Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood

Abstract

:1. Introduction

2. Experimental

2.1. Materials

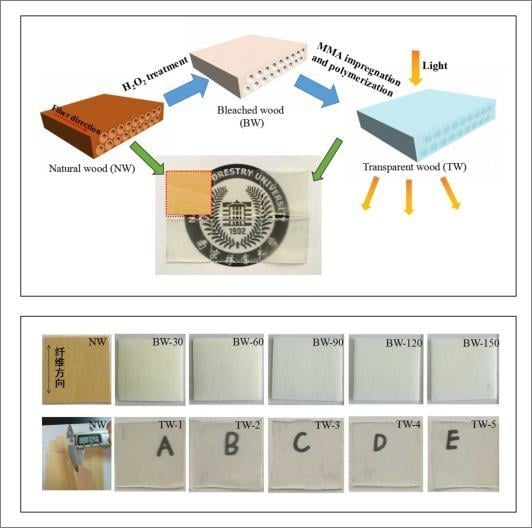

2.2. Fabrication of Transparent Wood

2.3. Chemical Composition Content Analysis

2.4. Fourier Transform Infrared Analysis

2.5. Scanning Electron Microscopy

2.6. Optical Properties

2.7. Mechanical Properties

2.8. Nanoindentation

3. Results and Discussion

3.1. Chemical Composition Content Analysis

3.2. Fourier Transform Infrared Analysis

3.3. Scanning Electron Microscopy

3.4. Optical Properties

3.5. Mechanical Properties

3.6. Nanoindentation

4. Conclusions

Author Contributions

Fundings

Acknowledgments

Conflicts of Interest

References

- Zhao, Z.; Miao, Y.; Yang, Z.; Wang, H.; Sang, R.; Fu, Y.; Huang, C.; Wu, Z.; Zhang, M.; Sun, S.; et al. Effects of sulfuric acid on the curing behavior and bonding performance of tannin-sucrose adhesive. Polymers 2018, 10, 651. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Vasileva, E.; Sychugov, I.; Popov, S.; Berglund, L. Optically Transparent Wood: Recent Progress, Opportunities, and Challenges. Adv. Opt. Mater. 2018, 6, 1800059. [Google Scholar] [CrossRef]

- Yaddanapudi, H.S.; Hickerson, N.; Saini, S.; Tiwari, A. Fabrication and characterization of transparent wood for next generation smart building applications. Vacuum 2017, 146, 649–654. [Google Scholar] [CrossRef]

- Vasileva, E.; Li, Y.; Sychugov, I.; Mensi, M.; Berglund, L.; Popov, S. Lasing from organic dye molecules embedded in transparent wood. Adv. Opt. Mater. 2017, 5, 1700057. [Google Scholar] [CrossRef]

- Li, Y.; Yu, S.; Veinot, J.G.C.; Linnros, J.; Berglund, L.; Sychugov, I. Luminescent transparent wood. Adv. Opt. Mater. 2017, 5, 1600834. [Google Scholar] [CrossRef]

- Lang, A.W.; Li, Y.; Keersmaecker, M.D.; Shen, D.E.; Österholm, A.M.; Berglund, L.; Reynolds, J.R. Transparent Wood Smart Windows: Polymer Electrochromic Devices Based on Poly(3,4-Ethylenedioxythiophene):Poly(Styrene Sulfonate) Electrodes. ChemSusChem 2018, 11, 854–863. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Luo, W.; Pastel, G.; Yang, B.; Hu, L. Wood Composite as an Energy Efficient Building Material: Guided Sunlight Transmittance and Effective Thermal Insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Tang, Q.; Fang, L.; Wang, Y.; Zou, M.; Guo, W. Anisotropic flexible transparent films from remaining wood microstructures for screen protection and AgNW conductive substrate. Nanoscale 2018, 10, 4344–4353. [Google Scholar] [CrossRef]

- Zhu, M.; Li, T.; Davis, C.S.; Yao, Y.; Dai, J.; Wang, Y.; AlQatari, F.; Gilman, J.W.; Hu, L. Transparent and haze wood composites for highly efficient broadband light management in solar cells. Nano Energy 2016, 26, 332–339. [Google Scholar] [CrossRef]

- Fink, S. Transparent wood—A new approach in the functional study of wood structure. Holzforschung 1992, 46, 403–408. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef]

- Qiu, Z.; Xiao, Z.; Gao, L.; Li, J.; Wang, H.; Wang, Y.; Xie, Y. Transparent wood bearing a shielding effect to infrared heat and ultraviolet via incorporation of modified antimony-doped tin oxide nanoparticles. Compos. Sci. Technol. 2019, 172, 43–48. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly anisotropic, highly transparent wood composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, G.; Zhu, J.; Chen, W.; Hu, W.; Liu, Y.; Fang, Z. Preparation, structure and properties of strong, transparent cellulose materials. Chem. J. Chin. Univ. 2018, 39, 196–201. [Google Scholar] [CrossRef]

- Wang, M.; Li, R.; Chen, G.; Zhou, S.; Feng, X.; Chen, Y.; He, M.; Liu, D.; Song, T.; Qi, H. Highly stretchable, transparent and conductive wood fabricated by in-situ photopolymerization with polymerizable deep eutectic solvents. ACS Appl. Mater. Interfaces 2019, 11, 14313–14321. [Google Scholar] [CrossRef] [PubMed]

- Qian, X.; Yu, G.; Liu, H.; An, X. A new way to increase the pulp bleaching efficiency of hydrogen peroxide. Trans. China Pulp Pap. 2002, 17, 36–39. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Rojas, R.; Yan, M.; Lawoko, M.; Berglund, L. A new perspective on transparent wood: Lignin-retaining transparent wood. ChemSusChem 2017, 10, 3445–3451. [Google Scholar] [CrossRef]

- Yan, D.; Liu, M. Hydrogen peroxide bleaching of AS-AQ wheat straw pulp after oxygen delignification. China Pulp Pap. Ind. 2008, 9, 38–41. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP); Technical Report NREL/TP-510-42618; National Renewable Energy Laboratory: Golden, CO, USA, 2011. [Google Scholar]

- Wu, J.; Wu, Y.; Yang, F.; Tang, C.; Huang, Q.; Zhang, J. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, S.; Zhou, D.; Xing, C.; Zhang, Y. Use of Nanoindentation and Silviscan to Determine the Mechanical Properties of 10 Hardwood Species. Wood Fiber Sci. 2009, 41, 64–73. [Google Scholar]

- Wang, X.; Chen, X.; Xie, X.; Wu, Y.; Zhao, L.; Li, Y.; Wang, S. Effects of thermal modification on the physical, chemical and micromechanical properties of Masson pine wood (Pinus massoniana Lamb.). Holzforschung 2018. [Google Scholar] [CrossRef]

- Zhang, N.; Li, S.; Xiong, L.; Hong, Y.; Chen, Y. Cellulose-hemicellulose interaction in wood secondary cell-wall. Model. Simul. Mater. Sci. Eng. 2015, 23, 085010. [Google Scholar] [CrossRef]

- Huang, C.; Su, Y.; Shi, J.; Yuan, C.; Zhai, S.; Yong, Q. Revealing the effects of centuries ageing on the chemically structural features of lignin in archaeological fir woods. New J. Chem. 2019, 43, 3520–3528. [Google Scholar] [CrossRef]

- Huang, C.; He, J.; Du, L.; Min, D.; Yong, Q. Structural Characterization of the Lignins from the Green and Yellow Bamboo of Bamboo Culm (Phyllostachys pubescens). J. Wood Chem. Technol. 2016, 36, 157–172. [Google Scholar] [CrossRef]

- Pang, J.; Liu, Z.; Hui, L.; Jiang, H. Recent Developments of Hydrogen Peroxide Bleaching Technology. Pap. Pap. Mak. 2013, 32, 28–32. [Google Scholar] [CrossRef]

- Wang, L.; Ouyang, T.; Dai, X.; Lu, X.; Liang, H.; Deng, R.; Cheng, F. Preparation of Transparent Cellulose Membrane by Hydrogen Peroxide Bleaching of Cellulose-Rich Materials. For. Eng. 2018, 34, 41–45. [Google Scholar]

- Qu, L.; Zhu, S.; Liu, M.; Wang, S. The mechanism and technology parameters optimization of alkali-H2O2 one-bath cooking and bleaching of hemp. J. Appl. Polym. Sci. 2010, 97, 2279–2285. [Google Scholar] [CrossRef]

- Wang, X.; Chen, J.; Pang, Z.; Yang, G. The Technology of Chlorine Dioxide and Hydrogen Peroxide Bleaching. Shanghai Pap. Mak. 2011, 42, 55–61. [Google Scholar] [CrossRef]

- Li, C.; Knierim, B.; Manisseri, C.; Arora, R.; Scheller, H.V.; Auer, M.; Vogel, K.P.; Simmons, B.A.; Singh, S. Comparison of dilute acid and ionic liquid pretreatment of switchgrass: Biomass recalcitrance, delignification and enzymatic saccharification. Bioresour. Technol. 2010, 101, 4900–4906. [Google Scholar] [CrossRef]

- Xiong, X.; Bao, Y.; Liu, H.; Zhu, Q.; Lu, R.; Miyakoshi, T. Study on mechanical and electrical properties of cellulose nanofibrils/graphene-modified natural rubber. Mater. Chem. Phys. 2019, 223, 535–541. [Google Scholar] [CrossRef]

- Wójciak, A.; Kasprzyk, H.; Sikorska, E.; Khmelinskii, I.; Krawczyk, A.; Oliveira, A.S.; Ferreira, L.F.V.; Sikorski, M. Changes in chromophoric composition of high-yield mechanical pulps due to hydrogen peroxide bleaching under acidic and alkaline conditions. J. Photochem. Photobiol. A 2010, 215, 157–163. [Google Scholar] [CrossRef]

- Gierlinger, N.; Goswami, L.; Schmidt, M.; Burgert, I.; Coutand, C.; Rogge, T.; Schwanninger, M. In Situ FT-IR Microscopic Study on Enzymatic Treatment of Poplar Wood Cross-Sections. Biomacromolecules 2008, 9, 2194–2201. [Google Scholar] [CrossRef] [PubMed]

- Yap, M.G.S.; Que, Y.T.; Chia, L.H.L. FTIR characterization of tropical wood-polymer composites. J. Appl. Polym. Sci. 1991, 43, 2083–2090. [Google Scholar] [CrossRef]

- Yang, W.; Feng, Y.; He, H.; Yang, Z. Environmentally-Friendly Extraction of Cellulose Nanofibers from Steam-Explosion Pretreated Sugar Beet Pulp. Materials 2018, 11, 1160. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhan, T.; Liu, Y.; Shi, J.; Pan, B.; Zhang, Y.; Cai, L.; Shi, S. Large-Size Transparent Wood for Energy-Saving Building Applications. Chem. Sus. Chem. 2018. [Google Scholar] [CrossRef]

- Gan, W.; Xiao, S.; Gao, L.; Gao, R.; Li, J.; Zhan, X. Luminescent and transparent wood composites fabricated by PMMA and γ-Fe2O3@YVO4:Eu3+ nanoparticles impregnation. ACS Sustain. Chem. Eng. 2017, 5, 3855–3862. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yang, X.; Berglund, L. Transparent wood for functional and structural applications. Phil. Trans. R. Soc. A 2018, 376, 20170182. [Google Scholar] [CrossRef]

- Yadav, M.; Chiu, F.-C. Cellulose nanocrystals reinforced-carrageenan based UV resistant transparent bionanocomposite films for sustainable packaging applications. Carbohydr. Polym. 2019, 211, 181–194. [Google Scholar] [CrossRef]

- Jiang, F.; Li, T.; Li, Y.; Zhang, Y.; Gong, A.; Dai, J.; Hitz, E.; Luo, W.; Hu, L. Wood-Based Nanotechnologies toward Sustainability. Adv. Mater. 2017, 30, 1703453. [Google Scholar] [CrossRef] [Green Version]

- Yu, Z.; Yao, Y.; Yao, J.; Zhang, L.; Chen, Z.; Gao, Y.; Luo, H. Transparent wood containing CsxWO3 nanoparticles for heat-shielding window applications. J. Mater. Chem. A 2017, 5, 6019–6024. [Google Scholar] [CrossRef]

- Yano, H.; Hirose, A.; Collins, P.J.; Yazaki, Y. Effects of the removal of matrix substances as a pretreatment in the production of high strength resin impregnated wood based materials. J. Mater. Sci. Lett. 2001, 20, 1125–1126. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, Z.; Fei, B.; Yu, Y.; Zhang, S. Effects of chemical components on longitudinal MOE and hardness of wood cell wall. J. Beijing For. Univ. 2012, 34, 107–110. [Google Scholar]

- Konnerth, J.; Gierlinger, N.; Keckes, J.; Gindl, W. Actual versus apparent within cell wall variability of nanoindentation results from wood cell walls related to cellulose microfibril angle. J. Mater. Sci. 2009, 44, 4399–4406. [Google Scholar] [CrossRef] [Green Version]

- Tze, W.T.Y.; Wang, S.; Rials, T.G.; Pharr, G.M.; Kelley, S.S. Nanoindentation of wood cell walls: Continuous stiffness and hardness measurements. Compos. Part A 2007, 38, 945–953. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Rials, T.G.; Xing, C.; Zhang, Y. Effects of decreasing carbohydrate content on properties of wood strands. Cellulose 2011, 18, 841–850. [Google Scholar] [CrossRef]

- Huang, C.; Tang, S.; Zhang, W.; Tao, Y.; Lai, C.; Li, X.; Yong, Q. Unveiling the structural properties of lignin–carbohydrate complexes in bamboo residues and its functionality as antioxidants and immunostimulants. ACS Sustain. Chem. Eng. 2018, 6, 12522–12531. [Google Scholar] [CrossRef]

| Sample Name | Cellulose Content (%) | Hemicellulose Content (%) | Lignin Content (%) |

|---|---|---|---|

| NW | 48.3 | 17.2 | 24.3 |

| BW-30 | 45.0 | 16.8 | 19.5 |

| BW-60 | 44.4 | 16.5 | 18.4 |

| BW-90 | 44.0 | 16.4 | 16.6 |

| BW-120 | 43.9 | 15.9 | 15.2 |

| BW-150 | 43.5 | 15.7 | 14.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Wu, J.; Yang, F.; Tang, C.; Huang, Q. Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood. Polymers 2019, 11, 776. https://doi.org/10.3390/polym11050776

Wu Y, Wu J, Yang F, Tang C, Huang Q. Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood. Polymers. 2019; 11(5):776. https://doi.org/10.3390/polym11050776

Chicago/Turabian StyleWu, Yan, Jiamin Wu, Feng Yang, Caiyun Tang, and Qiongtao Huang. 2019. "Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood" Polymers 11, no. 5: 776. https://doi.org/10.3390/polym11050776

APA StyleWu, Y., Wu, J., Yang, F., Tang, C., & Huang, Q. (2019). Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood. Polymers, 11(5), 776. https://doi.org/10.3390/polym11050776