Reversible Self-Healing Carbon-Based Nanocomposites for Structural Applications

Abstract

:1. Introduction

2. Material and Methods

2.1. Materials

2.1.1. Preparation of Functionalized MWCNTs

2.1.2. Modification of the Hosting Toughened Matrix

2.1.3. Manufacturing of Multifunctional Self-Healing Nanocomposites

2.2. Methods

2.2.1. Thermo-Mechanical Characterization

2.2.2. Calorimetric Analysis

2.2.3. Thermogravimetric Analysis (TGA)

2.2.4. High-Resolution Transmission Electron Microscopy (HRTEM) Analysis

2.2.5. Electrical Properties

2.2.6. Self-Healing Efficiency

2.2.7. Infrared Spectroscopy Characterization

3. Results and Discussion

3.1. Toughening of the Hosting Epoxy Matrix

3.2. Dynamic Mechanical Analysis (DMA)

3.2.1. Hosting Epoxy Matrix

- the reduced crosslink density highlighted by the decrease in the Tg values increases the chain flexibility and mobility, hence enhancing the ability of the composite to activate autorepair mechanisms;

- the modified epoxy matrix can better interact with self-healing moieties on MWCNTs due to the reduced rigidity of the matrix;

3.2.2. Self-Healing Epoxy Formulation

3.3. Thermal Properties

3.4. Transmission Electron Microscopy (TEM)

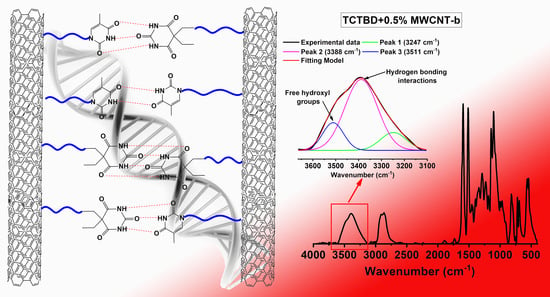

3.5. Infrared Spectroscopy Characterization

3.6. Electrical Properties

3.7. Self-Healing Efficiency

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amendola, E.; Iacono, S.D.; Pastore, A.; Curcio, M.; Iadonisi, A. Epoxy thermosets with self-healing ability. J. Mater. Sci. Chem. Eng. 2015, 3, 162. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Naddeo, C.; Longo, P. Application of self-healing materials in aerospace engineering. In Self-Healing Polymers: From Principles to Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 401–412. [Google Scholar]

- Cho, S.H.; White, S.R.; Braun, P.V. Self-healing polymer coatings. Adv. Mater. 2009, 21, 645–649. [Google Scholar] [CrossRef]

- Chowdhury, R.A.; Hosur, M.V.; Nuruddin, M.; Tcherbi-Narteh, A.; Kumar, A.; Boddu, V.; Jeelani, S. Self-healing epoxy composites: Preparation, characterization and healing performance. J. Mater. Res. Technol. 2015, 4, 33–43. [Google Scholar] [CrossRef]

- Chung, K.; Lee, S.; Park, M.; Yoo, P.; Hong, Y. Preparation and characterization of microcapsule-containing self-healing asphalt. J. Ind. Eng. Chem. 2015, 29, 330–337. [Google Scholar] [CrossRef]

- Everitt, D.T.; Luterbacher, R.; Coope, T.S.; Trask, R.S.; Wass, D.F.; Bond, I.P. Optimisation of epoxy blends for use in extrinsic self-healing fibre-reinforced composites. Polymer 2015, 69, 283–292. [Google Scholar] [CrossRef]

- Guadagno, L.; Longo, P.; Raimondo, M.; Naddeo, C.; Mariconda, A.; Sorrentino, A.; Vittoria, V.; Iannuzzo, G.; Russo, S. Cure behavior and mechanical properties of structural self-healing epoxy resins. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 2413–2423. [Google Scholar] [CrossRef]

- Guadagno, L.; Longo, P.; Raimondo, M.; Naddeo, C.; Mariconda, A.; Vittoria, V.; Iannuzzo, G.; Russo, S. Use of Hoveyda-Grubbs’ second generation catalyst in self-healing epoxy mixtures. Compos. Part B Eng. 2011, 42, 296–301. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Naddeo, C.; Longo, P.; Mariconda, A. Self-healing materials for structural applications. Polym. Eng. Sci. 2014, 54, 777–784. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Naddeo, C.; Longo, P.; Mariconda, A.; Binder, W.H. Healing efficiency and dynamic mechanical properties of self-healing epoxy systems. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vietri, U.; Naddeo, C.; Stojanovic, A.; Sorrentino, A.; Binder, W.H. Evaluation of the Mechanical Properties of Microcapsule-Based Self-Healing Composites. Int. J. Aerosp. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Jin, H.; Hart, K.R.; Coppola, A.M.; Gergely, R.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing epoxies and their composites. In Self-Healing Polymers: From Principles to Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 361–380. [Google Scholar]

- Kessler, M.R.; Sottos, N.R.; White, S.R. Self-healing structural composite materials. Compos. Part A Appl. Sci. Manuf. 2003, 34, 743–753. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Y.; Wang, R. MD simulation of single-wall carbon nanotubes employed as container in self-healing materials. Polym. Polym. Compos. 2011, 19, 333–338. [Google Scholar] [CrossRef]

- Raimondo, M.; De Nicola, F.; Volponi, R.; Binder, W.; Michael, P.; Russo, S.; Guadagno, L. Self-repairing CFRPs targeted towards structural aerospace applications. Int. J. Struct. Integr. 2016, 7, 656–670. [Google Scholar] [CrossRef]

- Raimondo, M.; Guadagno, L. Healing efficiency of epoxy-based materials for structural applications. Polym. Compos. 2013, 34, 1525–1532. [Google Scholar] [CrossRef]

- Raimondo, M.; Longo, P.; Mariconda, A.; Guadagno, L. Healing agent for the activation of self-healing function at low temperature. Adv. Compos. Mater. 2015, 24, 519–529. [Google Scholar] [CrossRef]

- Rule, J.D.; Brown, E.N.; Sottos, N.R.; White, S.R.; Moore, J.S. Wax-protected catalyst microspheres for efficient self-healing materials. Adv. Mater. 2005, 17, 205–208. [Google Scholar] [CrossRef]

- Toohey, K.S.; Hansen, C.J.; Lewis, J.A.; White, S.R.; Sottos, N.R. Delivery of two-part self-healing chemistry via microvascular networks. Adv. Funct. Mater. 2009, 19, 1399–1405. [Google Scholar] [CrossRef]

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.S.; White, S.R. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585. [Google Scholar] [CrossRef] [PubMed]

- Toohey, K.S.; Sottos, N.R.; White, S.R. Characterization of microvascular-based self-healing coatings. Exp. Mech. 2009, 49, 707–717. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. (Oxf.) 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Döhler, D.; Michael, P.; Binder, W. Principles of self-healing polymers. In Self-Healing Polymers: From Principles to Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 5–60. [Google Scholar]

- Yuan, Y.C.; Yin, T.; Rong, M.Z.; Zhang, M.Q. Self healing in polymers and polymer composites. Concepts, realization and outlook: A review. Express Polym. Lett. 2008, 2, 238–250. [Google Scholar] [CrossRef]

- Patrick, J.F.; Robb, M.J.; Sottos, N.R.; Moore, J.S.; White, S.R. Polymers with autonomous life-cycle control. Nature 2016, 540, 363–370. [Google Scholar] [CrossRef]

- White, S.R.; Moore, J.S.; Sottos, N.R.; Krull, B.P.; Santa Cruz, W.A.; Gergely, R.C.R. Restoration of large damage volumes in polymers. Science 2014, 344, 620–623. [Google Scholar] [CrossRef] [PubMed]

- Boulatov, R. Polymer Mechanochemistry; Springer International Publishing: Basel, Switzerland, 2015; Volume 369. [Google Scholar]

- Michael, P.; Biewend, M.; Binder, W.H. Mechanochemical Activation of Fluorogenic CuAAC “Click” Reactions for Stress-Sensing Applications. Macromol. Rapid Commun. 2018, 39. [Google Scholar] [CrossRef] [PubMed]

- Michael, P.; Binder, W.H. A Mechanochemically Triggered “click” Catalyst. Angew. Chem. Int. Ed. 2015, 54, 13918–13922. [Google Scholar] [CrossRef] [PubMed]

- Amamoto, Y.; Otsuka, H.; Takahara, A.; Matyjaszewski, K. Self-healing of covalently cross-linked polymers by reshuffling thiuram disulfide moieties in air under visible light. Adv. Mater. 2012, 24, 3975–3980. [Google Scholar] [CrossRef]

- Brutman, J.P.; Delgado, P.A.; Hillmyer, M.A. Polylactide vitrimers. ACS Macro Lett. 2014, 3, 607–610. [Google Scholar] [CrossRef]

- Campanella, A.; Döhler, D.; Binder, W.H. Self-Healing in Supramolecular Polymers. Macromol. Rapid Commun. 2018, 39. [Google Scholar] [CrossRef]

- Cheng, C.C.; Chang, F.C.; Chen, J.K.; Wang, T.Y.; Lee, D.J. High-efficiency self-healing materials based on supramolecular polymer networks. RSC Adv. 2015, 5, 101148–101154. [Google Scholar] [CrossRef]

- Cromwell, O.R.; Chung, J.; Guan, Z. Malleable and Self-Healing Covalent Polymer Networks through Tunable Dynamic Boronic Ester Bonds. J. Am. Chem. Soc. 2015, 137, 6492–6495. [Google Scholar] [CrossRef]

- Deng, G.; Li, F.; Yu, H.; Liu, F.; Liu, C.; Sun, W.; Jiang, H.; Chen, Y. Dynamic hydrogels with an environmental adaptive self-healing ability and dual responsive Sol-Gel transitions. ACS Macro Lett. 2012, 1, 275–279. [Google Scholar] [CrossRef]

- Deng, W.; You, Y.; Zhang, A. Supramolecular network-based self-healing polymer materials. In Recent Advances in Smart Self-Healing Polymers and Composites; Woodhead Publishing, an imprint of Elsevier: Kidlington, UK, 2015; pp. 181–210. [Google Scholar]

- Denissen, W.; Rivero, G.; Nicolaÿ, R.; Leibler, L.; Winne, J.M.; Du Prez, F.E. Vinylogous urethane vitrimers. Adv. Funct. Mater. 2015, 25, 2451–2457. [Google Scholar] [CrossRef]

- Fortman, D.J.; Brutman, J.P.; Cramer, C.J.; Hillmyer, M.A.; Dichtel, W.R. Mechanically Activated, Catalyst-Free Polyhydroxyurethane Vitrimers. J. Am. Chem. Soc. 2015, 137, 14019–14022. [Google Scholar] [CrossRef]

- Herbst, F.; Döhler, D.; Michael, P.; Binder, W.H. Self-healing polymers via supramolecular forces. Macromol. Rapid Commun. 2013, 34, 203–220. [Google Scholar] [CrossRef]

- Imato, K.; Takahara, A.; Otsuka, H. Self-Healing of a Cross-Linked Polymer with Dynamic Covalent Linkages at Mild Temperature and Evaluation at Macroscopic and Molecular Levels. Macromolecules 2015, 48, 5632–5639. [Google Scholar] [CrossRef]

- Ji, S.; Cao, W.; Yu, Y.; Xu, H. Visible-Light-Induced Self-Healing Diselenide-Containing Polyurethane Elastomer. Adv. Mater. 2015, 27, 7740–7745. [Google Scholar] [CrossRef]

- Lai, J.C.; Mei, J.F.; Jia, X.Y.; Li, C.H.; You, X.Z.; Bao, Z. A Stiff and Healable Polymer Based on Dynamic-Covalent Boroxine Bonds. Adv. Mater. 2016, 8277–8282. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.X.; Zhang, C.; Zhang, H.; Zhao, N.; Yu, Z.X.; Xu, J. Oxime-Based and Catalyst-Free Dynamic Covalent Polyurethanes. J. Am. Chem. Soc. 2017, 139, 8678–8684. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.X.; Guan, Z. Olefin metathesis for effective polymer healing via dynamic exchange of strong carbon-carbon double bonds. J. Am. Chem. Soc. 2012, 134, 14226–14231. [Google Scholar] [CrossRef] [PubMed]

- Michal, B.T.; Jaye, C.A.; Spencer, E.J.; Rowan, S.J. Inherently photohealable and thermal shape-memory polydisulfide networks. ACS Macro Lett. 2013, 2, 694–699. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-like malleable materials from permanent organic networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Obadia, M.M.; Mudraboyina, B.P.; Serghei, A.; Montarnal, D.; Drockenmuller, E. Reprocessing and Recycling of Highly Cross-Linked Ion-Conducting Networks through Transalkylation Exchanges of C-N Bonds. J. Am. Chem. Soc. 2015, 137, 6078–6083. [Google Scholar] [CrossRef] [PubMed]

- Rekondo, A.; Martin, R.; Ruiz De Luzuriaga, A.; Cabañero, G.; Grande, H.J.; Odriozola, I. Catalyst-free room-temperature self-healing elastomers based on aromatic disulfide metathesis. Mater. Horiz. 2014, 1, 237–240. [Google Scholar] [CrossRef]

- Roy, N.; Buhler, E.; Lehn, J.M. Double dynamic self-healing polymers: Supramolecular and covalent dynamic polymers based on the bis-iminocarbohydrazide motif. Polym. Int. 2014, 63, 1400–1405. [Google Scholar] [CrossRef]

- Sordo, F.; Michaud, V. Processing and damage recovery of intrinsic self-healing glass fiber reinforced composites. Smart Mater. Struct. 2016, 25. [Google Scholar] [CrossRef]

- Tian, Q.; Yuan, Y.C.; Rong, M.Z.; Zhang, M.Q. A thermally remendable epoxy resin. J. Mater. Chem. 2009, 19, 1289–1296. [Google Scholar] [CrossRef]

- Xu, W.M.; Rong, M.Z.; Zhang, M.Q. Sunlight driven self-healing, reshaping and recycling of a robust, transparent and yellowing-resistant polymer. J. Mater. Chem. A 2016, 4, 10683–10690. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, R.; Wu, Q.; Chen, T.; Sun, P. Bio-inspired high-performance and recyclable cross-linked polymers. Adv. Mater. 2013, 25, 4912–4917. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Rong, M.Z.; Zhang, M.Q. Self-healing polyurethane elastomer with thermally reversible alkoxyamines as crosslinkages. Polymer 2014, 55, 1782–1791. [Google Scholar] [CrossRef]

- Zhang, Y.; Ying, H.; Hart, K.R.; Wu, Y.; Hsu, A.J.; Coppola, A.M.; Kim, T.A.; Yang, K.; Sottos, N.R.; White, S.R.; et al. Malleable and Recyclable Poly(urea-urethane) Thermosets bearing Hindered Urea Bonds. Adv Mater. 2016, 28, 7646–7651. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.P.; Lu, Y.; Rong, M.Z.; Zhang, M.Q. A thermally remendable and reprocessable crosslinked methyl methacrylate polymer based on oxygen insensitive dynamic reversible C-ON bonds. RSC Adv. 2016, 6, 6350–6357. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Mechanically Robust, Self-Healable, and Highly Stretchable “Living” Crosslinked Polyurethane Based on a Reversible C—C Bond. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Guadagno, L.; Naddeo, C.; Raimondo, M.; Barra, G.; Vertuccio, L.; Sorrentino, A.; Binder, W.H.; Kadlec, M. Development of self-healing multifunctional materials. Compos. Part B Eng. 2017, 128, 30–38. [Google Scholar] [CrossRef]

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Self-healing epoxy nanocomposites via reversible hydrogen bonding. Compos. Part B Eng. 2019, 157, 1–13. [Google Scholar] [CrossRef]

- Varadwaj, P.R.; Varadwaj, A.; Marques, H.M.; Yamashita, K. Significance of hydrogen bonding and other noncovalent interactions in determining octahedral tilting in the CH 3 NH 3 PbI 3 hybrid organic-inorganic halide perovskite solar cell semiconductor. Sci. Rep. 2019, 9, 50. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Vittoria, V.; Vertuccio, L.; Naddeo, C.; Lamberti, P.; Tucci, V.; Russo, S. Epoxy Resin with Low Humidity Content. EU Patent EP2873682A1, 20 May 2015. [Google Scholar]

- Guadagno, L.; Raimondo, M.; Longo, P.; Bonnaud, L.; Murariu, O.; Dubois, P.; Russo, S.; Iannuzzo, G. Multifunctional Epoxy Resin with Enhanced Flame Resistance. EU Patent EP2883896A1, 17 June 2015. [Google Scholar]

- Guadagno, L.; Raimondo, M.; Vietri, U.; Vertuccio, L.; Barra, G.; De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V.; Volponi, R.; et al. Effective formulation and processing of nanofilled carbon fiber reinforced composites. RSC Adv. 2015, 5, 6033–6042. [Google Scholar] [CrossRef]

- Guadagno, L.; Vietri, U.; Raimondo, M.; Vertuccio, L.; Barra, G.; De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V.; De Nicola, F.; et al. Correlation between electrical conductivity and manufacturing processes of nanofilled carbon fiber reinforced composites. Compos. Part B Eng. 2015, 80, 7–14. [Google Scholar] [CrossRef]

- Guadagno, L.; Longo, P.; Mariconda, A.; Calabrese, E.; Raimondo, M.; Naddeo, C.; Vertuccio, L.; Russo, S.; Iannuzzo, G. Grubbs-Hoveyda Type Catalyst for Metathesis Reactions in Highly Reactive Environments. EU Patent EP3141303 (A1), 15 March 2017. [Google Scholar]

- Naddeo, C.; Vertuccio, L.; Barra, G.; Guadagno, L. Nano-charged polypropylene application: Realistic perspectives for enhancing durability. Materials 2017, 10, 943. [Google Scholar] [CrossRef]

- Raimondo, M.; Guadagno, L.; Vertuccio, L.; Naddeo, C.; Barra, G.; Spinelli, G.; Lamberti, P.; Tucci, V.; Lafdi, K. Electrical conductivity of carbon nanofiber reinforced resins: Potentiality of Tunneling Atomic Force Microscopy (TUNA) technique. Compos. Part B Eng. 2018, 143, 148–160. [Google Scholar] [CrossRef]

- Viscardi, M.; Arena, M.; Guadagno, L.; Vertuccio, L.; Barra, G. Multi-functional nanotechnology integration for aeronautical structures performance enhancement. Int. J. Struct. Integr. 2018, 9, 737–752. [Google Scholar] [CrossRef]

- Guadagno, L.; Naddeo, C.; Raimondo, M.; Barra, G.; Vertuccio, L.; Russo, S.; Lafdi, K.; Tucci, V.; Spinelli, G.; Lamberti, P. Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology 2017, 28. [Google Scholar] [CrossRef]

- Huang, Y.; Kinloch, A.J. The toughness of epoxy polymers containing microvoids. Polymer 1992, 33, 1330–1332. [Google Scholar] [CrossRef]

- Saadati, P.; Baharvand, H.; Rahimi, A.; Morshedian, J. Effect of modified liquid rubber on increasing toughness of epoxy resins. Iran. Polym. J. (Engl. Ed.) 2005, 14, 637–646. [Google Scholar]

- Guadagno, L.; Raimondo, M.; Vertuccio, L.; Naddeo, C.; Barra, G.; Longo, P.; Lamberti, P.; Spinelli, G.; Nobile, M.R. Morphological, rheological and electrical properties of composites filled with carbon nanotubes functionalized with 1-pyrenebutyric acid. Compos. Part B Eng. 2018, 147, 12–21. [Google Scholar] [CrossRef]

- Kashiwagi, T. Progress in flammability studies of nanocomposites with new types of nanoparticles. Flame Retard. Polym. Nanocomposites 2007, 10, 285–324. [Google Scholar]

- Taylor, R.; Kennard, O.; Versichel, W. The geometry of the N–H⋯ O=C hydrogen bond. 3. Hydrogen-bond distances and angles. Acta Crystallogr. Sect. B Struct. Sci. 1984, 40, 280–288. [Google Scholar] [CrossRef]

- Apaya, R.P.; Bondí, M.; Price, S.L. The orientation of NH... O=C and NH... N hydrogen bonds in biological systems: How good is a point charge as a model for a hydrogen bonding atom? J. Comput.-Aided Mol. Des. 1997, 11, 479–490. [Google Scholar] [CrossRef] [PubMed]

- Maddams, W. The scope and limitations of curve fitting. Appl. Spectrosc. 1980, 34, 245–267. [Google Scholar] [CrossRef]

- Vertuccio, L.; De Santis, F.; Pantani, R.; Lafdi, K.; Guadagno, L. Effective de-icing skin using graphene-based flexible heater. Compos. Part B Eng. 2019, 162, 600–610. [Google Scholar] [CrossRef]

- Mariconda, A.; Longo, P.; Agovino, A.; Guadagno, L.; Sorrentino, A.; Raimondo, M. Synthesis of ruthenium catalysts functionalized graphene oxide for self-healing applications. Polymer 2015, 69, 330–342. [Google Scholar] [CrossRef]

| Sample | MWCNT Type | MWCNT [%] | CTNB [phr] |

|---|---|---|---|

| TCTBD | MWCNT | 0 | 12.5 |

| TCTBD + 0.5% MWCNT | MWCNT | 0.5 | 12.5 |

| TCTBD + 0.5% MWCNT-b | MWCNT-b | 0.5 | 12.5 |

| TCTBD + 0.5% MWCNT-t | MWCNT-t | 0.5 | 12.5 |

| TCTBD + 2% MWCNT-b | MWCNT-b | 2.0 | 12.5 |

| TCTBD + 2% MWCNT-t | MWCNT-t | 2.0 | 12.5 |

| Sample | Cure Degree DC [%] | ΔHRes [Jg−1] | ΔHT [Jg−1] |

|---|---|---|---|

| TCTBD | 97 | 8.16 | 283.42 |

| TCTBD + 0.5% MWCNT | 89 | 48.48 | 429.32 |

| TCTBD + 0.5% MWCNT-b | 93 | 25.21 | 365.56 |

| TCTBD + 0.5% MWCNT-t | 93 | 30.63 | 415.64 |

| TCTBD + 2% MWCNT-b | 98 | 9.00 | 437.87 |

| TCTBD + 2% MWCNT-t | 95 | 21.22 | 451.45 |

| Sample | % MWCNT | Electrical Conductivity [S/m] |

|---|---|---|

| TCTBD | 1.16 × 10−14 | |

| TCTBD + 0.5%MWCNT | 0.5 | 2.56 × 10−2 |

| TCTBD + 0.5%MWCNT-b | 0.38 | 6.28 × 10−12 |

| TCTBD + 0.5%MWCNT-t | 0.38 | 6.47 × 10−12 |

| TCTBD + 2.0%MWCNT-b | 1.50 | 6.76 × 10−3 |

| TCTBD + 2.0%MWCNT-t | 1.50 | 3.77 × 10−2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Reversible Self-Healing Carbon-Based Nanocomposites for Structural Applications. Polymers 2019, 11, 903. https://doi.org/10.3390/polym11050903

Guadagno L, Vertuccio L, Naddeo C, Calabrese E, Barra G, Raimondo M, Sorrentino A, Binder WH, Michael P, Rana S. Reversible Self-Healing Carbon-Based Nanocomposites for Structural Applications. Polymers. 2019; 11(5):903. https://doi.org/10.3390/polym11050903

Chicago/Turabian StyleGuadagno, Liberata, Luigi Vertuccio, Carlo Naddeo, Elisa Calabrese, Giuseppina Barra, Marialuigia Raimondo, Andrea Sorrentino, Wolfgang H. Binder, Philipp Michael, and Sravendra Rana. 2019. "Reversible Self-Healing Carbon-Based Nanocomposites for Structural Applications" Polymers 11, no. 5: 903. https://doi.org/10.3390/polym11050903

APA StyleGuadagno, L., Vertuccio, L., Naddeo, C., Calabrese, E., Barra, G., Raimondo, M., Sorrentino, A., Binder, W. H., Michael, P., & Rana, S. (2019). Reversible Self-Healing Carbon-Based Nanocomposites for Structural Applications. Polymers, 11(5), 903. https://doi.org/10.3390/polym11050903