Currently, in the production of plastics, there is an obvious trend towards innovation and environmental friendliness of products [

1,

2]. Medicine [

3,

4] and packaging industry [

5] are some of the numerous industries where various plastics are in demand. At the same time, the problem of environmental pollution is aggravated every year, including the consumption of these materials [

6], therefore, the direction of biodegradable polymers is actively developing—polymers, capable of rapid biodegradation under the influence of environmental factors and microorganisms and having properties similar to traditional polymers [

7].

According to the report of European Bioplastics (EUBP, Germany) and nova-Institut (Germany) “Bio-based Building Blocks and Polymers—Global Capacities, Production and Trends 2019–2024”, the world market for all types of polymers in 2019 amounted to 478 million tons, while the share of bioplastics produced was approximately 1%. According to experts, the world capacity for the production of biopolymers will reach about 2.43 million tons per year by 2024, which is 15.2% more compared to 2019 [

8]. One of the widely known and promising bioplastics is polybutylene adipate terephthalate (PBAT). In the segment of biodegradable materials in 2019, the share of PBAT was 13.4%. According to experts from European Bioplastics (EUBP, Germany) and nova-Institut (Germany), production capacities for the production of bioplastics increased in 2018–2019 due to the expansion of the production of PBAT [

8]. PBAT refers to aliphatic-aromatic copolyesters, produced as the result of polycondensation between 1,4-butanediol, adipic acid, and terephthalic acid [

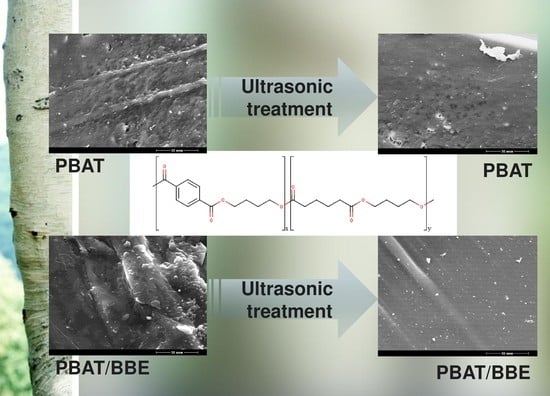

9]. The structure of the PBAT block copolymer is shown in

Figure 1.

The combination of starting materials used makes it possible to obtain a polymer with high flexibility, excellent impact strength and elongation at break (over 500%), good melting ability (melting point 115–125 °C) and good biodegradability [

9]. The rate of biodegradation of PBAT depends on the content of terephthalic acid [

9]. PBAT is subject to enzymatic degradation and is suitable for composting [

9,

10]. Good deformation and strength characteristics and biodegradability allow PBAT to be the alternative replacement for plastic packaging [

9], in particular, polyethylene.

Packaging is an integral part of any food product, which ensures its quality and safety. The use of biodegradable packaging, alternative to traditional polymeric materials, will reduce the amount of hardly degradable polymers, which will reduce the negative impact on the environment [

11]. At the same time, to ensure the quality and safety of food products, packaging must have antimicrobial properties, since the most common is microbiological contamination of food products [

12]. Bacteria, fungi, parasites, and viruses can act as sources of microbial spoilage of food products [

13]. In this regard, it became necessary to create packaging materials with antimicrobial properties, which remains relevant today. Today there are many developed antimicrobial polymeric materials [

14], where substances of natural origin [

15,

16,

17] and synthetic origin [

18], including nanoparticles [

19,

20], act as antimicrobial components. Modification of PBAT will make it possible to obtain biodegradable packaging materials with antimicrobial properties [

21]. One of the successful additions to PBAT was oregano essential oil, described in [

22]. Packaging based on PBAT with oregano essential oil was used for packaging fish fillets, which, in terms of microbiological indicators, increased the shelf life of packaged products by 10 days. Among the variety of natural antimicrobial additives with antibacterial, antiviral, anti-inflammatory, antimutagenic properties, as well as mold resistance, it seems possible to use birch bark extract (BBE) to modify packaging materials [

23,

24]. In the studies researches [

25,

26] of antibacterial properties and resistance of birch bark extract to mold are presented. With wide range of antimicrobial activity BBE can be used to create materials with antimicrobial properties. Also, BBE is resistant to oxygen and sunlight, nontoxic [

24], which allows it to be used in polymeric materials, in contact with food. In the process of introduction of modifiers into the composition of the polymer matrix difficulties, connected with melting temperature of the components used, can appear. The melting temperature of components should be close to the melting temperature of the polymer to prevent destruction of modifiers during processing. The high temperature of melting (240–260 °C) of BBE [

27] allows it to be used in the extrusion process of obtaining modified polymer materials. Another technological difficulty appearing in the process of extrusion is the uneven distribution of component, which is introduced in the polymer matrix. Using of ultrasonic treatment of polymer melt allows getting more uniform distribution of modifier in the polymer matrix. Ultrasonic treatment of polymer melt is used to solve various scientific and technical problems, in particular, the use of ultrasonic treatment leads to homogenization, increases density of forming materials, reduces the surface tension at the interface between melt and matrix, which increases productivity [

28]. In some researches [

28,

29,

30,

31] the effect of ultrasonic treatment on the extrusion performance of polyolefins (HDPE, LDPE, LLDPE), also polystyrene (PS) and blends HDPE/PS is presented. Regardless of the polymer matrix ultrasonic treatment reduced the viscosity of polymer melts, improved productivity and led to better compatibility of polymer blends, as well as smoother surface layer compared to non-sonicated materials. In this way, the use of ultrasonic treatment can improve the compatibility of filled polymer materials and promote more uniform distribution of additives in the polymer matrix, which provides the stability of the properties of the resulting materials. It was also found out that ultrasonic treatment of melts of polymer compositions leads to accelerated destruction of the polymer matrix due to the increase in oxygen-containing groups in the polymer matrix and the increase in water absorption [

32]. Based on the above, the purpose of this study was to develop a modified biodegradable material based on PBAT with antimicrobial properties.