Influence of the Characteristics of Expandable Graphite on the Morphology, Thermal Properties, Fire Behaviour and Compression Performance of a Rigid Polyurethane Foam

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Foam Preparation

2.3. Characterization

3. Results and Discussion

3.1. Cellular Structure Analysis and Thermal Conductivity

3.2. Thermogravimetric Analysis

3.3. Fire Behaviors

3.3.1. LOI and UL 94 Tests

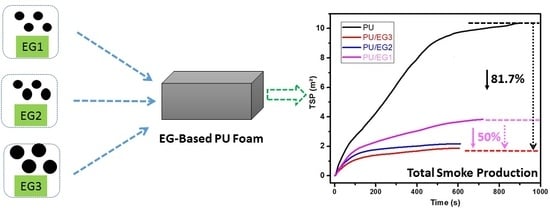

3.3.2. Cone Calorimeter Test

3.4. Mechanical Properties

Compression Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shi, L.; Li, Z.-M.; Yang, M.-B.; Yin, B.; Zhou, Q.-M.; Tian, C.-R.; Wang, J.-H. Expandable Graphite for Halogen-Free Flame-Retardant of High-Density Rigid Polyurethane Foams. J. Polym. Plast. Technol. Eng. 2005, 44, 1323–1327. [Google Scholar] [CrossRef]

- Xi, W.; Qian, L.; Chen, Y.; Wang, J.; Liu, X. Addition flame-retardant behaviors of expandable graphite and [bis(2-hydroxyethyl)amino]-methyl-phosphonic acid dimethyl ester in rigid polyurethane foams. Polym. Degrad. Stab. 2015, 122, 36–43. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Zhou, Y.; Hu, L. The study of mechanical behavior and flame retardancy of castor oil phosphate-based rigid polyurethane foam composites containing expanded graphite and triethyl phosphate. Polym. Degrad. Stab. 2013, 98, 2784–2794. [Google Scholar] [CrossRef]

- Heinen, M.; Gervase, A.E.; Petzhold, C.L. Vegetable oil-based rigid polyurethanes and phosphorylated flame-retardants derived from epoxydized soybean oil. Polym. Degrad. Stab. 2014, 108, 76–86. [Google Scholar] [CrossRef]

- SCHER Opinion on the risk assessment report on tris(2-chloro-1-methylethyl) phosphate (TCPP); CAS no. 13674-84-5; Environmental Part: Brussels, Belgium, 20 September 2007.

- Wu, D.; Zhao, P.; Liu, Y.; Liu, X.; Wang, X. Halogen Free flame retardant rigid polyurethane foam with a novel phosphorus–nitrogen intumescent flame retardant. J. Appl. Polym. Sci. 2014, 131, 39581. [Google Scholar] [CrossRef]

- Zhang, M.; Luo, Z.; Zhang, J.; Chen, S.; Zhou, Y. Effects of a novel phosphorus–nitrogen flame retardant on rosin-based rigid polyurethane foams. Polym. Degrad. Stab. 2015, 120, 427–434. [Google Scholar] [CrossRef]

- Liu, Y.; He, J.; Yang, R. Effects of Dimethyl Methylphosphonate, Aluminum Hydroxide, Ammonium Polyphosphate, and Expandable Graphite on the Flame Retardancy and Thermal Properties of Polyisocyanurate–Polyurethane Foams. Ind. Eng. Chem. Res. 2015, 54, 5876–5884. [Google Scholar] [CrossRef]

- Feng, F.; Qian, L. The flame retardant behaviors and synergistic effect of expandable graphite and dimethyl methylphosphonate in rigid polyurethane foams. Polym. Comp. 2014, 35, 301–309. [Google Scholar] [CrossRef]

- Qian, L.; Feng, F.; Tang, S. Bi-phase flame-retardant effect of hexa-phenoxy-cyclotriphosphazene on rigid polyurethane foams containing expandable graphite. Polymers 2014, 55, 95–101. [Google Scholar] [CrossRef]

- Wang, W.; He, K.; Dong, Q.; Fan, Y.; Zhu, N.; Xia, Y.; Li, H.; Wang, J.; Yuan, Z.; Wang, E.; et al. Influence of Aluminum Hydroxide and Expandable Graphite on the Flammability of Polyisocyanurate-Polyurethane Foams. Appl. Mech. Mater. 2013, 368–370, 741–746. [Google Scholar] [CrossRef]

- Jin, J.; Dong, Q.; Shu, Z.; Wang, W.; He, K. Flame Retardant Properties of Polyurethane/Expandable Praphite Composites. Procedia Eng. 2014, 71, 304–309. [Google Scholar] [CrossRef] [Green Version]

- Modesti, M.; Lorenzetti, A. Halogen-free flame retardants for polymeric foams. Polym. Degrad. Stab. 2002, 78, 167–173. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A.; Simioni, F.; Camino, G. Expandable graphite as an intumescent flame retardant in polyisocyanurate–polyurethane foams. Polym. Degrad. Stab. 2002, 77, 195–202. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Xie, Y. Synergistic effect of expandable graphite, melamine polyphosphate and layered double hydroxide on improving the fire behavior of rosin-based rigid polyurethane foam. Ind. Crops Prod. 2013, 50, 638–647. [Google Scholar] [CrossRef]

- Xiling, C.; Kemin, S.; Jihui, L.; Jinpeng, L. Preparation of lower-sulfur content and expandable graphite. Carbon 1996, 34, 1599–1603. [Google Scholar] [CrossRef]

- Camino, G.; Duquesne, S.; Delobel, R.; Eling, B.; Lindsay, C.; Roels, T. Mechanism of Expandable Graphite Fire Retardant Action in Polyurethanes. In Fire and Polymers: Materials and Solutions for Hazard Prevention; Nelson, G.L., Wilkie, C.A., Eds.; ACS Symposium Series 797; American Chemical Society: Washington, DC, USA, 2001; Volume 8, pp. 90–109. [Google Scholar]

- Chen, X.; Zhuo, J.; Song, W.; Jiao, C.; Qian, Y.; Li, S. Flame retardant effects of organic inorganic hybrid intumescent flame retardant based on expandable graphite in silicone rubber composites. Polym. Adv. Technol. 2014, 25, 1530–1537. [Google Scholar] [CrossRef]

- Kirpluks, M.; Cabulis, U.; Zeltins, V.; Stiebra, L.; Avots, A. Rigid Polyurethane Foam Thermal Insulation Protected with Mineral Intumescent Mat. Autex Res. J. 2014, 14, 259–269. [Google Scholar] [CrossRef] [Green Version]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-based polyurethane-polyisocyanurate composites with an intumescent flame retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Bian, X.; Tang, J.; Li, Z.; Lu, Z.; Lu, A. Dependence of flame-retardant properties on density of expandable graphite filled rigid polyurethane foam. J. Appl. Polym. Sci. 2007, 104, 3347–3355. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Effect of foam density on the properties of water blown rigid polyurethane foam. J. Appl. Polym. Sci. 2008, 108, 1810–1817. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Effect of expandable graphite on the properties of intumescent flame-retardant polyurethane foam. J. Appl. Polym. Sci. 2008, 110, 2586–2594. [Google Scholar] [CrossRef]

- Luo, W.; Li, Y.; Zou, H.; Liang, M. Study of different-sized sulfur-free expandable graphite on morphology and properties of water-blown semi-rigid polyurethane foams. RSC Adv. 2014, 4, 37302–37310. [Google Scholar] [CrossRef]

- Lorenzetti, A.; Dittrich, B.; Schartel, B.; Roso, M.; Modesti, M. Expandable graphite in polyurethane foams: The effect of expansion volume and intercalants on flame retardancy. J. Appl. Polym. Sci. 2017, 134, 45173. [Google Scholar] [CrossRef]

- Zhang, X.L.; Duan, H.J.; Yan, D.X.; Kang, L.Q.; Zhang, W.Q.; Tang, J.-H.; Li, Z.M. A facile strategy to fabricate microencapsulated expandable graphite as a flame-retardant for rigid polyurethane foams. J. Appl. Polym. Sci. 2015, 132, 42364. [Google Scholar] [CrossRef]

- ASTM D1622-08, Standard Test Method for Apparent Density of Rigid Cellular Plastics; ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D6226-10, Standard Test Method for Open Cell Content of Rigid Cellular Plastics; ASTM International: West Conshohocken, PA, USA, 2010.

- Pinto, J.; Solorzano, E.; Rodríguez-Pérez, M.A.; de Saja, J.A. Characterization of the cellular structure based on user-interactive image analysis procedures. J. Cell. Plast. 2013, 49, 555–575. [Google Scholar] [CrossRef]

- ISO 22007-2. Plastics-Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method; International Organization for Standardization (ISO): Geneva, Switzerland, 2008. [Google Scholar]

- Almanza, O.; Rodríguez, M.A.; de Saja, J.A. Applicability of the transient plane source method to measure the thermal conductivity of low-density polyethylene foams. J. Polym. Sci. B 2004, 42, 1226–1234. [Google Scholar] [CrossRef]

- ASTM D2863-13, Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index); ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D3801-10, Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position; ASTM International: West Conshohocken, PA, USA, 2010.

- ISO 5660-1: Reaction-to-Fire Tests. Heat Release, Smoke Production and Mass Loss Rate. Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement); International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- ASTM D1621-00, Standard Test Method for Compressive Properties Of Rigid Cellular Plastics; ASTM International: West Conshohocken, PA, USA, 2000.

- Chattopadhyay, D.K.; Webster, D.C. Thermal Stability and flame Retardancy of Polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Li, Y.; Zou, J.; Zhou, S.; Chen, Y.; Zou, H.; Liang, M.; Luo, W. Effect of expandable graphite particle size on the flame retardant, mechanical, and thermal properties of water-blown semi-rigid polyurethane foam. J. Appl. Polym. Sci. 2014, 131, 39885. [Google Scholar] [CrossRef]

- Estravís, S.; Tirado-Mediavilla, J.; Santiago-Calvo, M.; Ruiz-Herrero, J.L.; Villafañe, F.; Rodríguez-Pérez, M.A. Rigid polyurethane foams with infused nanoclays: Relationship between cellular structure and thermal conductivity. Eur. Polym. J. 2016, 80, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Pérez, M.A.; Alonso, O.; Alonso, J.; de Saja, J.A. Thermal conductivity of physically crosslinked closed cell polyolefin foams. Polym. Test. 1997, 16, 287–298. [Google Scholar] [CrossRef]

- Solórzano, E.; Rodríguez-Pérez, M.A.; Lázaro, J.; de Saja, J.A. Influence of Solid Phase Conductivity and Cellular Structure on the Heat Transfer Mechanisms of Cellular Materials: Diverse Case Studies. Adv. Eng. Mater. 2009, 11, 818–824. [Google Scholar] [CrossRef]

- Debelak, B.; Lafdi, K. Use of exfoliated graphite filler to enhance polymer physical properties. Carbon 2007, 45, 1727–1734. [Google Scholar] [CrossRef]

- Chuang, F.S. Analysis of thermal degradation of diacetylene-containing polyurethane copolymers. Polym. Degrad. Stab. 2007, 92, 1393–1407. [Google Scholar] [CrossRef]

- Jiao, L.; Xiao, H.; Wang, Q.; Sun, J. Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 2013, 98, 2687–2696. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Y.; Bai, S.; Wang, Q. Macromolecular Nitrogen-Phosphorous Compound/Expandable Graphite Synchronous Expansion Flame Retardant Polystyrene Foam. Polym. Plast. Technol. Eng. 2014, 53, 1402–1407. [Google Scholar] [CrossRef]

- Duquesne, S.; Le Bras, M.; Bourbigot, S.; Delobel, R.; Camino, G.; Eling, B.; Lindsay, C.; Roels, T. Thermal degradation of polyurethane and polyurethane/expandable graphite coatings. Polym. Degrad. Stab. 2001, 74, 493–499. [Google Scholar] [CrossRef]

- Kang, F.; Leng, Y.; Zhang, T. Influences of density and flake size on the mechanical properties of flexible graphite. Carbon 1998, 36, 875–881. [Google Scholar]

- Lefebvre, J.; Bastin, B.; Le Bras, M.; Duquesne, S.; Ritter, C.; Paleja, R.; Poutch, F. Flame spread of flexible polyurethane foam: Comprehensive study. Polym. Test. 2004, 23, 281–290. [Google Scholar] [CrossRef]

- Schartel, B.; Hull, T.R. Development of fire-retarded materials—Interpretation of cone calorimeter data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Wang, S.; Qian, L.; Xin, F. The synergistic flame-retardant behaviors of pentaerythritol phosphate and expandable graphite in rigid polyurethane foams. Polym. Compos. 2018, 39, 329–336. [Google Scholar] [CrossRef]

- Zhang, M.; Pan, H.; Zhang, L.; Hu, L.; Zho, Y. Study of the mechanical, thermal properties and flame retardancy of rigid polyurethane foams prepared from modified castor-oil-based polyols. Ind. Crops Prod. 2014, 59, 135–143. [Google Scholar] [CrossRef]

- Chen, X.; Yu, J.; Guo, S.; Luo, Z.; He, M. Flammability and Thermal Oxidative Degradation Kinetics of Magnesium Hydroxide and Expandable Graphite Flame Retarded Polypropylene Composites. J. Macromol. Sci. Pure 2008, 45, 712–720. [Google Scholar] [CrossRef]

- Chen, X.; Yu, J.; Lu, S.; Wu, H.; Guo, S.; Zuo, Z. Combustion Characteristics of Polypropylene/Magnesium Hydroxide/Expandable Graphite Composites. J. Macromol. Sci. Part B 2009, 48, 1081–1092. [Google Scholar] [CrossRef]

- Xiaolang, C.; Hong, W.; Zhu, L. Synergistic effects of expandable graphite with magnesium hydroxide on the flame retardancy and thermal properties of polypropylene. Polym. Eng. Sci. 2007, 47, 1756–1760. [Google Scholar]

- Du, L.; Zhang, Y.; Yuan, X.; Chen, J. Combustion Characteristics and Synergistic Effect of Halogen-Free Flame-Retarded EVA/Hydrotalcite Blends with Expandable Graphite and Fumed Silica. Polym. Plast. Technol. 2009, 48, 1002–1007. [Google Scholar] [CrossRef]

- Modesti, M.; Lorenzetti, A. Flame retardancy of polyisocyanurate–polyurethane foams: Use of different charring agents. Polym. Degrad. Stab. 2002, 78, 341–347. [Google Scholar] [CrossRef]

- Bian, X.; Tang, J.; Li, Z. Flame retardancy of hollow glass microsphere/rigid polyurethane foams in the presence of expandable graphite. J. Appl. Polym. Sci. 2008, 109, 1935–1943. [Google Scholar] [CrossRef]

| Samples | EG content (wt %) |

|---|---|

| PU | 0 |

| EG1-6 | 6 |

| EG2-6 | 6 |

| EG3-6 | 6 |

| EG1-8 | 8 |

| EG2-8 | 8 |

| EG3-8 | 8 |

| EG1-10 | 10 |

| EG2-10 | 10 |

| EG3-10 | 10 |

| SAMPLES | Density (Kg/m3) | Open Cell (%) | Cell Size (µm) | NSD | AC | AR | Thermal Conductivity (mW/mK) |

|---|---|---|---|---|---|---|---|

| PU | 95.9 ± 0.1 | 6.9 ± 0.2 | 467 ± 120 | 0.26 | −0.26 | 1.14 | 48.9 ± 0.1 |

| EG1-6 | 100.9 ± 1.1 | 9.4 ± 0.4 | 310 ± 105 | 0.34 | 0.61 | 1.26 | 52.7 ± 0.2 |

| EG1-8 | 104.7 ± 1.7 | 7.8 ± 0.6 | 339 ± 132 | 0.39 | 0.57 | 1.23 | 53.0 ± 0.2 |

| EG1-10 | 104.9 ± 0.3 | 9.5 ± 0.1 | 339 ± 108 | 0.32 | 0.56 | 1.25 | 56.0 ± 0.1 |

| EG2-6 | 96.5 ± 1.7 | 9.4 ± 1.5 | 329 ± 126 | 0.38 | 0.67 | 1.30 | 50.4 ± 0.1 |

| EG2-8 | 99.6 ± 0.5 | 9.1 ± 0.1 | 349 ± 121 | 0.35 | 0.85 | 1.04 | 51.6 ± 0.2 |

| EG2-10 | 102.8 ± 5 | 9.9 ± 0.2 | 340 ± 104 | 0.31 | 0.83 | 1.14 | 52.8 ± 0.2 |

| EG3-6 | 97.5 ± 1.5 | 10.8 ± 0.7 | 423 ± 148 | 0.35 | 0.97 | 1.21 | 51.0 ± 0.3 |

| EG3-8 | 102.7 ± 0.6 | 9.3 ± 1.2 | 383 ± 181 | 0.47 | 1.12 | 1.12 | 52.0 ± 0.2 |

| EG3-10 | 101.6 ± 0.9 | 9.5 ± 0.6 | 408 ± 155 | 0.38 | 1.13 | 1.13 | 52.2 ± 0.4 |

| SAMPLE | T5 wt% (°C) | Tmax (°C) | Residue (wt %) |

|---|---|---|---|

| PU | 231 | 329 | 9.8 |

| EG1-6 | 231 | 307 | 14.6 |

| EG1-8 | 238 | 313 | 17.6 |

| EG1-10 | 228 | 311 | 22.6 |

| EG2-6 | 236 | 322 | 15.0 |

| EG2-8 | 237 | 325 | 17.2 |

| EG2-10 | 238 | 303 | 17.7 |

| EG3-6 | 234 | 316 | 14.8 |

| EG3-8 | 226 | 313 | 14.9 |

| EG3-10 | 229 | 315 | 19.6 |

| SAMPLE | EG Loading (wt %) | LOI (%) | UL94 Test | Total Burning Time (s) |

|---|---|---|---|---|

| PU | 0 | 19.2 | NO RATING | - |

| EG1-6 | 6 | 26.8 | NO RATING | - |

| EG2-6 | 6 | 28 | NO RATING | - |

| EG3-6 | 6 | 28.6 | V-1 | 49.6 |

| EG1-8 | 8 | 27.8 | V-0 | 37.0 |

| EG2-8 | 8 | 30 | V-0 | 42.5 |

| EG3-8 | 8 | 29.2 | V-0 | 28.1 |

| EG1-10 | 10 | 29.8 | V-0 | 20.9 |

| EG2-10 | 10 | 31.8 | V-0 | 29.0 |

| EG3-10 | 10 | 31.8 | V-0 | 14.6 |

| SAMPLE | pHRR (kW/m2) | THR (MJ/m2) | TSP (m2) | TSR (m2/m2) | Mass Loss (wt %) |

|---|---|---|---|---|---|

| PU | 220 ± 39 | 68.7 ± 15.4 | 10.4 ± 0.4 | 1171 ± 42 | 87 |

| EG1-6 | 150 ± 14 | 56.2 ± 4.4 | 7.8 ± 1.3 | 880 ± 149 | 71 |

| EG2-6 | 165 ± 4 | 48.8 ± 0.8 | 4.9 ± 0.6 | 556 ± 76 | 66 |

| EG3-6 | 126 ± 2 | 56.4 ± 3.4 | 3.4 ± 0.1 | 390 ± 5 | 69 |

| EG1-8 | 135 ± 8 | 45.3 ± 1.7 | 3.8 ± 0.2 | 428 ± 26 | 59 |

| EG2-8 | 127 ± 9 | 38.9 ± 3.5 | 2.2 ± 0.7 | 246 ± 81 | 54 |

| EG3-8 | 107 ± 2 | 36.7 ± 19.1 | 1.9 ± 0.2 | 213 ± 17 | 49 |

| EG1-10 | 111 ± 5 | 50.3 ± 7.6 | 2.0 ± 0.1 | 226 ± 1 | 54 |

| EG2-10 | 113 ± 7 | 41.3 ± 0.5 | 2.1 ± 0.4 | 241 ± 43 | 53 |

| EG3-10 | 101 ± 7 | 36.3 ± 0.8 | 1.7 ± 0.5 | 192 ± 54 | 50 |

| SAMPLE | Compressive Strength (MPa) | Density (Kg/m3) |

|---|---|---|

| PU | 0.85 ± 0.07 | 95.9 ± 0.1 |

| EG1-6 | 0.77 ± 0.06 | 100.9 ± 0.3 |

| EG2-6 | 0.86 ± 0.02 | 97.2 ± 1.7 |

| EG3-6 | 0.90 ± 0.04 | 97.5 ± 1.5 |

| EG1-8 | 0.84 ± 0.02 | 104.7 ± 1.7 |

| EG2-8 | 0.81 ± 0.06 | 101.7 ± 2.6 |

| EG3-8 | 0.83 ± 0.02 | 102.7 ± 0.6 |

| EG1-10 | 0.78 ± 0.03 | 104.9 ± 0.3 |

| EG2-10 | 0.81 ± 0.09 | 102.5 ± 3.1 |

| EG3-10 | 0.72 ± 0.05 | 101.6 ± 0.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acuña, P.; Li, Z.; Santiago-Calvo, M.; Villafañe, F.; Rodríguez-Perez, M.Á.; Wang, D.-Y. Influence of the Characteristics of Expandable Graphite on the Morphology, Thermal Properties, Fire Behaviour and Compression Performance of a Rigid Polyurethane Foam. Polymers 2019, 11, 168. https://doi.org/10.3390/polym11010168

Acuña P, Li Z, Santiago-Calvo M, Villafañe F, Rodríguez-Perez MÁ, Wang D-Y. Influence of the Characteristics of Expandable Graphite on the Morphology, Thermal Properties, Fire Behaviour and Compression Performance of a Rigid Polyurethane Foam. Polymers. 2019; 11(1):168. https://doi.org/10.3390/polym11010168

Chicago/Turabian StyleAcuña, Pablo, Zhi Li, Mercedes Santiago-Calvo, Fernando Villafañe, Miguel Ángel Rodríguez-Perez, and De-Yi Wang. 2019. "Influence of the Characteristics of Expandable Graphite on the Morphology, Thermal Properties, Fire Behaviour and Compression Performance of a Rigid Polyurethane Foam" Polymers 11, no. 1: 168. https://doi.org/10.3390/polym11010168

APA StyleAcuña, P., Li, Z., Santiago-Calvo, M., Villafañe, F., Rodríguez-Perez, M. Á., & Wang, D.-Y. (2019). Influence of the Characteristics of Expandable Graphite on the Morphology, Thermal Properties, Fire Behaviour and Compression Performance of a Rigid Polyurethane Foam. Polymers, 11(1), 168. https://doi.org/10.3390/polym11010168