers in Polypropylene Based Thermoplastic Dynamic Vulcanizates" Polymers 10, no. 7: 767. https://doi.org/10.3390/polym10070767

APA StyleSimon, D. Á., Halász, I. Z., Karger-Kocsis, J., & Bárány, T. (2018). Microwave Devulcanized Crumb Rubbers in Polypropylene Based Thermoplastic Dynamic Vulcanizates. Polymers, 10(7), 767. https://doi.org/10.3390/polym10070767