The Potential of Graphene Nanoplatelets in the Development of Smart and Multifunctional Ecocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Flax Fabrics Pretreatment

2.2.2. Optimization of the GNPs’ Polymeric Formulations

2.2.3. Ground State Diffuse Reflectance and CIELAB Color Coordinates

2.3. Samples Characterization

2.3.1. Thermogravimetric (TGA)

2.3.2. Raman Spectroscopy

2.3.3. Field Emission Scanning Electron Microscopy (FESEM)

2.4. Multifunctional Properties’ Evaluation

2.4.1. Water Contact Angle Measurement (WCA)

2.4.2. UV Protection

2.4.3. Electrical Conductivity

2.4.4. Piezoresistive Tests

3. Results

3.1. TGA

3.2. Raman Spectroscopy

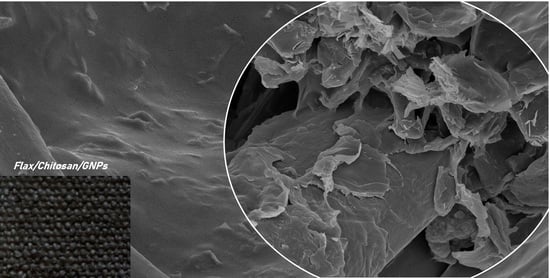

3.3. Field Emission Scanning Electron Microscopy (FESEM)

3.4. Electrical Properties

3.5. Multifunctional Properties: UV Protection and Water Repellency Behavior

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Costa, S.M.; Ferreira, D.P.; Ferreira, A.; Vaz, F.; Fangueiro, R. Multifunctional Flax Fibres Based on the Combined Effect of Silver and Zinc Oxide (Ag/ZnO) Nanostructures. Nanomater 2018, 8, 1069. [Google Scholar] [CrossRef] [Green Version]

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Zhang, K.; Dai, X.-X.; Li, Y.; Guo, J.; Liu, H.; Li, G.-H.; Tan, Y.-J.; Zeng, J.-B.; Guo, Z. Enhanced electrical conductivity and piezoresistive sensing in multi-wall carbon nanotubes/polydimethylsiloxane nanocomposites via the construction of a self-segregated structure. Nanoscale 2017, 9, 11017–11026. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef] [PubMed]

- Giesz, P.; Mackiewicz, E.; Nejman, A.; Celichowski, G.; Cieślak, M. Investigation on functionalization of cotton and viscose fabrics with AgNWs. Cellulose 2017, 24, 409–422. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, D.P.; Ferreira, A.; Fangueiro, R. Searching for Natural Conductive Fibrous Structures via a Green Sustainable Approach Based on Jute Fibers and Silver Nanoparticles. Polymers 2018, 10, 63. [Google Scholar] [CrossRef] [Green Version]

- Lund, A.; van der Velden, N.M.; Persson, N.-K.; Hamedi, M.M.; Müller, C. Electrically conducting fibres for e-textiles: An open playground for conjugated polymers and carbon nanomaterials. Mater. Sci. Eng. R Rep. 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Cataldi, P.; Athanassiou, A.; Bayer, S.I. Graphene Nanoplatelets-Based Advanced Materials and Recent Progress in Sustainable Applications. Appl. Sci. 2018, 8, 1438. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, E.; Oxfall, H.; Wandelt, W.; Rychwalski, R.; Hagström, B. Melt spinning of conductive textile fibers with hybridized graphite nanoplatelets and carbon black filler. J. Appl. Polym. Sci. 2013, 130, 2579–2587. [Google Scholar] [CrossRef]

- Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Prolongo, S.G.; Ureña, A. Graphene nanoplatelets coated glass fibre fabrics as strain sensors. Compos. Sci. Technol. 2017, 146, 59–64. [Google Scholar] [CrossRef]

- Souri, H.; Bhattacharyya, D. Wearable strain sensors based on electrically conductive natural fiber yarns. Mater. Des. 2018, 154, 217–227. [Google Scholar] [CrossRef]

- Mohan, V.B.; Bhattacharyya, D. Mechanical characterization of functional graphene nanoplatelets coated natural and synthetic fiber yarns using polymeric binders. Int. J. Smart Nano Mater. 2020, 11, 78–91. [Google Scholar] [CrossRef] [Green Version]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly Stretchable and Wearable Graphene Strain Sensors with Controllable Sensitivity for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef] [PubMed]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-Performance Graphene-Based Natural Fiber Composites. ACS Appl. Mater. Interfaces 2018, 10, 34502–34512. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, D.P.; Conceição, D.S.; Calhelha, R.C.; Sousa, T.; Socoteanu, R.; Ferreira, I.C.F.R.; Vieira Ferreira, L.F. Porphyrin dye into biopolymeric chitosan films for localized photodynamic therapy of cancer. Carbohydr. Polym. 2016, 151, 160–171. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Majeti, N.V. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Wang, T.; Ouyang, Z.; Wang, F.; Liu, Y. A review on graphene strain sensors based on fiber assemblies. SN Appl. Sci. 2020, 2, 862. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Kruse, B. Revised Kubelka—Munk theory. I. Theory and application. J. Opt. Soc. Am. 2004, 21, 1933–1941. [Google Scholar] [CrossRef]

- Gonçalves, B. Desenvolvimento de uma Matriz de Sensores Piezoresistivos Baseados em Técnicas de Impressão; University of Minho: Braga, Portugal, 2015. [Google Scholar]

- Yang, S.; Lu, N. Gauge factor and stretchability of silicon-on-polymer strain gauges. Sensors 2013, 13, 8577–8594. [Google Scholar] [CrossRef] [Green Version]

- Costa, P.; Ribeiro, S.; Lanceros-Mendez, S. Mechanical vs. electrical hysteresis of carbon nanotube/styrene-butadiene-styrene composites and their influence in the electromechanical response. Compos. Sci. Technol. 2015, 109, 1–5. [Google Scholar] [CrossRef]

- Bishay, A.G.; El-Gamal, S. Effect of γ-irradiation on the gauge factor of two-dimensional island platinum films. Radiat. Phys. Chem. 2012, 81, 740–744. [Google Scholar] [CrossRef]

- Tanevska, V.; Colomban, P.; Minčeva-Šukarova, B.; Grupče, O. Characterization of pottery from the Republic of Macedonia I: Raman analyses of Byzantine glazed pottery excavated from Prilep and Skopje (12th–14th century). J. Raman Spectrosc. 2009, 40, 1240–1248. [Google Scholar] [CrossRef]

- Corazzari, I.; Nisticò, R.; Turci, F.; Faga, M.G.; Franzoso, F.; Tabasso, S.; Magnacca, G. Advanced physico-chemical characterization of chitosan by means of TGA coupled on-line with FTIR and GCMS: Thermal degradation and water adsorption capacity. Polym. Degrad. Stab. 2015, 112, 1–9. [Google Scholar] [CrossRef]

- Thanakkasaranee, S.; Kim, D.; Seo, J. Preparation and Characterization of Poly (ether-block-amide)/Polyethylene Glycol Composite Films with Temperature-Dependent Permeation. Polymers 2018, 10, 225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmad, I.; Joseph, E.; McCarthy, A.B.; Gun’ko, Y.K. Development of Graphene Nano-Platelet Based Counter Electrodes for Solar Cells. Materials 2015, 8, 5953–5973. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, D.P.; Costa, S.M.; Felgueiras, H.P.; Fangueiro, R. Smart and Sustainable Materials for Military Applications Based on Natural Fibres and Silver Nanoparticles. Key Eng. Mater. 2019, 812, 66–74. [Google Scholar] [CrossRef]

- Saidina, D.S.; Zubir, S.A.; Fontana, S.; Hérold, C.; Mariatti, M. Synthesis and Characterization of Graphene-Based Inks for Spray-Coating Applications. J. Electron. Mater. 2019, 48, 5757–5770. [Google Scholar] [CrossRef]

- Al-Madeed, M.A.; Ponnamma, D.; Khanam, P.N. Electrical Properties of Graphene Polymer Nanocomposites. Springer 2015. [Google Scholar] [CrossRef]

- Jun, Y.S.; Um, J.G.; Jiang, G.; Yu, A. A study on the effects of graphene nano-platelets (GnPs) sheet sizes from a few to hundred microns on the thermal, mechanical, and electrical properties of polypropylene (PP)/GnPs composites. Express Polym. Lett. 2018, 12, 885–897. [Google Scholar] [CrossRef]

- Zheng, N.; Wang, L.; Wang, H.; Gao, J.; Dong, X.; Mai, Y.W. Conductive graphite nanoplatelets (GNPs)/polyethersulfone (PES) composites with inter-connective porous structure for chemical vapor sensing. Compos. Sci. Technol. 2019, 184, 1–27. [Google Scholar] [CrossRef]

- Ferreira, A.J.B. Development of a pressure Sensor Network System for Static and dynamic Pressure Measurements: Application to the limb/Prosthesis Pressure Mapping; University of Minho: Braga, Portugal, 2014. [Google Scholar]

- Ferrreira, A.; Rocha, J.G.; Ansón-Casaos, A.; Martínez, M.T.; Vaz, F.; Lanceros-Mendez, S. Electromechanical performance of poly(vinylidene fluoride)/carbon nanotube composites for strain sensor applications. Sens. Actuators A Phys. 2012, 178, 10–16. [Google Scholar] [CrossRef]

- Costa, P.; Silva, J.; Sencadas, V.; Simoes, R.; Viana, J.C.; Lanceros-Méndez, S. Mechanical, electrical and electro-mechanical properties of thermoplastic elastomer styrene-butadiene-styrene/multiwall carbon nanotubes composites. J. Mater. Sci. 2013, 48, 1172–1179. [Google Scholar] [CrossRef] [Green Version]

- Gupta, A.; Kumar, A. Chemical properties of natural fiber composites and mechanisms of chemical modifications. Asian J. Chem. 2012, 24, 1831–1836. [Google Scholar]

- Mondal, S.; Hu, J.L. A Novel Approach to Excellent UV Protecting Cotton Fabric with Functionalized MWNT Containing Water Vapor Permeable PU Coating. J. Appl. Polym. Sci. 2007, 103, 3370–3376. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S. Characterization of electrical heating textile coated by graphene nanoplatelets/PVDF-HFP composite with various high graphene nanoplatelet contents. Polymers 2019, 11, 928. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Tian, M.; Qu, L.; Zhu, S.; Han, G. Multifunctional cotton fabrics with graphene/polyurethane coatings with far-infrared emission, electrical conductivity, and ultraviolet-blocking properties. Carbon N. Y. 2015, 95, 625–633. [Google Scholar] [CrossRef]

- Tissera, N.D.; Wijesena, R.N.; Perera, J.R.; De Silva, K.M.N.; Amaratunge, G.A.J. Hydrophobic cotton textile surfaces using an amphiphilic graphene oxide (GO) coating. Appl. Surf. Sci. 2015, 324, 455–463. [Google Scholar] [CrossRef]

- Benyahia, A.; Merrouche, A.; Rokbi, M.; Kouadri, Z. Study the effect of alkali treatment of natural fibers on the mechanical behavior of the composite unsaturated Polyester-fiber Alfa. 21ème Congrès Français de Mécanique 2013, 21, 1–6. [Google Scholar] [CrossRef]

- Jia, G.; Plentz, J.; Dellith, J.; Dellith, A.; Wahyuono, R.A.; Andrä, G. Large area graphene deposition on hydrophobic surfaces, flexible textiles, glass fibers and 3D structures. Coatings 2019, 9, 183. [Google Scholar] [CrossRef] [Green Version]

- Prolongo, S.G.; Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Ureña, A. Advantages and disadvantages of the addition of graphene nanoplatelets to epoxy resins. Eur. Polym. J. 2014, 61, 206–214. [Google Scholar] [CrossRef]

| Flax | FlaxCPG | FlaxCPG + 0.1% | FlaxCPG + 0.5% | FlaxCPG + 1% | FlaxCPG + 2% | |

|---|---|---|---|---|---|---|

| Lightness parameter | L* | L* | L* | L* | L* | L* |

| Measurement 1 | 52.1 | 51.69 | 48.53 | 36.35 | 37.77 | 34.17 |

| Measurement 2 | 51.7 | 50.95 | 48.95 | 37.36 | 37.27 | 34.97 |

| Measurement 3 | 50.23 | 43.74 | 53.95 | 38.86 | 36.87 | 33.19 |

| Measurement 4 | 53.27 | 48.98 | 54.58 | 36.83 | 36.95 | 32.98 |

| Measurement 5 | 53.66 | 52.39 | 42.68 | 36.56 | 35.74 | 34.68 |

| Mean | 52.2 | 49.7 | 49.6 | 37.2 | 36.9 | 33.9 |

| Standard deviation | 1.2 | 3.1 | 4.3 | 0.9 | 0.7 | 0.8 |

| Samples | Electrical Conductivity (S m−1) | Error |

|---|---|---|

| Flax | - | - |

| FlaxCPG | 3.0 × 10−6 | ±4.0 × 10−7 |

| FlaxCPG + 0.1% | 2.0 × 10−5 | ±3.8 × 10−6 |

| FlaxCPG + 0.5% | 1.0 × 10−4 | ±1.7 × 10−5 |

| FlaxCPG + 1% | 1.8 × 10−3 | ±1.0 × 10−4 |

| FlaxCPG + 2% | 4.0 × 10−2 | ±2.0 × 10−3 |

| Samples | GF | Error |

|---|---|---|

| FlaxCPG | 1.45 | 0.06 |

| FlaxCPG + 0.1% | 1.85 | 0.07 |

| FlaxCPG + 0.5% | 1.89 | 0.10 |

| FlaxCPG + 1% | 1.33 | 0.05 |

| FlaxCPG + 2% | 1.08 | 0.12 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, P.; Ferreira, D.P.; Araújo, J.C.; Ferreira, A.; Fangueiro, R. The Potential of Graphene Nanoplatelets in the Development of Smart and Multifunctional Ecocomposites. Polymers 2020, 12, 2189. https://doi.org/10.3390/polym12102189

Pereira P, Ferreira DP, Araújo JC, Ferreira A, Fangueiro R. The Potential of Graphene Nanoplatelets in the Development of Smart and Multifunctional Ecocomposites. Polymers. 2020; 12(10):2189. https://doi.org/10.3390/polym12102189

Chicago/Turabian StylePereira, Pedro, Diana P. Ferreira, Joana C. Araújo, Armando Ferreira, and Raul Fangueiro. 2020. "The Potential of Graphene Nanoplatelets in the Development of Smart and Multifunctional Ecocomposites" Polymers 12, no. 10: 2189. https://doi.org/10.3390/polym12102189

APA StylePereira, P., Ferreira, D. P., Araújo, J. C., Ferreira, A., & Fangueiro, R. (2020). The Potential of Graphene Nanoplatelets in the Development of Smart and Multifunctional Ecocomposites. Polymers, 12(10), 2189. https://doi.org/10.3390/polym12102189