Manufacturing and Characterization of Functionalized Aliphatic Polyester from Poly(lactic acid) with Halloysite Nanotubes

Abstract

:1. Introduction

2. Experimental

2.1. Materials

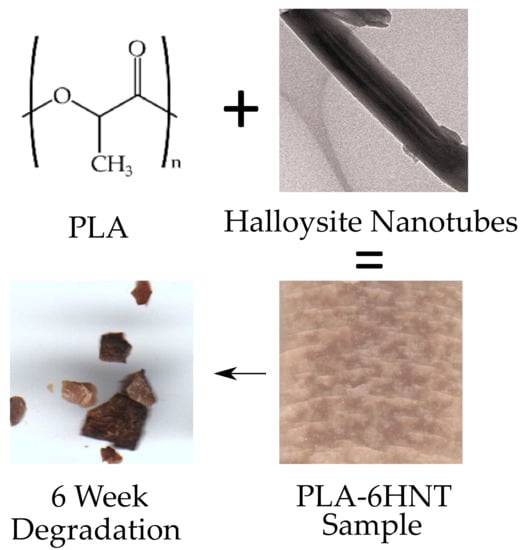

2.2. Manufacturing of PLA/HNTs Composites

2.3. Thermal Characterization

2.4. Mechanical Properties

2.5. Morphology Characterization

2.6. Water Uptake of PLA/HNTs

2.7. Disintegration in Controlled Compost Soil

3. Results and Discussion

3.1. Influence of HNTs Content on Mechanical Performance of PLA/HNTs Biocomposites

3.2. Influence of HNTs Content on Thermal Behaviour of PLA/HNTs Biocomposites

3.3. Study of the Water Uptake of PLA/HNTs Biocomposites

3.4. Disintegration in Controlled Compost Soil of PLA/HNTs Biocomposites

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Andreessen, C.; Steinbuechel, A. Recent developments in non-biodegradable biopolymers: Precursors, production processes, and future perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 143–157. [Google Scholar] [CrossRef] [PubMed]

- Djukic-Vukovic, A.; Mladenovic, D.; Ivanovic, J.; Pejin, J.; Mojovic, L. Towards sustainability of lactic acid and poly-lactic acid polymers production. Renew. Sustain. Energy Rev. 2019, 108, 238–252. [Google Scholar] [CrossRef]

- Matson, J.B.; Baker, M.B. Polymers for biology, medicine and sustainability. Polym. Int. 2019, 68, 1219. [Google Scholar] [CrossRef]

- Fombuena, V.; Sanchez-Nacher, L.; Samper, M.D.; Juarez, D.; Balart, R. Study of the properties of thermoset materials derived from epoxidized soybean oil and protein fillers. J. Am. Oil Chem. Soc. 2013, 90, 449–457. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Bernardi, L.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Development of environmentally friendly composite matrices from epoxidized cottonseed oil. Eur. Polym. J. 2015, 63, 1–10. [Google Scholar] [CrossRef]

- Espana, J.M.; Samper, M.D.; Fages, E.; Sanchez-Nacher, L.; Balart, R. Investigation of the effect of different silane coupling agents on mechanical performance of basalt fiber composite laminates with biobased epoxy matrices. Polym. Compos. 2013, 34, 376–381. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Sutera, F.; Gulino, E.F.; Morreale, M. Degradation and recycling of films based on biodegradable polymers: A short review. Polymers 2019, 11, 651. [Google Scholar] [CrossRef] [PubMed]

- Narayan, R. Biodegradable and biobased plastics: An overview. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Malinconico, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 23–34. [Google Scholar]

- Li, Y.; Chu, Z.; Li, X.; Ding, X.; Guo, M.; Zhao, H.; Yao, J.; Wang, L.; Cai, Q.; Fan, Y. The effect of mechanical loads on the degradation of aliphatic biodegradable polyesters. Regen. Biomater. 2017, 4, 179–190. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Segura Gonzalez, E.A.; Olmos, D.; Angel Lorente, M.; Velaz, I.; Gonzalez-Benito, J. Preparation and characterization of polymer composite materials based on PLA/TiO2 for antibacterial packaging. Polymers 2018, 10, 1365. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liao, C.; Tjong, S.C. Synthetic biodegradable aliphatic polyester nanocomposites reinforced with nanohydroxyapatite and/or graphene oxide for bone tissue engineering applications. Nanomaterials 2019, 9, 590. [Google Scholar] [CrossRef]

- Boronat, T.; Fombuena, V.; Garcia-Sanoguera, D.; Sanchez-Nacher, L.; Balart, R. Development of a biocomposite based on green polyethylene biopolymer and eggshell. Mater. Des. 2015, 68, 177–185. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbo, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. 3D printable filaments made of biobased polyethylene biocomposites. Polymers 2018, 10, 314. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Jorda-Vilaplana, A.; Balart, R.; Garcia-Sanoguera, D. Development and characterization of green composites from bio-based polyethylene and peanut shell. J. Appl. Polym. Sci. 2016, 133, 43940. [Google Scholar] [CrossRef]

- Samper-Madrigal, M.D.; Fenollar, O.; Dominici, F.; Balart, R.; Kenny, J.M. The effect of sepiolite on the compatibilization of polyethylene-thermoplastic starch blends for environmentally friendly films. J. Mater. Sci. 2015, 50, 863–872. [Google Scholar] [CrossRef]

- Yu, X.; Wang, X.; Zhang, Z.; Peng, S.; Chen, H.; Zhao, X. High-performance fully bio-based poly(lactic acid)/polyamide11 (PLA/PA11) blends by reactive blending with multi-functionalized epoxy. Polym. Test. 2019, 78, 105980. [Google Scholar] [CrossRef]

- Gandini, A.; Lacerda, T.M.; Carvalho, A.J.F.; Trovatti, E. Progress of polymers from renewable resources: Furans, vegetable oils, and polysaccharides. Chem. Rev. 2016, 116, 1637–1669. [Google Scholar] [CrossRef] [PubMed]

- Abedini, F.; Ebrahimi, M.; Roozbehani, A.H.; Domb, A.J.; Hosseinkhani, H. Overview on natural hydrophilic polysaccharide polymers in drug delivery. Polym. Adv. Technol. 2018, 29, 2564–2573. [Google Scholar] [CrossRef]

- Rajoka, M.S.R.; Zhao, L.; Mehwish, H.M.; Wu, Y.; Mahmood, S. Chitosan and its derivatives: Synthesis, biotechnological applications, and future challenges. Appl. Microbiol. Biotechnol. 2019, 103, 1557–1571. [Google Scholar] [CrossRef]

- Ferrero, B.; Boronat, T.; Moriana, R.; Fenollar, O.; Balart, R. Green composites based on wheat gluten matrix and posidonia oceanica waste fibers as reinforcements. Polym. Compos. 2013, 34, 1663–1669. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of natural fiber-reinforced plastics (NFRP) based on biobased polyethylene and waste fibers from Posidonia oceanica seaweed. Polym. Compos. 2015, 36, 1378–1385. [Google Scholar] [CrossRef]

- DeFrates, K.; Markiewicz, T.; Gallo, P.; Rack, A.; Weyhmiller, A.; Jarmusik, B.; Hu, X. Protein polymer-based nanoparticles: Fabrication and medical applications. Int. J. Mol. Sci. 2018, 19, 1717. [Google Scholar] [CrossRef] [PubMed]

- Rai, K.; Sun, Y.; Shaliutina-Kolesova, A.; Nian, R.; Xian, M. Proteins: Natural polymers for tissue engineering. J. Biomater. Tissue Eng. 2018, 8, 295–308. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Boronat, T.; Quiles-Carrillo, L.; Balart, R. Melt grafting of sepiolite nanoclay onto poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by reactive extrusion with multi-functional epoxy-based styrene-acrylic oligomer. Eur. Polym. J. 2016, 84, 693–707. [Google Scholar] [CrossRef]

- Haddadi, M.H.; Asadolahi, R.; Negahdari, B. The bioextraction of bioplastics with focus on polyhydroxybutyrate: A review. Int. J. Environ. Sci. Technol. 2019, 16, 3935–3948. [Google Scholar] [CrossRef]

- Zubir, N.H.M.; Sam, S.T.; Zulkepli, N.N.; Omar, M.F. The effect of rice straw particulate loading and polyethylene glycol as plasticizer on the properties of polylactic acid/polyhydroxybutyrate-valerate blends. Polym. Bull. 2018, 75, 61–76. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Garcia-Sanoguera, D.; Fombuena, V.; Lopez-Martine, J.; Balart, R. Improvement of mechanical and thermal properties of poly(3-hydroxybutyrate) (PHB) blends with surface-modified halloysite nanotubes (HNT). Appl. Clay Sci. 2018, 162, 487–498. [Google Scholar] [CrossRef]

- Pramanik, N.; Bhattacharya, S.; Rath, T.; De, J.; Adhikary, A.; Basu, R.K.; Kundu, P.P. Polyhydroxybutyrate-co-hydroxyvalerate copolymer modified graphite oxide based 3D scaffold for tissue engineering application. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 94, 534–546. [Google Scholar] [CrossRef] [PubMed]

- Quiles-Carrillo, L.; Montanes, N.; Jorda-Vilaplana, A.; Balart, R.; Torres-Giner, S. A comparative study on the effect of different reactive compatibilizers on injection-molded pieces of bio-based high-density polyethylene/polylactide blends. J. Appl. Polym. Sci. 2019, 136, 47396. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, H.; Wang, Z.; Li, Q.; Tian, N. Simultaneous enhancement of strength and toughness of PLA induced by miscibility variation with PVA. Polymers 2018, 10, 1178. [Google Scholar] [CrossRef]

- Behera, K.; Sivanjineyulu, V.; Chang, Y.-H.; Chiu, F.-C. Thermal properties, phase morphology and stability of biodegradable PLA/PBSL/HAp composites. Polym. Degrad. Stab. 2018, 154, 248–260. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.M.; Bennani, B.; Dubois, P. Tailoring polylactide (PLA) properties for automotive applications: Effect of addition of designed additives on main mechanical properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Zhang, L.; Lv, S.; Sun, C.; Wan, L.; Tan, H.; Zhang, Y. Effect of MAH-g-PLA on the properties of wood fiber/polylactic acid composites. Polymers 2017, 9, 591. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Yan, C.; Wang, K.; Shi, D.; Liu, Z.; Yang, M. Super-toughed PLA blown film with enhanced gas barrier property available for packaging and agricultural applications. Materials 2019, 12, 1663. [Google Scholar] [CrossRef] [PubMed]

- Radusin, T.; Tomsik, A.; Saric, L.; Ristic, I.; Baschetti, M.G.; Minelli, M.; Novakovic, A. Hybrid Pla/wild garlic antimicrobial composite films for food packaging application. Polym. Compos. 2019, 40, 893–900. [Google Scholar] [CrossRef]

- Lopusiewicz, L.; Jedra, F.; Mizielinska, M. New poly(lactic acid) active packaging composite films incorporated with fungal melanin. Polymers (Basel) 2018, 10, 386. [Google Scholar] [CrossRef] [PubMed]

- Behera, K.; Chang, Y.-H.; Chiu, F.-C.; Yang, J.-C. Characterization of poly(lactic acid)s with reduced molecular weight fabricated through an autoclave process. Polym. Test. 2017, 60, 132–139. [Google Scholar] [CrossRef]

- Mistro Matos, B.D.; Rocha, V.; da Silva, E.J.; Moro, F.H.; Bottene, A.C.; Ribeiro, C.A.; Dias, D.d.S.; Antonio, S.G.; do Amaral, A.C.; Cruz, S.A.; et al. Evaluation of commercially available polylactic acid (PLA) filaments for 3D printing applications. J. Therm. Anal. Calorim. 2019, 137, 555–562. [Google Scholar] [CrossRef]

- Alturkestany, M.T.; Panchal, V.; Thompson, M.R. Improved part strength for the fused deposition 3D printing technique by chemical modification of polylactic acid. Polym. Eng. Sci. 2019, 59, E59–E64. [Google Scholar] [CrossRef]

- Fairag, R.; Rosenzweig, D.H.; Ramirez-Garcialuna, J.L.; Weber, M.H.; Haglund, L. Three-dimensional printed polylactic acid scaffolds promote bone-like matrix deposition in vitro. ACS Appl. Mater. Interfaces 2019, 11, 15306–15315. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Cayla, A.; Campagne, C.; Nierstrasz, V. Morphological and electrical characterization of conductive polylactic acid based nanocomposite before and after FDM 3D printing. J. Appl. Polym. Sci. 2019, 136, 47040. [Google Scholar] [CrossRef]

- Song, B.; Li, W.; Chen, Z.; Fu, G.; Li, C.; Liu, W.; Li, Y.; Qin, L.; Ding, Y. Biomechanical comparison of pure magnesium interference screw and polylactic acid polymer interference screw in anterior cruciate ligament reconstruction—A cadaveric experimental study. J. Orthop. Transl. 2017, 8, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Leksakul, K.; Phuendee, M. Development of hydroxyapatite-polylactic acid composite bone fixation plate. Sci. Eng. Compos. Mater. 2018, 25, 903–914. [Google Scholar] [CrossRef]

- Zhan, X.; Guo, X.; Liu, R.; Hu, W.; Zhang, L.; Xiang, N. Intervention using a novel biodegradable hollow stent containing polylactic acid-polyprolactone-polyethylene glycol complexes against lacrimal duct obstruction disease. PLoS ONE 2017, 12, e0178679. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Murphy, A.; Scholz, D.; Geever, L.M.; Lyons, J.G.; Devine, D.M. Surface-modified halloysite nanotubes reinforced poly(lactic acid) for use in biodegradable coronary stents. J. Appl. Polym. Sci. 2018, 135, 46521. [Google Scholar] [CrossRef]

- Dillon, B.; Doran, P.; Fuenmayor, E.; Healy, A.V.; Gately, N.M.; Major, I.; Lyons, J.G. The influence of low shear microbore extrusion on the properties of high molecular weight poly(l-lactic acid) for medical tubing applications. Polymers 2019, 11, 710. [Google Scholar] [CrossRef] [PubMed]

- Haroosh, H.J.; Dong, Y.; Lau, K.-T. Tetracycline hydrochloride (TCH)-loaded drug carrier based on PLA:PCL nanofibre mats: Experimental characterisation and release kinetics modelling. J. Mater. Sci. 2014, 49, 6270–6281. [Google Scholar] [CrossRef]

- Park, J.W.; Shin, J.H.; Shim, G.S.; Sim, K.B.; Jang, S.W.; Kim, H.J. Mechanical strength enhancement of polylactic acid hybrid composites. Polymers 2019, 11, 349. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Torres, A.; Ferrandiz, M.; Fombuena, V.; Balart, R. Antimicrobial activity of metal cation-exchanged zeolites and their evaluation on injection-molded pieces of bio-based high-density polyethylene. J. Food Saf. 2017, 37, e12348. [Google Scholar] [CrossRef] [Green Version]

- Jamroz, E.; Kulawik, P.; Kopel, P. The effect of nanofillers on the functional properties of biopolymer-based films: A review. Polymers 2019, 11, 675. [Google Scholar] [CrossRef]

- Huang, T.; Qian, Y.; Wei, J.; Zhou, C. Polymeric antimicrobial food packaging and its applications. Polymers 2019, 11, 560. [Google Scholar] [CrossRef]

- Sharmeen, S.; Rahman, A.F.M.M.; Lubna, M.M.; Salem, K.S.; Islam, R.; Khan, M.A. Polyethylene glycol functionalized carbon nanotubes/gelatin-chitosan nanocomposite: An approach for significant drug release. Bioact. Mater. 2018, 3, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Stango, A.X.; Vijayalakshmi, U. Electrochemically grown functionalized-Multi-walled carbon nanotubes/hydroxyapatite hybrids on surgical grade 316L SS with enhanced corrosion resistance and bioactivity. Colloids Surf. B Biointerfaces 2018, 171, 186–196. [Google Scholar]

- Van den Broeck, L.; Piluso, S.; Soultan, A.H.; De Volder, M.; Patterson, J. Cytocompatible carbon nanotube reinforced polyethylene glycol composite hydrogels for tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 98, 1133–1144. [Google Scholar] [CrossRef] [PubMed]

- Osfoori, A.; Selahi, E. Performance analysis of bone scaffolds with carbon nanotubes, barium titanate particles, hydroxyapatite and polycaprolactone. Biomater. Biomech. Bioeng. 2019, 4, 33–44. [Google Scholar]

- Zhang, X.; Zhang, D.; Peng, Q.; Lin, J.; Wen, C. Biocompatibility of nanoscale hydroxyapatite coating on TiO2 nanotubes. Materials 2019, 12, 1979. [Google Scholar] [CrossRef] [PubMed]

- Beke, S.; Barenghi, R.; Farkas, B.; Romano, I.; Koroesi, L.; Scaglione, S.; Brandi, F. Improved cell activity on biodegradable photopolymer scaffolds using titanate nanotube coatings. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 44, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Chandanshive, B.B.; Rai, P.; Rossi, A.L.; Ersen, O.; Khushalani, D. Synthesis of hydroxyapatite nanotubes for biomedical applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 2981–2986. [Google Scholar] [CrossRef]

- Zhang, Y.; Nayak, T.R.; Hong, H.; Cai, W. Biomedical applications of zinc oxide nanomaterials. Curr. Mol. Med. 2013, 13, 1633–1645. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Ferri, J.M.; Ripoll, L.; Hidalgo, M.; Lopez-Martinez, J.; Balart, R. Characterization of selectively etched halloysite nanotubes by acid treatment. Appl. Surf. Sci. 2017, 422, 616–625. [Google Scholar] [CrossRef]

- Venkatesh, C.; Clear, O.; Major, I.; Lyons, J.G.; Devine, D.M. Faster release of lumen-loaded drugs than matrix-loaded equivalent in polylactic acid/halloysite nanotubes. Materials 2019, 12, 1830. [Google Scholar] [CrossRef]

- Pluta, M.; Bojda, J.; Piorkowska, E.; Murariu, M.; Bonnaud, L.; Dubois, P. The effect of halloysite nanotubes and N,N′-ethylenebis (stearamide) on morphology and properties of polylactide nanocomposites with crystalline matrix. Polym. Test. 2017, 64, 83–91. [Google Scholar] [CrossRef]

- Yin, X.; Wang, L.; Li, S.; He, G.; Yang, Z. Effects of surface modification of halloysite nanotubes on the morphology and the thermal and rheological properties of polypropylene/halloysite composites. J. Polym. Eng. 2018, 38, 119–127. [Google Scholar] [CrossRef]

- Padhi, S.; Achary, P.G.R.; Nayak, N.C. Mechanical and morphological properties of modified halloysite nanotube filled ethylene-vinyl acetate copolymer nanocomposites. J. Polym. Eng. 2018, 38, 271–279. [Google Scholar] [CrossRef]

- Gorrasi, G.; Bugatti, V.; Ussia, M.; Mendichi, R.; Zampino, D.; Puglisi, C.; Carroccio, S.C. Halloysite nanotubes and thymol as photo protectors of biobased polyamide 11. Polym. Degrad. Stab. 2018, 152, 43–51. [Google Scholar] [CrossRef]

- Massaro, M.; Cavallaro, G.; Colletti, C.G.; D′Azzo, G.; Guernelli, S.; Lazzara, G.; Pieraccini, S.; Riela, S. Halloysite nanotubes for efficient loading, stabilization and controlled release of insulin. J. Colloid Interface Sci. 2018, 524, 156–164. [Google Scholar] [CrossRef] [PubMed]

- Sikora, J.W.; Gajdos, I.; Puszka, A. Polyethylene-matrix composites with halloysite nanotubes with enhanced physical/thermal properties. Polymers 2019, 11, 787. [Google Scholar] [CrossRef] [PubMed]

- Therias, S.; Murariu, M.; Dubois, P. Bionanocomposites based on PLA and halloysite nanotubes: From key properties to photooxidative degradation. Polym. Degrad. Stab. 2017, 145, 60–69. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Ke, T.Y.; Sun, X.Z. Effects of moisture content and heat treatment on the physical properties of starch and poly(lactic acid) blends. J. Appl. Polym. Sci. 2001, 81, 3069–3082. [Google Scholar] [CrossRef]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of structure of solution grown crystals of lactide copolymers by means of chemical-reactions. Kolloid Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- Li, Y.; Venkateshan, K.; Sun, X.S. Mechanical and thermal properties, morphology and relaxation characteristics of poly(lactic acid) and soy flour/wood flour blends. Polym. Int. 2010, 59, 1099–1109. [Google Scholar] [CrossRef]

- Russo, P.; Cammarano, S.; Bilotti, E.; Peijs, T.; Cerruti, P.; Acierno, D. Physical properties of poly lactic acid/clay nanocomposite films: Effect of filler content and annealing treatment. J. Appl. Polym. Sci. 2014, 131, 39798. [Google Scholar] [CrossRef]

- Prashantha, K.; Lecouvet, B.; Sclavons, M.; Lacrampe, M.F.; Krawczak, P. Poly(lactic acid)/halloysite nanotubes nanocomposites: Structure, thermal, and mechanical properties as a function of halloysite treatment. J. Appl. Polym. Sci. 2013, 128, 1895–1903. [Google Scholar] [CrossRef]

- De Silva, R.T.; Soheilmoghaddam, M.; Goh, K.L.; Wahit, M.U.; Bee, S.A.H.; Chai, S.-P.; Pasbakhsh, P. Influence of the processing methods on the properties of poly(lactic acid)/halloysite nanocomposites. Polym. Compos. 2016, 37, 861–869. [Google Scholar] [CrossRef]

- De Silva, R.T.; Pasbakhsh, P.; Goh, K.L.; Chai, S.P.; Chen, J. Synthesis and characterisation of poly (lactic acid)/halloysite bionanocomposite films. J. Compos. Mater. 2014, 48, 3705–3717. [Google Scholar] [CrossRef]

- Pracella, M.; Haque, M.M.-U.; Puglia, D. Morphology and properties tuning of PLA/cellulose nanocrystals bio-nanocomposites by means of reactive functionalization and blending with PVAc. Polymer 2014, 55, 3720–3728. [Google Scholar] [CrossRef]

- Kontou, E.; Niaounakis, M.; Georgiopoulos, P. Comparative study of PLA nanocomposites reinforced with clay and silica nanofillers and their mixtures. J. Appl. Polym. Sci. 2011, 122, 1519–1529. [Google Scholar] [CrossRef]

- Chen, Y.; Geever, L.M.; Killion, J.A.; Lyons, J.G.; Higginbotham, C.L.; Devine, D.M. Halloysite nanotube reinforced polylactic acid composite. Polym. Compos. 2017, 38, 2166–2173. [Google Scholar] [CrossRef]

- Guo, J.; Qiao, J.; Zhang, X. Effect of an alkalized-modified halloysite on PLA crystallization, morphology, mechanical, and thermal properties of PLA/halloysite nanocomposites. J. Appl. Polym. Sci. 2016, 133, 44272. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Y.; Zhou, C. Nanocomposites of halloysite and polylactide. Appl. Clay Sci. 2013, 75–76, 52–59. [Google Scholar] [CrossRef]

- Tham, W.L.; Poh, B.T.; Ishak, Z.A.M.; Chow, W.S. Thermal behaviors and mechanical properties of halloysite nanotube-reinforced poly(lactic acid) nanocomposites. J. Therm. Anal. Calorim. 2014, 118, 1639–1647. [Google Scholar] [CrossRef]

- Murariu, M.; Doumbia, A.; Bonnaud, L.; Dechief, A.-L.; Paint, Y.; Ferreira, M.; Campagne, C.; Devaux, E.; Dubois, P. High-performance Polylactide/ZnO nanocomposites designed for films and fibers with special end-use properties. Biomacromolecules 2011, 12, 1762–1771. [Google Scholar] [CrossRef] [PubMed]

- Murariu, M.; Dechief, A.-L.; Paint, Y.; Peeterbroeck, S.; Bonnaud, L.; Dubois, P. Polylactide (PLA)-halloysite nanocomposites: Production, morphology and key-properties. J. Polym. Environ. 2012, 20, 932–943. [Google Scholar] [CrossRef]

- Zhu, T.; Qian, C.; Zheng, W.; Bei, R.; Liu, S.; Chi, Z.; Chen, X.; Zhang, Y.; Xu, J. Modified halloysite nanotube filled polyimide composites for film capacitors: High dielectric constant, low dielectric loss and excellent heat resistance. RSC Adv. 2018, 8, 10522–10531. [Google Scholar] [CrossRef]

- Kumar, R.; Yakubu, M.K.; Anandjiwala, R.D. Biodegradation of flax fiber reinforced poly lactic acid. Express Polym. Lett. 2010, 4, 423–430. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J. Appl. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Aguero, A.; Quiles-Carrillo, L.; Jorda-Vilaplana, A.; Fenollar, O.; Montanes, N. Effect of different compatibilizers on environmentally friendly composites from poly(lactic acid) and diatomaceous earth. Polym. Int. 2019, 68, 893–903. [Google Scholar] [CrossRef]

- Paul, M.A.; Delcourt, C.; Alexandre, M.; Degée, P.; Monteverde, F.; Dubois, P. Polylactide/montmorillonite nanocomposites: Study of the hydrolytic degradation. Polym. Degrad. Stab. 2005, 87, 535–542. [Google Scholar] [CrossRef]

| Code | PLA (wt%) | HNTs (wt%) | PVAc (phr) * |

|---|---|---|---|

| PLA | 100 | - | - |

| PLA-3HNT | 97 | 3 | 0.3 |

| PLA-6HNT | 94 | 6 | 0.6 |

| PLA-9HNT | 91 | 9 | 0.9 |

| Code | Tensile | Flexural | Shore D Hardness | Impact Strength (kJ m−2) | |||

|---|---|---|---|---|---|---|---|

| Modulus, Et (MPa) | Strength, σt (MPa) | Elongation at Break (εb%) | Modulus, Ef (MPa) | Strength, σf (MPa) | |||

| PLA | 2086 ± 82 | 64.6 ± 1.6 | 6.1 ± 0.8 | 3570 ± 39 | 116.1 ± 2.1 | 81.7 ± 1.0 | 1.46 ± 0.5 |

| PLA-3HNT | 2097 ± 73 | 59.2 ± 2.6 | 3.7 ± 0.5 | 3701 ± 100 | 105.5 ± 3.9 | 81.0 ± 2.0 | 1.18 ± 0.2 |

| PLA-6HNT | 2160 ± 78 | 58.7 ± 0.7 | 3.9 ± 0.1 | 3918 ± 252 | 110.4 ± 3.4 | 82.0 ± 2.0 | 1.03 ± 0.2 |

| PLA-9HNT | 2311 ± 132 | 57.7 ± 2.4 | 3.3 ± 0.2 | 3927 ± 128 | 107.6 ± 6.8 | 83.2 ± 2.7 | 0.71 ± 0.2 |

| Code | Tg (°C) | Tcc (°C) | ΔHcc (J g−1) | Tm (°C) | ΔHm (J g−1) | Td (°C) | χc_s * (%) | χc_max ** (%) |

|---|---|---|---|---|---|---|---|---|

| PLA | 64.2 ± 3.2 | 112.4 ± 7.9 | 25.1 ± 2.6 | 172.6 ± 13.8 | −33.7 ± 0.6 | 326.2 ± 6.9 | 9.2 ± 0.2 | 36.0 ± 0.8 |

| PLA-3HNT | 64.0 ± 2.7 | 109.6 ± 6.7 | 24.8 ± 3.1 | 172.6 ± 12.0 | −32.3 ± 1.2 | 321.0 ± 18.5 | 8.2 ± 0.3 | 35.6 ± 1.1 |

| PLA-6HNT | 64.6 ± 4.5 | 106.2 ± 10.8 | 23.4 ± 1.2 | 174.0 ± 12.8 | −29.2 ± 1.8 | 323.0 ± 23.7 | 6.6 ± 0.2 | 33.4 ± 0.9 |

| PLA-9HNT | 64.6 ± 4.0 | 105.4 ± 4.5 | 22.7 ± 2.6 | 171.6 ± 6.0 | −28.6 ± 0.7 | 327.1 ± 20.4 | 6.9 ± 0.2 | 33.8 ± 1.0 |

| Code | Max tan δ | ||||

|---|---|---|---|---|---|

| PLA | 1599 | 1455 | 2.10 | 95.26 | 2.621 |

| PLA-3 HNT | 1678 | 1549 | 2.24 | 102.5 | 2.582 |

| PLA-6 HNT | 1731 | 1650 | 2.31 | 109.1 | 2.543 |

| PLA-9 HNT | 1843 | 1756 | 2.70 | 123.7 | 2.382 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montava-Jorda, S.; Chacon, V.; Lascano, D.; Sanchez-Nacher, L.; Montanes, N. Manufacturing and Characterization of Functionalized Aliphatic Polyester from Poly(lactic acid) with Halloysite Nanotubes. Polymers 2019, 11, 1314. https://doi.org/10.3390/polym11081314

Montava-Jorda S, Chacon V, Lascano D, Sanchez-Nacher L, Montanes N. Manufacturing and Characterization of Functionalized Aliphatic Polyester from Poly(lactic acid) with Halloysite Nanotubes. Polymers. 2019; 11(8):1314. https://doi.org/10.3390/polym11081314

Chicago/Turabian StyleMontava-Jorda, Sergi, Victor Chacon, Diego Lascano, Lourdes Sanchez-Nacher, and Nestor Montanes. 2019. "Manufacturing and Characterization of Functionalized Aliphatic Polyester from Poly(lactic acid) with Halloysite Nanotubes" Polymers 11, no. 8: 1314. https://doi.org/10.3390/polym11081314

APA StyleMontava-Jorda, S., Chacon, V., Lascano, D., Sanchez-Nacher, L., & Montanes, N. (2019). Manufacturing and Characterization of Functionalized Aliphatic Polyester from Poly(lactic acid) with Halloysite Nanotubes. Polymers, 11(8), 1314. https://doi.org/10.3390/polym11081314