Preparation of Organo-Montmorillonite Modified Poly(lactic acid) and Properties of Its Blends with Wood Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of OMMT

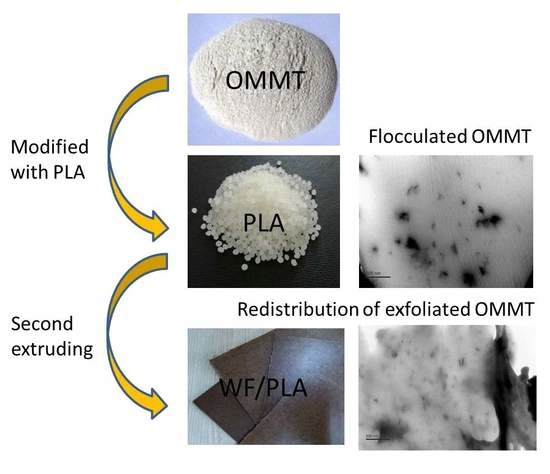

2.3. Modification of PLA

2.4. Preparation of PLA/WF Composites

2.5. Characterization and Tests

3. Results and Discussion

3.1. OMMT Characterization

3.2. Water Uptake and Thickness Swelling

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zahedi, M.; Tabarsa, T.; Ashori, A.; Madhoushi, M.; Shakeri, A. A comparative study on some properties of wood plastic composites using canola stalk, paulownia, and nanoclay. J. Appl. Polym. Sci. 2013, 129, 1491–1498. [Google Scholar] [CrossRef]

- Ansari, F.; Granda, L.A.; Joffe, R.; Berglund, L.A.; Vilaseca, F. Experimental evaluation of anisotropy in injection molded polypropylene/wood fiber biocomposites. Compos. Part A Appl. Sci. 2017, 96, 147–154. [Google Scholar] [CrossRef]

- Sohn, J.S.; Cha, S.W. Effect of chemical modification on mechanical properties of wood-plastic composite injection-molded parts. Polymers 2018, 10, 1391. [Google Scholar] [CrossRef]

- Shahi, P.; Behravesh, A.H.; Daryabari, S.Y.; Lotfi, M. Experimental investigation on reprocessing of extruded wood flour/HDPE composites. Polym. Compos. 2012, 33, 753–763. [Google Scholar] [CrossRef]

- Smith, P.M.; Wolcott, M.P. Opportunities for wood/natural fiber-plastic composites in residential and industrial applications. For. Prod. J. 2006, 56, 4–11. [Google Scholar]

- Guo, X.; Cao, J.; Peng, Y.; Liu, R. Incorporation of microencapsulated dodecanol into wood flour/high-density polyethylene composite as a phase change material for thermal energy storage. Mater. Des. 2016, 89, 1325–1334. [Google Scholar] [CrossRef]

- Teuber, L.; Militz, H.; Krause, A. Dynamic particle analysis for the evaluation of particle degradation during compounding of wood plastic composites. Compos. Part A Appl. Sci. 2016, 84, 464–471. [Google Scholar] [CrossRef]

- Teuber, L.; Osburg, V.S.; Toporowski, W.; Militz, H.; Krause, A. Wood polymer composites and their contribution to cascading utilization. J. Clean. Prod. 2016, 110, 9–15. [Google Scholar] [CrossRef]

- Wei, L.; Agarwal, U.P.; Matuana, L.; Sabo, R.C.; Stark, N.M. Performance of high lignin content cellulose nanocrystals in poly(lactic acid). Polymer 2018, 135, 305–313. [Google Scholar] [CrossRef]

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused deposition modeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef]

- Charlet, K.; Saulnier, F.; Dubois, M.; Béakou, A. Improvement of wood polymer composite mechanical properties by direct fluorination. Mater. Des. 2015, 74, 61–66. [Google Scholar] [CrossRef]

- Hosseinihashemi, S.K.; Arwinfar, F.; Najafi, A.; Nemli, G.; Ayrilmis, N. Long-term water absorption behavior of thermoplastic composites produced with thermally treated wood. Measurement 2016, 86, 202–208. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Nicolae, C.A.; Vuluga, Z.; Vitelaru, C.; Sanporean, C.G.; Zaharia, C.; Florea, D.; Vasilievici, G. Influence of hemp fibers with modified surface on polypropylene composites. J. Ind. Eng. Chem. 2016, 37, 137–146. [Google Scholar] [CrossRef]

- Tian, S.; He, H.; Yu, P.; Zhou, L.; Luo, Y.; Jia, D. Sustainable utilization of waste printed circuit boards powders in HDPE-wood composites: Synergistic effects of multicomponents on structure and properties. J. Clean. Prod. 2017, 164, 840–847. [Google Scholar] [CrossRef]

- Saba, N.; Md Tahir, P.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Cosnita, M.; Cazan, C.; Duta, A. The influence of inorganic additive on the water stability and mechanical properties of recycled rubber, polyethyleneterephthalate, high density polyethylene and wood composites. J. Clean. Prod. 2017, 165, 630–636. [Google Scholar] [CrossRef]

- Zhou, H.; Hao, X.; Wang, H.; Wang, X.; Liu, T.; Xie, Y.; Wang, Q. The reinforcement efficacy of nano- and microscale silica for extruded wood flour/HDPE composites: The effects of dispersion patterns and interfacial modification. J. Mater. Sci. 2018, 53, 1899–1910. [Google Scholar] [CrossRef]

- Thellen, C.; Orroth, C.; Froio, D.; Ziegler, D.; Lucciarini, J. Influence of montmorillonite layered silicate on plasticized poly (L-lactide) blown films. Polymer 2005, 46, 11716–11727. [Google Scholar] [CrossRef]

- Fukusima, K.; Abbate, C.; Tabuani, D.; Gennari, M.; Camino, G. Biodegradation of poly(lactic acid) and its nanocomposites. Polym. Degrad. Stabil. 2009, 94, 1646–1655. [Google Scholar] [CrossRef]

- Cao, J.; Wen, N.; Zheng, Y. The preparation of calcium pimelate modified OMMT from natural Ca-montmorillonite and its application as β-nucleating agent for polypropylene. Polym. Test. 2018, 65, 352–359. [Google Scholar] [CrossRef]

- Meyers, K.P.; Decker, J.J.; Olson, B.G.; Lin, J.; Jamieson, A.M.; Nazarenko, S. Probing the confining effect of clay particles on an amorphous intercalated dendritic polyester. Polymer 2017, 112, 76–86. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Liao, L.; Xia, Z. Synergistic effect of cationic and anionic surfactants for the modification of Ca-montmorillonite. Mater. Res. Bull. 2013, 48, 1811–1816. [Google Scholar] [CrossRef]

- Zhong, Y.; Poloso, T.; Hetzer, M.; De Kee, D. Enhancement of wood/polyethylene composites via compatibilization and incorporation of organoclay particles. Polym. Eng. Sci. 2007, 47, 797–803. [Google Scholar] [CrossRef]

- Tabari, H.Z.; Nourbakhsh, A.; Ashori, A. Effects of nanoclay and coupling agent on the physico-mechanical, morphological, and thermal properties of wood flour/polypropylene composites. Polym. Eng. Sci. 2011, 51, 272–277. [Google Scholar] [CrossRef]

- Madhoushi, M.; Chavooshi, A.; Ashori, A.; Ansell, M.; Shakeri, A. Properties of wood plastic composite panels made from waste sanding dusts and nanoclay. J. Compos. Mater. 2014, 48, 1661–1669. [Google Scholar] [CrossRef]

- Liu, R.; Cao, J.; Luo, S.; Wang, X. Effects of two types of clay on physical and mechanical properties of poly(lactic acid)/wood flour composites at various wood flour contents. J. Appl. Polym. Sci. 2013, 127, 2566–2573. [Google Scholar] [CrossRef]

- Meng, Q.K.; Hetzer, M.; De Kee, D. PLA/clay/wood nanocomposites: Nanoclay effects on mechanical and thermal properties. J. Compos. Mater. 2010, 45, 1145–1158. [Google Scholar] [CrossRef]

- Liu, R.; Chen, Y.; Cao, J. Effects of modifier type on properties of in situ organo-montmorillonite modified wood flour/poly(lactic acid) composites. ACS Appl. Mater. Interfaces 2016, 8, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Qian, X.; Liao, M.; Zhang, W. Surface modification of montmorillonite and application to the preparation of polybutadiene/montmorillonite nanocomposites. Polym. Int. 2007, 56, 399–408. [Google Scholar] [CrossRef]

- Nikkhah, S.J.; Ramazani, S.A.A.; Baniasadi, H.; Tavakolzadeh, F. Investigation of properties of polyethylene/clay nanocomposites prepared by new in situ Ziegler-Natta catalyst. Mater. Des. 2009, 30, 2309–2315. [Google Scholar] [CrossRef]

- Kim, J.W.; Harper, D.P.; Taylor, A.M. Effect of extractives on water sorption and durability of wood-plastic composites. Wood Fiber Sci. 2009, 41, 279–290. [Google Scholar]

- Gregorova, A.; Sedlarik, V.; Pastorek, M.; Jachandra, H.; Stelzer, F. Effect of compatibilizing agent on the properties of highly crystalline composites based on poly(lactic acid) and wood flour and/or mica. J. Polym. Envrion. 2011, 19, 372–381. [Google Scholar] [CrossRef]

- Liao, H.T.; Wu, C.S. Preparation of poly(ethylene-octene) elastomer/clay/wood flour nanocomposites by a melting method. Macromol. Mater. Eng. 2005, 290, 695–703. [Google Scholar] [CrossRef]

- Drozdov, A.D.; deC Christiansen, J.; Gupta, R.K.; Shah, A.P. Model for anomalous moisture diffusion through a polymer-clay nanocomposite. J. Polym. Sci. Pol. Phys. 2003, 41, 476–492. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Yan, N. Crystallization behavior of organo-nanoclay treated and untreated kraft fiber-HDPE composites. Compos. Part B Eng. 2013, 54, 180–187. [Google Scholar] [CrossRef]

| Labels | OMMT (wt %) | PLA (wt %) | WF (wt %) |

|---|---|---|---|

| PLA | 0 | 100 | 0 |

| 0.5/PLA | 0.5 | 99.5 | 0 |

| 1/PLA | 1 | 99 | 0 |

| 1.5/PLA | 1.5 | 98.5 | 0 |

| 2/PLA | 2 | 98 | 0 |

| PLA/WF | 0 | 50 | 50 |

| 0.5/PLA/WF | 0.25 | 49.75 | 50 |

| 1/PLA/WF | 0.5 | 49.5 | 50 |

| 1.5/PLA/WF | 0.75 | 49.25 | 50 |

| 2/PLA/WF | 1 | 49 | 50 |

| Labels | Final Water Uptake (%) | Diffusion Coefficient (×10-10) (m2/s) | Thickness Swelling (%) | Crystallinity (%) |

|---|---|---|---|---|

| PLA | 0.71(0.01) | 1.59(0.04) | 0(0) | 30.0 |

| 0.5/PLA | 0.58(0.02) | 1.38(0.02) | 0(0) | 31.5 |

| 1/PLA | 0.60(0.03) | 1.38(0.07) | 0(0) | 31.9 |

| 1.5/PLA | 0.66(0.03) | 1.46(0.03) | 0(0) | 32.3 |

| 2/PLA | 0.66(0.05) | 1.42(0.02) | 0(0) | 32.7 |

| PLA/WF | 12.22(0.12) | 2.37(0.11) | 12.68(0.58) | 39.6 |

| 0.5/PLA/WF | 9.81(0.08) | 2.12(0.15) | 9.26(0.34) | 40.0 |

| 1/PLA/WF | 9.87(0.20) | 2.00(0.11) | 8.79(0.17) | 39.9 |

| 1.5/PLA/WF | 9.28(0.10) | 1.75(0.09) | 7.36(0.26) | 40.1 |

| 2/PLA/WF | 11.04(0.27) | 2.19(0.13) | 10.68(0.64) | 40.1 |

| Labels | Flexural Strength (MPa) | Flexural Modulus (GPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Impact Strength (J/m2) |

|---|---|---|---|---|---|

| PLA | 33.5(2.4) | 2.54(0.35) | 29.0(1.8) | 1.21(0.05) | 3.4(0.4) |

| 0.5/PLA | 57.2(3.8) | 3.08(0.40) | 43.9(2.2) | 1.29(0.09) | 10.9(2.2) |

| 1/PLA | 42.2(4.5) | 3.59(0.18) | 37.3(1.0) | 1.36(0.05) | 7.3(0.6) |

| 1.5/PLA | 38.9(4.0) | 4.72(0.17) | 35.2(2.1) | 2.13(0.18) | 6.0(0.7) |

| 2/PLA | 38.1(2.0) | 3.49(0.22) | 29.1(0.9) | 1.54(0.20) | 4.8(0.7) |

| PLA/WF | 38.0(1.2) | 6.99(0.23) | 18.7(2.9) | 1.66(0.22) | 2.2(0.7) |

| 0.5/PLA/WF | 40.9(5.4) | 6.80(0.31) | 20.9(3.9) | 2.03(0.15) | 3.6(0.9) |

| 1/PLA/WF | 48.3(4.3) | 7.19(0.81) | 28.5(1.7) | 2.22(0.15) | 3.9(0.5) |

| 1.5/PLA/WF | 55.4(5.9) | 7.40(0.47) | 32.9(2.1) | 2.26(0.10) | 5.5(0.4) |

| 2/PLA/WF | 38.2(3.3) | 7.33(0.44) | 25.1(3.0) | 2.03(0.19) | 3.6(0.4) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Yin, X.; Huang, A.; Wang, C.; Ma, E. Preparation of Organo-Montmorillonite Modified Poly(lactic acid) and Properties of Its Blends with Wood Flour. Polymers 2019, 11, 204. https://doi.org/10.3390/polym11020204

Liu R, Yin X, Huang A, Wang C, Ma E. Preparation of Organo-Montmorillonite Modified Poly(lactic acid) and Properties of Its Blends with Wood Flour. Polymers. 2019; 11(2):204. https://doi.org/10.3390/polym11020204

Chicago/Turabian StyleLiu, Ru, Xiaoqian Yin, Anmin Huang, Chen Wang, and Erni Ma. 2019. "Preparation of Organo-Montmorillonite Modified Poly(lactic acid) and Properties of Its Blends with Wood Flour" Polymers 11, no. 2: 204. https://doi.org/10.3390/polym11020204

APA StyleLiu, R., Yin, X., Huang, A., Wang, C., & Ma, E. (2019). Preparation of Organo-Montmorillonite Modified Poly(lactic acid) and Properties of Its Blends with Wood Flour. Polymers, 11(2), 204. https://doi.org/10.3390/polym11020204