High-Repetition-Rate Femtosecond Laser Processing of Acrylic Intra-Ocular Lenses

Abstract

:1. Introduction

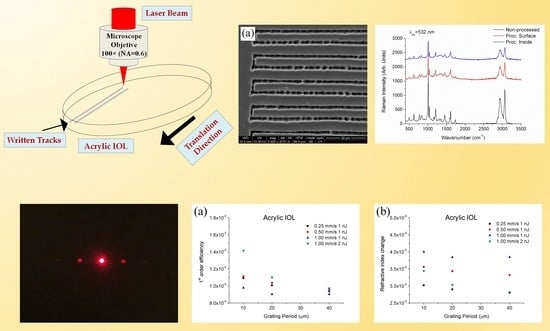

2. Experimental

2.1. Laser Processing

2.2. Characterization Techniques

3. Results

3.1. Ultrafast Laser Inscription of Diffraction Gratings

3.2. Microstructural and Compositional Characterization

3.3. Optical Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rubinstein, M.; Colby, R.H. Polymer Physics, 1st ed.; Oxford University Press Inc.: New York, NY, USA, 2003. [Google Scholar]

- Schnabel, W. Polymers and Light; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2007. [Google Scholar]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Polymer-matrix Nanocomposites, processing, manufacturing, and application: An overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Jou, J.H.; Kumar, S.; Agrawal, A.; Li, T.H.; Sahoo, S. Approaches for fabricating high efficiency organic light emitting diodes. J. Mater. Chem. C 2015, 3, 2974–3002. [Google Scholar] [CrossRef]

- Behl, M.; Razzaq, M.Y.; Lendlein, A. Multifunctional shape-memory polymers. Adv. Mater. 2010, 22, 3388–3410. [Google Scholar] [CrossRef] [PubMed]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic-inorganic nanocomposites—A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Scholz, C. Polymers for Biomedicine: Synthesis, Characterization and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Deligkaris, K.; Tadele, T.S.; Olthuis, W.; van den Berg, A. Hydrogel devices for biomedical applications. Sens. Actuators B 2010, 147, 765–774. [Google Scholar] [CrossRef]

- Hunter, A.C.; Moghimi, M.S. Smart polymers in drug delivery: A biological perspective. Polym. Chem. 2017, 8, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Calo, E.; Khutoryanskiy, V.V. Biomedical applications of hydrogels: A review of patents and commercial products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef] [Green Version]

- Maulvi, F.A.; Soni, T.G.; Sha, D.O. A review on therapeutic contact lenses for ocular drug delivery. Drug Deliv. 2016, 23, 3017–3026. [Google Scholar] [CrossRef]

- Hassler, C.; Boretius, T.; Stieglitz, T. Polymers for Neural Implants. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 18–33. [Google Scholar] [CrossRef]

- Allen, N.S. Photochemistry and Photophysics of Polymeric Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Culbertson, C.T.; Mickleburgh, T.G.; Stewart-James, S.A.; Sellens, K.A.; Pressnall, M. Micro total analysis systems: Fundamental advances and biological applications. Anal. Chem. 2014, 86, 95–118. [Google Scholar] [CrossRef] [Green Version]

- Deepak, K.L.N.; Rao, S.V.; Rao, D.N. Femtosecond laser-fabricated microstructures in bulk poly(methylmethacrylate) and poly(dimethylsiloxane) at 800 nm towards lab-on-a-chip applications. Pramana J. Phys. 2010, 75, 1221–1232. [Google Scholar] [CrossRef]

- Ni, M.; Tong, W.H.; Choudhury, D.; Rahim, N.A.A.; Iliescu, C.; Yu, H. Cell Culture on MEMS platforms: A review. Int. J. Mol. Sci. 2009, 12, 5411–5441. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suriano, R.; Kuznetsov, A.; Eaton, S.M.; Kiyan, R.; Cerullo, G.; Osellame, R.; Chichkov, B.N.; Levi, M.; Turri, S. Femtosecond laser ablation of polymeric substrates for the fabrication of microfluidic channels. Appl. Surf. Sci. 2011, 257, 6243–6250. [Google Scholar] [CrossRef]

- Narayana, L.; Kallepalli, D.; Soma, V.R.; Desai, N.R. Femtosecond-laser direct writing in polymers and potential applications in microfluidics and memory devices. Opt. Eng. 2012, 51, 073402. [Google Scholar]

- Kallepalli, D.L.N.; Desai, N.R.; Soma, V.R. Fabrication and optical characterization of microstructures in poly(methylmethacrylate) and poly(dimethylsiloxane) using femto second pulses for photonic and microfluidic applications. Appl. Opt. 2010, 49, 2475–2489. [Google Scholar] [CrossRef] [Green Version]

- Eaton, S.M.; de Marco, C.; Martinez-Vazquez, R.; Ramponi, R.; Turri, S.; Cerullo, G.; Osellame, R. Femtosecond laser microstructuring for polymeric lab-on-chips. J. Biophotonics 2012, 5, 687–702. [Google Scholar] [CrossRef]

- Belluchi, R. An introduction to intraocular lenses: Material, optics, haptics, design and aberration. Cataract 2013, 3, 38–55. [Google Scholar]

- Misawa, H.; Juodkazis, S. 3D Laser Microfabrication; Wiley-VCH Verlag: Weinheim, Germany, 2006. [Google Scholar]

- Osellame, R.; Cerullo, G.; Ramponi, R. Femtosecond Laser Micromachining, Photonic and Microfluidic Devices in Transparent Materials; Springer: Heidelberg, Germany, 2012. [Google Scholar]

- Sola, D.; Escartin, A.; Cases, R.; Peña, J.I. Crystal growth induced by Nd: YAG laser irradiation in patterning glass ceramic substrates with dots. Opt. Mater. 2011, 33, 728–734. [Google Scholar] [CrossRef]

- Davis, K.M.; Miura, K.; Sugimoto, N.; Hirao, K. Writing waveguides in glass with a femtosecond laser. Opt. Lett. 1996, 21, 1729–1731. [Google Scholar] [CrossRef]

- Nolte, S.; Will, M.; Burghoff, J.; Tuennermann, A. Femtosecond waveguide writing: A new avenue to three-dimensional integrated optics. Appl. Phys. A 2003, 77, 109–111. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Juodkazis, S.; Misawa, H.; Luther-Davies, B.; Rode, A.V.; Hallo, L.; Nicolai, P.; Tikhonchuk, V.T. Formation of nano-voids in transparent dielectrics by femtosecond laser. Curr. Appl. Phys. 2008, 8, 412–415. [Google Scholar] [CrossRef]

- Sola, D.; Martinez de Mendibil, J.; Vazquez de Aldana, J.R.; Lifante, G.; Balda, R.; de Aza, A.H.; Pena, P.; Fernandez, J. Stress-induced buried waveguides in the 0.8CaSiO3-0.2Ca3(PO4)2 eutectic glass doped with Nd3+ ions. Appl. Surf. Sci. 2013, 278, 289–294. [Google Scholar] [CrossRef]

- Martinez de Mendivil, J.; Sola, D.; Vazquez de Aldana, J.R.; Lifante, G.; de Aza, A.H.; Pena, P.; Peña, J.I. Ultrafast direct laser writing of cladding waveguides in the 0.8CaSiO3-0.2Ca3(PO4)2 eutectic glass doped with Nd3+ ions. J. Appl. Phys. 2015, 117, 043104. [Google Scholar] [CrossRef]

- Chen, F.; Vazquez de Aldana, J.R. Optical waveguides in crystalline dielectric materials produced by femtosecond-laser micromachining. Laser Photonics Rev. 2014, 8, 251–275. [Google Scholar] [CrossRef]

- Zoubir, A.; Lopez, C.; Richardson, M.; Richarson, K. Femtosecond laser fabrication of tubular waveguides in poly (methyl methacrylate). Opt. Lett. 2004, 29, 1840–1842. [Google Scholar] [CrossRef]

- Ding, L.; Blackwell, R.; Künzler, J.F.; Knox, W.H. Large refractive index change in silicone-based and non-silicone-based hydrogel polymers induced by femtosecond laser micro-machining. Opt. Express 2006, 14, 11901–11909. [Google Scholar] [CrossRef]

- Ding, L.; Blackwell, R.I.; Künzler, J.F.; Knox, W.H. Femtosecond laser micromachining of waveguides in silicone-based hydrogel polymers. Appl. Opt. 2008, 47, 3100–3108. [Google Scholar] [CrossRef]

- Xu, L.; Knox, W.H. Lateral gradient index microlenses written in ophthalmic hydrogel polymers by femtosecond laser machining. Opt. Mater. Express 2011, 1, 1416–1424. [Google Scholar] [CrossRef]

- Gandara-Montano, G.A.; Ivansky, A.; Savage, D.E.; Ellis, J.D.; Knox, W.H. Femtosecond laser writing of freeform gradient index microlenses in hydrogel-based contact lenses. Opt. Mater. Express 2015, 5, 2258–2271. [Google Scholar] [CrossRef]

- Srinivasan, R.; Mayne-Banton, V. Self-developing photoetching of poly(ethylene terephthalate) films by far-ultraviolet excimer laser radiation. Appl. Phys. Lett. 1982, 41, 576–578. [Google Scholar] [CrossRef]

- Kawamura, Y.; Toyoda, K.; Namba, S. Effective deep ultraviolet photoetching of polymethyl methacrylate by an excimer laser. Appl. Phys. Lett. 1982, 40, 374–375. [Google Scholar] [CrossRef]

- Srinivasan, V.; Smrtic, M.A.; Badu, S.V. Excimer laser etching of polymers. J. Appl. Phys. 1986, 59, 3861–3867. [Google Scholar] [CrossRef]

- Srinivasan, R.; Braren, B.; Casey, K.G. Nature of incubation pulses in the ultraviolet laser ablation of polymethyl methacrylate. J. Appl. Phys. 1990, 68, 1842–1847. [Google Scholar] [CrossRef]

- Cain, S.R.; Burns, F.C.; Otis, C.E. On single-photon ultraviolet ablation of polymeric materials. J. Appl. Phys. 1992, 71, 4107–4116. [Google Scholar] [CrossRef]

- Blanchet, G.B.; Cotts, P.; Fincher, C.R. Incubation: Subthreshold ablation of poly- (methyl methacrylate) and the nature of the decomposition pathways. J. Appl. Phys. 2000, 88, 2975–2978. [Google Scholar] [CrossRef]

- Sola, D.; Lavieja, C.; Orera, A.; Clemente, M.J. Direct laser interference patterning of ophthalmic polydimethylsiloxane (PDMS) polymers. Opt. Lasers Eng. 2018, 106, 139–146. [Google Scholar] [CrossRef]

- Sola, D.; Alamri, S.; Lasagni, A.F.; Artal, P. Fabrication and characterization of diffraction gratings in ophthalmic polymers by using UV direct laser interference patterning. Appl. Surf. Sci. 2019, 476, 128–135. [Google Scholar] [CrossRef]

- Behar-Cohen, F.; Baillet, G.; de Ayguavives, T.; Ortega Garcia, P.; Krutmann, J.; Peña-García, C.; Reme, C.; Wolffsohn, J.S. Ultraviolet damage to the eye revisited: Eye-sun protection factor (E-SPF®), a new ultraviolet protection label for eyewear. Clin. Ophthalmol. 2014, 8, 87–104. [Google Scholar] [CrossRef] [Green Version]

- Rohde, M.; Hemberger, F.; Bauer, T.; Blumm, J.; Fend, T.; Häusler, T.; Hammerschmidt, U.; Hohenauer, W.; Jaenicke-Rössler, K.; Kaschnitz, E.; et al. Intercomparison of thermal diffusivity measurements on CuCrZr and PMMA. High Temp. High Press. 2013, 42, 469–474. [Google Scholar]

- Willis, H.; Zichy, V.; Hendra, P. The laser-Raman and infra-red spectra of poly (methyl methacrylate). Polymer 1969, 10, 737–746. [Google Scholar] [CrossRef]

- Pallikari, F.; Chondrokoukis, G.; Rebelakis, M.; Kotsalas, Y. Raman spectroscopy: A technique for estimating extent of polymerization in PMMA. Mater. Res. Innov. 2001, 4, 89–92. [Google Scholar] [CrossRef]

- Thomas, K.J.; Sheeba, M.; Nampoori, V.P.N.; Vallabhan, C.P.G.; Radhakrishnan, P. Raman spectra of polymethyl methacrylate optical fibres excited by a 532 nm diode pumped solid state laser. J. Opt. Apure Appl. Opt. 2008, 10, 055303. [Google Scholar] [CrossRef]

- Rusciano, G.; Capaccio, A.; Pesce, G.; Sasso, A. Experimental study of the mechanisms leading to the formation of glistenings in intraocular lenses by Raman spectroscopy. Biomed. Opt. Express 2019, 10, 1870–1881. [Google Scholar] [CrossRef]

- Mailis, S.; Anderson, A.A.; Barrington, S.J.; Brocklesby, W.S.; Greef, R.; Rutt, H.N.; Eason, R.W.; Vainos, N.A.; Grivas, G. Photosensitivity of lead germanate glass waveguides grown by pulsed laser deposition. Opt. Lett. 1998, 23, 1751–1753. [Google Scholar] [CrossRef] [PubMed]

- Park, J.K.; Cho, S.H. Flexible gratings fabricated in polymeric plate using femtosecond laser irradiation. Opt. Lasers Eng. 2011, 49, 589–593. [Google Scholar] [CrossRef]

- Scully, P.J.; Jones, D.; Jaroszynski, D.A. Femtosecond laser irradiation of polymethylmethacrylate for refractive index gratings. J. Opt. A Pure Appl. Opt. 2003, 5, S92–S96. [Google Scholar] [CrossRef]

- Cho, S.H.; Chang, W.S.; Kim, K.R.; Hong, J.W. Femtosecond laser embedded grating micromachining of flexible PDMS plates. Opt. Commun. 2009, 282, 317–1321. [Google Scholar] [CrossRef]

- Watanabe, W.; Matsuda, K.; Hirono, S.; Mochizuki, H. Writing Speed Dependency of Femtosecond Laser Refractive Index Modification in Poly (dimethylsiloxane). J. Laser Micro Nanoeng. 2012, 7, 171–175. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sola, D.; Cases, R. High-Repetition-Rate Femtosecond Laser Processing of Acrylic Intra-Ocular Lenses. Polymers 2020, 12, 242. https://doi.org/10.3390/polym12010242

Sola D, Cases R. High-Repetition-Rate Femtosecond Laser Processing of Acrylic Intra-Ocular Lenses. Polymers. 2020; 12(1):242. https://doi.org/10.3390/polym12010242

Chicago/Turabian StyleSola, Daniel, and Rafael Cases. 2020. "High-Repetition-Rate Femtosecond Laser Processing of Acrylic Intra-Ocular Lenses" Polymers 12, no. 1: 242. https://doi.org/10.3390/polym12010242

APA StyleSola, D., & Cases, R. (2020). High-Repetition-Rate Femtosecond Laser Processing of Acrylic Intra-Ocular Lenses. Polymers, 12(1), 242. https://doi.org/10.3390/polym12010242