Preparation and Characterization of Semi-Flexible Substrates from Natural Fiber/Nickel Oxide/Polycaprolactone Composite for Microstrip Patch Antenna Circuitries for Microwave Applications

Abstract

:1. Introduction

2. Materials and Fabrication Process

2.1. Materials

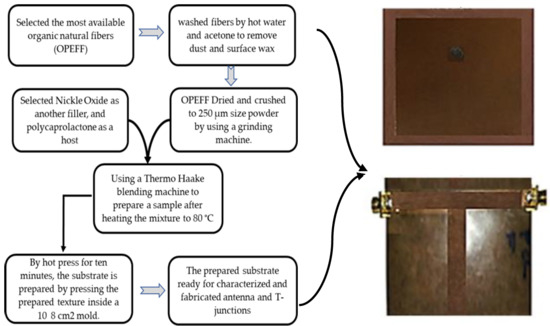

2.2. Substrates Fabrication

2.3. Substrates Characterization

2.4. Electromagnetic Properties of Substrates

2.5. S-Parameters Measurement

3. Microstrip Patch Antennas and Transmission Line Structure Manufacturing

3.1. Microstrip Patch Antenna Structure Manufacturing

3.2. Transmission Line Structure Manufacturing

4. Results and Discussion

4.1. X-ray Diffraction

4.2. Fourier Transforms Infrared (FT-IR) Spectroscopy

4.3. Thermal Analysis (DTG and TGA) Properties of Materials

4.4. Structural Characterization of the Prepared Substrates

4.5. Dielectric Properties of Fabricated Substrates

4.6. Comparison Between S-Parameters Measurement and Simulation

4.7. Antenna Performance Measurement

4.7.1. Return Loss (R.L.)

4.7.2. Radiation Pattern

5. Conclusions and Future Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ullah, M.H.; Islam, M.T. A new metasurface reflective structure for simultaneous enhancement of antenna bandwidth and gain. Smart Mater. Struct. 2014, 23, 085015. [Google Scholar] [CrossRef]

- Panda, P.K.; Ghosh, D. Isolation and gain enhancement of patch antennas using EMNZ superstrate. AEU Int. J. Electron. Commun. 2018, 86, 164–170. [Google Scholar] [CrossRef]

- Vahdati, A.; Parandin, F. Antenna Patch Design Using a Photonic Crystal Substrate at a Frequency of 1.6 THz. Wirel. Pers. Commun. 2019, 109, 2213–2219. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Aziz, S.A.; Obaiys, S.J.; Zaid, M.H.M.; Matori, K.A.; Samikannu, K.; Aliyu, U.S.A. Biodegradable Poly (lactic acid)/Poly (ethylene glycol) Reinforced Multi-Walled Carbon Nanotube Nanocomposite Fabrication, Characterization, Properties, and Applications. Polymers 2020, 12, 427. [Google Scholar] [CrossRef] [Green Version]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, M.; Kumar, S.; Mohapatra, S.K. Properties of glass-fiber hybrid composites: A review. Polym. Plast. Technol. Eng. 2017, 56, 455–469. [Google Scholar] [CrossRef]

- Fu, S.Y.; Yue, C.Y.; Hu, X.; Mai, Y.W. On the elastic stress transfer and longitudinal modulus of unidirectional multi-short-fiber composites. Compos. Sci. Technol. 2000, 60, 3001–3012. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- TG, Y.G.; MR, S.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. Sci. 2019, 6, 226. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Abbas, Z.; Obaiys, S.J.; Ibrahim, N.; Hashim, M.; Khaleel, H. Theoretical and Numerical Approaches for Determining the Reflection and Transmission Coefficients of OPEFB-PCL Composites at X-Band Frequencies. PLoS ONE 2015, 10, e0140505. [Google Scholar] [CrossRef]

- Kozlowski, R.; Wladyka-Przybylak, M. Uses of natural fiber reinforced plastics. In Natural Fibers, Plastics and Composites; Springer: Boston, MA, USA, 2004; pp. 249–274. [Google Scholar] [CrossRef]

- Sharma, P.R.; Chattopadhyay, A.; Zhan, C.; Sharma, S.K.; Geng, L.; Hsiao, B.S. Lead removal from water using carboxy cellulose nanofibers prepared by the nitro-oxidation method. Cellulose 2018, 25, 1961–1973. [Google Scholar] [CrossRef]

- Sharma, P.R.; Joshi, R.; Sharma, S.K.; Hsiao, B.S. A simple approach to prepare carboxycellulose nanofibers from untreated biomass. Biomacromolecules 2017, 18, 2333–2342. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Sharma, S.K.; Sharma, P.R.; Yeh, H.; Johnson, K.; Hsiao, B.S. Arsenic (iii) removal by nanostructured dialdehyde cellulose–cysteine microscale and nanoscale fibers. ACS Omega 2019, 4, 22008–22020. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, P.R.; Sharma, S.K.; Antoine, R.; Hsiao, B.S. Efficient removal of arsenic using zinc oxide nanocrystal-decorated regenerated microfibrillated cellulose scaffolds. ACS Sustain. Chem. Eng. 2019, 7, 6140–6151. [Google Scholar] [CrossRef]

- Khamis, A.M.; Abbas, Z.; Ahmad, A.F.; Abdalhadi, D.M.; Mensah, E.E. Experimental and computational study on epoxy resin reinforced with micro-sized OPEFB using rectangular waveguide and finite element method. IET Microw. Antennas Propag. 2020, 14, 752–758. [Google Scholar] [CrossRef]

- Sarker, F.; Potluri, P.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Karim, N. Ultrahigh Performance of Nanoengineered Graphene-Based Natural Jute Fiber Composites. ACS Appl. Mater. Interfaces 2019, 11, 21166–21176. [Google Scholar] [CrossRef]

- Islam, M.T.; Ullah, M.H.; Singh, M.J.; Faruque, M.R.I. A new metasurface superstrate structure for antenna performance enhancement. Materials 2013, 6, 3226–3240. [Google Scholar] [CrossRef] [Green Version]

- Abbas, M.; Buntinx, M.; Deferme, W.; Peeters, R. (Bio) polymer/ZnO nanocomposites for packaging applications: A review of gas barrier and mechanical properties. Nanomaterials 2019, 9, 1494. [Google Scholar] [CrossRef] [Green Version]

- Kamau-Devers, K.; Kortum, Z.; Miller, S.A. Hydrothermal aging of bio-based poly (lactic acid) (PLA) wood polymer composites: Studies on sorption behavior, morphology, and heat conductance. Constr. Build Mater. 2019, 214, 290–302. [Google Scholar] [CrossRef]

- Parandeh, S.; Kharaziha, M.; Karimzadeh, F. An eco-friendly triboelectric hybrid nanogenerators based on graphene oxide incorporated polycaprolactone fibers and cellulose paper. Nano Energy 2019, 59, 412–421. [Google Scholar] [CrossRef]

- Ghosal, K.; Chandra, A.; Praveen, G.; Snigdha, S.; Roy, S.; Agatemor, C.; Thomas, S.; Provaznik, I. Electrospinning over solvent casting: Tuning of mechanical properties of membranes. Sci. Rep. 2018, 8, 5058. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fahad Ahmad, A.; Abbas, Z.; Shaari, A.H.J.; Obaiys, S.; Sa’ad Aliyu, U. Synthesis, thermal, dielectric, and microwave reflection loss properties of nickel oxide filler with natural fiber-reinforced polymer composite. J. Appl. Polym. Sci. 2019, 136, 46998. [Google Scholar] [CrossRef]

- Patil, V.P.; Pawar, S.; Chougule, M.; Godse, P.; Sakhare, R.; Sen, S.; Joshi, P. Effect of annealing on structural, morphological, electrical and optical studies of nickel oxide thin films. J. Surf. Eng. Mater. Adv. Technol. 2011, 1, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Yadav, M.; Mishra, D.K.; Hwang, J.S. Catalytic hydrogenation of xylose to xylitol using ruthenium catalyst on NiO modified TiO2 support. Appl. Catal. A Gen. 2012, 425, 110–116. [Google Scholar] [CrossRef]

- Danjumma, S.G.; Abubakar, Y.; Suleiman, S. Nickel Oxide (NiO) Devices and Applications: A Review. J. Eng. Res. Technol. 2019, 8, 12–21. [Google Scholar]

- Kakumani, A.D.; Ruthramurthy, B.; Wong, H.Y.; Ong, B.H.; Tan, K.B.; Yow, H.K. Microstructure and Dielectric Properties of Nickel-Doped Ba0.7Sr0.3TiO3 Ceramics Fabricated by Sol gel Method. Int. J. Appl. Ceram. Technol. 2016, 13, 177–184. [Google Scholar] [CrossRef]

- Siyamak, S.; Ibrahim, N.A.; Abdolmohammadi, S.; Yunus, W.M.Z.W.; Rahman, M.Z.A. Effect of fiber esterification on fundamental properties of oil palm empty fruit bunch fiber/poly (butylene adipate-co-terephthalate) biocomposites. Int. J. Mol. Sci. 2012, 13, 1327–1346. [Google Scholar] [CrossRef] [Green Version]

- Wong, S.; Shanks, R.; Hodzic, A. Interfacial improvements in poly (3-hydroxybutyrate)-flax fibre composites with hydrogen bonding additives. Compos. Sci. Technol. 2004, 64, 1321–1330. [Google Scholar] [CrossRef]

- Tomlal, E.J.; Thomas, P.C.; George, K.C.; Jayanarayanan, K.; Joseph, K. Impact, tear, and dielectric properties of cotton/polypropylene commingled composites. J. Reinf. Plast. Compos. 2010, 29, 1861–1874. [Google Scholar] [CrossRef]

- Aba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T.; Hassan, A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J. Reinf. Plast. Compos. 2016, 35, 447–470. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Abbas, Z.; Obaiys, S.J.; Ibrahim, N.A.; Zainuddin, M.F.; Salem, A. Permittivity Properties of Nickel Zinc Ferrite-Oil Palm Empty Fruit Bunch-Polycaprolactone Composite. Procedia Chem. 2016, 19, 603–610. [Google Scholar] [CrossRef] [Green Version]

- George, G.; Joseph, K.; Nagarajan, E.R.; Jose, E.T.; George, K.C. Dielectric behaviour of PP/jute yarn commingled composites: Effect of fibre content, chemical treatments, temperature and moisture. Compos. Part A Appl. Sci. Manuf. 2013, 47, 12–21. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, Z.; Mao, F.; Yang, C.; Yang, J.; Zhu, X.; Zuo, H. Polymer composites with balanced dielectric constant and loss via constructing trilayer architecture. J. Mater. Sci. 2018, 53, 13230–13242. [Google Scholar] [CrossRef]

- Hasar, U.C.; Simsek, O. An accurate complex permittivity method for thin dielectric materials. Prog. Elect. Res. 2009, 91, 123–138. [Google Scholar] [CrossRef] [Green Version]

- Narayanan, P.M. Microstrip transmission line method for broadband permittivity measure-ment of dielectric substrates. IEEE Trans. Microw. Theory Tech. 2014, 62, 2784–2790. [Google Scholar] [CrossRef]

- Kumar, G.A.; Sarath, I.B.A. Design and Simulation of EU Slot Microstrip Patch Antenna for Broadband Applications. Int. J. Eng. Sci. 2016, 6, 3593–3595. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Ab Aziz, S.; Abbas, Z.; Obaiys, S.J.; Khamis, A.M.; Hussain, I.R.; Zaid, M.H.M. Preparation of a chemically reduced graphene oxide reinforced epoxy resin polymer as a composite for electromagnetic interference shielding and microwave-absorbing applications. Polymers 2018, 10, 1180. [Google Scholar] [CrossRef] [Green Version]

- Gehrman, O.; El Yaghoobi, M.; El Maanaoui, H.; Meier, J. Lifetime prediction of simple shear loaded filled elastomers based on the probability distribution of particles. Polym. Test. 2019, 75, 229–236. [Google Scholar] [CrossRef]

- Rayung, M.; Ibrahim, N.A.; Zainuddin, N.; Saad, W.Z.; Razak, N.I.A.; Chieng, B.W. The effect of fiber bleaching treatment on the properties of poly (lactic acid)/oil palm empty fruit bunch fiber composites. Int. J. Mol. 2014, 15, 14728–14742. [Google Scholar] [CrossRef] [Green Version]

- Hamid, M.Z.A.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Zaman, K.; Dahlan, M. Effect of grafting on properties of oil palm empty fruit bunch fiber reinforced polycaprolactone biocomposites. J. Reinf. Plast. Compos. 2010, 29, 2723–2731. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Ahmad, S.N.A.; Yunus, W.M.Z.W.; Dahlan, K.Z.M. Effect of electron beam irradiation and poly (vinyl pyrrolidone) addition on mechanical properties of polycaprolactone with empty fruit bunch fibre (OPEFB) composite. Express Polym. 2009, 3, 226–234. [Google Scholar] [CrossRef]

- Yang, J.; Ching, Y.C.; Chuah, C.H. Applications of lignocellulosic fibers and lignin in bioplastics: A review. Polymers 2019, 11, 751. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dorez, G.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J.M. Thermal and fire behavior of natural fibers/PBS biocomposites. Polym. Degrad. Stab. 2013, 98, 87–95. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S.; Rahman, M.R.; Bakri, M.B. Comparative study of dielectric properties of hybrid natural fiber composites. Procedia Eng. 2014, 97, 536–544. [Google Scholar] [CrossRef] [Green Version]

- Abdel-karim, A.M.; Salama, A.H.; Hassan, M.L. Electrical conductivity and dielectric properties of nanofibrillated cellulose thin films from bagasse. J. Phys. Org. Chem. 2018, 31, e3851. [Google Scholar] [CrossRef]

- Abdalhadi, D.M.; Abbas, Z.; Ahmad, A.F.; Ibrahim, N.A. Determining the complex permittivity of oil palm empty fruit bunch fibre material by open-ended coaxial probe technique for microwave applications. Bioresources 2017, 12, 3976–3991. [Google Scholar] [CrossRef] [Green Version]

- Dimitriadis, A.I.; Debogović, T.; Favre, M.; Billod, M.; Barloggio, L.; Ansermet, J.P.; De Rijk, E. Polymer-based additive manufacturing of high-performance waveguide and antenna components. Proc. IEEE 2016, 105, 668–676. [Google Scholar] [CrossRef]

- Chan, Y.L.; You, K.Y.; Mayzan, M.Z.H.; Jusoh, M.A.; Abbas, Z.; Esa, F. Investigation into Return Loss Characteristic of Graphene Oxide/Zinc Ferrite/epoxy composite at X-band frequency. J. Appl. Sci. Eng. 2020, 23, 593–602. [Google Scholar] [CrossRef]

- Tong, X.C. Advanced Materials and Design for Electromagnetic Interference Shielding; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Cao, Y.; Cai, Y.; Cao, W.; Xi, B.; Qian, Z.; Wu, T.; Zhu, L. Broadband and high-gain microstrip patch antenna loaded with parasitic mushroom-type structure. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1405–1409. [Google Scholar] [CrossRef]

| NiO wt. % | OPEFF wt. % | PCL wt. % |

|---|---|---|

| - | 12.2 | 87.8 |

| 12.2 | - | 87.8 |

| 25 | 25 | 50 |

| Dimensions | (mm) |

|---|---|

| Thickness of substrate | 4.35 |

| Thickness of patch | 0.05 |

| Patch feed line | 4.4 |

| Patch size (L × W) | 62 × 62 |

| Substrates Content | Return Loos (RL) dB | Resonance Frequency GHz |

|---|---|---|

| 12.2 wt. % OPEFF/87.8 wt. % PCL | −11.93 | 1.79 |

| 12.2 wt. % NiO/87.8 wt. % PCL | −14.2 | 1.80 |

| 25 wt. % OPEFF/25 wt. % NiO/50 wt. % PCL | −16.3 | 1.724 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.F.; Aziz, S.A.; Yaakob, Y.; Abd Ali, A.; Issa, N.A. Preparation and Characterization of Semi-Flexible Substrates from Natural Fiber/Nickel Oxide/Polycaprolactone Composite for Microstrip Patch Antenna Circuitries for Microwave Applications. Polymers 2020, 12, 2400. https://doi.org/10.3390/polym12102400

Ahmad AF, Aziz SA, Yaakob Y, Abd Ali A, Issa NA. Preparation and Characterization of Semi-Flexible Substrates from Natural Fiber/Nickel Oxide/Polycaprolactone Composite for Microstrip Patch Antenna Circuitries for Microwave Applications. Polymers. 2020; 12(10):2400. https://doi.org/10.3390/polym12102400

Chicago/Turabian StyleAhmad, Ahmad Fahad, Sidek Ab Aziz, Yazid Yaakob, Ammar Abd Ali, and Nour Attallah Issa. 2020. "Preparation and Characterization of Semi-Flexible Substrates from Natural Fiber/Nickel Oxide/Polycaprolactone Composite for Microstrip Patch Antenna Circuitries for Microwave Applications" Polymers 12, no. 10: 2400. https://doi.org/10.3390/polym12102400

APA StyleAhmad, A. F., Aziz, S. A., Yaakob, Y., Abd Ali, A., & Issa, N. A. (2020). Preparation and Characterization of Semi-Flexible Substrates from Natural Fiber/Nickel Oxide/Polycaprolactone Composite for Microstrip Patch Antenna Circuitries for Microwave Applications. Polymers, 12(10), 2400. https://doi.org/10.3390/polym12102400