Durability and Electrical Conductivity of Carbon Fiber Cloth/Ethylene Propylene Diene Monomer Rubber Composite for Active Deicing and Snow Melting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

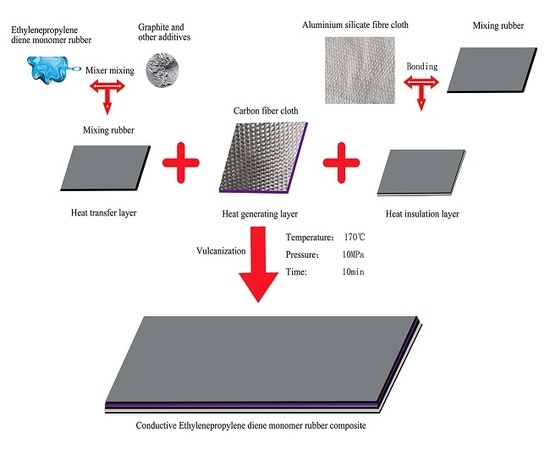

2.2. Preparations of Conductive EPDM Rubber Composite Material

2.3. Measurements

2.3.1. Mechanical Properties Tests

2.3.2. High Temperature Durability Tests

2.3.3. Low Temperature Cycle Tests

2.3.4. Heat Production Uniformity Tests

2.3.5. Resistance Stability and Thermal Efficiency Tests

3. Results and Discussion

3.1. Effect of Carbon Fiber Cloth on Mechanical Properties of EPDM Rubber Composite

3.2. Durability of Conductive EPDM Rubber Composite Material at 60 °C

3.3. Mechanical Properties After Low Temperature Cycling

3.4. Heat Production Uniformity of Conductive EPDM Rubber Composite Material

3.5. Electric Resistance Stability

3.6. Joule Heating Performance of Conductive EPDM Rubber Composite Material

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Menzies, T.R. Overview of national research council study on the comparative costs of using rock salt and cma for highway deicing. Resour. Conserv. Recycl. 1992, 7, 43–50. [Google Scholar] [CrossRef]

- French, H.; van der Zee, S.; Leijnse, A. Transport and degradation of propyleneglycol and potassium acetate in the unsaturated zone. J. Contam. Hydrol. 2001, 49, 23–48. [Google Scholar] [CrossRef]

- Poursaee, A.; Laurent, A.; Hansson, C.M. Corrosion of steel bars in opc mortar exposed to nacl, mgcl2 and cacl2: Macro-and micro-cell corrosion perspective. Cem. Concr. Res. 2010, 40, 426–430. [Google Scholar] [CrossRef]

- Pruckner, F.; Gjørv, O.E. Effect of cacl2 and nacl additions on concrete corrosivity. Cem. Concr. Res. 2004, 34, 1209–1217. [Google Scholar] [CrossRef]

- Laffray, X.; Alaoui-Sehmer, L.; Bourioug, M.; Bourgeade, P.; Alaoui-Sosse, B.; Aleya, L. Effects of sodium chloride salinity on ecophysiological and biochemical parameters of oak seedlings (Quercus robur L.) from use of de-icing salts for winter road maintenance. Environ. Monitor. Assess. 2018, 190, 266. [Google Scholar] [CrossRef]

- Zýval, V.; Křenová, Z.; Raus, M.; Štrupl, V.; Zýval, V., Jr.; Zývalová, J. Effects of deicing salt in protected areas: Water quality monitoring in the river basin with the occurrence of a rare pearl mussel. Inz. Miner. 2018, 19, 99–102. [Google Scholar]

- Rivett, M.O.; Cuthbert, M.O.; Gamble, R.; Connon, L.E.; Pearson, A.; Shepley, M.G.; Davis, J. Highway deicing salt dynamic runoff to surface water and subsequent infiltration to groundwater during severe uk winters. Sci. Total Environ. 2016, 565, 324–338. [Google Scholar] [CrossRef] [Green Version]

- Marques, J.E.; Marques, J.M.; Carvalho, A.; Carreira, P.M.; Moura, R.; Mansilha, C. Groundwater resources in a mediterranean mountainous region: Environmental impact of road de-icing. Sustain. Water Res. Manag. 2017, 5, 305–317. [Google Scholar] [CrossRef]

- Gao, J.; Guo, H.; Wang, X.; Wang, P.; Wei, Y.; Wang, Z.; Huang, Y.; Yang, B. Microwave deicing for asphalt mixture containing steel wool fibers. J. Clean. Prod. 2019, 206, 1110–1122. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Chen, Z.; Tao, G.; Xiao, Y. Enhanced heat release and self-healing properties of steel slag filler based asphalt materials under microwave irradiation. Constr. Build. Mater. 2018, 193, 32–41. [Google Scholar] [CrossRef]

- Vo, H.V.; Park, D.-W.; Seo, W.-J.; Yoo, B.-S. Evaluation of asphalt mixture modified with graphite and carbon fibers for winter adaptation: Thermal conductivity improvement. J. Mater. Civ. Eng. 2017, 29, 04016176. [Google Scholar] [CrossRef]

- Notani, M.A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K. Effect of carbon-fiber properties on volumetrics and ohmic heating of electrically conductive asphalt concrete. J. Mater. Civ. Eng. 2019, 31, 04019200. [Google Scholar] [CrossRef]

- Koenig, G.G.; Ryerson, C.C. An investigation of infrared deicing through experimentation. Cold Reg. Sci. Technol. 2011, 65, 79–87. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Sassani, A.; Gopalakrishnan, K.; Mina, M. Electrically-conductive asphalt mastic: Temperature dependence and heating efficiency. Mater. Des. 2018, 157, 303–313. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Su, X.; Ye, Q.; Fu, J. Experimental investigation of concrete runway snow melting utilizing heat pipe technology. Sci. World J. 2018, 2018, 4343167. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, K.; Huang, S.; Xie, H.; Wang, F. Multi-objective optimization of the design and operation for snow-melting pavement with electric heating pipes. Appl. Ther. Eng. 2017, 122, 359–367. [Google Scholar] [CrossRef]

- Han, C.; Wu, G.; Yu, X.B. Performance analyses of geothermal and geothermoelectric pavement snow melting system. J. Energy Eng. 2018, 144, 04018067. [Google Scholar] [CrossRef]

- Liu, H.; Maghoul, P.; Bahari, A.; Kavgic, M. Feasibility study of snow melting system for bridge decks using geothermal energy piles integrated with heat pump in canada. Renew. Energy 2019, 136, 1266–1280. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, X.; Li, H.; Xiong, G.; Hu, H.; Fisher, T.S. Mechanically robust honeycomb graphene aerogel multifunctional polymer composites. Carbon 2015, 93, 659–670. [Google Scholar] [CrossRef]

- Ge, J.; Shi, L.A.; Wang, Y.C.; Zhao, H.Y.; Yao, H.B.; Zhu, Y.B.; Zhang, Y.; Zhu, H.W.; Wu, H.A.; Yu, S.H. Joule-heated graphene-wrapped sponge enables fast clean-up of viscous crude-oil spill. Nat. Nanotechnol. 2017, 12, 434–440. [Google Scholar] [CrossRef]

- Chu, H.; Zhang, Z.; Liu, Y.; Leng, J. Self-heating fiber reinforced polymer composite using meso/macropore carbon nanotube paper and its application in deicing. Carbon 2014, 66, 154–163. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, Y.; Chen, W.; Chen, T.; Zhou, Y.; Li, H. Outdoor experiment of flexible sandwiched graphite-pet sheets based self-snow-thawing pavement. Cold Reg. Sci. Technol. 2016, 122, 10–17. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, Y.; Yang, K.; Zhang, B.; Zhao, K.; Xiong, G.; Zhang, X. Mechanically robust and electrically conductive graphene-paper/glass-fibers/epoxy composites for stimuli-responsive sensors and joule heating deicers. Carbon 2017, 124, 296–307. [Google Scholar] [CrossRef]

- Yang, L.; Zhou, W.; Jia, J.; Xiong, T.; Zhou, K.; Feng, C.; Zhou, J.; Tang, Z.; Chen, S. Nickel nanoparticles partially embedded into carbon fiber cloth via metal-mediated pitting process as flexible and efficient electrodes for hydrogen evolution reactions. Carbon 2017, 122, 710–717. [Google Scholar] [CrossRef]

- Yao, Y.; Fu, K.K.; Yan, C.; Dai, J.; Chen, Y.; Wang, Y.; Zhang, B.; Hitz, E.; Hu, L. Three-dimensional printable high-temperature and high-rate heaters. ACS Nano 2016, 10, 5272–5279. [Google Scholar] [CrossRef]

- Kim, S.Y.; Baek, S.J.; Youn, J.R. New hybrid method for simultaneous improvement of tensile and impact properties of carbon fiber reinforced composites. Carbon 2011, 49, 5329–5338. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Ben-Aarosh, S.; Rabinovitch, O.; Quadflieg, T.; Gries, T. Integrated self-monitoring of carbon based textile reinforced concrete beams under repeated loading in the un-cracked region. Carbon 2016, 98, 238–249. [Google Scholar] [CrossRef]

- Lim, C.; Park, K.; Lee, J.; Lee, B. Fundamental study for development of an anti-icing pavement system using carbon-fiber sheet. Int. J. Highw. Eng. 2016, 18, 59–65. [Google Scholar] [CrossRef]

- Mohammed, A.G.; Ozgur, G.; Sevkat, E. Electrical resistance heating for deicing and snow melting applications: Experimental study. Cold Reg. Sci. Technol. 2019, 160, 128–138. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, X.; Li, L.; Ling, H.; Zhou, P.; Cheng, Z.; Su, A.; Du, Y. Prefabricated flexible conductive composite overlay for active deicing and snow melting. J. Mater. Civ. Eng. 2018, 30, 04018283. [Google Scholar] [CrossRef]

- Yang, T.; Yang, Z.J.; Singla, M.; Song, G.; Li, Q. Experimental study on carbon fiber tape–based deicing technology. J. Cold Reg. Eng. 2011, 26, 55–70. [Google Scholar] [CrossRef]

- Standardization Administration of China. Rubber, Vulcanized or Thermoplastic-Determination of Tensile Stress-Strain Properties, 528-2009; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2009.

- Standardization Administration of China. Rubber, Vulcanized or Thermoplastic-Determination of Tear Strength (Trouser, Angle and Crescent Test Pieces) 529-2008; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- Standardization Administration of China. Rubber, Vulcanized or Thermoplastic Determination of Compression Stress-Strain Properties, 7757-2009; Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2009.

- Posadas, P.; Fernández-Torres, A.; Chamorro, C.; Mora-Barrantes, I.; Rodríguez, A.; González, L.; Valentín, J.L. Study on peroxide vulcanization thermodynamics of ethylene–vinyl acetate copolymer rubber using 2,2,6,6,-tetramethylpiperidinyloxyl nitroxide. Polym. Int. 2013, 62, 909–918. [Google Scholar] [CrossRef]

- Sharma, B.K.; Chowdhury, S.R.; Mahanwar, P.A.; Sarma, K.S.S. Structure-property relationship in terms of dynamic mechanical properties of high energy radiation treated industrially important thermoplastic elastomer blend. Adv. Mater. Phys. Chem. 2015, 5, 383–398. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Wu, S.; Liu, Q.; Hu, J.; Yuan, Y.; Ye, Q. Snow and ice melting properties of self-healing asphalt mixtures with induction heating and microwave heating. Appl. Therm. Eng. 2018, 129, 871–883. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Sadati, S.M.S.; Gopalakrishnan, K.; Taylor, P.C.; Abdualla, H. Carbon fiber-based electrically conductive concrete for salt-free deicing of pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

| Tensile Strength/(MPa) | Tear Strength/(KN/m) | Compressive Strength/(MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Without Carbon Fiber Cloth | Experiment | 3.70 | 3.52 | 3.63 | 13.43 | 13.57 | 13.26 | 3.87 | 3.84 | 3.84 |

| Average ± Standard Deviation | 3.61 ± 0.075 | 13.42 ± 0.127 | 3.85 ± 0.014 | |||||||

| Existing Carbon Fiber Cloth | Experiment | 6.30 | 6.58 | 6.44 | 17.04 | 16.61 | 15.91 | 3.88 | 3.85 | 3.89 |

| Average ± Standard Deviation | 6.44 ± 0.114 | 16.52 ± 0.466 | 3.87 ± 0.017 | |||||||

| Heating Time/h | 0 | 24 | 48 | 72 | 96 | 120 |

| Tensile Strength/(MPa) | 6.44 | 7.91 | 8.44 | 8.89 | 9.07 | 9.13 |

| Tear Strength/(KN/m) | 16.52 | 17.04 | 17.62 | 17.97 | 17.99 | 17.99 |

| Compressive Strength/(MPa) | 3.84 | 4.61 | 4.85 | 5.14 | 5.22 | 5.24 |

| Number of Cryogenic Cycles | 0 | 5 | 10 | 15 | 20 |

| Tensile Strength/(MPa) | 6.44 | 6.43 | 6.39 | 6.37 | 6.45 |

| Tear Strength/(KN/m) | 16.52 | 16.48 | 16.35 | 16.61 | 16.59 |

| Compressive Strength/(MPa) | 3.84 | 3.60 | 3.82 | 3.52 | 3.73 |

| Input Power/(W/m2) | 80 | 160 | 320 | ||||||

| Temperature Sensor | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| Initial Temperature/°C | 23.2 | 22.7 | 23.0 | 23.5 | 24.2 | 24.0 | 22.5 | 23.5 | 23.7 |

| Power on for 30 min/°C | 26.0 | 25.5 | 25.8 | 27.7 | 28.4 | 28.2 | 28.7 | 29.7 | 29.9 |

| Difference Value/°C | 2.8 | 2.8 | 2.8 | 4.2 | 4.2 | 4.2 | 6.2 | 6.2 | 6.2 |

| Time/min | 0 | 5 | 10 | 15 | 20 | 25 | 30 | |

| Resistance Value/Ω | Input 80W/m2 | 0.618 | 0.607 | 0.596 | 0.593 | 0.591 | 0.596 | 0.602 |

| Input 160W/m2 | 0.628 | 0.609 | 0.607 | 0.609 | 0.612 | 0.615 | 0.614 | |

| Input 320W/m2 | 0.617 | 0.609 | 0.613 | 0.608 | 0.607 | 0.604 | 0.610 | |

| Heat Flux Density/(W/m2) | 80 | 160 | 320 | |

| Temperature Rise Rate/(°C/h) | Upper layer | 5.6 | 8.4 | 12.4 |

| Lower layer | 2.0 | 3.2 | 5.4 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Wei, H.; Han, L.; Li, Q. Durability and Electrical Conductivity of Carbon Fiber Cloth/Ethylene Propylene Diene Monomer Rubber Composite for Active Deicing and Snow Melting. Polymers 2019, 11, 2051. https://doi.org/10.3390/polym11122051

Han S, Wei H, Han L, Li Q. Durability and Electrical Conductivity of Carbon Fiber Cloth/Ethylene Propylene Diene Monomer Rubber Composite for Active Deicing and Snow Melting. Polymers. 2019; 11(12):2051. https://doi.org/10.3390/polym11122051

Chicago/Turabian StyleHan, Shuanye, Haibin Wei, Leilei Han, and Qinglin Li. 2019. "Durability and Electrical Conductivity of Carbon Fiber Cloth/Ethylene Propylene Diene Monomer Rubber Composite for Active Deicing and Snow Melting" Polymers 11, no. 12: 2051. https://doi.org/10.3390/polym11122051

APA StyleHan, S., Wei, H., Han, L., & Li, Q. (2019). Durability and Electrical Conductivity of Carbon Fiber Cloth/Ethylene Propylene Diene Monomer Rubber Composite for Active Deicing and Snow Melting. Polymers, 11(12), 2051. https://doi.org/10.3390/polym11122051