Fabric Composites Reinforced with Thermally Bonded and Irregularly Aligned Filaments: Preparation and Puncture Resistant Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

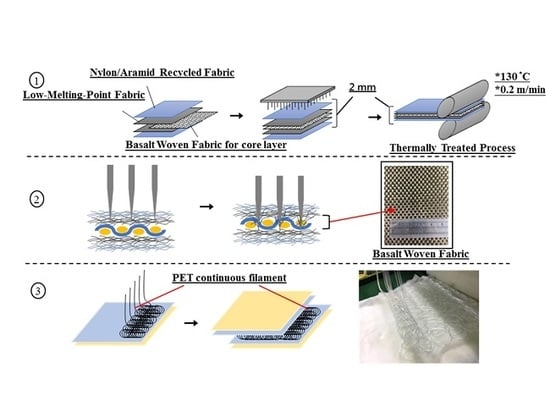

2.2. Preparation of Filament/Woven-Reinforced Fabric Composites

2.3. Tests

2.3.1. Tearing Strength Test

2.3.2. Static Puncture Resistance Test

2.3.3. Dynamic Puncture Resistance Test

3. Results

3.1. Tearing Strength

3.2. Static Puncture Strength

3.3. Dynamic Puncture Strength

3.4. Summary of Comparison

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bartkowiak, G.; Dąbrowska, A.; Marszalek, A. Assessment of an active liquid cooling garment intended for use in a hot environment. Appl. Ergon. 2017, 58, 182–189. [Google Scholar] [CrossRef] [PubMed]

- Małek, E.; Miedzińska, D.; Stankiewicz, M. Heat resistance research and surface analysis of fireproof textiles with titanium silicide coating. Procedia Struct. Integr. 2017, 5, 508–515. [Google Scholar] [CrossRef]

- Silva-Santos, M.C.; Oliveira, M.S.; Giacomin, A.M.; Laktim, M.C.; Baruque-Ramos, J. Flammability on textile of business uniforms: Use of natural fibers. Procedia Eng. 2017, 200, 148–154. [Google Scholar] [CrossRef]

- Xu, Y.; Sheng, J.; Yin, X.; Yu, J.; Ding, B. Functional modification of breathable polyacrylonitrile/polyurethane/TiO2 nanofibrous membranes with robust ultraviolet resistant and waterproof performance. J. Colloid Interface Sci. 2017, 508, 508–516. [Google Scholar] [CrossRef] [PubMed]

- Termonia, Y. Puncture resistance of fibrous structures. Int. J. Impact Eng. 2006, 32, 1512–1520. [Google Scholar] [CrossRef]

- Wang, Q.-S.; Sun, R.-J.; Tian, X.; Yao, M.; Feng, Y. Quasi-static puncture resistance behaviors of high-strength polyester fabric for soft body armor. Results Phys. 2016, 6, 554–560. [Google Scholar] [CrossRef]

- Gürgen, S.; Kuşhan, M.C. The ballistic performance of aramid based fabrics impregnated with multi-phase shear thickening fluids. Polym. Test. 2017, 64, 296–306. [Google Scholar] [CrossRef]

- Barnes, H.A. Shear-Thickening (“Dilatancy”) in Suspensions of Nonaggregating Solid Particles Dispersed in Newtonian Liquids. J. Rheol. 1989, 33, 329–366. [Google Scholar] [CrossRef]

- Hassan, T.A.; Rangari, V.K.; Jeelani, S. Synthesis, processing and characterization of shear thickening fluid (STF) impregnated fabric composites. Mater. Sci. Eng. A 2010, 527, 2892–2899. [Google Scholar] [CrossRef]

- Li, W.; Xiong, D.S.; Zhao, X.S.; Sun, L.L.; Liu, J. Dynamic stab resistance of ultra-high molecular weight polyethylene fabric impregnated with shear thickening fluid. Mater. Des. 2016, 102, 162–167. [Google Scholar] [CrossRef]

- Egres, R.G., Jr.; Halbach, C.J.; Decker, M.J.; Wetzel, E.D.; Wagner, N.J. Stab performance of shear thickening fluid (STF)–fabric composites for body armor applications. In Proceedings of the Society for the Advancement of Material and Process Engineering (SAMPE 2005): New Horizons for Materials and Processing Technologies, Long Beach, CA, USA, 1–5 May 2005. [Google Scholar]

- Decker, M.J.; Halbach, C.J.; Nam, C.H.; Wagner, N.J.; Wetzel, E.D. Stab resistance of shear thickening fluid (STF)-treated fabrics. Compos. Sci. Technol. 2007, 67, 565–578. [Google Scholar] [CrossRef]

- Mayo, J.B., Jr.; Wetzel, E.D.; Hosur, M.V.; Jeelani, S. Stab and puncture characterization of thermoplastic-impregnated aramid fabrics. Int. J. Impact Eng. 2009, 36, 1095–1105. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, X.G.; Wang, Y.L.; Yuan, Z.S. Stabbing resistance of body armour panels impregnated with shear thickening fluid. Compos. Struct. 2017, 163, 465–473. [Google Scholar] [CrossRef]

- Bao, L.M.; Sato, S.; Wang, Y.; Wakatsuki, K.; Morikawa, H. Development of Flexible Stab-proof Textiles Impregnated with Microscopic Particles. J. Text. Eng. 2017, 63, 43–48. [Google Scholar] [CrossRef]

- Baharvandi, H.R.; Alebooyeh, M.; Alizadeh, M.; Heydari, M.S.; Kordani, N.; Khaksari, P. The influences of particle–particle interaction and viscosity of carrier fluid on characteristics of silica and calcium carbonate suspensions-coated Twaron® composite. J. Exper. Nanosci. 2016, 11, 550–563. [Google Scholar] [CrossRef]

- Park, Y.; Kim, Y.H.; Baluch, A.H.; Kim, C.G. Numerical simulation and empirical comparison of the high velocity impact of STF impregnated Aramid fabric using friction effects. Compos. Struct. 2015, 125, 520–529. [Google Scholar] [CrossRef]

- Rao, M.P.; Duan, Y.; Keefe, M.; Powers, B.M.; Bogetti, T.A. Modeling the effects of yarn material properties and friction on the ballistic impact of a plain-weave fabric. Compos. Struct. 2009, 89, 556–566. [Google Scholar] [CrossRef]

- Li, T.-T.; Wang, R.; Lou, C.W.; Lin, J.-Y.; Lin, J.-H. Static and dynamic puncture failure behaviors of 3D needle-punched compound fabric based on Weibull distribution. Text. Res. J. 2014, 84, 1903–1914. [Google Scholar] [CrossRef]

- Li, T.T.; Fang, J.; Huang, C.H.; Lou, C.W.; Lin, J.Y.; Lin, M.C.; Lin, J.H. Numerical simulation of dynamic puncture behaviors of woven fabrics based on the Finite Element Method. Text. Res. J. 2017, 87, 1308–1317. [Google Scholar] [CrossRef]

- Li, T.-T.; Wang, R.; Lou, C.-W.; Lin, J.-H. Acoustic absorption evaluation of high-modulus puncture resistance composites made by recycled selvages. Text. Res. J. 2012, 82, 1597–1611. [Google Scholar] [CrossRef]

- ASTM D5035-11(2015). Standard Test Method for Breaking Force and Elongation of Textile Fabrics; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM F1342. Standard Test Method for Protective Clothing Material Resistance to Puncture; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- NIJ standard 0115.00. Stab Resistance of Personal Body Armor; Office of Law Enforcement Standards, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Li, J.H. Industrial-Grade High-Modulus Composite Geotextiles: Manufacturing Techniques and Property Evaluations. Ph.D. Thesis, Feng Chia University, Taichung City, Taiwan, 2016. [Google Scholar]

| Static Puncture (N) | Dynamic Puncture (N) | |||

|---|---|---|---|---|

| Double-Layered Matrices | Matrix/F/Matrix | Double-Layered Matrices | Matrix/F/Matrix | |

| Commercially Available Geotextiles | ≈ 55.9 | ≈ 35.5 | ||

| Our Sample | 148.4 | 149.4 | 79.0 | 84.8 |

| EN 388:2016 Performance Levels | 3 (100 < * < 150) | 3 (100 < * < 150) | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuang, Y.-C.; Bao, L.; Lin, M.-C.; Lin, T.A.; Lou, C.-W. Fabric Composites Reinforced with Thermally Bonded and Irregularly Aligned Filaments: Preparation and Puncture Resistant Performance. Polymers 2019, 11, 706. https://doi.org/10.3390/polym11040706

Chuang Y-C, Bao L, Lin M-C, Lin TA, Lou C-W. Fabric Composites Reinforced with Thermally Bonded and Irregularly Aligned Filaments: Preparation and Puncture Resistant Performance. Polymers. 2019; 11(4):706. https://doi.org/10.3390/polym11040706

Chicago/Turabian StyleChuang, Yu-Chun, Limin Bao, Mei-Chen Lin, Ting An Lin, and Ching-Wen Lou. 2019. "Fabric Composites Reinforced with Thermally Bonded and Irregularly Aligned Filaments: Preparation and Puncture Resistant Performance" Polymers 11, no. 4: 706. https://doi.org/10.3390/polym11040706

APA StyleChuang, Y. -C., Bao, L., Lin, M. -C., Lin, T. A., & Lou, C. -W. (2019). Fabric Composites Reinforced with Thermally Bonded and Irregularly Aligned Filaments: Preparation and Puncture Resistant Performance. Polymers, 11(4), 706. https://doi.org/10.3390/polym11040706